Thepha ukuchofoza

Ukuthepha kuyinqubo enzima kakhulu yokwenza imishini, ngoba umkhawulo wayo wokusika uxhumene ne-workpiece engu-100%, ngakho-ke izinkinga ezihlukahlukene ezingase ziphakame kufanele zicatshangelwe kusengaphambili, njengokusebenza kwe-workpiece, ukukhethwa kwamathuluzi namathuluzi omshini, kanye nesivinini esikhulu sokusika. , okuphakelayo, njll.

Ukukhetha ompompi

Ukukhetha ompompi kanye nenani lokusika

Okokuqala, imibuzo emihlanu kufanele icaciswe ngaphambi kokuthepha:

1. Iyiphi impahla okufanele isetshenzwe?

2. Ayini amandla we-workpiece material?

3. Ingabe izimbobo zezikulufo ezenziwe ngomshini ziphuma emigodini noma emigodini eyimpumputhe?

4. Ijule kangakanani imbobo yesikulufu (noma buyini ukujiya?

5. Yiziphi izinhlobo nobukhulu bezimbobo zezikulufa okufanele zicutshungulwe?

Ngezinto zokwakha ezinobunzima obuphezulu bomshini namandla, umpompi kufanele ukhethe i-eccentric relief angle kusukela onqenqemeni lokusika.3 i-axis cnc machining

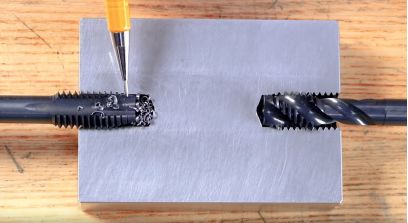

Ukukhethwa kweTap Chip Flutes

Umdwebo wokubukeka wohlobo lwe-groove eqondile, uhlobo lwe-spiral groove kanye nohlobo lwe-apex spiral groove:

I-groove eqondile, ukukhetha okulinganiselayo.

I-Spiral Tap

Ifanele ukucutshungulwa kwembobo eyimpumputhe, ukungahambi kahle ukuthi umkhawulo omuhle ubukhali kakhulu, ukuqina akukuhle futhi intengo iyabiza.

Ithiphu Spiral Groove

Kuyazuzisa ukuthi ukukhishwa kwe-chip kuhlale isikhathi eside futhi kulungele ngokusebenzisa izimbobo uma kuqhathaniswa nemigodi eqondile. Ububi ukuthi intambo engavumelekile ekugcineni yinde kakhulu.

Ubudlelwano obulula bokuqhathanisa phakathi komtshingo oqondile, umtshingo ovunguzayo kanye nompompi we-apex spiral flute:

Impompi eshaywa nge-spiral

Ompompi aba-spiral fluted basetshenziswa kakhulu ukuhlanganisa izimbobo eziyizimpumputhe. Uma kwenziwa umshini wokusebenza ngobulukhuni obuphakeme namandla, ompompi abane-engeli encane ye-helix bangasetshenziswa ukuthuthukisa amandla esakhiwo.

Okokwenza uchungechunge lwensimbi engama-400 (i-engeli ye-helix engu-15°)

Okokwenza uchungechunge lwensimbi engama-300 (i-engeli ye-helix ingu-41°) Umdwebo 3

I-Spiral vs. Apex Spiral

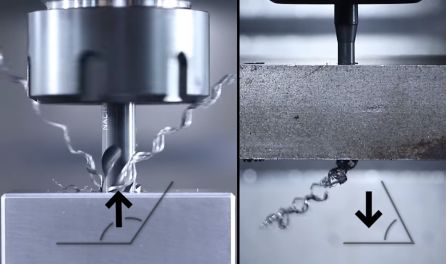

Umumo ovunguzayo ufanelekile emigodini eyimpumputhe, futhi amafayili ensimbi akhishwa ngaphandle komgodi. I-apex i-helical, futhi ama-chips asuswa phansi.3d imishini

Ukuqhathanisa okunembile komumo oqondile kanye ne-helical

Ukuthepha izinto zokusebenza ezikhethekile

I-machinability yezinto zokusebenza ziyisihluthulelo sobunzima bokuthepha. Ngokusho kwezakhiwo zezinto ezibonakalayo, kubaluleke kakhulu ukushintsha i-geometry yengxenye yokusika kampompi, ikakhulukazi i-rake angle yayo kanye nezinga le-concave phambi kwenani le-concave.4 axis cnc machining

Thatha i-angle bese ugoqa

Ukucutshungulwa kwezinto zokusebenza ezisezingeni eliphezulu

Okwezinto zokusebenza ezisezingeni eliphezulu, ompompi bavamise ukuba ne-engeli encane ye-rake kanye ne-undercut, okwandisa amandla okusika. Izinto zokuqopha isikhathi eside zidinga ama-engeli amarakhi amakhulu kanye nama-undercuts ukuze kugoqeke ama-chip nokuphuka kwe-chip. Ukucupha izinto zokusebenza eziqinile kudinga ama-engeli amakhulu okusiza ukunciphisa ukungqubuzana nokupholisa ngokwanele unqenqema lokusika.

Izinto zomshini ezinamadigri ahlukene wokuthamba nobulukhuni

Ngezinto zokwakha ezinobunzima obuphezulu bomshini namandla, umpompi kufanele ukhethe i-eccentric relief angle kusukela onqenqemeni lokusika.

Isibonelo, lapho kwenziwa izinto zensimbi engagqwali, i-helical groove ene-engeli encane yokuzungezisa isetshenziselwa ukubhekana nezici zokucubungula eziqinile nezinamathelayo zensimbi engagqwali, ukuze kube lula ukusika okuhlala isikhathi eside kanye nokukhishwa kwe-chip of blind hole tapping.

Izinkinga ezijwayelekile kunqubo yokuthepha

Kunezizathu eziningi zokuphuka kompompi: amathuluzi omshini, izinto ezilungiswayo, izinto zokusebenza, izinqubo, ama-chucks, amathuluzi, njll. konke kungenzeka, futhi isizathu sangempela singase singatholakali ephepheni. Zonke lezi zinkinga ezingenhla zidinga opharetha ukuthi benze izahlulelo noma impendulo kochwepheshe.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Mar-01-2022