1. Z-isiqondiso ithuluzi setting of machining centre

Ngokuvamile kunezindlela ezintathu zokusethwa kwethuluzi le-Z-direction yezikhungo zemishini:

1) Indlela yokusetha ithuluzi emshinini 1

Le ndlela yokusetha ithuluzi iwukunquma ngokulandelana ubudlelwano bendawo phakathi kwethuluzi ngalinye nesiqeshana sokusebenza ohlelweni lokuxhumanisa ithuluzi lomshini ngokusetha ithuluzi ngesikhathi.Izingxenye zemishini ye-CNCfuthiIzingxenye zokuguqula ze-CNC. Izinyathelo zayo zokusebenza eziqondile zimi kanje.

(1) Qhathanisa ubude bethuluzi, thola ithuluzi elide kunawo wonke njengethuluzi lereferensi, yenza ukulungiselelwa kwethuluzi le-Z-direction, futhi usebenzise inani lokusetha ithuluzi (C) ngalesi sikhathi njengenani lika-Z lesistimu yokuxhumanisa ucezu lokusebenza, kanye no-H03= 0 ngalesi sikhathi.

(2) Faka amathuluzi u-T01 kanye ne-T02 ku-spindle ngokulandelana, futhi unqume amanani ka-A no-B njengenani lesinxephezelo sobude ngokulungiselelwa kwamathuluzi. (Le ndlela ayilinganisi ngokuqondile isinxephezelo samathuluzi, kodwa yehlukile endleleni yesi-3 enqunywa ukulungiselelwa kwamathuluzi alandelanayo.)

(3) Gcwalisa inani lesinxephezelo sobude obunqunyiwe (ubude bethuluzi elide kunawo wonke ukhiphe ubude bethuluzi obusele) ekhasini lezilungiselelo. Izimpawu ezinhle nezingezinhle zinqunywa i-G43 ne-G44 ohlelweni, futhi ngalesi sikhathi ngokuvamile imelelwa i-G44H—. Uma usebenzisa i-G43, isinxephezelo sobude siyinani elingalungile.

Le ndlela yokusetha ithuluzi inokusebenza kahle nokunemba kokusetha amathuluzi, kanye nokutshalwa kwezimali okuncane, kodwa akulula ukubhala amadokhumenti enqubo, okunomthelela othile enhlanganweni yokukhiqiza.

2) Indlela yokusetha ithuluzi emshinini 2

Izinyathelo ezithile zokusebenza zale ndlela yokusetha ithuluzi zimi kanje:

(1) Ukulungiselelwa kokuqondisa kwe-XY kuyafana nangaphambili, faka inani le-offset entweni ye-XY ku-G54, bese usetha into ethi Z kuqanda.

(2) Faka esikhundleni i-T1 esetshenziselwa ukucutshungulwa nge-shaft eyinhloko, sebenzisa i-block gauge ukuze uqondanise isiqondiso se-Z, funda inani le-Z1 lesistimu yokuxhumanisa ithuluzi lomshini ngemva kokuqina okufanele, futhi ugcwalise inani lesinxephezelo sobude H1 ngemva kwalokho. ukudonsa ubude be-block gauge.

(3) Faka i-T2 ku-shaft eyinhloko, iqondanise ne-block gauge, funda i-Z2, ukhiphe ubude be-block gauge bese ugcwalisa u-H2.

(4) Ngokufanisa, sebenzisa ama-block gauge ukuze uqondanise zonke izindikimba zamathuluzi, futhi ugcwalise u-Hi ngemva kokukhipha ubude bama-block gauge.

(5) Uma wenza izinhlelo, sebenzisa izindlela ezilandelayo ukunxephezela:

i-T1;

I-G91 G30 Z0;

i-M06;

I-G43 H1;

I-G90 G54 G00 X0 Y0;

I-Z100;

…(Okulandelayo ukucubungula ithuluzi lokudlula ithuluzi leNo. 1 kuze kube sekupheleni)

i-T2;

I-G91 G30 Z0;

i-M06;

I-G43 H2;

I-G90 G54 G00 X0 Y0;

I-Z100;

…(Konke okuqukethwe kommese onguNo.2)

…M5;

i-M30;

3) Ukusetha ithuluzi elingaphandle komshini + ukulungiselelwa kwethuluzi elisemshinini

Le ndlela yokusetha ithuluzi iwukusebenzisa i-presetter yamathuluzi ukukala ngokunembile ubukhulu be-axial kanye ne-radial yethuluzi ngalinye ngaphandle kwethuluzi lomshini, ukunquma inani lesinxephezelo sobude bethuluzi ngalinye, bese usebenzisa ithuluzi elide kunawo wonke ethuluzini lomshini ukwenza u-Z To ukulungiselelwa kwethuluzi, nquma uhlelo lokuxhumanisa i-workpiece.

Le ndlela yokusetha ithuluzi inokunemba nokusebenza kahle kwesilungiselelo samathuluzi, futhi ilungele ukulungiswa kwamadokhumenti enqubo kanye nenhlangano yokukhiqiza, kodwa ukutshalwa kwezimali kukhulu uma kuqhathaniswa.

2. Okokufaka kwedatha yokusetha ithuluzi

(1) Idatha yokusetha ithuluzi etholwe ngokuya ngemisebenzi engenhla, okungukuthi, amanani we-X, Y, kanye no-Z womsuka wesistimu yokudidiyela izinhlelo ohlelweni lokudidiyela umshini, kufanele ifakwe ngesandla ku-G54~G59 ukuze igcinwe. Izinyathelo zokusebenza zimi kanje:

①Cindezela okuthi【MENU OFFSET】ukhiye.

②Cindezela ukhiye wekhesa ukuze uye ku-Izingxenye zokugaya ze-CNCfuthiIzingxenye zokuguqula ze-CNCxhumanisa uhlelo lwe-G54~G59 oluzocutshungulwa.

③Cindezela u【X】ukhiye wokufaka u-X ivelu yokudidiyela.

④Cindezela okuthi【INPUT】ukhiye.

⑤Cindezela u-【Y】ukhiye wokufaka u-Y ivelu yokuxhumanisa.

⑥Cindezela okuthi【INPUT】ukhiye.

⑦Cindezela u-【Z】ukhiye wokufaka u-Z ivelu yokudidiyela.

⑧Cindezela okuthi【INPUT】ukhiye.

(2) Inani lesinxephezelo sethuluzi ngokuvamile lifakwa ethuluzini lomshini ngaphambi kokulungisa iphutha lohlelo nge-MDI (ukufaka idatha mathupha). Izinyathelo ezijwayelekile zokusebenza yilezi:

①Cindezela okuthi【MENU OFFSET】ukhiye.

②Cindezela ukhiye wokunyakaza kwekhesa enombolweni yesinxephezelo.

③Ivelu yesinxephezelo sokufaka.

④Cindezela okuthi【INPUT】ukhiye.

3. Indlela yokusika isilingo yokubeka ummese

Indlela yokusika isilingo iyindlela elula yokusetha ithuluzi, kodwa izoshiya amamaki kucezu lokusebenza, futhi ukunemba kwesilungiselelo samathuluzi kuphansi. Ilungele ukulungiselelwa kwamathuluzi ngesikhathi sokusebenza kanzima kwezingxenye. Indlela yayo yokusetha ithuluzi iyafana neyesitholi sonqenqema esingumshini.

4. Isilungiselelo sethuluzi se-Lever dial gauge

Ukunemba kokusetha ithuluzi kwenkomba yokudayela kwe-lever kuphezulu, kodwa le ndlela yokusebenza inzima futhi ukusebenza kahle kuphansi. Ifanele ukulungiselelwa kwamathuluzi embobo yokuqeda (indawo engaphezulu), kodwa ayifanele umgodi womshini omangelengele.

Indlela yokusetha ithuluzi imi kanje: sebenzisa isisekelo sewashi kazibuthe ukuze uhehe inkomba yokudayela kwelever ku-spindle yesikhungo somshini, futhi wenze ikhanda legeji lisondele odongeni lwembobo (noma indawo eyicylindrical). Ngaphakathi kwephutha, elifana no-0.02, kungacatshangwa ukuthi isikhungo sokuzungezisa se-spindle siqondana nendawo emaphakathi yembobo elinganisiwe ngalesi sikhathi, futhi kufakwa amanani okuxhumanisa u-X kanye no-Y ohlelweni lokuxhumanisa umshini ngalesi sikhathi ku-G54.

5. Ukusetha ithuluzi ku-Z direction

Uma kucatshangelwa ukwenziwa kokuhlelwa kwethuluzi, indawo engaphezulu yesiqeshana somsebenzi ngokuvamile ithathwa njengemvelaphi yesiqondisindlela sika-Z sesistimu yokuxhumanisa i-workpiece. Lapho indawo engaphezulu yengxenye ilukhuni futhi ingakwazi ukusetshenziswa njengereferensi yokumisa ithuluzi, i-vise noma ibhentshi lokusebenzela lingasetshenziswa njengemvelaphi yesiqondiso se-Z sesistimu yokuxhumanisa i-workpiece, bese kulungiswa ukuphakama kwendawo yokusebenza. phezulu ku-G54 noma ohlelweni olunwetshiwe lokudidiyela ukuze ugcwalise. Ukulungiselelwa kwethuluzi lomshini we-Z-direction ikakhulukazi kufaka phakathi ukulungiselelwa kwethuluzi lethuluzi lokulinganisa u-Z, ukulungiselelwa kwebhulokhi yokumisa ithuluzi kanye nokusetha ithuluzi lendlela yokusika isilingo nezinye izindlela.

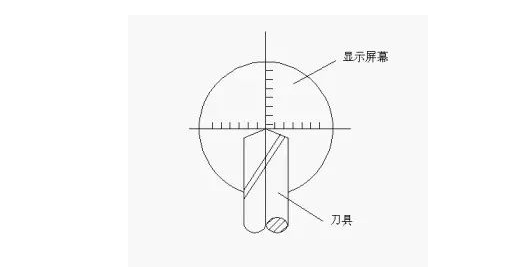

6. Ukulungiselelwa kwethuluzi ngethuluzi lokulinganisa elingu-Z

Ukunemba kokusetha ithuluzi kwethuluzi lokulinganisa i-Z-direction liphezulu, ikakhulukazi uma amathuluzi amaningi asethwe emshinini esikhungweni somshini wokugaya, ukusebenza kahle kokusetha ithuluzi kuphezulu, ukutshalwa kwezimali kuncane, futhi kulungele ingxenye yocezu olulodwa. ukucubungula.

1) Ukulungiselelwa kwethuluzi le-Z-direction ngesikhathi somshini wethuluzi elilodwa lesikhungo sokukhanda

Ukwenza imishini yethuluzi elilodwa esikhungweni somshini kuyafana nenkinga yokuthi asikho isinxephezelo sobude sokusetha ithuluzi emshinini wokugaya we-CNC. Izinyathelo zimi kanje:

(1) Shintshanisa ithuluzi elizosetshenziselwa ukucubungula;

(2) Hambisa ithuluzi phezulu kwendawo yokusebenza, ulinganise ibanga phakathi kwendawo yokusebenza nethuluzi ngethuluzi lokulinganisa elingu-Z, futhi urekhode i-Z-axis yokufunda Z yesistimu yamanje yomshini (umshini) wokuxhumanisa;

(3) Khipha inani elingu-Z ekuphakameni kwethuluzi lokulinganisa le-Z-direction ngalesi sikhathi (njengo-50.03mm), bese ugcwalisa inani elilinganisiwe entweni engu-Z ye-OFFSETSETTING–>coordinate system–>G54;

(4) Run G90 G54G0 X0 Y0 Z100; hlola ukuthi ukuqondanisa kulungile yini

Isikhathi sokuthumela: Jan-09-2023