1. Umsebenzi nokuqukethwe kwengxenye yomdwebo

1. Indima yengxenye yemidwebo

Noma yimuphi umshini wakhiwe izingxenye eziningi, futhi ukuze ukhiqize umshini, izingxenye kufanele zenziwe kuqala. Umdwebo wengxenye uyisisekelo sokukhiqiza nokuhlola izingxenye. Ibeka phambili izidingo ezithile zezingxenye ngokuma, ukwakheka, usayizi, impahla kanye nobuchwepheshe ngokuya ngokuma nokusebenza kwezingxenye zomshini.

2. Okuqukethwe kwezingxenye zemidwebo

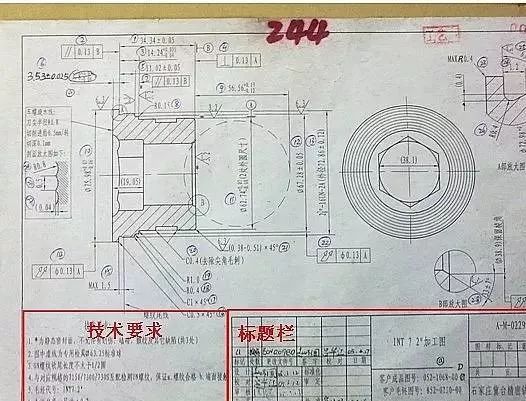

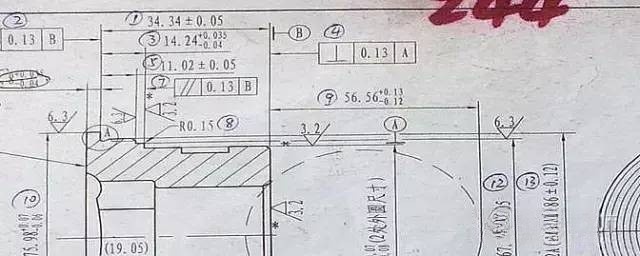

Ingxenye ephelele yomdwebo kufanele ihlanganise okuqukethwe okulandelayo, njengoba kukhonjisiwe kuMfanekiso 1:

Umfanekiso 1 Izingxenye zomdwebo we-INT7 2”

(1) Ikholomu yesihloko Itholakala ekhoneni elingezansi kwesokudla lomdwebo, ikholomu yesihloko ngokuvamile igcwalisa igama lengxenye, impahla, inani, ingxenye yomdwebo, isignesha yomuntu obhekele ikhodi nomdwebo, kanye igama leyunithi. Isiqondiso sebha yesihloko kufanele sihambisane nesiqondiso sokubuka isithombe.

(2) Iqoqo lezithombe ezisetshenziselwa ukuveza isimo sesakhiwo sengxenye, esingavezwa ngendlela yokubuka, isigaba, isigaba, indlela yokudweba enqunyiwe kanye nendlela yokudweba eyenziwe lula.

(3) Ubukhulu obudingekayo bukhombisa usayizi nobudlelwano obuhambisanayo bendawo ngayinye yengxenye, futhi buhlangabezana nezidingo zeizingxenye eziphendukayoukukhiqiza nokuhlola.

(4) Izidingo zobuchwepheshe Ubulukhuni obungaphezulu, ukubekezelelana kobukhulu, ukwakheka nokubekezelela indawo yezingxenye, kanye nokwelashwa kokushisa kanye nezidingo zokwelashwa okungaphezulu kwempahla kunikezwa.

2. Buka

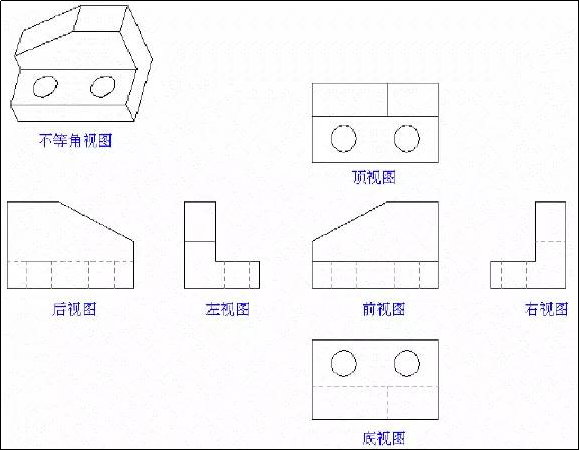

Ukubuka okuyisisekelo: ukubuka okutholwe ngokuveza into ezindaweni eziyisithupha eziyisisekelo zokuqagela (into imaphakathi nekhiyubhu, ifanekiselwa izikhombisi-ndlela eziyisithupha ngaphambili, emuva, kwesokunxele, kwesokudla, phezulu, phansi), yilezi:

Ukubuka okuphambili (ukubuka okuyinhloko), ukubuka kwesokunxele, ukubuka kwesokudla, ukubuka okuphezulu, ukubuka ngezansi nokubukwa kwangemuva.

3. Ukuhlukaniswa okuphelele nohhafu

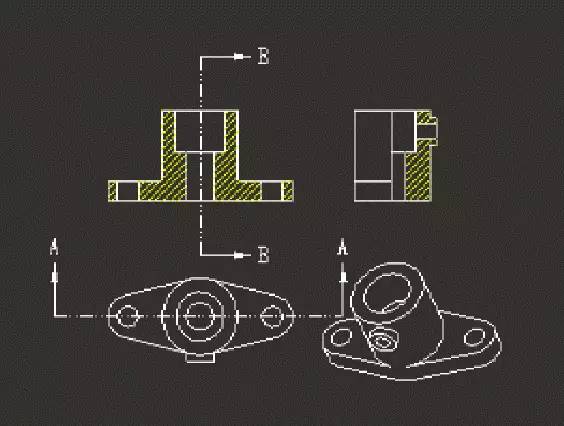

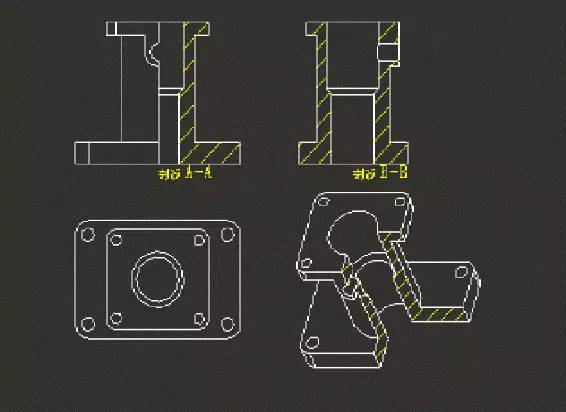

Ukuze usize ekuqondeni isakhiwo sangaphakathi kanye nemingcele ehlobene yento, ngezinye izikhathi kudingekile ukuhlukanisa umbono otholiwe ngokusika into ekubukeni kwesigaba esigcwele kanye nokubuka kwengxenye yengxenye.

Ukubuka kwesigaba esigcwele: Ukubuka kwesigaba okutholwe ngokusika into yonke ngendiza yesigaba kubizwa ngokuthi ukubuka kwesigaba esigcwele.

Ukubuka kwesigaba esiyingxenye: Uma into inendiza elinganayo, isibalo esivezwa endaweni ekhonjiwe ebheke endizeni yokulinganisa singaboshwa umugqa omaphakathi, ingxenye yawo edwetshwe njengokubuka kwengxenye, kanti enye ingxenye idwetshwa njengo ukubuka, okubizwa ngokuthi ukubuka kwesigaba esiyingxenye.

4. Ubukhulu nokulebula

1.Incazelo yosayizi: inani lenombolo elimelela inani lomugqa wobukhulu kuyunithi ethile

2. Ukuhlukaniswa kosayizi:

1)Usayizi oyisisekelo Usayizi womkhawulo kasayizi ungabalwa ngokusebenzisa ukuchezuka okuphezulu nangaphansi.

2)Usayizi wangempela Usayizi otholwe ngesilinganiso.

3)Usayizi womkhawulo Izilinganiso ezimbili ezeqisayo ezivunyelwe usayizi, omkhulu kunawo wonke ubizwa ngokuthi usayizi womkhawulo omkhulu; encane ibizwa ngokuthi usayizi womkhawulo omncane.

4)Ukuchezuka kosayizi Umehluko we-algebra otholakala ngokukhipha usayizi oyisisekelo kusayizi womkhawulo omkhulu ubizwa ngokuthi ukuchezuka okuphezulu; umehluko we-algebra otholakala ngokukhipha usayizi oyisisekelo kusayizi womkhawulo omncane ubizwa ngokuthi ukuchezuka okuphansi. Ukuchezuka okuphezulu nokuphansi kubizwa ngokuhlanganyela njengokuchezuka komkhawulo, futhi ukuchezuka kungaba kuhle noma kube kubi.

5)Ukubekezelelana kobukhulu, okubizwa ngokuthi ukubekezelelana, umehluko phakathi kobukhulu bomkhawulo kasayizi kukhishwe usayizi womkhawulo obuncane, okuwukushintsha kosayizi okuvunyelwe. Ukubekezelelana kwe-Dimensional kuhlale kukuhle

Isibonelo: Φ20 0.5 -0.31; lapho u-Φ20 engusayizi oyisisekelo futhi u-0.81 uwukubekezelela. 0.5 ukuchezuka okuphezulu, -0.31 ukuchezuka okuphansi. 20.5 kanye no-19.69 amasayizi omkhawulo aphezulu kanye nobuncane obuncane ngokulandelanayo.

6)Umugqa onguziro

Emdwebeni womkhawulo kanye nokulingana, umugqa oqondile omelela ubukhulu obuyisisekelo, ngokusekelwe lapho ukuchezuka nokubekezelelana kunqunywa khona.

7)Ukubekezelelana okujwayelekile

Noma yikuphi ukubekezelelana okucaciswe ohlelweni lwemikhawulo nokulingana. Izinga likazwelonke libeka ukuthi ngosayizi othile oyisisekelo, kunamazinga okubekezelelana angama-20 esilinganisweni sokubekezelelana.

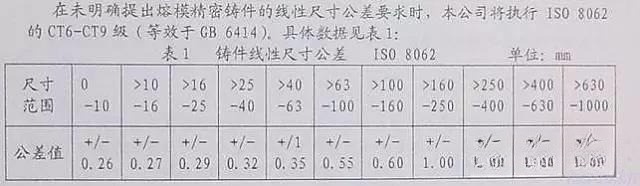

Ukubekezelelana kuhlukaniswe ngochungechunge lwezindinganiso ezintathu: CT, IT, kanye ne-JT. Uchungechunge lwe-CT luyindinganiso yokubekezelela ukuphonswa, i-ISO yi-ISO international dimension tolerance, i-JT iwukubekezelelana komnyango weMishini Yemishini yaseChina.

Amabanga ahlukene okubekezelela imikhiqizo ehlukene. Uma izinga liphezulu, ziphakeme izidingo zobuchwepheshe bokukhiqiza kanye nezindleko eziphakeme. Isibonelo, izinga lokubekezelela lokusakazwa kwesihlabathi ngokuvamile yi-CT8-CT10, kuyilapho inkampani yethu isebenzisa izinga lamazwe ngamazwe i-CT6-CT9 ngokusakazwa okunembayo.

8)Ukuchezuka okuyisisekelo Kuhlelo lomkhawulo kanye nokulingana, nquma ukuchezuka komkhawulo wendawo yokubekezelela ngokuhlobene nendawo yomugqa onguziro, ngokuvamile ukuchezuka eduze komugqa onguziro. Izinga likazwelonke libeka ukuthi ikhodi eyisisekelo yokuchezuka imelelwa izinhlamvu zesiLatini, uhlamvu olusonhlamvukazi lubonisa imbobo, kanti uhlamvu oluncane lubonisa umgodi, futhi ukuchezuka okuyisisekelo okungu-28 kubekwe esigabeni ngasinye sosayizi oyisisekelo wembobo kanye ne-shaft. Funda ukuhlela kwe-UG bese wengeza iqembu le-Q. 726236503 ukukusiza.

3. Ukumaka ubukhulu

1)Izidingo zokulinganisa

Usayizi wengxenye yomdwebo uyisisekelo sokucutshungulwa nokuhlolwa lapho kwenziwacnc imikhiqizo yokugaya. Ngakho-ke, ngaphezu kokulunga, okuphelele nokucacile, izilinganiso ezimakwe engxenyeni yemidwebo kufanele zibe nengqondo ngangokunokwenzeka, ngisho noma ubukhulu obuphawuliwe buhlangabezana nezidingo zokuklama futhi bulungele ukucutshungulwa nokukalwa.

2)Isithenjwa sikasayizi

Amabhentshimakhi anobukhulu amabhentshimakhi okumaka ubukhulu bokuma. Amabhentshimakhi anobukhulu ngokuvamile ahlukaniswa abe amabhentshimakhi edizayini (asetshenziselwa ukunquma indawo yesakhiwo sezingxenye phakathi nomklamo) futhi acubungule amabhentshimakhi (asetshenziselwa ukubeka, ukucubungula nokuhlola ngesikhathi sokukhiqiza).

Indawo engaphansi, indawo yokugcina, indiza yokulinganisa, i-axis kanye nendawo eyindilinga yengxenye ingasetshenziswa njengedamu yosayizi wedatha futhi ingahlukaniswa ngokwedatha eyinhloko kanye nedatha eyisizayo. Ngokuvamile, i-design datum eyodwa ikhethwa njengedatha eyinhloko kuhlangothi ngalunye lwezintathu zobude, ububanzi, nobude, futhi inquma ubukhulu bengxenye. Lezi zilinganiso eziyinhloko zithinta ukusebenza kokusebenza kanye nokunemba komhlangano wezingxenye emshinini. Ngakho-ke, izilinganiso eziyinhloko kufanele zijovwe ngokuqondile ku-datum eyinhloko. Amanye ama-datum anobukhulu ngaphandle kwedatha eyinhloko angama-datum ayisiza ukuze kube lula ukucutshungulwa nokukalwa. Ama-datum esibili anobukhulu obuhlobene nedatha eyisisekelo.

5. Ukubekezelelana nokufaneleka

Lapho ukhiqiza futhi uhlanganisa imishini ngamaqoqo, kuyadingeka ukuthi iqoqo lezingxenye ezifanayo lingahlangabezana nezidingo zokuklama kanye nezidingo zokusebenzisa inqobo nje uma zicutshungulwa ngokuvumelana nemidwebo futhi zihlanganiswe ngaphandle kokukhethwa. Lesi sakhiwo phakathi kwezingxenye sibizwa ngokuthi ukushintshashintsha. Ngemuva kokuthi izingxenye zishintshashintsha, ukukhiqizwa nokugcinwa kwezingxenye kanye nezingxenye kwenziwa lula kakhulu, umjikelezo wokukhiqiza umkhiqizo ufinyezwa, ukukhiqiza kuyathuthukiswa, futhi izindleko ziyancipha.

Umqondo wokubekezelelana nokufaneleka

1 ukubekezelelana

Uma ubukhulu bezingxenye ezizokwenziwa futhi zicutshungulwe bunembile ngokuphelele, empeleni akunakwenzeka. Kodwa-ke, ukuze kuqinisekiswe ukushintshashintsha kwezingxenye, ukuhluka okuvunyelwe kobukhulu okunqunywa ngokuya ngezidingo zokusetshenziswa kwezingxenye phakathi nomklamo kubizwa ngokuthi ukubekezelelana kwe-dimensional, noma ukubekezelelana ngamafuphi. Ukuba ncane kwevelu yokubekezelela, okungukuthi, ukuhluka kobubanzi obuncane bephutha elivumelekile, kuba nzima kakhulu ukucubungula

2 Umqondo womumo nokubekezelelana kwesikhundla (okubhekiselwa kukho njengokubekezelelana kwesimo)

Ingaphezulu lengxenye ecutshunguliwe ayinawo amaphutha e-dimensional kuphela, kodwa futhi ikhiqiza amaphutha omumo nokuma. Lawa maphutha awagcini nje ukunciphisa ukunemba kwecnc machining izingxenye zensimbi, kodwa futhi kuthinte ukusebenza. Ngakho-ke, indinganiso kazwelonke ibeka umumo nokubekezelelana kwesikhundla sobuso bengxenye, okubhekiselwa kukho njengokuma nokubekezelelana kwesikhundla.

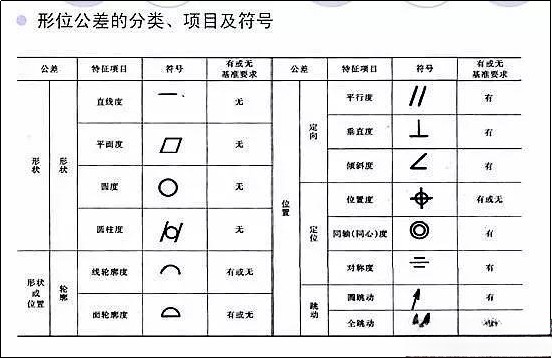

1) Izimpawu zesici sokubekezelelana kwejiyomethri

Njengoba kuboniswe kuthebula 2

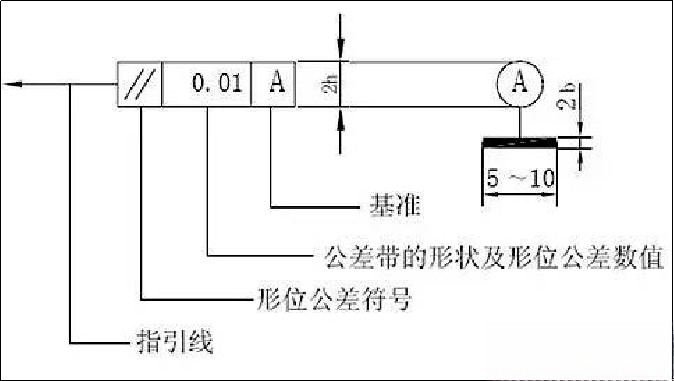

2) Qaphela indlela yokubekezelelana kwe-dimensional emidwebeni yeizingxenye zemishini ye-cnc

Ukubekezelelwa kwe-Dimensional engxenyeni yemidwebo kuvame ukuphawulwa ngamavelu okuchezuka omkhawulo, njengoba kuboniswe emfanekisweni.

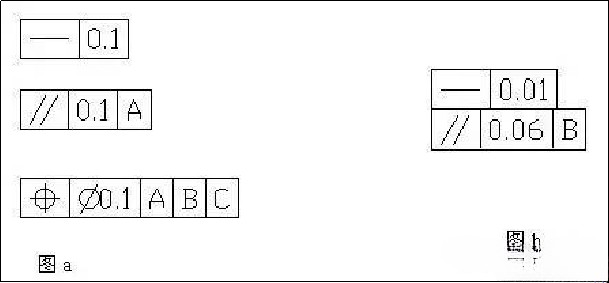

I-3) Izidingo zokuma nokubekezelelana kwesikhundla se-sash zinikezwa ku-sash, futhi i-sash yakhiwe ngamagridi amabili noma ngaphezulu. Okuqukethwe kuhlaka kuzogcwaliswa ngohlelo olulandelayo ukusuka kwesobunxele kuye kwesokudla: Uphawu lwesici sokubekezela, inani lokubekezelela, kanye nohlamvu olulodwa noma ngaphezulu ukuze kuboniswe isici sedatha noma isistimu yedatha uma kudingeka. Njengoba kuboniswe emfanekisweni a. Isici esingaphezu kwesisodwa sokubekezelela isici esifanayo

Uma kudingwa iphrojekthi, ibhande elilodwa lingafakwa ngaphansi kwesinye ibhande, njengoba kuboniswe kuMfanekiso b.

4) Izakhi ezilinganisiwe

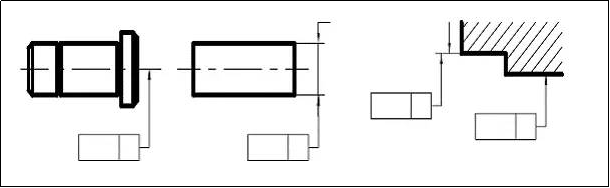

Xhuma into elinganisiwe ekugcineni kohlaka lokubekezelela ngomugqa womhlahlandlela onomcibisholo, futhi umcibisholo womugqa womhlahlandlela ukhomba ububanzi noma ububanzi bendawo yokubekezelela. Izingxenye ezikhonjiswe imicibisholo eholayo zingafaka:

(1)Uma isici esizolinganiswa siyi-eksisi iyonke noma indiza evamile emaphakathi, umcibisholo oholayo ungakhomba ngokuqondile i-eksisi noma umugqa omaphakathi, njengoba kuboniswe kwesokunxele emfanekisweni ongezansi.

(2)Uma isici esizolinganiswa siyi-eksisi, indawo ephakathi nendawo noma indiza emaphakathi, umcibisholo oholayo kufanele uqondaniswe nomugqa wobukhulu we-elementi, njengoba kuboniswe emfanekisweni ongezansi.

(3)Uma isici okufanele silinganiswe siwumugqa noma indawo, umcibisholo womugqa oholayo kufanele ukhombe kumugqa oyikhonco wesici noma umugqa wayo ophuma phambili, futhi kufanele unyakaziswe ngokucacile ngomugqa wobukhulu, njengoba kuboniswe kwesokudla. esithombeni esingezansi

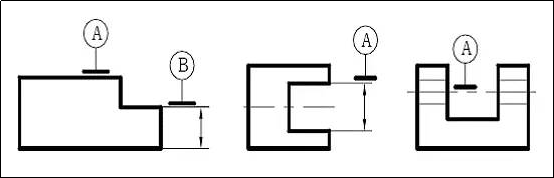

5) Izinto zeDatum

Xhuma i-elementi ye-datum nenye ingxenye yohlaka lokubekezelelana ngomugqa womholi onophawu lwedatha, njengoba kuboniswe kwesokunxele emfanekisweni ongezansi.

(1)Uma isici se-datum siwumugqa oyinhloko noma indawo engaphezulu, uphawu lwedatha kufanele limakwe eduze kohlaka noma umugqa oholela ngaphandle wesici, futhi kufanele libalangiswe ngokucacile ngomcibisholo womugqa wobukhulu, njengoba kuboniswe kwesokunxele emfanekisweni ongezansi. .

(2)Lapho isici se-datum siyi-eksisi, isikhungo sendilinga noma indiza emaphakathi, uphawu lwedatha kufanele lube

Qondanisa nomcibisholo womugqa wobukhulu besici, njengoba kukhonjisiwe esithombeni esingezansi.

(3)Uma i-elementi ye-datum iyi-eksisi iyonke noma indiza evamile emaphakathi, uphawu lwe-datum lungaba

Maka ngokuqondile eduze kwe-eksisi evamile (noma umugqa ophakathi nendawo), njengoba kukhonjisiwe kwesokudla somfanekiso ongezansi.

3 Incazelo Eningiliziwe Yokubekezelelana Kwejiyomethri

Yakha Izinto Zokubekezelela Nezimpawu Zazo

Isibonelo Sokubekezelela Ifomu

| Iphrojekthi | Inombolo yomkhiqizo | Umdwebo isichasiselo | Indawo yokubekezelela | Incazelo | ||||||||||

| Ukuqondile | 1 |

|

| Umugqa wangempela kufanele ube phakathi kwezindiza ezimbili ezihambisanayo ezinebanga elingu-0.02mm ohlangothini olukhonjiswe umcibisholo. | ||||||||||

| 2 | |

| Umugqa wangempela kufanele ube phakathi kweprism eyi-quadrangular enebanga elingu-0.04mm ohlangothini oluvundlile kanye nebanga elingu-0.02mm ohlangothini oluqondile. | |||||||||||

| 3 | |

| I-eksisi yangempela ye-Φd kufanele ibe kusilinda obubanzi bayo bungu-Φ0.04mm ne-eksisi ekahle njenge-eksisi. | |||||||||||

| 4 | |

| Noma yimuphi umugqa oyinhloko endaweni eyi-cylindrical kufanele ube endizeni ye-axial naphakathi kwemigqa emibili eqondile ehambisanayo enebanga elingu-0.02mm. | |||||||||||

| 5 |

|

| Noma yimuphi umugqa we-elementi ohlangothini lobude bondawo kufanele ubekwe phakathi kwemigqa emibili eqondile ehambisanayo enebanga elingu-0.04mm esigabeni se-axial ngaphakathi kwanoma yibuphi ubude buka-100mm. | |||||||||||

| Ukucaba | 6 | |

| Ubuso bangempela kufanele bubekwe ezindizeni ezimbili ezifanayo ezinebanga elingu-0.1mm lapho kukhonjiswa khona umcibisholo. | ||||||||||

| Ukujikeleza | 7 |

|

| Kunoma yisiphi isigaba esivamile esincikene ne-eksisi, iphrofayela yesigaba sayo kufanele ibekwe phakathi kwemibuthano egxilile emibili enomehluko werediyasi ongu-0.02mm. | ||||||||||

| I-Cylindricity | 8 | |

| Indawo eyi-cylindrical yangempela kufanele ibe phakathi kwezindawo ezimbili eziyi-coaxial cylindrical ezinomehluko we-radius ongu-0.05mm. |

Isikhundla Sokubekezelela Isibonelo 1

| Iphrojekthi | Inombolo yomkhiqizo | Umdwebo isichasiselo | Indawo yokubekezelela | Incazelo | ||||||||||

| Ukufana | 1 | |

| I-eksisi ka-Φd kufanele ibe phakathi kwezindiza ezimbili ezifanayo ezinebanga elingu-0.1mm futhi ihambisane ne-eksisi eyireferensi ohlangothini oluqondile. | ||||||||||

| 2 |

|

| I-eksisi ka-Φd kufanele ibe ku-quadrangular prism enebanga elingu-0.2mm ohlangothini oluvundlile kanye nebanga elingu-0.1mm endleleni eqondile futhi ihambisane ne-eksisi eyireferensi. | |||||||||||

| 3 |

|

| I-eksisi ka-Φd kufanele ibe endaweni eyisilinda enobubanzi obungu-Φ0.1mm futhi ihambisane ne-eksisi eyireferensi. | |||||||||||

| Ukuma | 4 |

|

| Indawo yokugcina kwesokunxele kufanele ibe phakathi kwezindiza ezimbili ezifanayo ezinebanga elingu-0.05mm kanye ne-perpendicular ku-eksisi yereferensi. | ||||||||||

| 5 | |

| I-eksisi ye-Φd kufanele ibe endaweni eyisilinda enobubanzi obungu-Φ0.05mm futhi ihambisane nendiza yedatha. | |||||||||||

| 6 | |

| I-axis ye-Φd kufanele ibe kuprism eyi-quadrangular enengxenye engu-0.1mm×0.2mm futhi iqonde endizeni yedatha. | |||||||||||

| Ukuthambekela | 7 |

|

| I-eksisi ka-Φd kufanele ibekwe phakathi kwezindiza ezimbili ezifanayo ezinebanga elingu-0.1mm kanye ne-engeli elungile ngokomqondo engu-60° nge-eksisi eyireferensi. |

Isikhundla Sokubekezelela Isibonelo 2

| Iphrojekthi | Inombolo yomkhiqizo | Umdwebo isichasiselo | Indawo yokubekezelela | Incazelo | ||||||||||

| I-Concentricity | 1 |

|

| I-eksisi ka-Φd kufanele ilele endaweni eyisilinda enobubanzi obungu-Φ0.1mm kanye ne-coaxial ne-axis yereferensi evamile AB. I-eksisi yereferensi evamile i-eksisi efanelekile eyabiwe ama-eksisi amabili angempela ka-A no-B, anqunywa ngokuya ngobuncane besimo. | ||||||||||

| I-Symmetry | 2 |

|

| Indiza emaphakathi yomsele kufanele ibe phakathi kwezindiza ezimbili ezifanayo ezinebanga elingu-0.1mm kanye nokuhlelwa okulinganayo ngokuphathelene nendiza yesikhungo sereferensi (0.05mm phezulu naphansi) | ||||||||||

| Isikhundla | 3 |

|

| Izimbazo zezimbobo ezine ze-Φd kufanele zibekwe ngokulandelana ezindaweni ezine-cylindrical ezinobubanzi obungu-Φt kanye nendawo ekahle njenge-eksisi. Izimbobo ezi-4 ziyiqembu lezimbobo izimbazo zazo ezikahle zakha uhlaka lwejometri. Ukuma kohlaka lwejiyomethri engxenyeni kunqunywa izilinganiso ezilungile ngokwethiyori ngokuhlobene namadamu A, B, kanye no-C. | ||||||||||

| Isikhundla | 4 | |

| Izimbazo zezimbobo ezingu-4 Φd kufanele zibekwe ngokulandelana endaweni eyisilinda engu-4 enobubanzi obungu-Φ0.05mm kanye nendawo ekahle njenge-eksisi. Uhlaka lwejiyomethri yeqembu layo le-4-hole lingahunyushwa, lijikelezwe futhi litshekiswe phezulu naphansi, kwesokunxele nakwesokudla ngaphakathi kwendawo yokubekezelela (±ΔL1 kanye ±ΔL2) yobukhulu bokuma kwayo (L1 kanye ne-L2). |

Isibonelo Sokubekezelela I-Runout

| Iphrojekthi | Inombolo yomkhiqizo | Umdwebo isichasiselo | Indawo yokubekezelela | Incazelo | ||||||||||

| I-Radial ukuphuma okuyisiyingi | 1 |

|

| (Kunoma iyiphi indiza yokulinganisa eqondane ne-eksisi yesithenjwa, imibuthano emibili egxilile umehluko wayo werediyasi ku-eksisi yereferensi ukubekezelela okungu-0.05mm) Lapho i-Φd cylindrical surface izungeza i-axis yesithenjwa ngaphandle kokunyakaza kwe-axial, ukuphuma kwe-radial kunoma iyiphi indiza yokulinganisa (umehluko phakathi komkhawulo wokufunda nokuncane okukalwa yinkomba) akufanele kube mkhulu kuno-0.05mm. | ||||||||||

| Qeda ukuphuma | 2 | |

| (Indawo eyisilinda enobubanzi obungu-0.05mm ngokuhambisana nesiqondisindlela se-generatrix endaweni eyisilinda elinganisiwe kunoma iyiphi indawo yobubanzi obuyi-coaxial ne-axis yedatha) Uma ingxenye elinganisiwe izungeza i-eksisi yereferensi ngaphandle kokunyakaza kwe-axial, ukuphuma kwe-axial kunoma isiphi isikali se-diameter dr (0 | ||||||||||

| I-Oblique ukuphuma okuyisiyingi | 3 | |

| (Indawo eyikhonikhi enobubanzi obungu-0.05 ngokuhambisana nendawo yejenereksi kunoma iyiphi indawo eyikhonika yokulinganisa eyi-coaxial ne-eksisi yereferensi futhi ogeneratrix wayo ophambana nendawo ofanele ukukalwa) Lapho i-conical surface izungeza i-axis yesithenjwa ngaphandle kokunyakaza kwe-axial, ukuphuma kunoma iyiphi indawo eyi-conical yokulinganisa akumele kudlule u-0.05mm. | ||||||||||

| I-Radial ukuphuma okugcwele | 4 | |

| (Izindawo ezimbili eziyi-coaxial cylindrical ezinomehluko werediyasi ongu-0.05mm kanye ne-coaxial ene-eksisi yesithenjwa) Ingaphezulu lika-Φd lizungeza ngokuqhubekayo eksisi yesithenjwa ngaphandle kokunyakaza kwe-axial, kuyilapho inkomba ihamba ngokuhambisana ngokuhambisana nendawo ye-eksisi yesithenjwa. Ukuphuma kuyo yonke indawo engu-Φd akufanele kube kukhulu kuno-0.05mm | ||||||||||

| Ukuphela okuphelele | 5 |

|

| (Izindiza ezimbili ezihambisanayo ezincike ku-eksisi yesithenjwa ezinokubekezelela okungu-0.03mm) Ingxenye elinganisiwe yenza ukuzungezisa okuqhubekayo ngaphandle kokunyakaza kwe-axial eduze kwe-eksisi yesithenjwa, futhi ngesikhathi esifanayo, inkomba ihamba ngendlela ye-eksisi eqondile yendawo, futhi ukuphuma kuyo yonke indawo yokugcina akumele kube kukhulu kuno-0.03mm. |

I-Anebon inemishini yokukhiqiza ethuthuke kakhulu, onjiniyela abanolwazi nabaqeqeshiwe nabasebenzi, amasistimu aziwayo okulawula ikhwalithi kanye neqembu elinobungane lokuthengisa elinobungcweti elisekela ngaphambi/ngemuva kokuthengisa le-China wholesale OEM Plastic ABS/PA/POM CNC Lathe CNC Milling 4 Axis/5 Axis Izingxenye zemishini ye-CNC,Izingxenye zokuguqula ze-CNC. Njengamanje, i-Anebon ibheke phambili ekusebenzisaneni okukhulu nakakhulu namakhasimende aphesheya ngokuya ngezinzuzo ezifanayo. Sicela uzizwele mahhala ukuze uxhumane nathi ukuze uthole imininingwane eyengeziwe.

2022 Ikhwalithi ephezulu yaseChina CNC kanye Nemishini, Nethimba labasebenzi abanolwazi nabanolwazi, imakethe ye-Anebon ihlanganisa iNingizimu Melika, i-USA, Mid East, kanye neNyakatho Afrika. Amakhasimende amaningi abe ngabangane be-Anebon ngemuva kokubambisana okuhle ne-Anebon. Uma unesidingo sanoma yimiphi imikhiqizo yethu, khumbula ukusithinta manje. I-Anebon izolangazelela ukuzwa kuwe maduzane.

Isikhathi sokuthumela: May-08-2023