Izidingo zamathuluzi omshini we-CNC ezintweni zamathuluzi

Ukuqina okuphezulu nokumelana nokugqoka

Ukuqina kwengxenye yokusika yethuluzi kufanele kube kuphakeme kunobulukhuni bempahla yokusebenza. Ukuphakama kokuqina kwempahla yamathuluzi, kungcono ukumelana nokugqoka kwayo. Ukuqina kwempahla yamathuluzi ekamelweni lokushisa kuyoba ngaphezu kwe-HRC62. Ubulukhuni bungaba phezulu kunobujwayelekileIzingxenye zemishini ye-CNC.

Amandla anele nokuqina

Ithuluzi lithwala ingcindezi enhle kakhulu ohlelweni lokusika ngokweqile. Kwesinye isikhathi, isebenza ngaphansi kwezimo zokudlidliza. Ukuvimbela ithuluzi ukuthi lingaphuki futhi liphuke, impahla yamathuluzi kumele ibe namandla nokuqina okwanele. Ngokuvamile, amandla okugoba asetshenziselwa ukumela amandla ento yethuluzi, futhi inani lomthelela lisetshenziselwa ukuchaza ukuqina kwento yamathuluzi.

ukumelana nokushisa okuphezulu

Ukumelana nokushisa kubhekisela ekusebenzeni kwezinto zamathuluzi ukugcina ubulukhuni, ukumelana nokugqoka, amandla, nokuqina ngaphansi kwamazinga okushisa aphezulu. Kuyinkomba ehamba phambili yokulinganisa ukusebenza kokusika kwezinto zamathuluzi. Lokhu kusebenza kwaziwa nangokuthi ubulukhuni obubomvu bezinto zamathuluzi.

I-conductivity enhle ye-thermal

Uma kukhulu ukuqhutshwa kwe-thermal kwempahla yamathuluzi, ukushisa okungaphezulu kudluliselwa kusuka kuthuluzi, okulungele ukunciphisa izinga lokushisa lokusika ithuluzi nokuthuthukisa ukuqina kwalo.

Ukucutshungulwa okuhle

Ukuze kube lula ukucutshungulwa kwamathuluzi nokukhiqiza, izinto ezisetshenziswayo kufanele zibe nezakhiwo ezinhle zokucubungula, njengokufoja, ukugingqika, ukushisela, ukusika nokugaya, izindawo zokwelashwa kokushisa, kanye nezakhiwo zepulasitiki ezishintshashintshayo ezisezingeni eliphezulu zempahla yamathuluzi. I-carbide enosimende kanye nezinto zamathuluzi e-ceramic nazo zidinga izakhiwo ezinhle ze-sintering kanye ne-press-forming.

Uhlobo lwempahla yamathuluzi

insimbi enesivinini esikhulu

Insimbi enesivinini esiphezulu iyinsimbi yensimbi eyingxubevange eyakhiwe ngo-W, Cr, Mo, nezinye izakhi ze-alloy. Inokuqina kokushisa okuphezulu, amandla, ukuqina, kanye nezinga elithile lokuqina nokumelana nokugqoka, ngakho-ke ifaneleka ukucubungula izinto ezingezona ze-ferrnonferrous nezinsimbi ezihlukahlukene. Ngaphezu kwalokho, ngenxa yobuchwepheshe bayo bokucubungula umsindo, ilungele ukukhiqiza amathuluzi okwakha ayinkimbinkimbi, ikakhulukazi i-powder metallurgy high-speed steel, enezakhiwo zemishini ye-anisotropic futhi inciphisa ukucisha ukuguqulwa; ilungele ukukhiqiza ukunemba kanye namathuluzi okwakha ayinkimbinkimbi.

Ingxubevange eqinile

I-carbide enosimende inokuqina okuphezulu nokumelana nokugqoka. Lapho ukusikaIzingxenye zokuguqula ze-CNC, ukusebenza kwayo kungcono kunensimbi enesivinini esikhulu. Ukuqina kwayo izikhathi eziningana kuya kwezingamashumi amabili kunensimbi enesivinini esikhulu, kodwa ukuqina kwayo komthelela akulungile. Ngenxa yokusebenza kwayo okuhle kakhulu kokusika, isetshenziswa kabanzi njengethuluzi lempahla.

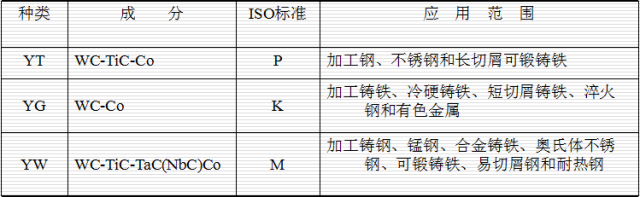

Ukuhlukaniswa nokumakwa kwama-carbides anosimende wamathuluzi okusika

I-blade eboshwe

I-1) Izinto zokugqoka zendlela ye-CVD yi-TiC, okwandisa ukuqina kwamathuluzi e-carbide enosimende izikhathi ezingu-1-3. Ukuqina kwe-coating: I-cutting Edge ayicacile futhi isiza ukuthuthukisa impilo yejubane.

2) Izinto zokumboza zendlela ye-PVD yokubeka umhwamuko obonakalayo yi-TiN, i-TiAlN, ne-Ti (C, N), ethuthukisa ukuqina kwamathuluzi e-carbide enosimende izikhathi ezingu-2-10. I-coating encane; Unqenqema olucijile; Kuyasiza ekunciphiseni amandla okusika.

★ Ubukhulu obukhulu be-coating ≤ 16um

I-CBN ne-PCD

I-Cubic boron nitride (CBN) Ukuqina kanye nokusebenza okushisayo kwe-cubic boron nitride (CBN) ingaphansi kwedayimane, futhi inokuqina okushisayo namakhemikhali. Ngakho-ke, ilungele ukukhanda insimbi eqinile, insimbi eqinile, i-superalloy, ne-carbide enosimende.

Idayimane le-Polycrystalline (PCD) Uma i-PCD isetshenziswa njengethuluzi lokusika, ifakwa ku-sinter ye-carbide substrate. Ingakwazi ukuqeda ukumelana nokuguga, ukuqina okuphezulu, okungeyona insimbi, kanye ne-nonferrononferrousaterials njenge-carbide enosimende, izitsha zobumba, ne-silicon aluminium alloy ephezulu.

★ ISO machine clamp blade classification material ★

Izingxenye zensimbi: P05 P25 P40

Insimbi engagqwali: M05 M25 M40

Insimbi yokufaka: K05 K25 K30

★ Uma inombolo encane, i-blade iyinkimbinkimbi kakhulu, kungcono ukumelana nokugqoka kwethuluzi, futhi kubi nakakhulu ukumelana nomthelela.

★ Uma inani lilikhulu, i-blade ithambile, kuba ngcono ukumelana komthelela wethuluzi kanye nokungagugi kahle.

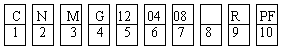

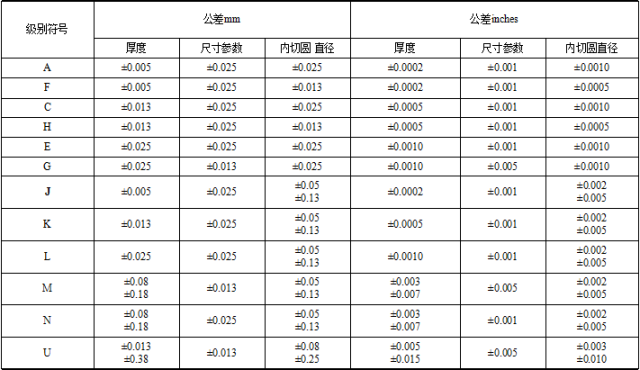

Iguqulelwa kumodeli ye-blade kanye nemithetho yokumelela i-ISO

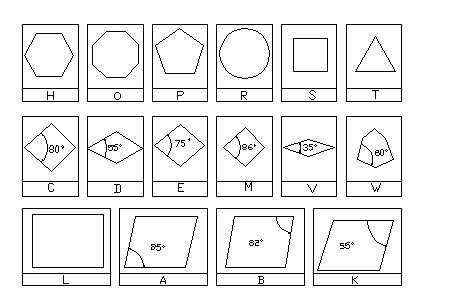

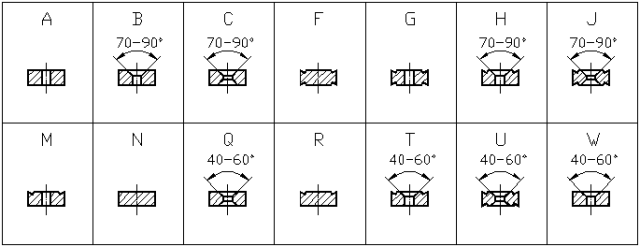

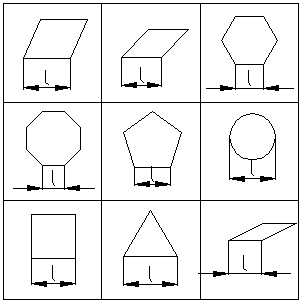

1. Ikhodi emele umumo weblade

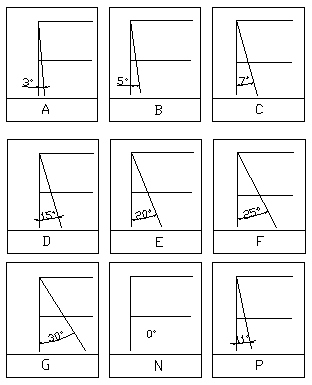

2. Ikhodi emele i-engeli yangemuva ye-edge ehamba phambili

3. Ikhodi emele ukubekezelelwa kwe-dimensional kwe-blade

4. Ikhodi emele ukuphulwa kwe-chip nokubopha uhlobo lwensingo

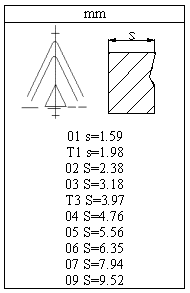

5. Imelwe ubude bokusika onqenqemeni

6. Ikhodi emele ukujiya kwensingo

7. Ikhodi emele unqenqema lokupholisha kanye ne-engeli engu-R

Incazelo yezinye izibalo

Isishiyagalombili sisho ikhodi ekhombisa izidingo ezikhethekile;

9 imele ikhodi yokuqondisa okuphakelayo; isibonelo, ikhodi R imele okuphakelayo kwesokudla, ikhodi L imele okuphakelayo kwesokunxele, futhi ikhodi N imele okuphakelayo okuphakathi;

10 imele ikhodi yohlobo lwe-chip breaking groove;

I-11 imele ikhodi yempahla yenkampani yamathuluzi;

ukusika isivinini

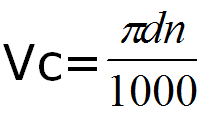

Ifomula yokubala yesivinini sokusika Vc:

Kufomula:

D - ububanzi obujikelezayo bocezu lokusebenza noma ithiphu yamathuluzi, iyunithi: mm

N - isivinini sokujikeleza se-workpiece noma ithuluzi, iyunithi: r/min

Isivinini Sokucupha Ngentambo Ejwayelekile

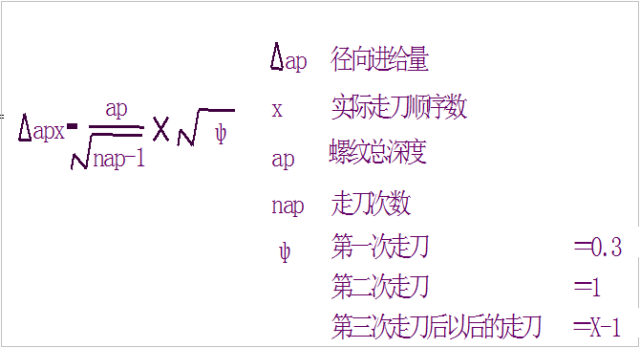

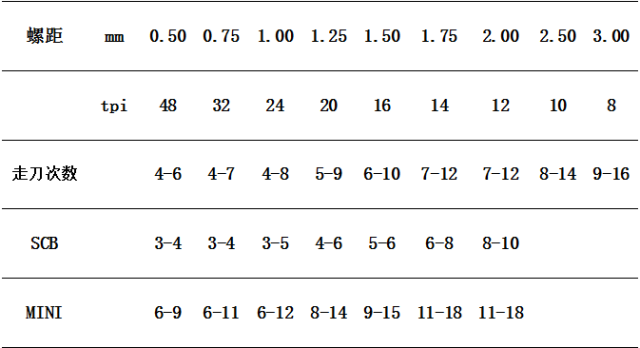

Ijubane lokuphotha n lokujika intambo. Lapho usika intambo, ijubane lokuphotha le-lathe lithintwa izici eziningi, njengosayizi we-pitch pitch (noma umthofu) we-workpiece, izici zokuphakamisa nokwehlisa ze-motor motor, kanye nesivinini sokufakelwa kwentambo. Ngakho-ke, umehluko othize ukhona ejubaneni lokuphotha lentambo yokujika yamasistimu ahlukene e-CNC. Okulandelayo ifomula yokubala isivinini sokuphotha lapho uvula izintambo kumalebula ajwayelekile e-CNC:

Kufomula:

I-P - intambo yentambo noma intambo ye-workpiece, iyunithi: mm.

K - i-coefficient yomshuwalense, ngokuvamile engu-80.

Ukubalwa kokujula kokuphakelayo ngakunye kochungechunge lomshini

Inombolo yezindlela zamathuluzi okuthunga

1) Ukwenza imishini enzima

Ifomula yokubala enamandla yokuphakelayo komshini rough: f rough=0.5 R

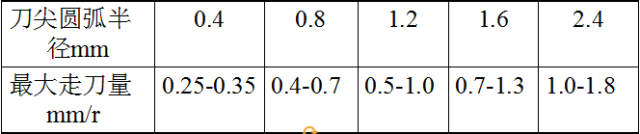

Kuphi: R ------ ithiphu yethuluzi i-arc radius mm

F ------ okuphakelayo kwethuluzi lomshini olukhuni mm

2) Ukuqeda

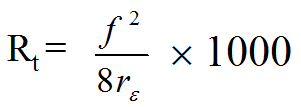

Kufomula: Rt ------ ukujula kwekhonta µ m

F ------ Isilinganiso sokuphakelayo mm/r

r ε ------ Irediyasi yethiphu yamathuluzi arc mm

Hlukanisa ukujika okumaholo nokuqeda ngokwezinga lokuphakelayo kanye nomsele wokuqhekeka kwe-chip

F ≥ 0.36 machining rough

0.36 > f ≥ 0.17 ukuqeda kancane

F < 0.17 qeda ukwenza imishini

Akuyona into yensingo kodwa i-chip-breaking groove ethinta umshini onzima futhi ophelile we-blade. Unqenqema lokusika lubukhali uma i-chamfer ingaphansi kwama-40um.

Isikhathi sokuthumela: Nov-29-2022