Kungakanani okwaziyo mayelana nokuhlukaniswa kwamathuluzi omshini we-CNC?

Ukuhlukaniswa kwamathuluzi omshini we-CNC kusekelwe emsebenzini, ukwakheka kanye nokusetshenziswa.

Manje sizobheka izigaba ezahlukene:

Ngokusekelwe Kumsebenzi

Imishini yokuvula:Le mishini yenza imisebenzi yokuvula ikakhulukazi izakhi eziyisilinda noma eziyindilinga.

Le mishini ingasetshenziselwa ukugaya indawo eyisicaba noma eyinkimbinkimbi.

Ngokusekelwe Kusakhiwo

Izikhungo Zomshini Ezivundlile:I-spindle kanye ne-workpiece kubekwa ngokuvundlile etafuleni.

Izikhungo zokumanisa ezimile:I-spindle ne-workpiece zibekwe ziqondile etafuleni.

Imishini ye-Multi-axis:Le mishini ifakwe izimbazo eziningi (3 noma ngaphezulu), eyivumela ukuthi yenze imisebenzi enembile neyinkimbinkimbi.

Ngokusekelwe kuhlelo lokusebenza

Imishini Yokubhoboza imishini eyenza ngokuyinhloko imisebenzi yokumba.

Imishini yokugaya:Le mishini ingasetshenziswa ukugaya nokupholisha insimbi.

Imishini yokusika i-Laser:Ubuchwepheshe be-Laser busetshenziselwa ukusika izinto ezihlukahlukene.

Imishini Yokukhipha I-Electro-Discharge (EDM):Le mishini ibumba futhi ibhoboze izinto ezisebenza ngogesi.

Izindlela zokuhlukanisa zemishini ye-CNC zihlukile. Kunezinhlobo eziningi kanye nokucaciswa. Ingahlukaniswa kusetshenziswa izindlela zokuhlukanisa ezingenhla, kanye nemigomo emine yokusebenza nesakhiwo.

1. Ukuhlukaniswa kwamathuluzi omshini ngokuya nge-trajectory yawo yokulawula

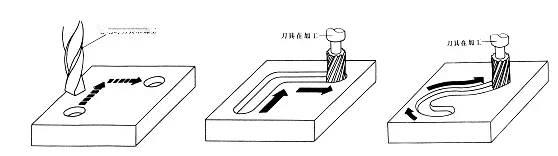

1) Imishini yokulawula amaphuzu ye-CNC

Okuwukuphela kwesidingo sokulawula amaphuzu ukuma okunembile kwezingxenye ezihambayo ukusuka kwelinye ithuluzi lomshini ukuya kwelinye. Izidingo ze-trajectory phakathi kwamaphoyinti okunyakaza aziqinile kakhulu. Ngesikhathi sokunyakaza, akukho ukucubungula okwenziwayo. Akubalulekile ukuthi ukunyakaza kwenzeka kanjani phakathi kwe-axis yokuxhumanisa ngayinye. Ukuze uthole ukuma okunembile nokusheshayo, kubalulekile ukuthi uqale ususe ibanga phakathi kwamaphoyinti amabili ngokushesha, bese usondela kancane endaweni ukuze uqinisekise ukunemba. I-trajectory yokunyakaza ikhonjiswe ngezansi.

Imishini yokugaya ye-CNC kanye nemishini yokubhoboza ye-CNC iyizibonelo zamathuluzi omshini anamakhono okulawula amaphuzu. Amasistimu e-CNC asetshenziselwa kuphela ukulawula amaphuzu aseyivelakancane ngenxa yokuthuthuka kobuchwepheshe be-CNC.

(2) Amathuluzi omshini we-CNC wokulawula umugqa

Ukulawula okuhambisanayo Imishini ye-CNC yaziwa nangokuthi imishini ye-CNC yokulawula umugqa. Inesici sokuthi ayilawuli kuphela ukuma okunembayo phakathi kwamaphoyinti kodwa futhi nesivinini sokunyakaza kanye nomzila (i-trajectory), phakathi kwamaphoyinti amabili. Ukunyakaza kwayo kuhlobene kuphela nethuluzi lomshini eliqondisa izimbazo ezihamba ngokuhambisana. Lokhu kusho ukuthi ukudidiyela okukodwa kuphela kulawulwa ngesikhathi. Ithuluzi lingasetshenziswa ukusika ngezinga lokuphakelayo elishiwo ngesikhathi sokushintsha. Ngokuvamile ingasetshenziswa kuphela ukucubungula izingxenye eziwunxande nezinyathelwe.

Izinhlobo ze-CNCngokulawulwa komugqa ikakhulukazi imishini yokugaya ye-CNC kanye nezigayi ze-CNC. Isistimu ye-CNC yaleli thuluzi lomshini yaziwa nangokuthi isistimu ye-CNC yokulawula umugqa. Ngendlela efanayo, imishini ye-CNC esetshenziselwa kuphela ukulawula umugqa ayijwayelekile.

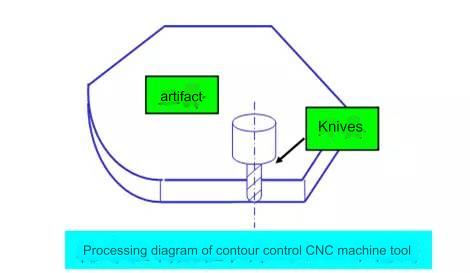

(3) Amathuluzi omshini we-CNC wokulawula ikhonsathi

Ukulawula okuqhubekayo imishini ye-CNC yaziwa nangokuthi imishini ye-CNC yokulawula ikhonsathi. Isici sokulawula salo mshini yikhono lokulawula izixhumanisi ezinyakazayo ezimbili noma ngaphezulu ngesikhathi esisodwa.

Ukuqinisekisa ukuthi ukunyakaza okuhlobene kwethuluzi ku-contour ye-workpiece kuhambisana ne-machining contour ye-workpiece, kuyadingeka ukuxhumanisa ngokunembile ukufuduka kanye nesivinini sokunyakaza ngakunye okudidiyelwe ngokuvumelana nobudlelwano obulinganiselwe obunqunyiwe.

Ukuze usebenzise le ndlela yokulawula, idivayisi ye-CNC kufanele ibe nomsebenzi wokuhumusha. I-interpolation ichaza umumo womugqa oqondile noma i-arc ngokucubungula kwezibalo okwenziwa opharetha be-interpolation ohlelweni lwe-CNC. Lokhu kusekelwe kudatha eyisisekelo efakwe uhlelo, njengezixhumanisi zamaphoyinti okugcina omugqa oqondile, izixhumanisi zamaphoyinti okugcina e-arc, noma irediyasi noma isixhumanisi esimaphakathi. Ngenkathi ubala, yabela ama-pulses kusilawuli ngasinye se-eksisi yokuxhumanisa ngokwemiphumela. Lokhu kulawula ukugudluzwa kokuxhumanisa kwesixhumanisi ngasinye ukuze kuhambisane nekhontolo oyifunayo. Ngesikhathi sokunyakaza, ithuluzi lisika ngokuqhubekayo indawo yokusebenza, okuvumela ukucutshungulwa okuhlukahlukene njengemigqa eqondile, amajika, nama-arcs. Umzila womshini olawulwa ikhonsathi.

Lawa mathuluzi omshini ahlanganisa izinsimbi ze-CNC nemishini yokugaya kanye nemishini yokusika izintambo ye-CNC, izikhungo zomshini, njll. Amadivayisi e-CNC ahambisana nawo abizwa ngokuthi ama-contour control systems. Ingahlukaniswa ngezinhlobo ezintathu ngokuya ngenani lezimbazo elizilawulayo: ifomu

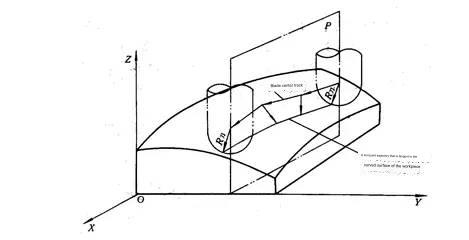

1 Izixhumanisi zama-eksisi amabili:esetshenziselwa ikakhulukazi ama-CNC lathes acubungula izindawo ezijikelezayo, noma imishini yokugaya ye-CNC ecubungula izindawo eziyisilinda ezigobile.

2 I-semi-linkage 2 izimbazo:Lokhu kusetshenziselwa kakhulu ukulawula amathuluzi omshini anezimbazo ezingaphezu kuka-3. Izimbazo ezimbili zingase zixhunywe futhi i-eksisi yesithathu ingase yenze ukudla ngezikhathi ezithile.

3 Ukuxhumana kwe-Three-eksisi:Lokhu ukuxhumanisa okubandakanya izimbazo ezintathu zomugqa ezihlanganisayo, ngokuvamile i-X/Y/Z, futhi kusetshenziswa imishini yokugaya ye-CNC, izikhungo zemishini, njll. Uhlobo lwesibili lukuvumela ukuthi ulawule izixhumanisi zomugqa ezimbili ngesikhathi esisodwa ku-X/Y/Z, kanye ne-eksisi yokuxhumanisa yokuzungeza ezungeza ama-eksisi wokuxhumanisa amugqa.

Esikhungweni somshini ojikajikayo, isibonelo, ukuxhumana phakathi kwama-eksisi amabili amugqa wokuxhumanisa (i-eksisi engu-X kanye ne-Z-eksisi endaweni yobude) kufanele kulawulwe kanyekanye nokuxhunywa kwe-spindle's (C-eksisi), ezungeza i-axis engu-Z. .

4 Ukuxhumana kwe-Four-eksisi:Lawula izixhumanisi zomugqa ezintathu X, Y kanye no-Z ngesikhathi esisodwa ukuze zixhunywe ne-eksisi yokuxhumanisa eyodwa ejikelezayo.

5 Ukuxhumanisa ama-axis amahlanu:Lokhu kukuvumela ukuthi ulawule ukuxhumanisa ama-ax amathathu okuxhumanisa ngesikhathi esisodwa, X/Y/Z. Ithuluzi liphinda lilawule kanyekanye izimbazo ezimbili ze-AB kanye no-C ezizungeza lezi zimbazo eziwumugqa. Lokhu kunikeza isamba sezimbazo ezinhlanu. Ithuluzi manje lingabekwa noma yikuphi esikhaleni.

Ithuluzi lingalawulwa ukuze lizungezise kuzo zombili izimbazo zika-x kanye no-y ngesikhathi esisodwa, ngakho-ke lihlala lisika libheke ohlangothini olufanayo nendawo ekhonkolo. Lokhu kuqinisekisa ukushelela nokunemba kwendawo. Indawo eyenziwe ngomshini ishelela, ikhulisa ukusebenza kahle.

2. Ukuhlelwa kwezinhlelo ezilawulwa yi-servo

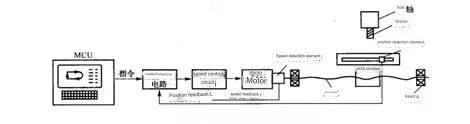

1) Amathuluzi omshini we-CNC ovulekile

Lolu hlobo lwethuluzi lomshini lune-servo yokuphakelayo evulekile, okusho ukuthi ayikho idivayisi yokuthola impendulo. I-motor yayo yokushayela imvamisa iyisitebhisi. Isici esiyinhloko se-stepper motor ukuthi izungeza isinyathelo esigcwele ngaso sonke isikhathi lapho uhlelo lokulawula lushintsha isignali ye-pulse. Injini inesici sokuzikhiya futhi ingasetshenziswa ukulungisa i-engeli yebanga.

Umsabalalisi we-pulse ulawula isekethe yedrayivu ngokusebenzisa isignali yomyalo wokuphakelayo kusukela kusistimu ye-CNC. Inombolo yama-pulses kanye nemvamisa ye-pulse ingashintshwa ukuze kulawulwe ukuhanjiswa okudidiyelwe, isivinini sokufuduka, noma ukugudluzwa. isiqondiso.

Izici eziyinhloko zale ndlela ubulula bayo, ukusetshenziswa kalula, nezindleko eziphansi. Ayikho inkinga yokungazinzi ohlelweni lokulawula ngoba uhlelo lwe-CNC luthumela kuphela izimpawu zendlela eyodwa. Ukunemba kokugudluza kuphansi, nokho, ngoba iphutha lokudlulisa ngomshini alilungiswa ngempendulo.

Le ndlela yokulawula yayisetshenziswa yiyo yonke imishini yokuqala ye-CNC, kodwa yayinezinga eliphezulu lokuhluleka. Naphezu kokuthuthukiswa kwamasekethe okushayela, le ndlela yokulawula isasetshenziswa kabanzi namuhla. Le ndlela yokulawula, ikakhulukazi ezweni lakithi isetshenziselwa izinhlelo ezijwayelekile ze-CNC ezongayo kanye nokuguqula imishini emidala isebenzisa i-CNC. Le ndlela yokulawula iphinde ivumele ikhompuyutha ye-chip eyodwa noma ikhompuyutha yebhodi elilodwa ukuthi imiswe njengomshini we-CNC, okwehlisa izindleko zesistimu.

Amathuluzi omshini anokulawula iluphu evaliwe

Lolu hlobo lwethuluzi lomshini we-CNC lusebenzisa isilawuli se-loop evaliwe. I-motor drive ingaba yi-DC noma i-AC futhi kufanele ibe nakho kokubili impendulo yendawo kanye nempendulo yesivinini elungiselelwe ukuthola noma yikuphi ukunyakaza kwangempela kwengxenye ehambayo nganoma yisiphi isikhathi phakathi nokucubungula. Uhlelo lwe-CNC luphakela inani emuva ngesikhathi sangempela kumqhathanisi. Isignali yomyalo itholakala ngokuhumusha futhi iqhathaniswa nenani. Umehluko ube ususetshenziselwa ukulawula i-servodrive, eshayela ingxenye yokususa ukuze kuqedwe iphutha.

Ngokuya ngendawo nedivayisi yempendulo yomtshina wempendulo yendawo, kunezindlela ezimbili: iluphu evaliwe (igcwele) kanye neluphu evalwe kancane (iluphu evalwe kancane).

1 Ukulawula iluphu evaliwe

Idivayisi yempendulo yendawo, njengoba kuboniswe emfanekisweni isebenzisa isici somugqa wokuthola ibanga. (Okwamanje, umthetho wokugaya usetshenziswa kakhulu) Lokhu kubekwe phezu kwesihlalo sethuluzi lomshini. Ithola ngokuqondile ukugudluka komugqa kuzixhumanisi zethuluzi lomshini. Isignali evela motor ingaqedwa ngokusebenzisa impendulo. Iphutha lokudlulisela liyancishiswa ochungechungeni lokudluliswa kwemishini, okuholela ekunembeni okuphezulu kokuma okumile komshini.

Ukusabela okuguquguqukayo kochungechunge lokudluliswa kwemishini sekukonke kude kakhulu kunempendulo kagesi. Lonke uhlelo lokulawula iluphu evaliwe lunzima kakhulu ukuzinza, futhi ukwakheka nokulungiswa kwalo kuyinkimbinkimbi impela. Le ndlela yokulawula iluphu evaliwe isetshenziswa ngokuyinhloko emishinini yokuxhumanisa i-CNC, imishini yokugaya enembayo ye-CNC, njll. Okudinga ukunemba okuphezulu.

2 Isilawuli seluphu esivalwe kancane

Impendulo yendawo isekelwe ezingxenyeni zokuthola i-engeli, okwamanje ikakhulukazi ezifaka ikhodi. Ama-servo motors noma izikulufu zifakwe izingxenye zokuthola i-engeli (okwamanje ikakhulukazi izishumeki). Izici zokulawula zesistimu zizinze kakhulu ngoba izixhumanisi eziningi zokudlulisa imishini azikho ku-loop evaliwe. Isinxephezelo senani elingaguquki lesofthiwe singathuthukisa ukunemba kwamaphutha okudlulisa ngomshini, njengephutha lesikulufu. Imishini eminingi ye-CNC isebenzisa imodi yeluphu evalwe kancane.

3 Dimensional hybrid control imishini CNC

Ukwakha uhlelo lokulawula oluxubile, izici zendlela yokulawula ngayinye zingagxilwa ngokukhetha. Ukuze kuhlangatshezwane nezidingo zamathuluzi athile omshini futhi kunxeshezelwe umehluko phakathi kwalezi zindlela ezimbili, kunconywa ukuthi kusetshenziswe isikimu sokulawula esiyingxube. Izindlela ezimbili ezijwayelekile wuhlobo olunxephezela iluphu evulekile kanye nohlobo olunxephezela iluphu evaliwe.

3. Amasistimu e-CNC ahlukaniswa ngokwezinga lawo lokusebenza

Amasistimu e-CNC ahlukaniswa abe izigaba ezintathu ngokusekelwe ezingeni lawo lokusebenza: eliphansi, eliphakathi, neliphezulu. Le ndlela yokuhlukanisa isetshenziswa kakhulu ezweni lakithi. Amazinga okuhlukanisa ahlukile enkathini eyodwa kuya kwesinye. Ngokwezinga lamanje lokuthuthukiswa, izinhlobo ezahlukene zezinhlelo ze-CNC zihlukaniswa ngezigaba ezintathu ngokusekelwe emisebenzini ethile kanye nezinkomba. Izinhlelo ze-CNC ezimaphakathi neziphezulu zivame ukubizwa ngokuthi zisebenza ngokugcwele noma i-CNC ejwayelekile.

(1) Ukusika Insimbi

Ibhekisela emishinini ye-CNC eyenza imisebenzi ehlukahlukene yokusika njengecnc turning & milling. Lokhu kungahlukaniswa izigaba ezimbili eziyinhloko.

Imishini ye-CNC efana nemishini yokugaya kanye nemishini yokugaya.

Isici esiyinhloko sesikhungo somshini umtapo wamathuluzi waso, onomshini ozenzakalelayo wokushintsha amathuluzi. Idlula i-workpiece emshinini kanye kuphela. Ngemuva kokubopha i-workpiece, amathuluzi okusika ashintshwa ngokuzenzakalelayo. Izinqubo ezihlukahlukene, okuhlanganisa ukugaya (ukujika), okhiye, ukuphinda (ukubhoboza), kanye nokuthepha intambo kwenziwa ngokuqhubekayo endaweni ngayinye yocezu emshinini ofanayo, isibonelo, (isakhiwo/ukugaya). Isikhungo, indawo yokujika, isikhungo sokumba, njll.

(2) Insimbi Forming

Isho imishini ye-CNC esetshenziselwa ukukhipha, ukubhoboza nokucindezela, kanye nokudweba, neminye imisebenzi yokwakha. Eminye yemishini evame ukusetshenziswa kakhulu ye-CNC ihlanganisa ukunyathelisa kwe-CNC kanye nama-bender amapayipi e-CNC.

(3) Isigaba Esikhethekile Sokucubungula

Imishini ye-EDM yocingo lwe-CNC ivame kakhulu, ilandelwacnc ukusika insimbiimishini kanye nemishini yokucubungula laser ye-CNC.

(4) Ukulinganisa nokudweba

Okufakiwe kulesi sigaba ikakhulukazi amathuluzi okulinganisa okudidiyelwa amathathu, izisetha zamathuluzi e-CNC, izihleli ze-CNC, njll.

Inhloso eyinhloko ye-Anebon kuzoba ukukunikeza abathengi bethu ubudlelwano bebhizinisi obungathi sína nobunomthwalo wemfanelo, ukunikeza ukunaka komuntu siqu kubo bonke nge-New Fashion Design ye-OEM Shenzhen Precision Hardware Factory Custom Fabrication.I-CNC yokugayainqubo, ukusakaza okunembayo, isevisi ye-prototyping. Ungathola inani eliphansi kakhulu lapha. Futhi uzothola imikhiqizo yekhwalithi enhle nezixazululo kanye nenkonzo enhle lapha! Akufanele ube manqikanqika ukubamba i-Anebon!

Idizayini Entsha Yemfashini Yensizakalo Yemishini Yemishini Ye-CNC kanye Nenkonzo Yeziko Lomshini Ye-CNC, i-Anebon inezinombolo zamapulatifomu okuhweba angaphandle, okuyi-Alibaba, Imithombo Yomhlaba, Imakethe Yomhlaba Wonke, I-Made-in-china. Imikhiqizo nezixazululo ze-"XinGuangYang" ze-HID zithengiswa kahle kakhulu eYurophu, eMelika, eMpumalanga Ephakathi nakwezinye izifunda emazweni angaphezu kuka-30.

Isikhathi sokuthumela: Oct-06-2023