I-Aluminium yinto esetshenziswa kakhulu yensimbi engeyona insimbi, futhi ububanzi bayo bokusebenza lusakhula. Izinhlobo ezingaphezu kuka-700,000 zemikhiqizo ye-aluminium zikhiqizwa kusetshenziswa izinto ze-aluminium. Ngokwezibalo, kunezinhlobo ezingaphezu kuka-700,000 zemikhiqizo ye-aluminium, futhi izimboni ezihlukahlukene, njengemboni yokwakha nezokuhlobisa, imboni yezokuthutha, imboni ye-aerospace, njll, inezidingo ezahlukene. Namuhla, uXiaobian uzokwethula ubuchwepheshe bokucubungula imikhiqizo ye-aluminium kanye nendlela yokugwema ukucubungula ukuguga.Ingxenye yemishini ye-CNC

Izinzuzo nezici ze-aluminium zimi kanje:

1. Ukuminyana okuphansi. Ukuminyana kwe-aluminium cishe ku-2.7 g/cm3. Ubuningi bawo buyi-1/3 kuphela yensimbi noma ithusi.

2. Ipulasitiki ephezulu. I-Aluminium iyaguquguquka futhi ingenziwa ibe yimikhiqizo ehlukahlukene ngezindlela zokucubungula ingcindezi njenge-extrusion nokwelula.

3. Ukumelana nokugqwala. I-Aluminium iyinsimbi enecala elibi kakhulu, futhi ifilimu ye-oxide evikelayo izokwakhiwa phezulu ngaphansi kwezimo zemvelo noma i-anodizing. Inokumelana nokugqwala okungcono kakhulu kunensimbi.

4, kulula ukuqinisa. I-aluminium ehlanzekile ayinamandla kakhulu, kodwa inganyuswa nge-anodizing.

5. Ukwelashwa kwendawo okulula. Ukwelapha okungaphezulu kungathuthukisa noma kuguqule izici ezingaphezulu ze-aluminium. Inqubo ye-aluminium anodizing ivuthiwe impela futhi izinzile futhi isetshenziswa kabanzi ukucubungula imikhiqizo ye-aluminium.

6. I-conductivity enhle futhi kulula ukuyigaya kabusha.

Ukucubungula ubuchwepheshe bemikhiqizo ye-aluminium

Ukubhoboza kwemikhiqizo ye-aluminium

1. Isibhakela esibandayo

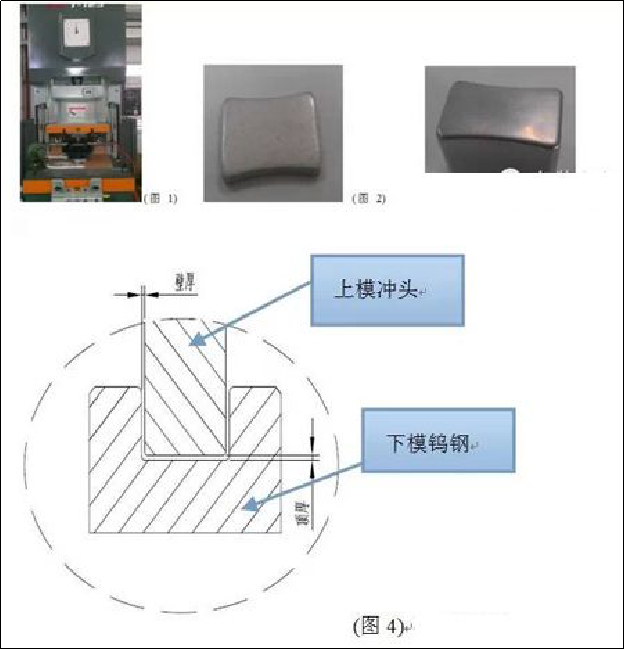

Sebenzisa ama-pellets e-aluminium. Umshini we-extrusion kanye ne-die kusetshenziselwa ukubumba isikhathi esisodwa futhi kufanelekile emikhiqizweni eyi-cylindrical noma izimo zomkhiqizo okunzima ukuzithola ngezinqubo zokwelula, ezifana nemikhiqizo e-oval, isikwele, kanye ne-rectangular.

I-tonnage yomshini osetshenzisiwe ihlobene nendawo ehlukanisayo yomkhiqizo. Ukujiya kodonga lomkhiqizo yigebe eliphakathi kwe-die punch ephezulu kanye nensimbi ephansi ye-die tungsten. Lapho i-punch ye-die punch kanye nensimbi ye-die tungsten ephansi kucindezelwa ndawonye, igebe eliqondile enkabeni ephansi efile Ngobukhulu obuphezulu bomkhiqizo.ingxenye ye-aluminium

Izinzuzo: Umjikelezo wokuvula isikhunta mfushane, futhi izindleko zokuthuthukiswa ziphansi kunalezo zesikhunta sokudweba.

Ukungalungi: Inqubo yokukhiqiza yinde, usayizi womkhiqizo ushintshashintsha kakhulu, futhi izindleko zabasebenzi ziphezulu.

2. Ukuzelula

Sebenzisa isikhumba se-aluminium esibonakalayo. Ilungele ukukhubaza imizimba engeyona i-cylindrical (imikhiqizo ye-aluminium enemikhiqizo egobile), ngokuvamile isebenzisa imishini yokufa eqhubekayo kanye nesikhunta ukuhlangabezana nezidingo zomumo.

Izinzuzo: imikhiqizo eyinkimbinkimbi futhi eminingi yokuguqulwa inokulawula okuzinzile kwe-dimensional enqubweni yokukhiqiza, futhi indawo yomkhiqizo iyashelela.

Ukungalungi: izindleko zesikhunta eziphezulu, umjikelezo wokuthuthukiswa omude, nokukhethwa komshini okuphezulu kanye nezidingo zokunemba.

Ukwelashwa okungaphezulu kwemikhiqizo ye-aluminium

1. Ukuqhunyiswa kwesihlabathi (ukuchama)

Inqubo yokuhlanza nokuqinisa izindawo zensimbi kusetshenziswa umthelela wokugeleza kwesihlabathi esinesivinini esikhulu.

Ukwelashwa okungaphezulu kwezingxenye ze-aluminium ngale ndlela kungathola izinga elithile lokuhlanzeka kanye nobulukhuni obuhlukile ebusweni be-workpiece ukuze izakhiwo zemishini yobuso be-workpiece zithuthukiswe, ngaleyo ndlela kuthuthukiswe ukumelana nokukhathala kwe-workpiece futhi kwandise i-workpiece. igebe phakathi kwaso kanye enamathelayo. Ukunamathela kwe-coating kwandisa ukuqina kwefilimu yokugqoka futhi kubuye kuhambisane nokulingana nokuhlobisa kwe-coating. Siyabona kule nqubo ukuthi imikhiqizo ye-Apple i-o2. Ukupholisha

Basebenzisa umshini, amakhemikhali, noma isenzo se-electrochemical ukunciphisa ubulukhuni obungaphezulu bomsebenzi futhi bathole indlela ekhanyayo, eyisicaba yokucubungula indawo. Inqubo yokupholisha ihlukaniswe yaba ukupholisha ngomshini, amakhemikhali, kanye ne-electrolytic. Ngemva kokupholisha ngomshini + ukupholisha nge-electrolytic, izingxenye ze-aluminium zingasondela kumphumela wesibuko sensimbi engagqwali. Le nqubo inikeza abantu umuzwa wokulula okuphezulu kanye nekusasa lemfashini.

3. Umdwebo

Umdwebo wocingo lwensimbi yinqubo yokukhiqiza yokukhuhla ishidi le-aluminium ngokuphindaphindiwe emigqeni nge-sandpaper. Umdwebo ungahlukaniswa ube oqondile, ongahleliwe, o-spiral, kanye nentambo. Inqubo yokudweba ngocingo lwensimbi ingabonisa ngokucacile lonke uphawu lukasilika oluncane, ngakho ukucwebezela kwezinwele ezicwengisisiwe kubonakala ku-metal matte, futhi umkhiqizo unomqondo wemfashini nobuchwepheshe.

4. Ukusika kwe-gloss ephezulu

Kusetshenziswa umshini wokuqopha, ummese wedayimane uqiniswa ku-shaft eyinhloko yomshini wokuqopha, uzungeza ngesivinini esikhulu (ngokuvamile u-20,000 rpm) ukuze usike izingxenye, futhi indawo evelele yendawo ikhiqizwa ebusweni bomkhiqizo. Ukukhanya kwezinto ezivelele zokusika kuthintwa ijubane lomshini wokugaya. Ukushesha kwejubane lokubhoboza, kugqama ukugqama kokusika, futhi okuphambene nalokho, kuba mnyama futhi kufinyeleleka kalula ukukhiqiza imigqa yokusika. Ukusika okucwebezelayo okuphezulu kanye nokucwebezela okuphezulu kusetshenziswa kakhulu kumaselula afana nama-iPhone. Amanye amafreyimu ensimbi ye-TV asezingeni eliphezulu asanda kusebenzisa inqubo yokugaya ecwebezelayo. Ngaphezu kwalokho, izinqubo zokudweba i-anodizing nezintambo zenza isethi ye-TV igcwale imfashini nobuchwepheshe.

5. I-Anodizing

I-anodic oxidation ibhekisela ku-electrochemical oxidation yezinsimbi noma ama-alloys. Ngaphansi kwezimo ezihambisanayo ze-electrolyte kanye nezimo ezithile zenqubo, i-aluminium nama-alloys ayo akha ifilimu ye-oxide emkhiqizweni we-aluminium (anode) ngenxa yesenzo se-current esetshenzisiwe. I-anodizing ayikwazi nje ukuxazulula izinkinga zokuqina kwe-aluminium ebusweni nokumelana nokuguga kodwa futhi yelule impilo yesevisi ye-aluminium futhi ithuthukise ubuhle. Isiphenduke ingxenye ebalulekile yokwelashwa kwe-aluminium ebusweni futhi njengamanje isetshenziswa kakhulu futhi iphumelela kakhulu. umsebenzi wezandla

6. I-anode enemibala emibili

I-anodizing yemibala emibili isho i-anodizing emkhiqizweni owodwa kanye nokudlulisa imibala ehlukene ezindaweni ezithile. Inqubo ye-anodizing yemibala emibili ayivamile ukusetshenziswa embonini ye-TV ngoba inqubo iyinkimbinkimbi futhi ibiza phezulu. Noma kunjalo, umehluko phakathi kwemibala emibili unga

bonisa kangcono ukubukeka okuphezulu nokuyingqayizivele komkhiqizo.

Izinyathelo zokucubungula kanye namakhono okusebenza ukunciphisa ukuwohloka kokucubungula kwe-aluminium

Kunezizathu eziningi zokuwohloka kwezingxenye ze-aluminium, ezihlobene nezinto ezibonakalayo, ukuma kwengxenye, nezimo zokukhiqiza. Ngokuyinhloko kukhona izici ezilandelayo: ukuguquguquka okubangelwa ukucindezeleka kwangaphakathi kokungenalutho, ukuguqulwa okubangelwa amandla okusika kanye nokushisa okusika, kanye nokuguqulwa okubangelwa amandla okubamba.

Izinyathelo zenqubo zokunciphisa ukuwohloka kokucubungula

1. Yehlisa ukucindezeleka kwangaphakathi kwesiko lezinwele

Ukwelashwa kokuguga okungokwemvelo noma okwenziwayo kanye nokudlidliza kungaqeda kancane ingcindezi yangaphakathi yokungenalutho. Ukucubungula kwangaphambili kuyindlela yenqubo ephumelelayo. Ngenxa yesibonelelo esikhulu, ukuwohloka ngemva kokucutshungulwa nakho kubalulekile kokungenalutho okunekhanda elinamafutha namadlebe amakhulu. Ake sithi ingxenye eyengeziwe yokungenalutho icutshungulwe ngaphambili, futhi imvume yengxenye ngayinye iyancipha. Kuleso simo, kunganciphisa ukuwohloka kokucubungula kwenqubo elandelayo futhi kukhulule okunye ukucindezeleka kwangaphakathi ngemva kokucubungula kwangaphambili isikhathi esithile.

2. Thuthukisa ikhono lokusika lethuluzi

Izinto ezibonakalayo kanye nemingcele yejometri yethuluzi inethonya elibalulekile emandleni okusika nokushisa okusika. Ukukhethwa okulungile kwethuluzi kuyadingeka ukunciphisa ukuguqulwa kwe-machining kwengxenye.

1) Ukukhetha okunengqondo kwethuluzi lamapharamitha wejometri.

①I-engeli ye-Rake: Ngaphansi kwesimo sokugcina amandla e-blade, i-engeli ye-rake ikhethwa ngokufanelekile ukuthi ibe nkulu; ngakolunye uhlangothi, ingakwazi ukugaya unqenqema olubukhali, futhi ngakolunye uhlangothi, inganciphisa ukuguqulwa kokusika, yenza ukukhishwa kwe-chip kube bushelelezi, bese kunciphisa amandla okusika kanye nokushisa kokusika. Ungalokothi usebenzise amathuluzi ane-engeli ye-rake engalungile.

②I-engeli yokukhulula: Usayizi we-engeli yokukhulula uthinta ngokuqondile ukuguga kweflank kanye nekhwalithi yendawo ewumshini. Ubukhulu bokusika kuyisimo esibalulekile sokukhetha i-angle yokususa. Ithuluzi lidinga ukukhishwa okuhle kokushisa ngesikhathi sokugaya kabi ngenxa yezinga lokuphakelayo elibalulekile, umthwalo osindayo wokusika, nokukhiqiza ukushisa okukhulu. Ngakho-ke, i-angle yokususa kufanele ikhethwe ukuze ibe mncane. Lapho ukugaya okuhle, unqenqema lokusika kufanele lube bukhali, ukungqubuzana phakathi kwe-flank face kanye ne-machined surface kuyancipha, futhi ukuguqulwa kwe-elastic kuyancipha. Ngakho-ke, i-angle yokususa kufanele ibaluleke kakhulu.

③ I-engeli ye-Helix: I-engeli ye-helix kufanele ibe nkulu ngangokunokwenzeka ukuze ishelele futhi inciphise amandla okugaya.

④I-engeli enkulu yokwehla: Ukwehlisa kahle i-engeli yokwehla emaphakathi kungathuthukisa izimo zokulahla ukushisa futhi kunciphise izinga lokushisa elimaphakathi lendawo yokucubungula.

2) Thuthukisa isakhiwo samathuluzi.

①Yehlisa inani lamazinyo esisiki sokugaya futhi wandise isikhala se-chip. Ngenxa yobukhulu bepulasitiki bezinto ze-aluminium kanye nokwakheka okukhulu kokusika ngesikhathi sokucutshungulwa, kudingeka isikhala esanele se-chip, ngakho-ke indawo engaphansi ye-chip groove kufanele ibe nkulu, futhi inani lamazinyo okugaya kufanele libe lincane.

② Gaya amazinyo kahle. Inani elibukhali lenqenqema lokusika lamazinyo okusika kufanele libe ngaphansi kuka-Ra=0.4um. Ngaphambi kokusebenzisa ummese omusha, kufanele usebenzise itshe elicolekileyo likawoyela ukuze ulole kancane ingaphambili nangemuva kwamazinyo ombese izikhathi ezimbalwa ukuze ukhiphe ama-burrs kanye nokusanhlamvu okuncane okusele lapho ulola amazinyo. Ngale ndlela, ukushisa okusika kungancishiswa, futhi i-deformation yokusika incane kakhulu.

③ Lawula ngokuqinile izinga lokuguga lethuluzi. Ngemuva kokuthi ithuluzi ligqokwe, inani lobunzima bomsebenzi liyakhuphuka, izinga lokushisa lokusika liyakhuphuka, futhi ukuguqulwa kwe-workpiece kuyanda. Ngakho-ke, ngaphezu kokukhetha izinto zamathuluzi ezinokumelana okuhle kokugqoka, izinga lokugqoka ithuluzi akufanele libe lihle kakhulu kune-0.2mm. Uma kungenjalo, kulula ukukhiqiza unqenqema olwakhiwe. Lapho usika, izinga lokushisa le-workpiece akufanele lidlule i-100 ℃ ukuvimbela ukuguquguquka.

3. Thuthukisa indlela yokuhlanganisa ye-workpiece

Ezindaweni zokusebenza ze-aluminium ezinezindonga ezincane ezinokuqina okubi, izindlela zokubopha ezilandelayo zingasetshenziswa ukunciphisa ukuwohloka:

①Ezingxenyeni zehlathi ezinezindonga ezincanyana, uma i-chuck enemihlathi emithathu egxile ngaphakathi noma i-spring chuck isetshenziselwa ukubamba i-radial, ucezu lomsebenzi luzokhubazeka nakanjani uma sesikhishiwe ngemva kokucubungula. Indlela yokucindezela ubuso bokuphela kwe-axial ngokuqina okungcono kufanele kusetshenziswe. Misa imbobo engaphakathi yengxenye, yenza i-mandrel ene-threaded, uyifake embobeni engaphakathi, cindezela ubuso bokuphela nge-cover plate kuyo, bese uyiqinisa nge-nati. I-clamping deformation ingagwenywa lapho kwenziwa umbuthano ongaphandle ukuze uthole ukunemba okwanelisayo.

② Lapho ucubungula ama-workpieces anezindonga ezincane nezincane, kungcono kakhulu ukusebenzisa izinkomishi zokumunca i-vacuum ukuze uthole amandla okubamba asakazwe ngokulinganayo bese ucubungula ngenani elincane lokusika, elingavimbela ukuwohloka kwengcezu yokusebenza.

Ngaphezu kwalokho, indlela yokupakisha ingasetshenziswa futhi. Ukwandisa ukuqina kokucubungula kwama-workpieces anezindonga ezincane, i-medium ingagcwaliswa ngaphakathi kwendawo yokusebenza ukuze kuncishiswe ukuguqulwa kwe-workpiece ngesikhathi sokugoqa nokusika. Isibonelo, i-urea melt equkethe u-3% kuya ku-6% we-potassium nitrate ithululelwa ku-workpiece. Ngemuva kokucubungula, i-workpiece ingacwiliswa emanzini noma utshwala, futhi isigcwalisi singaqedwa futhi sithululwe.

4. Ukuhlelwa okunengqondo kwezinqubo

Ngesikhathi sokusika ngesivinini esikhulu, ngenxa yemvume yomshini omkhulu kanye nokusikwa okuphazamisekile, inqubo yokugaya imvamisa ikhiqiza ukudlidliza, okuthinta ukunemba komshini kanye nokubangwa komhlaba. Ngakho-ke, inqubo yokusika isivinini se-CNC ngokuvamile ingahlukaniswa ibe yi-roughing-semi-finishing-corner-clearing-finishing nezinye izindlela. Kwesinye isikhathi kuyadingeka ukuthi izingxenye ezinezidingo ezinembayo eziphezulu zenze ukuqeda okwesibili nokuqeda. Ngemuva komshini onzima, izingxenye zingapholiswa ngokwemvelo, kuqedwe ukucindezeleka kwangaphakathi okubangelwa umshini onzima nokunciphisa ukuguqulwa. Isibonelelo esishiywe ngemva komshini onzima kufanele sibe sikhulu kunokwakheka, ngokuvamile sibe ngu-1 kuya ku-2 mm. Ngesikhathi sokuqeda, indawo yokuqedela yezingxenye kufanele igcine isibonelelo somshini ofanayo, ngokuvamile i-0.2 ~ 0.5mm, ukuze ithuluzi lizinzile phakathi nenqubo yomshini, okunganciphisa kakhulu ukucwiliswa kokusika, ukuthola ikhwalithi enhle yomshini womshini nokuqinisekisa ukunemba koMkhiqizo.

Amakhono okusebenza ukunciphisa ukuhlanekezela kwemishini

Ngaphezu kwezizathu ezingenhla, izingxenye zezingxenye ze-aluminium zikhubazekile ngesikhathi sokucubungula. Indlela yokusebenza nayo ibalulekile ekusebenzeni kwangempela.

1. Ezingxenyeni ezinesabelo esikhulu semishini, ukuze zinikeze izimo ezingcono zokushisa ukushisa ngesikhathi senqubo yomshini futhi zigweme ukugxila kokushisa, umshini wokulinganisa kufanele wamukelwe ngesikhathi somshini. Uma ishidi eliwugqinsi elingu-90mm lidinga ukucutshungulwa libe ngu-60mm uma uhlangothi olulodwa lugaywa futhi olunye uhlangothi lugaywa ngokushesha, futhi usayizi wokugcina ucutshungulwa ngesikhathi esisodwa, ukucaba kuzofinyelela ku-5mm; uma icutshungulwa ngokulinganayo ngokuphakelwa okuphindaphindiwe, uhlangothi ngalunye lucutshungulwa kabili ukuze Ubukhulu bokugcina buqinisekise ukucaba okungu-0.3mm.ingxenye yokunyathela

2. Uma kunezimbotshana eziningi ezingxenyeni zamapuleti, akufanelekile ukusebenzisa indlela yokucubungula ngokulandelana kwe-cavity eyodwa kanye nomgodi owodwa ngesikhathi sokucubungula, okuzokwenza ngokushesha ukuthi izingxenye zikhubazeke ngenxa yokucindezeleka okungalingani. Ukucubungula kwe-Multi-layer kuyamukelwa, futhi isendlalelo ngasinye sicutshungulwa kuzo zonke izimbobo ngesikhathi esifanayo, bese ungqimba olulandelayo lucutshungulwa ukwenza izingxenye zigcizelelwe ngokulinganayo futhi zinciphise ukuguqulwa.

3. Yehlisa amandla okusika nokusika ukushisa ngokushintsha inani lokusika. Phakathi kwezakhi ezintathu zenani lokusika, inani lokuzibandakanya emuva lithonya kakhulu amandla okusika. Uma imali yomshini inkulu kakhulu, amandla okusika iphasi eyodwa makhulu kakhulu, angeke nje akhubaze izingxenye ezithile kodwa futhi athinte ukuqina kwentokozo yokuphotha ithuluzi lomshini futhi anciphise ukuqina kwethuluzi—inani lemimese okufanele idliwe. Uma ingemuva lincishisiwe, ukusebenza kahle kokukhiqiza kuzoncishiswa kakhulu. Kodwa-ke, ukugaya ngesivinini esikhulu kusetshenziswa kumishini ye-CNC, enganqoba le nkinga. Ngenkathi kunciphisa inani le-back-cut, inqobo nje uma okuphakelayo kwanda ngokufanele futhi isivinini sethuluzi lomshini sikhuphuka, amandla okusika angancishiswa, futhi ukusebenza kahle kokucubungula kungaqinisekiswa ngesikhathi esisodwa.

4. Ukuhleleka kokuhamba kommese kufanele futhi kunakwe. Ukwenza imishini enzima kugcizelela ukuthuthukisa ukusebenza kahle nokuphishekela izinga lokususa ngeyunithi ngayinye yesikhathi. Ngokuvamile, i-up-cut milling ingasetshenziswa. Okusho ukuthi, izinto ezingaphezulu kwendawo engenalutho zisuswa ngesivinini esisheshayo kanye nesikhathi esifushane, futhi i-contour yejometri edingekayo ukuze iqedwe iyakhiwa. Nakuba ukuqeda kugcizelela ukunemba okuphezulu kanye nekhwalithi ephezulu, kuhle ukusebenzisa ukugaya phansi. Ngenxa yokuthi ubukhulu bokusika amazinyo wokusika buyancipha kancane kancane busuka phezulu bufika ku-zero ngesikhathi sokugaya phansi, izinga lokuqina komsebenzi liyancipha kakhulu, futhi izinga lokuguqulwa kwengxenye nalo liyancipha.

5. Ama-workpieces anezindonga ezincane akhubazekile ngenxa yokugoqa ngesikhathi sokucubungula; ngisho nokuqeda akunakugwenywa. Ukuze unciphise ukuguqulwa kwe-workpiece ibe ubuncane, ungakhulula ucezu olucindezelayo ngaphambi kokuqedela usayizi wokugcina ukuze i-workpiece ibuyele ngokukhululekile esimweni sayo sokuqala bese uyicindezela kancane, inqobo nje uma umsebenzi ungacindezelwa (ngokuphelele) . Ngokusho kokuzizwa kwesandla), umphumela omuhle wokucubungula ungatholakala ngale ndlela. Ngamanye amazwi, iphoyinti lesenzo lamandla okubamba kungcono endaweni esekelayo, futhi amandla okubamba kufanele asetshenziswe lapho kubheke khona ukuqina kwengcezu yokusebenza okuhle. Ukuqinisekisa ukuthi i-workpiece ayikhululekile, i-clamping force encane ingcono.

6. Lapho ugaya izingxenye ezinembobo, zama ukungavumeli isisiki sokugaya singene singene ngqo engxenyeni efana ne-drill lapho siklama imbobo, okuholela ekubeni kube nesikhala esanele sokusika isigayo ukuze sikwazi ukwamukela ama-chips kanye nokukhishwa kwe-chip okungekuhle, okuholela ekushiseni ngokweqile, ukwanda. , nokuwa kwezingxenye—imimese, ukuphuka, nezinye izenzakalo ezingathandeki. Okokuqala, bhoboza imbobo ngedrayivu elingana neyomshini wokusika noma usayizi owodwa obalulekile, bese uyigaya nge-milling cutter. Kungenjalo, isofthiwe ye-CAM ingasetshenziswa ukukhiqiza izinhlelo ze-spiral rundown.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Jun-16-2022