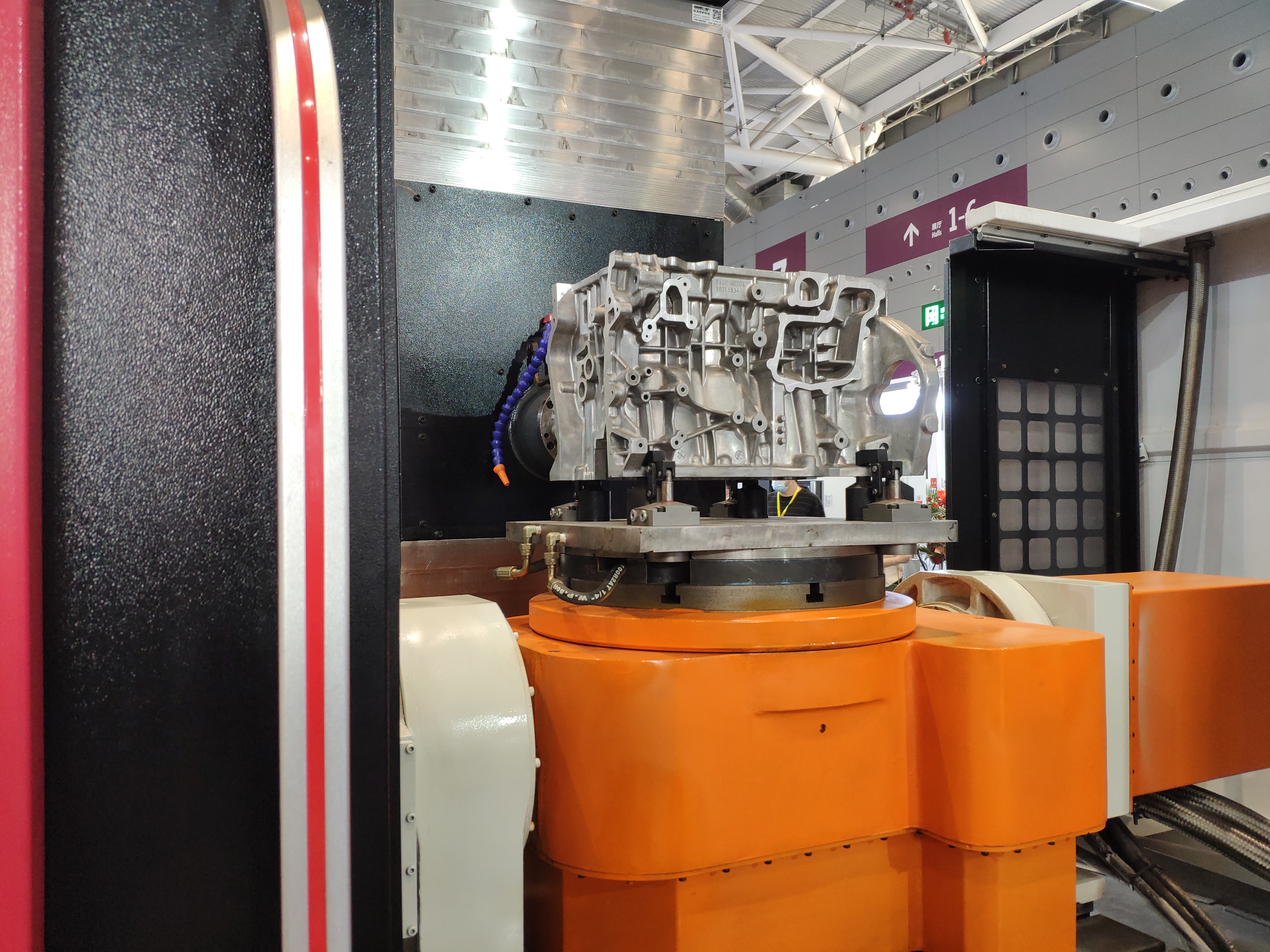

Ukwelashwa kokushisa kwensimbi ukushisa insimbi noma i-alloy workpiece ekushiseni okufanelekile endaweni ethile, futhi ngemva kokugcina izinga lokushisa isikhathi esithile, kupholiswe emithonjeni ehlukene ngesivinini esihlukile, ngokushintsha indawo noma ingaphakathi impahla yensimbi. Inqubo yesakhiwo se-microstructural ukulawula ukusebenza kwayo.cnc machining ingxenye

Isigaba esiyinhloko

Izinqubo zokwelashwa kokushisa kwensimbi zingahlukaniswa cishe zibe izigaba ezintathu: ukwelashwa kokushisa okuphelele, ukwelashwa kokushisa okungaphezulu kanye nokwelashwa kokushisa kwamakhemikhali. Ngokuya ngendawo yokushisa, izinga lokushisa lokushisa kanye nendlela yokupholisa, isigaba ngasinye singahlukaniswa ngezinqubo eziningana ezahlukene zokwelashwa kokushisa. Insimbi efanayo isebenzisa izinqubo ezahlukene zokwelashwa kokushisa ukuze ithole ama-microstructures ahlukene kanjalo nezakhiwo ezahlukene. Insimbi iyinsimbi esetshenziswa kakhulu embonini, futhi i-microstructure yensimbi nayo iyinkimbinkimbi kakhulu, ngakho-ke kunezinhlobo eziningi zezinqubo zokwelapha ukushisa kwensimbi.ingxenye yethusi cnc machining

Izici

Ukwelashwa kokushisa kwensimbi kungenye yezinqubo ezibalulekile ekwenziweni kwemishini. Uma kuqhathaniswa nezinye izindlela zokucubungula, ukwelashwa kokushisa ngokuvamile akushintshi ukuma kanye nokwakheka kwamakhemikhali okuphelele kwendawo yokusebenza, kodwa kushintsha i-microstructure ngaphakathi kwendawo yokusebenza noma kushintsha ukwakheka kwamakhemikhali ebusweni bomsebenzi. , ukunikeza noma ukuthuthukisa ukusebenza kwe-workpiece. Ibonakala ngekhwalithi yangaphakathi ethuthukisiwe ye-workpiece, ngokuvamile engabonakali ngeso lenyama. Ngakho-ke, kuyinqubo ekhethekile ekwenziweni kwemishini kanye nengxenye ebalulekile yokuphathwa kwekhwalithi.

Ukuze wenze i-workpiece yensimbi ibe nezakhiwo ezidingekayo zemishini, izakhiwo zomzimba kanye nezakhiwo zamakhemikhali, ngaphezu kokukhethwa okunengqondo kwezinto kanye nezinqubo ezihlukahlukene zokwakha, izinqubo zokwelashwa kokushisa ngokuvamile zibalulekile. Insimbi iyinto esetshenziswa kakhulu embonini yemishini. I-microstructure yensimbi iyinkimbinkimbi futhi ingalawulwa ngokwelashwa kokushisa. Ngakho-ke, ukwelashwa kokushisa kwensimbi kungukuqukethwe okuyinhloko kokwelashwa kokushisa kwensimbi. Ngaphezu kwalokho, i-aluminiyamu, ithusi, i-magnesium, i-titanium, nokunye okunjalo kungashintshwa futhi ngokwelashwa kokushisa ukuze kutholwe izakhiwo ezihlukene zemishini, izakhiwo ezingokomzimba, nezakhiwo zamakhemikhali.

Inqubo eyisisekelo

Ukwelashwa kokushisa sekukonke kuyinqubo yensimbi yokwelapha ukushisa okushisisa ucezu lokusebenza lulonke bese lupholisa ngesivinini esifanelekile ukuze kushintshwe izici zalo zokusebenza eziphelele. Ukwelashwa kokushisa okuphelele kwensimbi kunezinqubo ezine eziyisisekelo: ukuthungatha, ukujwayelekile, ukucisha kanye nokushisa.ingxenye yepulasitiki

I-Annealing iwukushisa ucezu lokusebenzela ezingeni lokushisa elifanele, kusetshenziswa izikhathi zokubamba ezihlukene ngokuya ngezinto kanye nobukhulu bocezu lokusebenza, bese upholisa kancane, ukuze ulethe ukwakheka kwangaphakathi kwensimbi ekulinganeni noma eduze, noma ukukhulula insimbi. ukucindezeleka kwangaphakathi okukhiqizwa yinqubo yangaphambilini. Thola ukusebenza okuhle kwenqubo nokusebenza, noma lungiselela ukucisha okwengeziwe.

Ukwenza okujwayelekile noma ukujwayela ukupholisa isiqeshana sokusebenza sibe ezingeni lokushisa elifanele bese sisipholisa emoyeni. Umthelela we-normalization ufana ne-annealing, kodwa isakhiwo esiwumphumela sihle, esivame ukusetshenziselwa ukuthuthukisa ukusebenza kokusika kwezinto, futhi ngezinye izikhathi sisetshenziselwa ezinye izidingo. Izingxenye ezingekho phezulu zisetshenziswa njengokwelashwa kokushisa kokugcina.

Ukucisha kuwukupholisa ngokushesha ucezu lomsebenzi ngemva kokuwufudumeza futhi uwubambe endaweni yokucisha njengamanzi, uwoyela noma esinye isixazululo sikasawoti esingaphili noma isixazululo esinamanzi esiphilayo. Ngemva kokucisha, insimbi iba lukhuni kodwa ibe brittle ngesikhathi esifanayo.

Ukuze kuncishiswe i-brittleness yensimbi, insimbi ecishiwe ifakwe isikhathi eside ekushiseni okufanelekile ngaphezu kokushisa kwegumbi nangaphansi kuka-650 ° C, bese ipholile. Le nqubo ibizwa ngokuthi ukuthambisa. I-Annealing, normalizing, quenching and tempering "yimililo emine" ekwelashweni kokushisa sekukonke. Phakathi kwazo, ukucisha nokushisa kuhlobene eduze, futhi kuvame ukusetshenziswa ndawonye, kubalulekile.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Aug-31-2019