1. Ibhentshimakhi

Izingxenye zihlanganisa izindawo ezimbalwa, ngayinye inosayizi othize kanye nezidingo zokuma okufanayo. Izidingo zokuma okuhlobene phakathi kwezindawo ezingaphezulu zezingxenye zifaka izici ezimbili: ibanga ukunemba kobukhulu phakathi kwezindawo ezingaphezulu kanye nokunemba kwendawo ehlobene (njengokubambisana, ukufana, i-perpendicularity kanye nokuphuma kwendilinga, njll.) izimfuneko. Ucwaningo lobudlelwano bendawo obuhlobene phakathi kwezindawo ezingaphezulu zezingxenye azihlukaniseki kudathamu, futhi indawo yengxenye engaphezulu ayikwazi ukunqunywa ngaphandle kwedatha ecacile. Ngomqondo wayo ojwayelekile, i-datum iyiphoyinti, umugqa, nendawo engxenyeni esetshenziselwa ukunquma indawo yamanye amaphuzu, imigqa, nezindawo. Ngokwemisebenzi yabo ehlukene, amabhentshimakhi angahlukaniswa abe izigaba ezimbili: amabhentshimakhi wokuklama kanye namabhentshimakhi okucubungula.

1. Isisekelo sokuklama

Idatha esetshenziselwa ukunquma amanye amaphuzu, imigqa nezindawo engxenyeni yomdwebo ibizwa ngokuthi i-design datum. Ngephiston, i-design datum ibhekisela kumugqa omaphakathi wepiston kanye nomugqa omaphakathi wembobo yephini.

2. Ibhentshimakhi yokucubungula

I-datum esetshenziswa izingxenye zenqubo yomshini nokuhlanganisa ibizwa ngokuthi i-process datum. Ngokusetshenziswa okuhlukene, amabhentshimakhi enqubo ahlukaniswa abe amabhentshimakhi okuma, amabhentshimakhi okulinganisa kanye namabhentshimakhi okuhlanganisa.

1) Idethi yokuma: Idatha esetshenziswa ukwenza ucezu lokusebenza luthathe indawo efanele ethuluzini lomshini noma endaweni lapho lucutshungulwa ibizwa ngokuthi i-positioning datum. Ngokusho kwezingxenye ezihlukene zokumisa, ezisetshenziswa kakhulu yizigaba ezimbili ezilandelayo:

Ukumisa maphakathi nendawo okuzenzakalelayo: njengokuma kwe-chuck yemihlathi emithathu.

Ukubeka indawo yomkhono: Isici sokuma senziwe saba umkhono wokumisa, njengokuma kwepuleti lokumisa.

Okunye kufaka phakathi ukuma kuhlaka olumise okwe-V, ukumiswa emgodini oyisiyingi, njll.

2) Idatha yokulinganisa: Idatha esetshenziselwa ukukala usayizi nendawo yendawo emshinini phakathi nokuhlolwa kwengxenye ibizwa ngokuthi i-datum yokulinganisa.

3) Idatha yomhlangano: Idatha esetshenziselwa ukunquma indawo yengxenye engxenyeni noma umkhiqizo phakathi nokuhlanganiswa ibizwa ngokuthi i-datum yomhlangano.

Okwesibili, indlela yokufaka i-workpiece

Ukuze kucutshungulwe indawo ehlangabezana nezidingo zobuchwepheshe ezishiwo engxenyeni ethile yendawo yokusebenza, isiqeshana somsebenzi kufanele sibe sesimweni esifanele ngokuhlobene nethuluzi elisethuluzini lomshini ngaphambi komshini. Le nqubo ivame ukubizwa ngokuthi "ukubekwa" kwe-workpiece. Ngemuva kokuthi i-workpiece ibekwe, ngenxa yesenzo samandla okusika, amandla adonsela phansi, njll. ngesikhathi sokucutshungulwa, indlela ethile kufanele isetshenziselwe "ukubopha" i-workpiece ukuze isikhundla esinqunyiwe sihlale singashintshi. Inqubo yokuthola i-workpiece endaweni efanele emshinini kanye nokubopha i-workpiece ibizwa ngokuthi "ukusetha".

Izinga lokufakwa kwe-workpiece liyindaba ebalulekile ekwenzeni imishini. Akuthinti kuphela ngokuqondile ukunemba kwemishini, isivinini nokuzinza kokufakwa kwe-workpiece, kodwa futhi kuthinta izinga lokukhiqiza. Ukuze kuqinisekiswe ukunemba okuhlobene kokuma phakathi kwendawo ewumshini kanye nedatha yokuklama kwayo, indawo yokusebenza kufanele ifakwe ukuze idatha yokuklama yendawo ewumshini ibe sendaweni efanele uma kuqhathaniswa nethuluzi lomshini. Isibonelo, ekuqedeni ama-grooves ring, ukuze kuqinisekiswe izidingo zokugijima okuyisiyingi kobubanzi obuphansi be-groove ring kanye ne-axis yesiketi, i-workpiece kufanele ifakwe ukuze i-datum yayo yokuklama ihambisane ne-axis. we-spindle yethuluzi lomshini.

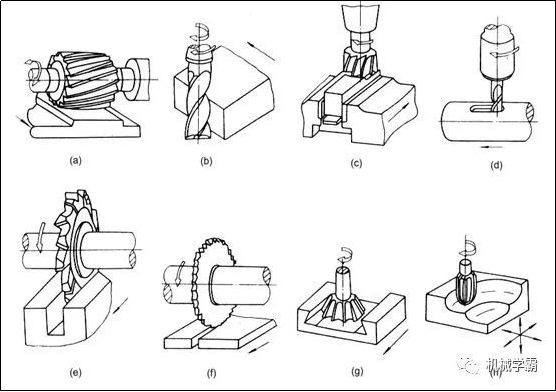

Lapho wenza izingxenye zemishini ehlukahlukene yamathuluzi omshini ahlukahlukene, kunezindlela ezahlukahlukene zokufaka. Izindlela zokufaka zingahlukaniswa zibe izinhlobo ezintathu: indlela yokuqondanisa okuqondile, indlela yokuqondanisa ababhali kanye nendlela yokufaka yokuhlanganisa.

1) Indlela yokuqondisa eqondile Lapho usebenzisa le ndlela, isikhundla esifanele okufanele isiqeshana sokusebenzela sibe ethuluzini lomshini sitholakala ngochungechunge lwemizamo. Indlela eqondile iwukusebenzisa inkomba yokudayela noma inaliti yokubhala epuletini lokubhala ukuze ulungise indawo efanele yesiqeshana sokusebenza ngokuhlola okubukwayo ngemva kokuba ucezu lokusebenza lubekwe ngokuqondile ethuluzini lomshini, kuze kube yilapho luhlangabezana nezidingo.

Ukunemba kokubeka kanye nesivinini sendlela yokuqondisa ngokuqondile kuncike ekunembeni kokuqondisa, indlela yokuqondisa, amathuluzi okuqondisa kanye nezinga lobuchwepheshe labasebenzi. Ububi bayo ukuthi ithatha isikhathi esiningi, ukukhiqiza okuncane, futhi idinga ukuqhutshwa isipiliyoni, futhi idinga amakhono aphezulu kubasebenzi, ngakho isetshenziswa kuphela ekukhiqizeni isiqeshana esisodwa kanye ne-batch encane. Isibonelo, ukuthembela ekulingiseni ukuqondanisa umzimba kuyindlela yokuqondisa eqondile.

2) Indlela yokuqondanisa i-scribing Le ndlela iwukusebenzisa inaliti yokubhala ethuluzini lomshini ukuze uqondanise isiqeshana somsebenzi ngokuya ngomugqa odwetshwe kumkhiqizo ongenalutho noma oqedwe kancane, ukuze ukwazi ukuthola indawo efanele. Ngokusobala, le ndlela idinga inqubo eyodwa yokubhala. Ulayini odwetshiwe ngokwawo unobubanzi obuthile, futhi kukhona iphutha lokubhala lapho ubhala, futhi kukhona iphutha lokubuka lapho kulungiswa indawo yomsebenzi. Ngakho-ke, le ndlela isetshenziswa kakhulu kumaqoqo amancane okukhiqiza, ukunemba okungenalutho okuphansi, kanye nezingxenye zokusebenza ezinkulu. Akufanelekile ukusebenzisa ama-fixtures. emishinini enzima. Isibonelo, indawo yembobo yephini yomkhiqizo we-stroke emibili inqunywa ngokusebenzisa indlela yokumaka yekhanda lokukhomba.

I-3) Ukusebenzisa indlela yokufaka i-fixture: imishini yenqubo esetshenziselwa ukugoqa ucezu lokusebenza futhi lulenze luthathe indawo efanele lubizwa ngokuthi ithuluzi lomshini. I-fixture iyidivayisi eyengeziwe yethuluzi lomshini. Isikhundla saso esihlobene nethuluzi ethuluzini lomshini silungisiwe kusengaphambili ngaphambi kokufakwa kwe-workpiece, ngakho-ke akudingekile ukuvumelanisa ukuma ngakunye lapho ucubungula iqoqo lezinto zokusebenza, ezingaqinisekisa izidingo zobuchwepheshe zokucubungula. Kuyindlela ephumelelayo yokumisa esindisa abasebenzi nezinkinga, futhi isetshenziswa kakhulu ekukhiqizeni inqwaba kanye nobuningi. Ukucutshungulwa kwethu kwamanje kwepiston kuyindlela yokufaka insimbi esetshenziswayo.

①. Ngemuva kokuthi i-workpiece ibekwe, ukusebenza kokugcina indawo yokuma ingashintshiwe phakathi nenqubo yomshini ibizwa ngokuthi i-clamping. Idivaysi esendaweni egcina ucezu lokusebenza lusendaweni efanayo ngesikhathi sokucubungula ibizwa ngokuthi i-clamping device.

②. Idivayisi yokubopha kufanele ihlangabezane nezidingo ezilandelayo: lapho i-clamping, ukuma kwe-workpiece akufanele yonakaliswe; ngemuva kokubopha, isikhundla se-workpiece ngesikhathi sokucubungula akufanele sishintshe, futhi ukubopha kufanele kube okunembile, okuphephile futhi okuthembekile; i-clamping Isenzo siyashesha, ukusebenza kulula futhi kusindisa abasebenzi; isakhiwo silula futhi ukwakheka kulula.

③. Izinyathelo zokuqapha lapho ubopha: amandla okubamba kufanele afaneleke. Uma inkulu kakhulu, i-workpiece izoba nokukhubazeka. Uma incane kakhulu, i-workpiece izosuswa ngesikhathi sokucutshungulwa futhi izolimaza ukuma kwe-workpiece.

3. Ulwazi oluyisisekelo lokusika insimbi

1. Ukunyakaza okuphendukayo nokwakheka kwendawo

Ukuguqula ukunyakaza: Enqubweni yokusika, ukuze kukhishwe insimbi eyengeziwe, kuyadingeka ukwenza i-workpiece kanye nethuluzi lenze ukunyakaza kokusika okuhlobene. Ukunyakaza kokukhipha insimbi eyeqile endaweni yokusebenza ngethuluzi elijikayo ku-lathe kubizwa ngokuthi ukunyakaza okuphendukayo, okungahlukaniswa kube ukunyakaza okuyinhloko kanye nokunyakaza kokuphakelayo. nikeza ukuzivocavoca.

Ukunyakaza okuyinhloko: Isendlalelo sokusika ku-workpiece sinqunywe ngokuqondile ukuze siguqulwe sibe ama-chips, ngaleyo ndlela sakhe ukunyakaza kwendawo entsha ye-workpiece, ebizwa ngokuthi ukunyakaza okuyinhloko. Lapho usika, ukunyakaza okujikelezayo kwe-workpiece kuwukunyakaza okuyinhloko. Ngokuvamile, isivinini sokunyakaza okuyinhloko siphezulu, futhi amandla okusika adliwe aphezulu.

Ukunyakaza kokuphakelayo: ukunyakaza kokwenza isendlalelo esisha sokusika sifakwe ngokuqhubekayo ekusikeni, ukunyakaza kokuphakelayo ukunyakaza okuhambisana nobuso bomsebenzi ozokwakhiwa, okungaba ukunyakaza okuqhubekayo noma ukunyakaza okuphakathi. Isibonelo, ukunyakaza kwethuluzi lokuguqula ku-lathe evundlile kuyaqhubeka, futhi ukunyakaza kokuphakelayo kwe-workpiece ku-planer ukunyakaza kwezikhawu.

Izindawo ezakhiwe ku-workpiece: Ngesikhathi senqubo yokusika, izindawo ezinomshini, izindawo ezinomshini, nezindawo ezizokwenziwa ngomshini kwakhiwa endaweni yokusebenza. Indawo eqediwe isho indawo entsha ekhishwe ensimbi eyeqile. Indawo ezokwenziwa ngomshini ibhekisela endaweni okuzosikwa kuyo ungqimba lwensimbi. Indawo eyenziwe ngomshini ibhekisela endaweni lapho unqenqema lokusika lwethuluzi lokujika lujika khona.

2. Izakhi ezintathu zenani lokusika zibhekisela ekujuleni kokusika, izinga lokudla kanye nesivinini sokusika.

1) Ukujula kokusika: ap=(dw-dm)/2(mm) dw=diameter of unmachineed workpiece dm=diameter of workpiece eyenziwe ngomshini, ukujula kokusika yilokho esivame ukukubiza ngokuthi inani lokusika.

Ukukhethwa kokujula kokusika: Ukujula kwe-αp kufanele kunqunywe ngokuya ngesibonelelo somshini. Lapho ugoqa, ngaphezu kokushiya isibonelelo sokuqeda, yonke i-roughing allowance kufanele isuswe endaweni eyodwa ngangokunokwenzeka. Lokhu akukwazi nje ukwenza umkhiqizo wokujula kokusika, izinga lokuphakelayo ƒ kanye nesivinini sokusika V esikhulu ngaphansi kwesisekelo sokuqinisekisa izinga elithile lokuqina, kodwa futhi kunciphise inani lokudlula. Uma isibonelelo somshini sikhulu kakhulu noma ukuqina kwesistimu yenqubo akwanele noma amandla we-blade enganele, kufanele ihlukaniswe ngamaphasi angaphezu kwamabili. Ngalesi sikhathi, ukujula kokusika kokudlula kokuqala kufanele kube kukhulu, okungabalelwa ku-2/3 kuya ku-3/4 wesamba esiphelele; futhi ukujula kokusika kokudlula kwesibili kufanele kube kuncane, ukuze inqubo yokuqeda ingatholakala. Ivelu yepharamitha yobukhulu obungaphezulu obuncane kanye nokunemba okuphezulu komshini.

Lapho ingaphezulu lezingxenye zokusika kuyi-castings enesikhumba esiqinile, i-forging noma insimbi engagqwali nezinye izinto ezibandayo ezibandayo, ukujula kokusika kufanele kudlule ukuqina noma ungqimba olubandayo ukuze kugwenywe ukusika imiphetho ekusikeni ungqimba oluqinile noma olubandayo.

2) Ukukhethwa kwenani lokuphakelayo: ukugudluzwa okuhlobene kwesiqeshana sokusebenza kanye nethuluzi eliqondiswe lapho ukunyakaza kokuphakelayo njalo lapho ucezu lokusebenza noma ithuluzi lizungeza noma libuyisela kanye, iyunithi ingu-mm. Ngemva kokukhethwa ukujula kokusika, ukudla okukhudlwana kufanele kukhethwe ngangokunokwenzeka. Ukukhethwa kwenani elifanele lokuphakelayo kufanele kuqinisekise ukuthi ithuluzi lomshini kanye nethuluzi ngeke lonakaliswe ngenxa yamandla amaningi okusika, ukuphambuka kwe-workpiece okubangelwa amandla okusika ngeke kudlule inani elivumelekile lokunemba kwe-workpiece, kanye nevelu yepharamitha yobukhulu obungaphezulu ngeke ibe nkulu kakhulu. Uma kudlanga, umkhawulo oyinhloko wokuphakela amandla okunciphisa, futhi ekuqedeni okuncane nokuqeda, umkhawulo oyinhloko wokuphakelayo ubuhwaqane obungaphezulu.

I-3) Ukukhethwa kwejubane lokusika: Ngesikhathi sokusika, isivinini esisheshayo sephuzu elithile onqenqemeni lokusika lwethuluzi elihlobene nobuso obuzokwenziwa ngomshini ohlangothini oluyinhloko lokunyakaza, iyunithi i-m / min. Uma ukujula kwe-cut αp kanye nesilinganiso sokuphakelayo ƒ kukhethwa, isivinini sokusika esiphezulu sikhethwa ngalezi sisekelo, futhi isiqondiso sokuthuthukiswa kokucubungula ukusika ukusika ngesivinini esikhulu.ingxenye yokunyathela

Okwesine, umqondo wemishini wokuba namahhadlahhadla

Kuomakhenikha, ubuhwaqane busho izici zejiyomethri ezincane ezincane ezihlanganisa izikhala ezincane neziqongo nezigodi endaweni eyenziwe ngomshini. Ingenye yezinkinga zocwaningo olushintshashintshayo. Ubulukhuni bobuso ngokuvamile bakheka indlela yokucubungula esetshenziswayo nezinye izici, njengokungqubuzana phakathi kwethuluzi nobuso bengxenye ngesikhathi sokucutshungulwa, ukuguqulwa kwepulasitiki yensimbi engaphezulu lapho ama-chip ehlukaniswa, kanye nokudlidliza kwemvamisa ephezulu uhlelo lwenqubo. Ngenxa yezindlela ezihlukene zokucubungula kanye nezinto zokusebenza, ukujula, ukuminyana, ukuma nokuthungwa kwamamaki asele endaweni yomshini kuhlukile. Ubulukhuni bobuso buhlobene eduze nezakhiwo ezifanayo, ukumelana nokugqokwa, amandla okukhathala, ukuqina kokuxhumana, ukudlidliza nomsindo wezingxenye eziwumshini, futhi kunomthelela obalulekile empilweni yesevisi nokwethembeka kwemikhiqizo eyimishini.aluminium casting ingxenye

Ukumelwa kokuqina

Ngemva kokuba ubuso bengxenye bucutshungulwe, bubukeka bushelelezi, kodwa alilingani ngemva kokukhulisa. Ubulukhuni bobuso bubhekisela ezicini zejiyomethri ezincane ezakhiwe amabanga amancane neziqongo nezigodi ezingaphezulu kwengxenye ecutshunguliwe, ngokuvamile ezakhiwe indlela yokucubungula kanye (noma) nezinye izici. Umsebenzi wobuso bengxenye uhlukile, futhi inani lepharamitha elidingekayo lokumahhadla kwendawo nalo lihlukile. Ikhodi ye-surface roughness (uphawu) kufanele imakwe engxenyeni yomdwebo ukuze ichaze izici ezingaphezulu okufanele zifezwe ngemva kokuqedwa kobuso. Kunezinhlobo ezi-3 zamapharamitha wobude bokuhwalala kobuso:

1. I-Contour arithmetic isho ukuchezuka Ra

Incazelo ye-arithmetic yenani eliphelele lebanga eliphakathi kwamaphoyinti emugqeni wekhonta esiqondisweni sokulinganisa (inkomba engu-Y) kanye nomugqa wereferensi ngaphakathi kobude besampula.

2. Ubude obunamaphoyinti ayishumi i-Rz yokungalingani kwe-microscopic

Ibhekisela esilinganisweni sesilinganiso sobude obuphakeme bephrofayela obuyi-5 obukhulu kanye nokujula kwesigodi sephrofayela esikhulukazi okungu-5 ngaphakathi kobude besampula.

3. Ubukhulu bobude bekhontowuthi Ry

Ibanga phakathi komugqa wokuphakama okuphezulu kakhulu kanye nomugqa wesigodi esiphansi kunazo zonke sephrofayela ngaphakathi kobude besampula.

Njengamanje, u-Ra. isetshenziswa kakhulu embonini ejwayelekile yokukhiqiza imishini.

isithombe

4. Indlela Yokumela Ukuqina

5. Umthelela wobunzima ekusebenzeni kwezingxenye

Izinga eliphezulu le-workpiece ngemva kokucutshungulwa lithinta ngqo izakhiwo zayo ezingokomzimba, zamakhemikhali, nezomshini. Ukusebenza kokusebenza, ukwethembeka kanye nempilo yomkhiqizo kuncike kakhulu kwikhwalithi ephezulu yezingxenye eziyinhloko. Ngokuvamile, izidingo zekhwalithi yangaphezulu yezingxenye ezibalulekile noma ezibucayi ziphakeme kunezingxenye ezijwayelekile ngoba izingxenye ezinekhwalithi engaphezulu zizothuthukisa kakhulu ukumelana kwazo nokugqokwa, ukumelana nokugqwala, nokumelana nokulimala kokukhathala.CNC machining aluminium ingxenye

6. Ukusika uketshezi

1) Indima yokusika uketshezi

Umphumela wokupholisa: Ukushisa okusikayo kungathatha inani elikhulu lokushisa okusika, kuthuthukise izimo zokulahla ukushisa, kunciphise izinga lokushisa lethuluzi kanye nendawo yokusebenza, ngaleyo ndlela kwandise impilo yesevisi yethuluzi futhi kuvimbele iphutha le-dimensional ye-workpiece ebangelwa deformation ezishisayo.

Ukugcoba: Uketshezi olusikayo lungangena phakathi kwe-workpiece nethuluzi, ukuze kwakheke ungqimba oluncane lwefilimu ye-adsorption endaweni encane phakathi kwe-chip nethuluzi, okunciphisa i-coefficient yokungqubuzana, ngakho-ke kunganciphisa ukungqubuzana phakathi kwethuluzi. i-chip kanye ne-workpiece , ukunciphisa amandla okusika kanye nokushisa okusika, ukunciphisa ukuguga kwethuluzi futhi kuthuthukise izinga eliphezulu le-workpiece. Ukuze uqedele, ukugcoba kubaluleke kakhulu.

Umphumela wokuhlanza: Ama-chips amancane akhiqizwe ngesikhathi sokuhlanza kulula ukunamathela kucezu lokusebenza kanye nethuluzi, ikakhulukazi lapho kubholwa izimbobo ezijulile kanye nezimbobo zokuvuselela kabusha, ama-chips avinjwa kalula kumtshingo we-chip, othinta ubulukhuni bomsebenzi futhi impilo yesevisi yethuluzi. . Ukusetshenziswa koketshezi lokusika kungageza ngokushesha ama-chips, ukuze ukusika kuqhutshwe kahle.

2) Uhlobo: Kunezinhlobo ezimbili zoketshezi lokusika oluvame ukusetshenziswa

I-Emulsion: Ngokuyinhloko idlala indima yokupholisa. I-emulsion yenziwa ngokuhlambulula amafutha e-emulsified nge-15 ~ 20 izikhathi zamanzi. Lolu hlobo loketshezi lokusika lunokushisa okukhulu okuqondile, i-viscosity ephansi kanye noketshezi oluhle, futhi lukwazi ukumunca ukushisa okuningi. Uketshezi lokusika lusetshenziselwa ikakhulukazi ukupholisa ithuluzi nomsebenzi, ukuthuthukisa impilo yamathuluzi nokunciphisa ukuwohloka kokushisa. I-emulsion iqukethe amanzi amaningi, futhi imisebenzi yokugcoba nokuvimbela ukugqwala impofu.

Amafutha okusika: Ingxenye eyinhloko yamafutha okusika amafutha amaminerali. Lolu hlobo loketshezi lokusika lunokushisa okuncane okuqondile, i-viscosity ephezulu kanye nokungabi namanzi. Idlala kakhulu indima yokugcoba. Amafutha amaminerali ane-viscosity ephansi avame ukusetshenziswa, njengamafutha emoto, amafutha e-diesel alula, i-Kerosene njll.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Jun-24-2022