Iyini i-asislender yemoto?

I-ekseli yemoto ezacile iwuhlobo olusetshenziswa ezimotweni futhi oludizayinelwe ukuthi lube lula. Ama-ekseli azacile ajwayele ukusetshenziswa ezimotweni ezigxile ekusebenzeni kahle kukaphethiloli kanye nokuba bukhali. Banciphisa isisindo semoto ngenkathi bethuthukisa ukuphatha kwayo. Lawa ma-ekseli ngokuvamile enziwa ngezinto ezingasindi, eziqinile njenge-aluminium noma insimbi enamandla amakhulu. Lawa ma-ekseli akhelwe ukuthi akwazi ukuphatha amandla okushayela, njengetorque ekhiqizwa injini, futhi aqhubeke nokugcina umklamo ohlangene, oqondile. Ama-ekseli azacile abalulekile ekudluliselweni kwamandla ukusuka enjini ukuya emasondweni.

Kungani kulula ukugoba nokukhubazeka lapho ucubungula umshini ozacile wemoto?

Kungaba nzima ukugoba noma ukuwohloza umgodi omncane kakhulu. Izinto ezisetshenziswayo ukwenza amashafu emoto (owaziwa nangokuthi ama-drive shaft noma ama-ekseli) ngokuvamile aqinile futhi aqinile, njengenhlanganisela ye-carbon fibre noma insimbi. Izinto ezisetshenzisiwe zikhethiwe ngenxa yamandla azo aphezulu, okudingekayo ukumelana ne-torque namandla akhiqizwa ukudluliselwa kanye nenjini yemoto.

Ngesikhathi sokukhiqiza, ama-shafts adlula ezinqubweni ezihlukahlukene, njengokubumba nokwelashwa kokushisa, ukuze agcine ukuqina namandla awo. Lezi zinto, kanye namasu okukhiqiza, zivimbela ama-shafts ukuthi angagobi ngaphansi kwezimo ezijwayelekile. Kodwa-ke, amandla amakhulu njengokushayisana nezingozi angagoba noma akhubaze noma iyiphi ingxenye yemoto, kuhlanganise namashafu. Kubalulekile ukulungisa noma ukushintsha noma yiziphi izingxenye ezilimele ukuze uqinisekise ukusebenza okuphephile nokusebenza kahle kwemoto yakho.

Inqubo yokwenza imishini:

Izingxenye eziningi ze-shaft zine-aspect ratio ye-L/d> 25. I-eksisi ezacile evundlile igoba kalula noma ingalahlekelwa ngisho nokuzinza kwayo ngaphansi kwethonya lamandla adonsela phansi, amandla okusika namandla okubamba phezulu. Inkinga yokucindezeleka ku-shaft encane kufanele incishiswe lapho uvula i-shaft.

Indlela yokucubungula:

Ukuguqula okuphakelayo okuhlanekezelwe kusetshenziswa, nenani lezinyathelo ezisebenzayo, njengokukhethwa kwamapharamitha wejiyomethri yamathuluzi, amanani okusika, amathuluzi okuqinisa amandla, nezindawo zokuphumula zamathuluzi e-bushing.

Ukuhlaziywa Kwezinto Ezibangela Ukuguquguquka Okugobisayo Kokuphenduka Kwe-Slender Shaft

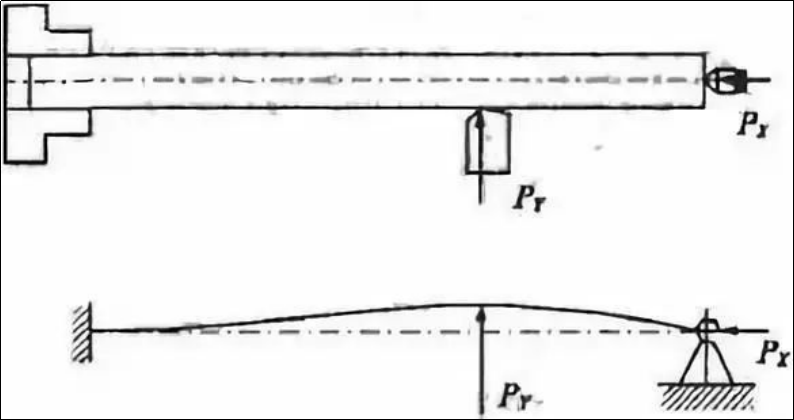

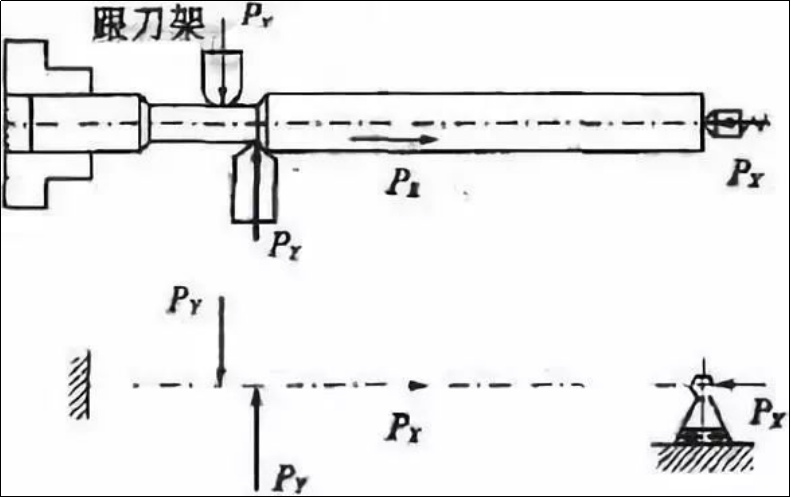

Kusetshenziswa izindlela ezimbili zendabuko zokubopha ukuze kuphendulelwe ama-shaft azacile kuma-lathes. Enye indlela isebenzisa i-clamp eyodwa enokufakwa okuphezulu okukodwa, kanti enye ifaka ezimbili eziphezulu. Sizogxila kakhulu kumasu wokubopha we-clamp eyodwa kanye nephezulu. Njengoba kuboniswe kuMfanekiso 1.

Umfanekiso 1 Isigxivizo esisodwa kanye nendlela eyodwa yokubamba phezulu kanye nokuhlaziya amandla

Izimbangela eziyinhloko zokuguquguquka kokugoba okubangelwa ukuphenduka kwe-shaft encane yilezi:

(1) Amandla okusika abangela ukuguquguquka

Amandla okusika angahlukaniswa abe izingxenye ezintathu: i-axial force PX (axial force), i-radial force PY (i-radial force) kanye ne-tangential force PZ. Lapho uguqula ama-shafts amancane, amandla okusika ahlukene angaba nemiphumela ehlukene ekuguquguqukeni kokugoba.

1) Ithonya lamandla okusika ama-radial PY

Amandla eradial anqamula aqonde ku-eksisi ye-shaft. Amandla okusika ama-radial agobisa i-shaft ezacile endizeni evundlile ngenxa yokungaqini kwayo kahle. Umfanekiso ubonisa umphumela wamandla okusika ekugobeni kwe-shaft ezacile. 1.

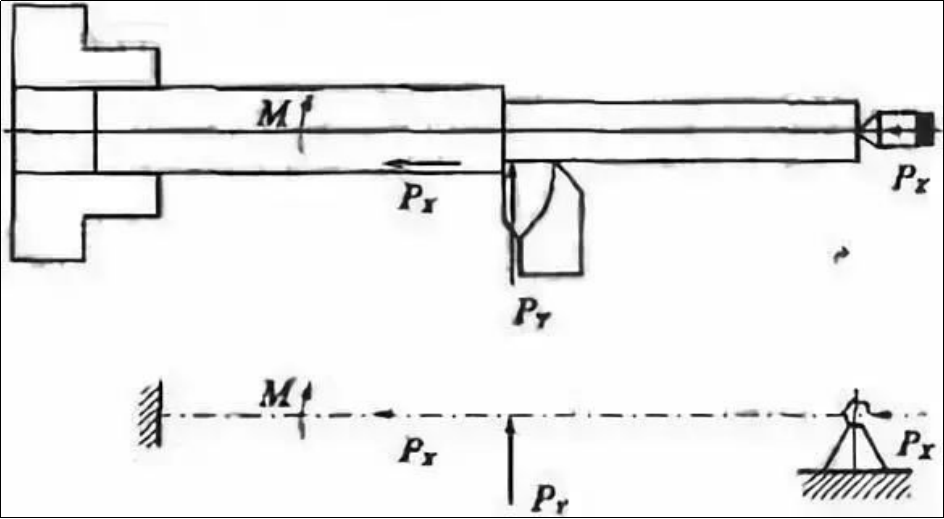

2) Umthelela we-axial cutting force (PX)

Amandla e-axial ahambisana ne-axis ku-shaft encane futhi akha umzuzu wokugoba endaweni yokusebenza. Amandla e-axial awabalulekile ekujikeni okujwayelekile futhi awanakwa. Ngenxa yokungaqini kahle kwawo, umgodi awuzinzi ngenxa yokungaqini kahle kwawo. I-shaft ezacile iyagoba lapho amandla e-axial emakhulu kunenani elithile. Njengoba kuboniswe esithombeni 2.

Umfanekiso 2: Umphumela wamandla okusika ku-axial force

(2) Ukusika ukushisa

I-thermal deformation ye-workpiece izokwenzeka ngenxa yokushisa okusika okukhiqizwa ngokucubungula. Ibanga phakathi kwe-chuck, phezulu kwe-rearstock kanye nendawo yokusebenza lilungisiwe ngoba i-chuck igxilile. Lokhu kunciphisa ukunwetshwa kwe-axial ye-shaft, okuholela ekugobeni kwe-shaft ngenxa ye-axial extrusion.

Kuyacaca ukuthi ukuthuthukisa ukunemba komshini we-shaft encane ngokuyisisekelo kuyinkinga yokulawula ukucindezeleka nokuguqulwa kokushisa ohlelweni lwenqubo.

Izinyathelo Zokuthuthukisa Ukunemba Kwemishini Ye-Slender Shaft

Ukuze uthuthukise ukunemba komshini we-shaft encane, kuyadingeka ukuthatha izinyathelo ezihlukene ngokuvumelana nezimo zokukhiqiza.

(1) Khetha indlela yokuqinisa elungile

I-clamping emaphakathi kabili, enye yezindlela ezimbili zokubopha ngokuvamile ezisetshenziselwa ukuphendulela ama-shaft azacile, ingasetshenziswa ukubeka kahle ucezu lokusebenza kuyilapho kuqinisekisa ukubumbana. Le ndlela yokubopha umkhono ozacile inokungaqini kahle, ukugoba okukhulu, futhi kulula ukudlidliza. Ngakho-ke ifaneleka kuphela ukufakwa okunesilinganiso esincane sobude kuya kobubanzi, isibonelelo esincane somshini kanye nezidingo eziphakeme ze-coaxiality. Mudeukunemba machining izingxenye.

Ezimweni eziningi, ukucutshungulwa kwama-shafts amancane kwenziwa kusetshenziswa i-clamping system ehlanganisa phezulu kanye ne-clamp eyodwa. Nokho, kule nqubo yokubopha, uma unethiphu eliqine kakhulu ngeke nje ligobe umgodi kodwa futhi liwuvimbele ukuthi unwebe lapho umgodi uphenduka. Lokhu kungabangela ukuthi i-shaft icindezeleke nge-axially futhi igobe ngaphandle kokuma. I-clamping surface ingase ingahambelani nembobo yethiphu, engabangela ukuthi i-shaft igobe ngemva kokuba iboshiwe.

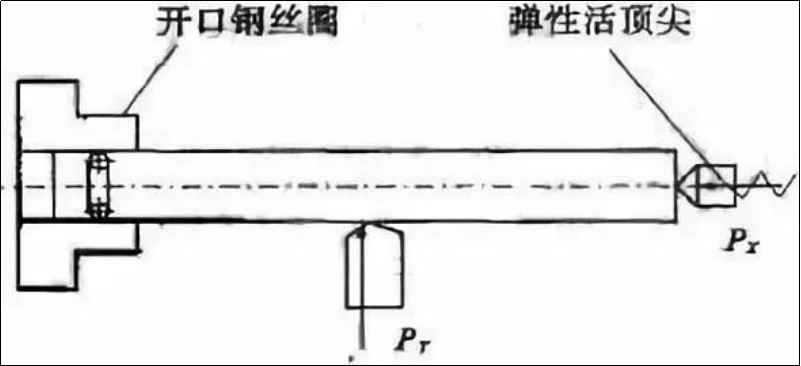

Uma usebenzisa i-clamping technique ye-clamp eyodwa ene-top eyodwa, phezulu kufanele kusebenzise izikhungo zokuhlala ezinwebekayo. Ngemva kokushisa umkhono ozacile, unganwetshwa ngokukhululekile ukuze unciphise ukuhlanekezela kwawo okugoba. Ngesikhathi esifanayo isihambi sensimbi evulekile sifakwa phakathi kwemihlathi kumkhono ozacile ukuze kuncishiswe ukuthintana kwe-axial phakathi kwemihlathi kumkhono omncane futhi kuqedwe ukuma ngokweqile. Umfanekiso 3 ubonisa ukufakwa.

Umfanekiso 3: Indlela yokuthuthukisa usebenzisa i-clamp eyodwa kanye ne-top clamp

Yehlisa amandla okuguqula ngokunciphisa ubude be-shaft.

1) Sebenzisa i-heelrest kanye nohlaka lwesikhungo

I-clamp eyodwa kanye ne-top eyodwa kusetshenziselwa ukuphendulela i-shaft ezacile. Ukuze kuncishiswe umthelela wamandla e-radial ekuwohlokeni okubangelwa i-shaft ezacile, i-toolrest yendabuko kanye nohlaka oluphakathi luyasetshenziswa. Lokhu kulingana nokwengeza usekelo. Lokhu kwandisa ukuqina futhi kunganciphisa umthelela wamandla e-radial ku-shaft.

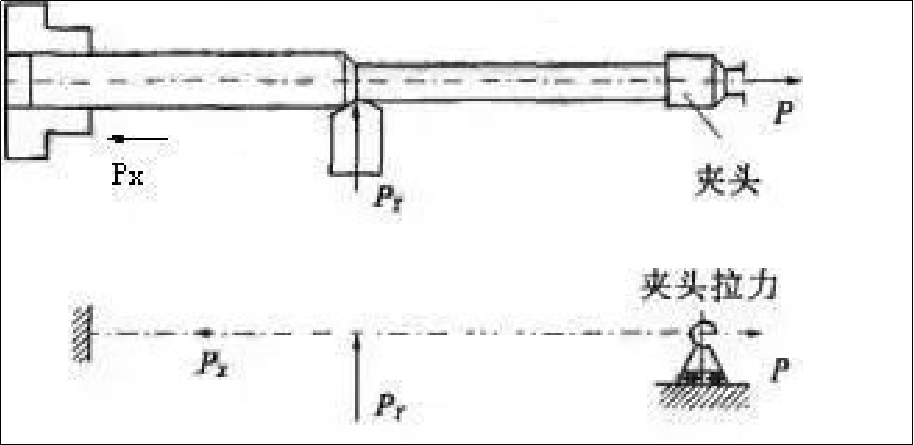

2) Umkhono ozacile uzungeziswa yi-axial clamping technique

Kungenzeka ukwandisa ukuqina futhi uqede umphumela wamandla e-radial ku-workpiece ngokusebenzisa ukuphumula kwamathuluzi noma ifreyimu ephakathi. Namanje ayikwazi ukuxazulula inkinga yamandla e-axial egoba ucezu lokusebenza. Lokhu kuyiqiniso ikakhulukazi ku-shaft ezacile enobubanzi obude ngokuqhathaniswa. Ngakho-ke i-shaft ezacile iyakwazi ukushintshwa kusetshenziswa indlela yokubopha i-axial. I-axial clamping isho ukuthi, ukuze ujike umphini omncane, umkhawulo owodwa we-shaft uboshelwe nge-chuck futhi umkhawulo wawo uboshwe ngekhanda eliklanywe ngokukhethekile. Ikhanda elibambayo lisebenzisa amandla e-axial kushaft. Umfanekiso 4 ukhombisa ikhanda elibambayo.

Umfanekiso 4 Ukuqina kwe-axial nezimo zengcindezi

Umkhono ozacile ubhekene ne-axial tension eqhubekayo phakathi nenqubo yokujika. Lokhu kuqeda inkinga ye-axial cutting force egoba umgodi. Amandla e-axial anciphisa ukuguqulwa kokugoba okubangelwa amandla okusika ama-radial. Iphinde inxephezele ukunwetshwa kwe-axial ngenxa yokushisa okusikayo. ukunemba.

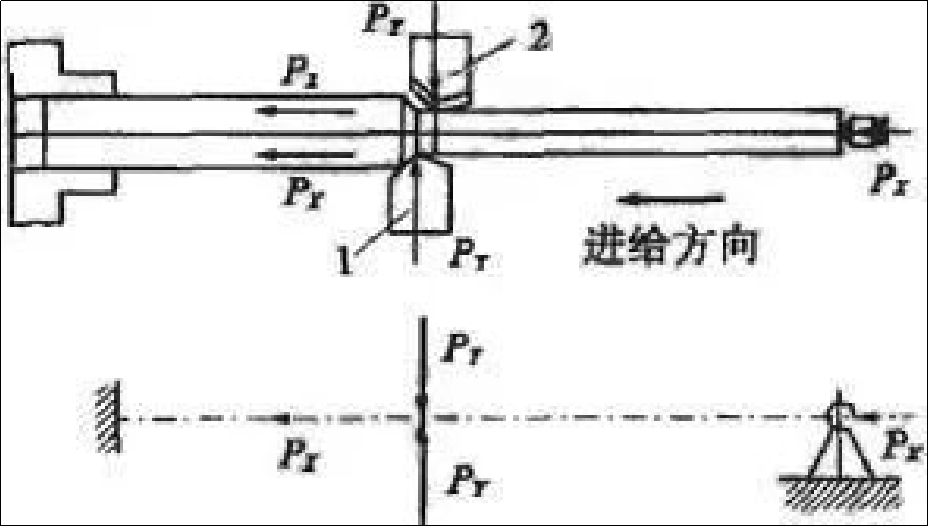

3) Hlehlisa ukusika i-shaft ukuze uyiphendule

Njengoba kukhonjisiwe kuMfanekiso 5, indlela yokusika ehlane ilapho ithuluzi lidliswa nge-spindle kuya esitokisini somsila phakathi nenqubo yokuphendula i-shaft ezacile.

Umfanekiso wesi-5 Ukuhlaziywa Kwezimpi Zomshini kanye Nemishini Ngokuhlehlisa Indlela Yokusika

Amandla e-axial akhiqizwa ngesikhathi sokucutshungulwa azoqinisa i-shaft, avimbele ukuguquguquka kokugoba. I-elastic tailstock nayo inganxephezela ukunwebeka okushisayo kanye nokuguqulwa kokucindezelwa okubangelwa ucezu lokusebenza njengoba lusuka ethuluzini lungena esitokisini. Lokhu kuvimbela deformation.

Njengoba kuboniswe kuMfanekiso 6, ipuleti lesilayidi eliphakathi lilungiswa ngokwengeza isibambi sethuluzi sangemuva nokujikisa kokubili amathuluzi angaphambili nangemuva ngesikhathi esisodwa.

Umfanekiso 6 Phoqelela ukuhlaziya kanye nokwenza imimese ekabili

Ithuluzi langaphambili lifakwe liqondile, kuyilapho ithuluzi elingemuva lifakwe ngokuhlehla. Amandla okusika akhiqizwa amathuluzi amabili akhansela omunye nomunye ngesikhathi sokuphenduka. I-workpiece ayikhubazekile noma idlidliza, futhi ukunemba kokucubungula kuphezulu kakhulu. Lokhu kulungele ukukhiqizwa ngobuningi.

4) Indlela yokusika kazibuthe yokuguqula i-shaft encane

Umgomo wokusika kazibuthe ufana nokusika okuhlanekezelwe. Amandla kazibuthe asetshenziselwa ukwelula i-shaft, ukunciphisa ukuwohloka ngesikhathi sokucubungula.

(3) Nciphisa inani lokusika

Inani lokushisa elikhiqizwa inqubo yokusika lizonquma ukufaneleka kwenani lokusika. I-deformation ebangelwa ukujikeleza kwe-shaft encane nayo izohluka.

1) Ukujula Kokusikwa (t)

Ngokokucabanga ukuthi ukuqina kunqunywa uhlelo lwenqubo, njengoba ukujula kokusika kukhula, kanjalo namandla okusika, nokushisa okukhiqizwa lapho kuguqulwa. Lokhu kubangela ukucindezeleka nokuhlanekezela okushisayo kwe-shaft encane kwanda. Lapho uguqula ama-shafts amancane, kubalulekile ukunciphisa ukujula kokusika.

2) Inani lokudla (f).

Ukwenyuka kwezinga lokudla kwandisa amandla okusika nokushuba. Amandla okusika ayanda, kodwa hhayi ngokulinganayo. Ngenxa yalokho, i-coefficient ye-deformation yamandla ye-shaft encane iyancipha. Mayelana nokwandisa ukusebenza kahle kokusika, kungcono ukwandisa izinga lokudla kunokwandisa ukujula kokusika.

3) Ijubane lokusika (v).

Kuyinzuzo ukwandisa ijubane lokusika ukuze unciphise amandla. Njengoba ijubane lokusika likhulisa izinga lokushisa kwethuluzi lokusika, ukungqubuzana phakathi kwethuluzi, i-workpiece, kanye ne-shaft kuzokwehla. Uma isivinini sokusika siphezulu kakhulu, khona-ke i-shaft ingagoba kalula ngenxa yamandla e-centrifugal. Lokhu kuzolimaza ukuzinza kwenqubo. Ijubane lokusika lama-workpieces amakhulu ngokuqhathaniswa ngobude nobubanzi kufanele kwehliswe.

(4) Khetha i-engeli efanelekile yethuluzi

Ukunciphisa ukuguqulwa kokugoba okubangelwa ukuguqula i-shaft encane, amandla okusika ngesikhathi sokuphenduka kufanele abe phansi ngangokunokwenzeka. I-rake, ama-engeli okuthambekela okuholayo nawonqenqema anethonya elikhulu kumandla okusika phakathi kwama-engeli wejometri wamathuluzi.

1) I-engeli yangaphambili (g)

Ubukhulu be-rake (g) i-engeli buthinta ngokuqondile amandla okusika, izinga lokushisa namandla. Amandla okusika angancishiswa kakhulu ngokwandisa ama-engeli e-rake. Lokhu kunciphisa ukuwohloka kwepulasitiki futhi kunganciphisa nenani lokusikwa kwensimbi. Ukuze unciphise amandla okusika, ukwandisa ama-engeli e-rake kungenziwa. Ama-engeli e-rake ngokuvamile aphakathi kuka-13deg no-17deg.

2) I-engeli ehamba phambili (kr)

Ukuchezuka okuyinhloko (kr), okuyi-engeli enkulu kunazo zonke, kuthinta ukulingana nosayizi wazo zonke izingxenye ezintathu zamandla okusika. Amandla eradial ayancishiswa njengoba i-engeli yokungena ikhula, kuyilapho amandla e-tangential enyuka phakathi kuka-60deg no-90deg. Ubudlelwano obulinganayo phakathi kwezingxenye ezintathu zamandla okusika bungcono kububanzi obungu-60deg75deg. I-engeli eholayo enkulu engu-60deg ivamise ukusetshenziswa lapho kuphendulwa ama-shafts azacile.

3) Ukuthambekela kwe-blade

Ukuthambekela kwe-blade (ls), kuthinta ukugeleza kwama-chips namandla wethiphu yethuluzi, kanye nobudlelwano obulinganayo phakathi kokuthathu.izingxenye eziphendukileyokusika ngesikhathi sokuphenduka. Amandla e-radial okusika ayancipha njengoba ukuthambekela kwanda. Kodwa-ke, amandla e-axial kanye ne-tangential ayanda. Ubudlelwano obulinganayo phakathi kwezingxenye ezintathu zamandla okusika bunengqondo uma ukuthambekela kwe-blade kungaphakathi kwebanga elingu -10deg+10deg. Ukuze wenze ama-chips ageleze abheke phezulu ku-shaft lapho uphendula i-shaft encane, kuvamile ukusebenzisa i-engeli yonqenqema ephakathi kuka-0deg no-+10deg.

Kunzima ukuhlangabezana nezindinganiso zekhwalithi ze-shaft encane ngenxa yokuqina kwayo okubi. Ikhwalithi yokucubungula ye-shaft emincane ingaqinisekiswa ngokuthatha izindlela zokucubungula ezithuthukisiwe nezindlela zokubopha, kanye nokukhetha ama-engeli amathuluzi alungile kanye nemingcele.

Umgomo we-Anebon ukuqaphela ukungapheleli okuhle kakhulu kokukhiqiza futhi unikeze isevisi engcono kakhulu kumakhasimende ethu asekhaya nawaphesheya kwezilwandle ngokuphelele ngo-2022 Ingxenye Yomshini Wokugawula Oyizinga eliphezulu we-Stainless Aluminium High Precision CNC ye-Aerospace yekhwalithi ephezulu kakhulu ye-Aerospace ukuze sandise imakethe yethu emhlabeni jikelele, i-Anebon ihlinzeka ikakhulukazi ngamakhasimende ethu aphesheya. ngemishini yekhwalithi ephezulu, izingcezu ezigayiwe kanyeIzinsizakalo zokuguqula i-CNC.

I-China wholesale China Machinery Parts kanye ne-CNC Machining Service, i-Anebon igcina umoya "wokusungula izinto ezintsha nokubumbana, ukusebenzisana, ukwabelana, umkhondo, ukuthuthuka okungokoqobo". Uma usinika ithuba, sizobonisa amandla ethu. Ngokusekela kwakho, i-Anebon ikholelwa ukuthi sizokwazi ukwakhela wena nomndeni wakho ikusasa eliqhakazile.

Isikhathi sokuthumela: Aug-28-2023