Iyini ukusetshenziswa kokubala amaketanga obukhulu bomhlangano?

Ukunemba nokunemba:

Ukubala amaketango obukhulu bomhlangano kuzoqinisekisa ukuthi unezilinganiso ezinembile nobukhulu bezingxenye. Lokhu kuzosiza futhi ekuqinisekiseni ukuqondanisa okufanele nokulingana.

Ukushintshelana:

Amaketanga obukhulu bomhlangano asetshenziselwa ukunquma imikhawulo yokubekezelelana yezingxenye futhi kuqinisekiswe ukuguquguquka. Lokhu kubaluleke kakhulu ekukhiqizeni ngobuningi lapho izingxenye kufanele zihlanganiswe noma zishintshwe kalula.

Ukugwema Ukugxambukela:

Ukubala amaketango obukhulu bomhlangano kungasiza ukuvimbela ukungqubuzana noma ukuphazamiseka phakathi kwezingxenye. Ungaqiniseka ukuthi izingxenye zizolingana ngokushelela ngokunquma ubukhulu bazo obuqondile.

Ukuhlaziywa Kwengcindezi:

Ngokubala amaketanga obukhulu bomhlangano, onjiniyela bangaqonda ukusatshalaliswa kwengcindezi ngaphakathi komhlangano. Lolu lwazi lubalulekile ekwakhiweni kwezingxenye zesakhiwo ukuqinisekisa ukuthi ziyakwazi ukumelana nemithwalo elindelwe noma amandla.

Ikhwalithi yokulawula:

Ngokubala ngokunembile amaketanga obukhulu bomhlangano ungakwazi ukusungula izindinganiso zokulawula ikhwalithi, okuzokuvumela ukuthi ubone noma yimaphi amaphutha noma ukuphambuka enqubweni yokukhiqiza. Lokhu kuzosiza ukugcina amazinga aphezulu futhi kunciphise amaphutha.

Ukuthuthukisa Izindleko:

Ngokunciphisa imfucuza, ukunciphisa amaphutha okukhiqiza kanye nokuqinisekisa ukusebenza kahle kwezinsiza, ukubalwa kwamaketanga obukhulu bomhlangano kuzoholela ekuthuthukisweni kwezindleko. Lokhu kubaluleke kakhulu ezimbonini ezidinga ukunemba okuphezulu, njenge-aerospace noma ukukhiqiza izimoto.

Incazelo yechungechunge lobukhulu:

Iketango lobukhulu bomhlangano liwuchungechunge lobukhulu eliqukethe ubukhulu kanye nokuma okufanayo kwezingxenye eziningi kunqubo yokuhlanganisa.

Iketango le-dimensional liqinisekisa ukunemba komhlangano kanye nokuhluzeka ngesikhathi senqubo yomhlangano.

Ukuqonda okulula kuzoba nochungechunge lobukhulu bezingxenye kanye nobudlelwano bomhlangano.

Iyini i-Size Chain?

I-dimension chain iqoqo lobukhulu obuxhumene elakhiwe ngesikhathi kuhlanganisa umshini noma kucutshungulwa ingxenye.

Iketango le-dimension lenziwe ngamasongo namasongo avaliwe. Iringi evaliwe ingakhiwa ngokwemvelo ngemva kokuhlanganisa noma ukusebenza komshini.

Iketango le-dimensional lingasetshenziselwa ukuhlaziya nokuklama ubukhulu benqubo yobuchwepheshe. Kubalulekile ekwakhiweni kwezinqubo zemishini kanye nokuqinisekisa ukunemba kokuhlangana.

Kungani kukhona uchungechunge lwe-dimension?

Iketango le-dimensional likhona ukuze kuqinisekiswe ukuthi ingxenye ngayinye yakhiwe ngokunemba okudingekayo.

Ukuqinisekisa ikhwalithi ekucubunguleni, ekuhlanganisweni nasekusetshenzisweni kuyadingeka ukubala futhi uhlaziye ezinye izilinganiso, ukubekezelela, kanye nezidingo zobuchwepheshe.

Iketango le-dimensional umqondo olula oqinisekisa ukukhiqizwa kwemikhiqizo ngobuningi. Ubudlelwano phakathi kwezingxenye zenqubo yokuhlanganisa okudala amaketango anobukhulu.

Izinyathelo zokuchazwa kochungechunge lobukhulu:

1. Ibhentshimakhi yomhlangano kufanele ikhiywe.

2. Lungisa igebe lomhlangano.

3. Ukubekezelela izingxenye zomhlangano kufanele kuchazwe.

4. Iketango le-dimension lidala uchungechunge lwe-dimension ye-loop evaliwe njengokuhlanganiswacnc machining izingxenye.

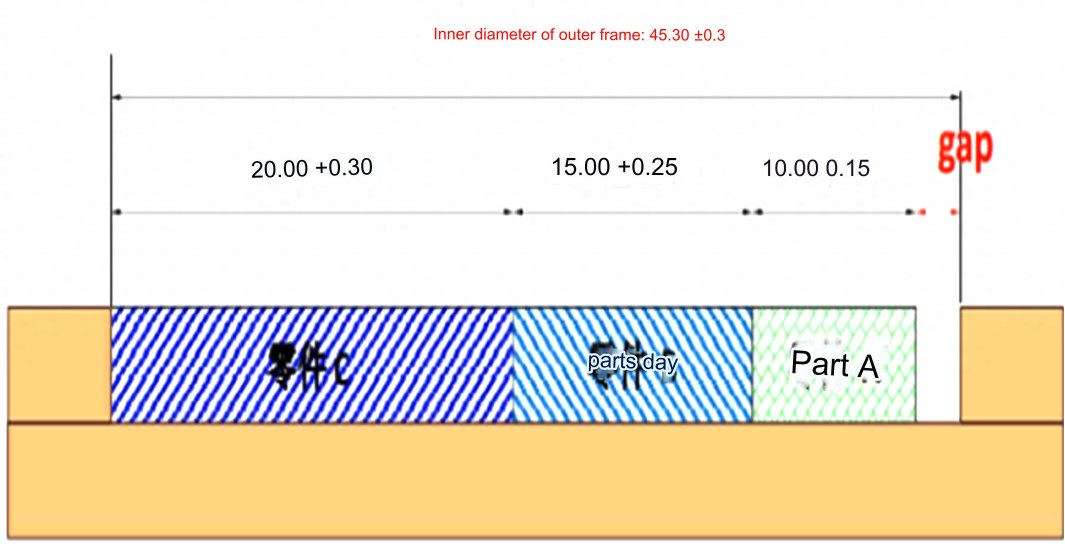

Ikesi lochungechunge lobukhulu bomhlangano 1

Njengoba kuboniswe emfanekisweni, ukuhlakanipha kokulebula kokubekezelela kuhlolwa ngokubala:

Okokuqala bala ngokuya ngokuchezuka okuphezulu:

Umkhawulo kasayizi wobubanzi bangaphakathi bohlaka lwangaphandle: 45.6

Usayizi womkhawulo ophezulu wengxenye A: 10.15

Umkhawulo kasayizi engxenyeni B: 15.25

Umkhawulo kasayizi engxenyeni C: 20.3

bala:

45.6-10.15-15.25-20.3=-0.1

Ukuphazamiseka kuzoba ngu-0.1mm uma izingxenye zifinyelela umkhawulo ongaphezulu. Lokhu kuzodala ukuthi izingxenye zingahlanganiswa kahle. Kuyacaca ukuthi ukubekezelelana komdwebo kudinga ukuthuthukiswa.

Bese ubale ukuchezuka ngokucindezela:

Usayizi womkhawulo ophansi wedayamitha yangaphakathi yohlaka lwangaphandle: 45.0

Usayizi womkhawulo ophansi wengxenye A: 9.85

Usayizi womkhawulo ophansi wengxenye B: 14.75

Usayizi womkhawulo ophansi wengxenye C: 19.7

bala:

45.0-9.85-14.75-19.7=0.7

Uma izingxenye zicutshungulwa ngokuchezuka okuphansi khona-ke igebe lomhlangano lizoba ngu-0.7mm. Akuqinisekisiwe ukuthi izingxenye zizoba nokuchezuka okuphansi uma sezicutshungulwa ngempela.

Bese ubala ngokusekelwe ekuchezukeni kweziro:

Idayamitha yangaphakathi eyisisekelo yohlaka lwangaphandle: 45.3

Ingxenye A usayizi oyisisekelo: 10

Ingxenye B usayizi oyisisekelo: 15

Ingxenye C usayizi oyisisekelo: 20

bala:

45.3-10-15-20=0.3

Qaphela:Uma sicabanga ukuthi izingxenye zingamasayizi ayisisekelo, kuzoba negebe lomhlangano elingu-0.3mm. Futhi asikho isiqinisekiso sokuthi ngeke kube khona umehluko kumasayizi wezingxenye ngesikhathi sokucubungula kwangempela.

Izikhala ezingase zivele ngemva kokucubungula imidwebo ngokuvumelana nokubekezelela okujwayelekile kobukhulu.

Igebe elikhulu: 45.6-9.85-14.75-19.7= 1.3

Igebe elincane: 45-10.15-15.25-20.3= -0.7

Umdwebo ubonisa ukuthi ngisho nalapho izingxenye zingaphakathi kokubekezelelana, kungase kube negebe noma ukuphazamiseka okufika ku-0.7 mm. Izimfuneko zokuhlanganisa azikwazanga ukufezwa kulezi zimo ezimbi kakhulu.

Ukuhlanganisa ukuhlaziya okungenhla, izikhala zokuhlanganisa zalezi zinto ezintathu ezidlulele yilezi: -0.1, +0.7, kanye no-0.3. Bala isilinganiso sokukhubazeka:

Bala inani lezingxenye ezinesici ukuze ubale izinga lokukhubazeka.

Isilinganiso esinephutha yilesi:

(x+y+z) / nx 100%

Ngokwemibandela enikezwe embuzweni, uhlelo olulandelayo lwezibalo lungafakwa kuhlu:

x + y + z = n

x = n * ( – 0.1 / ( – 0.1 + 0.3 + 0.7) )

y = n * ( 0.7 / ( – 0.1 + 0.3 + 0.7))

z = n * ( 0.3 / ( – 0.1 + 0.3 + 0.7) )

Faka izibalo ezingenhla kufomula elandelayo ukuze ubale isilinganiso esinesici:

( – 0.1 * n / ( – 0.1 + 0.3 + 0.7) ) + ( 0.7 * n / ( – 0.1 + 0.3 + 0.7) ) + ( 0.3 * n / ( – 0.1 + 0.3 + 0.7) ) / nx 100%

Izinga lesixazululo elibi liyi-15.24%.

Ukuhlanganisa ukubalwa kokubekezelelana nobungozi bezinga lesici esingu-15,24%, umkhiqizo kufanele ulungiswe ukuze uvumelane nomhlangano.

1. Alukho uchungechunge lwe-dimension ye-loop evaliwe, futhi ukuhlaziya nokuqhathanisa akusekelwe kuchungechunge oluphelele lobukhulu.

2. Kunamaphutha amaningi omqondo. Umhleli uguqule "ukubekezelelana okuphezulu", "ukubekezelelana okuphansi", "nokubekezelelana okujwayelekile".

3. Kubalulekile ukuqinisekisa i-algorithm yokubala amanani esivuno.

Izinga lesivuno lokucubungula izingxenye lijwayelekile. Okungukuthi, amathuba okuthicnc ngomshini izingxenye zepulasitikikumanani abo aphakathi mkhulu kakhulu. Kulokhu, ubukhulu obunokwenzeka kakhulu bengxenye ubukhulu bayo obuyisisekelo.

Bala izinga elinesici. Lesi isilinganiso esiphakathi kwenani lezingxenye ezinesici ezikhiqiziwe kanye nenani eliphelele elikhiqizwayo. Singazibala kanjani izingxenye zezinombolo sisebenzisa inani le-gap? Ayihlangene nenani lokugcina elidingekayo? Uma ubukhulu buyisisekelo, khona-ke bungahlukaniswa futhi busetshenziswe ekubalweni kwesilinganiso esinesici.

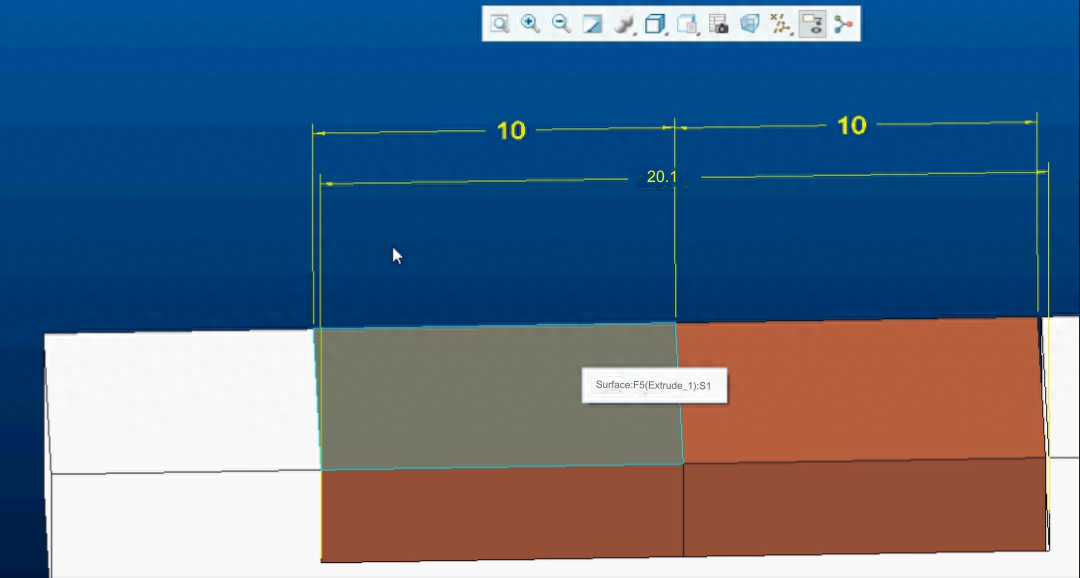

Ikesi lochungechunge lobukhulu bomhlangano 2

Qinisekisa ukuthi igebe phakathi kwezingxenye likhulu kuno-0.1mm

Ukubekezelelana kwengxenye 1 ngu-10.00 + 0.00/-0.10

Ukubekezelelana kwengxenye 2 ngu-10.00 + 0.00/-0.10

Ukubekezelela umhlangano kungu-20.1+0.10/0.00.

Uma nje umhlangano usabekezelelana, ngeke ube namaphutha.

1. Akucaci ukuthi igebe lokugcina lomhlangano liyini, ngakho-ke kunzima ukwahlulela ukuthi liyafaneleka yini.

2. Bala amanani aphezulu kanye nobuncane bokuvunyelwa ngokusekelwe kubukhulu bephrojekthi.

Inani eliphakeme legebe : 20.2-9.9-9.9=0.4

Inani elincane legebe ngu-20-10-10=0

Akunakwenzeka ukunquma ukuthi ifanelekile yini ngokususelwa kugebe eliphakathi kuka-0-0.4. Isiphetho sokuthi "akukho mkhuba wokuhlangana okungekuhle" akulona iqiniso. .

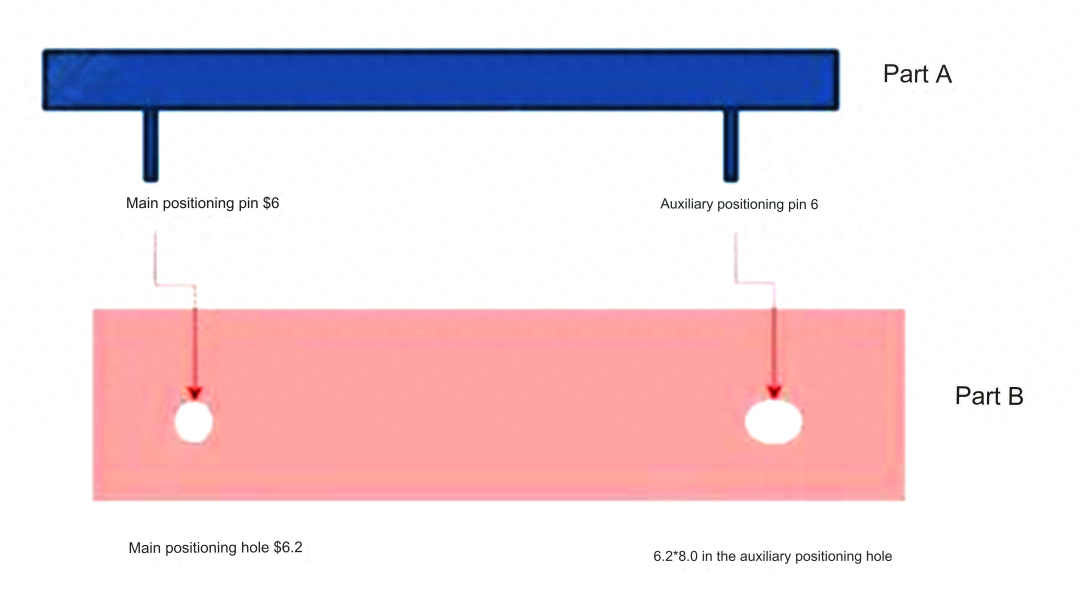

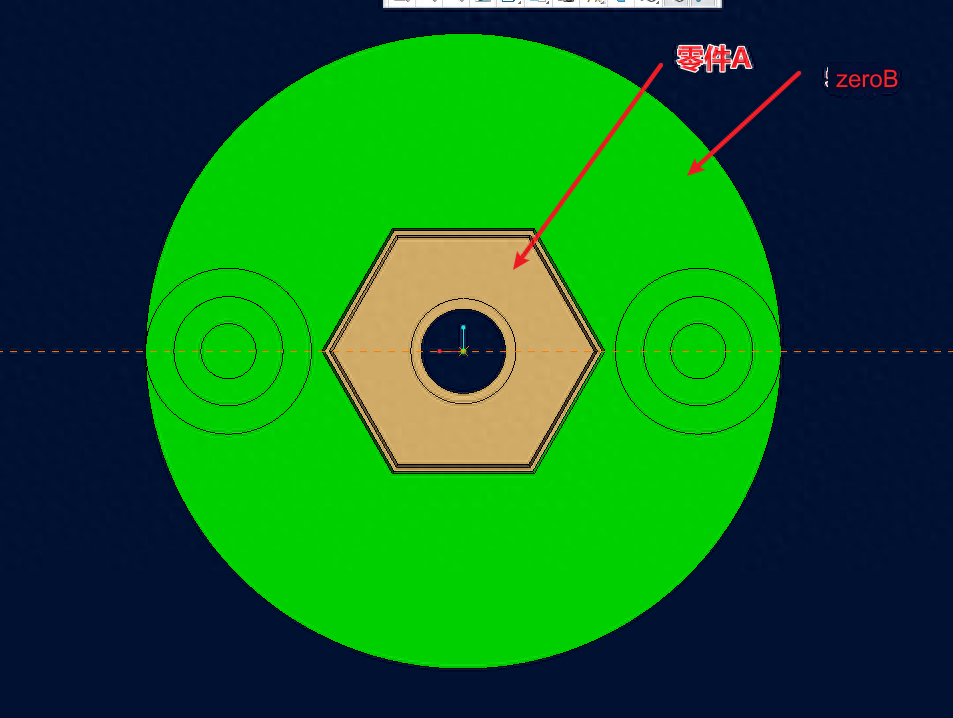

Ikesi lochungechunge lobukhulu bomhlangano 3

Phakathi kwezimbobo zegobolondo nezigxobo, kukhona osayizi abathathu beketango.

Ukubekezelela ibanga eliphakathi nendawo phakathi kwamaposi amabili kufanele kube ngaphansi kokubekezelelana komhlangano kwabesilisa ochungechungeni lobukhulu bokuqala.

Ukubekezelelana phakathi kwezigxobo zokuma kanye nezimbobo kufanele kube kuncane kuchungechunge lobukhulu besibili kunebanga elimaphakathi lamagxolo amabili.

I-Third Dimension Chain: Ukubekezelela okuthunyelwe kwesikhundla kufanele kube ngaphansi kwalokho kwembobo.

Ukubekezelela ingxenye A kungu-100+-0.15

Ukubekezelela ingxenye B: 99.8+0.15

Ibanga phakathi kwezikhonkwane ezimaphakathi zengxenye A nengxenye B ngu-70+-0.2

Ibanga phakathi kwezimbobo ezimaphakathi zengxenye B ngu-70+-0.2

Ububanzi bephinikhodi yengxenye A ngu-6+0.00/0.1

Ububanzi bembobo yokuma yengxenye B ngu-6.4+0.1/0.0

Njengoba kuboniswe kulo mfanekiso, uphawu lokubekezelelana ngeke luthinte umhlangano uma luhlangabezana nokubekezelelana.

Ukubekezelelana kwezikhundla kusetshenziselwa ukuqinisekisa ukuthi izidingo zomhlangano wokugcina zingahlangatshezwana nazo. Izikhonkwane nezikhonkwane engxenyeni A no-B kanye nezindawo zazo zimakwe kusetshenziswa amadigri ezikhundla.

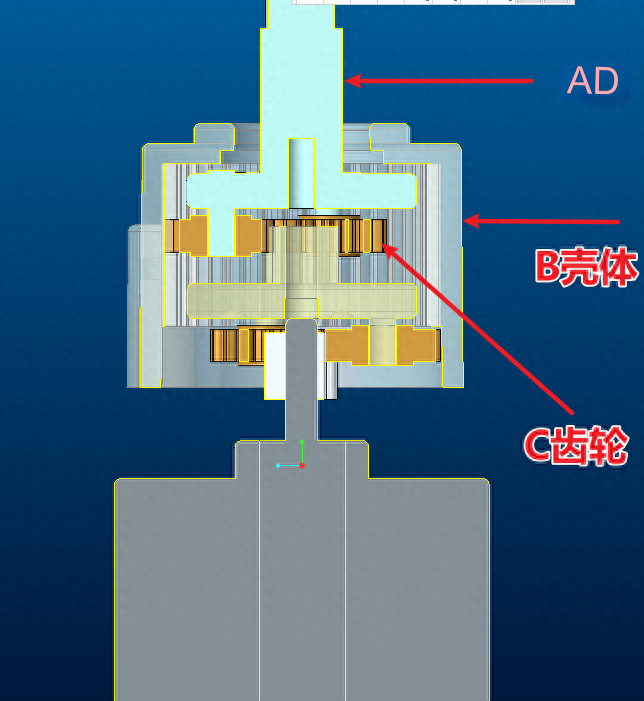

Ikesi lochungechunge lobukhulu bomhlangano 4

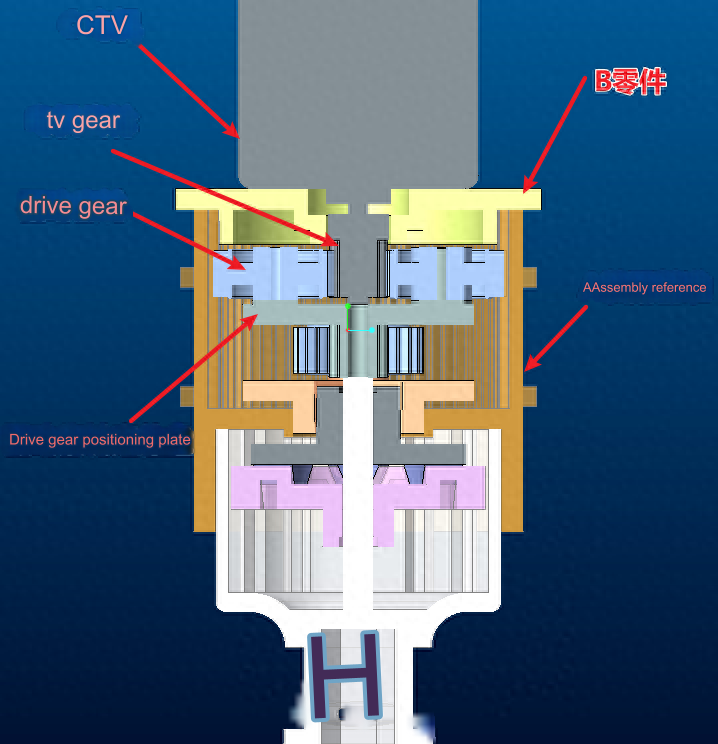

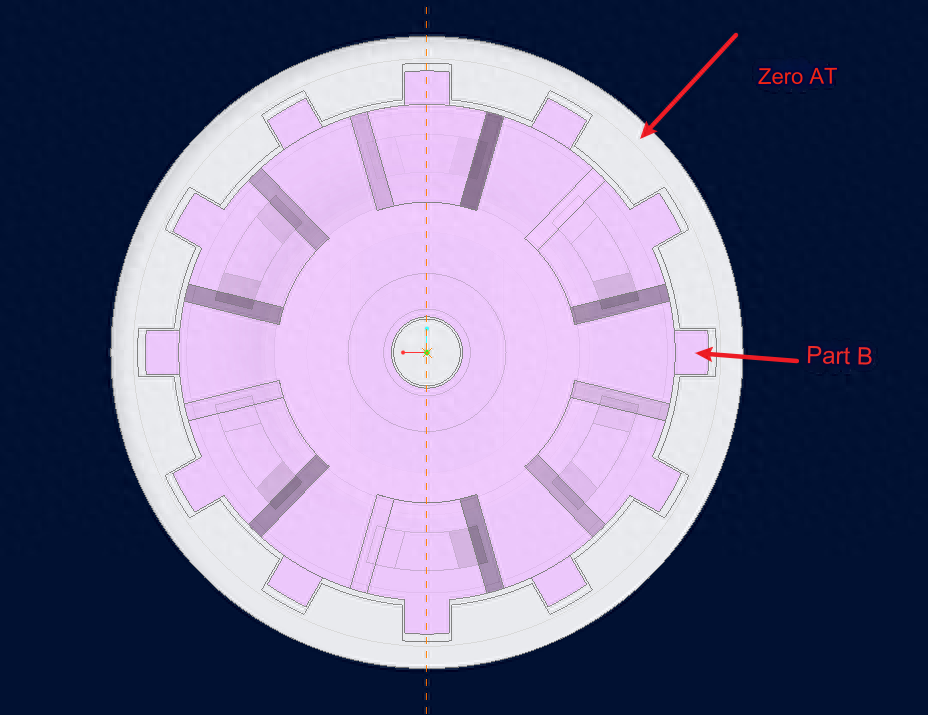

Njengoba kuboniswe emfanekisweni, okokuqala qinisekisa ukubekezelelana kwezindlu B. Ukubekezelela ukuhlanganiswa kwe-axis kufanele kube ngaphansi kwalokho kwe-B housing kanye negiya elingu-C. Ukudluliswa kwezindlu B ngeke kuphazamiseke uma kusetshenziswa igiya elingu-C.

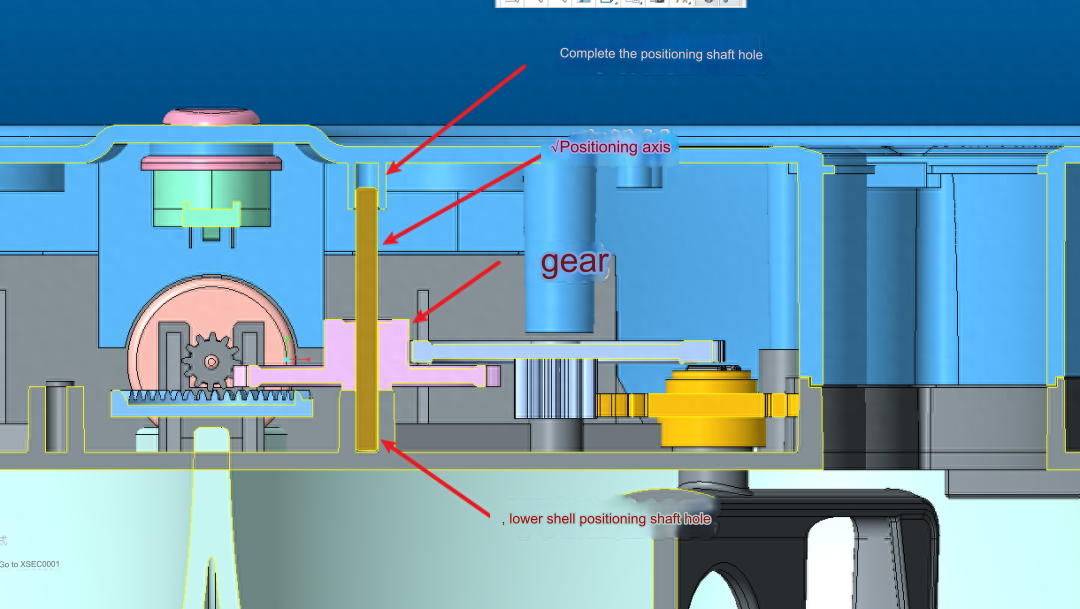

Ikesi lochungechunge lobukhulu bomhlangano 5

I-perpendicularity ye-axis yendawo kugobolondo eliphansi ikhiyiwe.

Ukuqinisekisa ukuma, igobolondo eliphansi kanye ne-shaft yokumisa kufanele kuhlanganiswe ngokubekezelelana okukhulu kunokwegobolondo eliphezulu.

Ukuze uvimbele ukukhishwa kwe-shaft endaweni yayo uma igobolondo eliphezulu selihlanganisiwe, ukubekezelelana phakathi kwamagobolondo angaphezulu naphansi kufanele kube kukhulu kunokubekezela kokuhlangana kwe-shaft yokumisa.

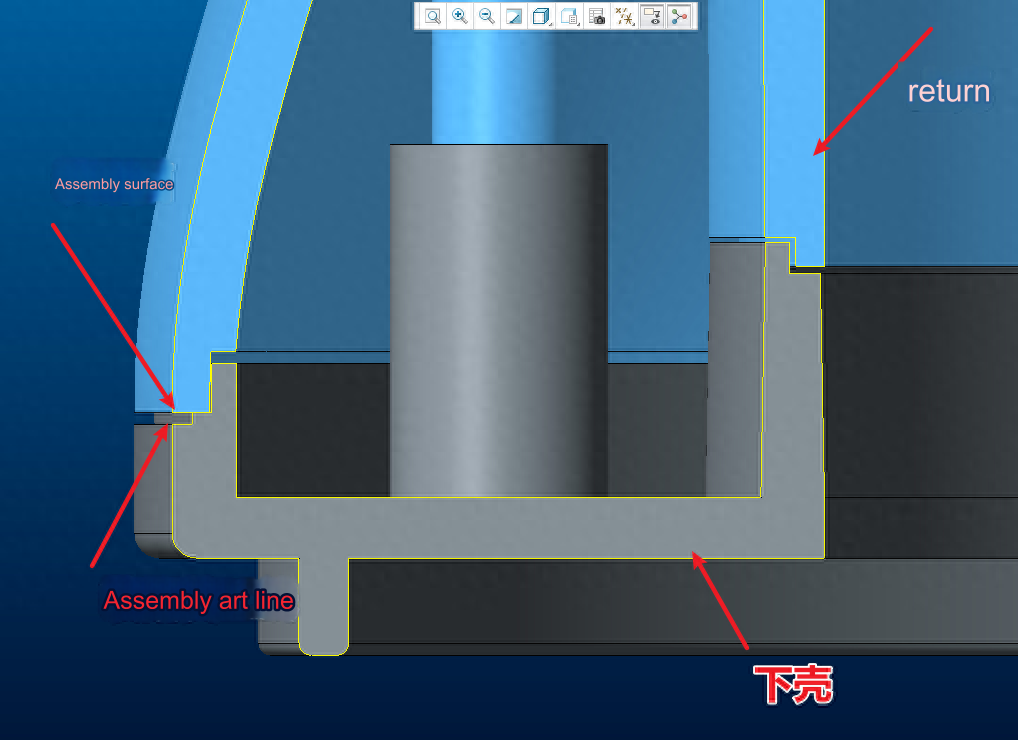

Ikesi lochungechunge lobukhulu bomhlangano 6

Ukuqinisekisa ukuvumelana ekuphakameni komugqa wobuciko ngaphandle komhlangano, ukubekezelelana kokuhlanganiswa kwe-concave yezindlu eziphansi kufanele kube kuncane kunaleyo ye-convex ehlangene yezindlu eziphezulu.

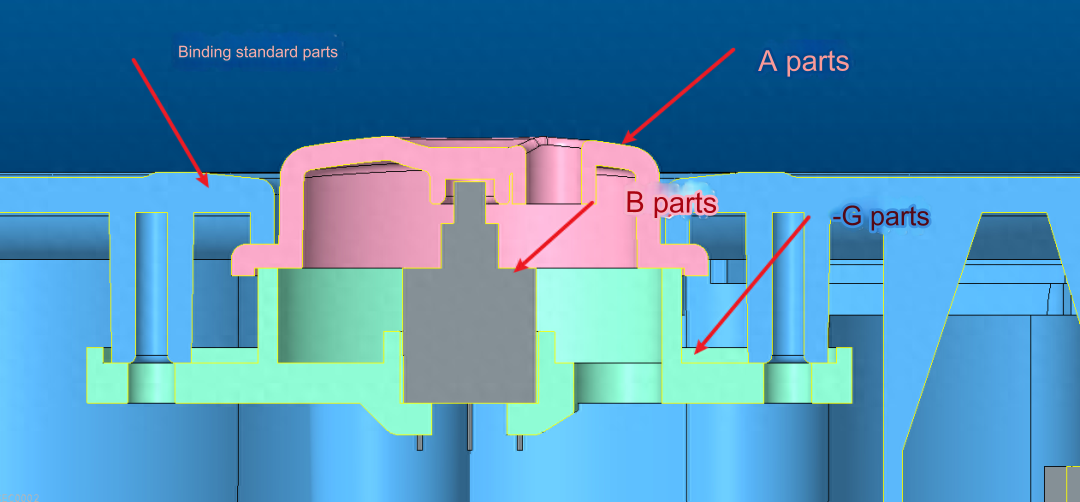

Ikesi lochungechunge lobukhulu bomhlangano 7

Ukuqinisekisa ukuthi alikho igebe phakathi kwezingxenye A no-B, ukubekezelelwa kwengxenye A kanye nengxenye yomhlangano wesisekelo kufanele kube kukhulu kunengxenye B nengxenye C kuhlangene.

Ikesi lochungechunge lobukhulu bomhlangano 8

Okokuqala, njengoba kuboniswe emfanekisweni: okokuqala hlola ukubekezelelana komhlangano A.

Ukubekezelela phakathi kwedatha ye-A kanye ne-motor C kufanele kube kuncane kunalokho okuphakathi kwe-motor B nengxenye B.

Ukuqinisekisa ukujikeleza okushelelayo, igiya lokushayela kufanele lijikeleze ngokushelela. Idatha yokuhlanganisa i-A kanye nokubekezelelana kwegiya kufanele kube kuncane kunokunye.

Ikesi lochungechunge lobukhulu bomhlangano 9

Ukumaka ukubekezelelana esimweni somhlangano we-multipoint, i-shaft encane kanye nesimiso sezimbobo ezinkulu sisetshenziswa. Lokhu kuzoqinisekisa ukuthi akukho ukuphazamiseka komhlangano.

Ikesi le-Assembly dimension chain 10

Ukuphazanyiswa komhlangano ngeke kwenzeke ngoba ukubekezelelana kwembobo kuhle futhi i-axis inegethivu.

Ngobuchwepheshe obuhamba phambili be-Anebon ngokufanayo njengomoya wethu wokusungula, ukubambisana, izinzuzo kanye nentuthuko, sizokwakha ikusasa eliqhakazile kanye nebhizinisi lakho elihlonishwayo le-OEM Manufacturer Custom High.Izingxenye ze-aluminium eziqondile, izingxenye zensimbi eziphendukayo,izingxenye zokugaya ze-cnc, Futhi kukhona abangani abaningi abasondelene baphesheya kwezilwandle abeze ukuze babonwe, noma basiphathise ukuthi sibathengele ezinye izinto. Uzokwamukeleka kakhulu ukuza e-China, edolobheni lase-Anebon kanye nasesikhungweni sokukhiqiza sase-Anebon!

I-China Wholesale yase-China eyenziwe ngomshini, imikhiqizo ye-cnc, izingxenye zensimbi eziphendulwe kanye nethusi lokunyathela. I-Anebon inobuchwepheshe obuthuthukisiwe bokukhiqiza, futhi iphishekela izinto ezintsha emikhiqizweni. Ngesikhathi esifanayo, inkonzo enhle iye yathuthukisa idumela elihle. I-Anebon ikholelwa ukuthi inqobo nje uma uqonda umkhiqizo wethu, kufanele uzimisele ukuba ozakwethu nathi. Ngibheke ngabomvu uphenyo lwakho.

Isikhathi sokuthumela: Oct-12-2023