1. Iziganeko ezibonakalayo ze-titanium machining

Amandla okusika i-titanium alloy processing iphezulu kancinane kunentsimbi enobunzima obufanayo. Nangona kunjalo, into ebonakalayo yokusetyenzwa kwe-titanium alloy intsonkothe ngakumbi kuneyokusetyenzwa kwentsimbi, eyenza ukuba ukusetyenzwa kwe-titanium alloy kujongane nobunzima obuninzi.

I-thermal conductivity ye-titanium alloys iphantsi kakhulu, kuphela i-1/7 yensimbi kunye ne-1/16 ye-aluminium. Ngoko ke, ubushushu obuveliswayo xa usika i-titanium alloys abuyi kudluliselwa ngokukhawuleza kwi-workpiece okanye ithathwe yi-chips. Sekunjalo, iya kuqokelelana kwindawo yokusika, kwaye ubushushu obuveliswayo bunokuphakama njenge-1,000 ° C okanye ngaphezulu, okuya kubangela ukuba i-cut cut edge yesixhobo igugile, i-chip, kwaye iqhekeke ngokukhawuleza. Ukuqulunqwa komphetho owenziweyo kunye nokubonakala ngokukhawuleza kwecala eligugileyo kuvelisa ubushushu obuninzi kwindawo yokusika, kunciphisa ngakumbi ubomi besixhobo.ukwenziwa kwe-titanium

Amaqondo okushisa aphezulu avelisiweyo ngexesha lenkqubo yokusika aphinde atshabalalise ingqibelelo yendawo ye-titanium alloy parts, okubangela ukuncipha kokuchaneka kwejometri yamacandelo kunye nomsebenzi onzima onciphisa kakhulu amandla abo okukhathala.

I-elasticity ye-titanium alloys inokuba luncedo ekusebenzeni kwenxalenye, kodwa ngexesha lokusika, i-deformation elastic ye-workpiece yimbangela ebalulekileyo yokungcangcazela. Uxinzelelo lokusika lubangela ukuba i-workpiece "elastic" ihambe kude nesixhobo kunye ne-bounce, ngoko ke ingxabano phakathi kwesixhobo kunye ne-workpiece inkulu kunesenzo sokusika. Inkqubo yokukhuhlana iphinda ivelise ubushushu, nto leyo eyenza kube mandundu ngakumbi ingxaki yokungahambi kakuhle kwe-thermal ye-titanium alloys.

Le ngxaki iba mbi ngakumbi xa kusenziwa izixhobo ezinodonga olucekethekileyo okanye ezimise okweringi, iindawo ezinokukhubazeka ngokulula. Akukho lula ukwenza umatshini we-titanium alloy alloy iinxalenye ezicekethekileyo zokuchaneka okulindelweyo. Xa isixhobo sityhala i-workpiece imathiriyeli kude, i-deformation yodonga olucekeceke lwendawo idlula uluhlu lwe-elastic; ukuguqulwa kweplastiki kwenzeka, kwaye amandla ezinto eziphathekayo kunye nobunzima bendawo yokusika banda kakhulu. Ukutshiza ngesantya esigqitywe ngaphambili sokusika kuba phezulu kakhulu, okukhokelela ekunxityweni kwesixhobo esibukhali.

"Kushushu" "lityala" elenza kube nzima ukwenza iialloys zetitanium!

2. Ulwazi lwetekhnoloji ye-titanium CNC machining

Ngokusekwe ekuqondeni indlela yokucutshungulwa kwe-titanium alloys kunye nokongeza amava, eyona nkqubo iphambili yokwazi indlela yokusetyenzwa kwe-titanium alloys yile ilandelayo:

1

(2) Gcina isondlo rhoqo ukuze ugweme ukuqina kwe-workpiece. Isixhobo kufuneka sihlale sikwimeko yokutya ngexesha lenkqubo yokusika, kwaye inani lokusika i-radial kufuneka libe yi-30% ye-radius ngexesha lokugaya.

(3) I-high-pressure kunye ne-flow flowing cutting cutting fluid isetyenziselwa ukuqinisekisa ukuzinza kwe-thermal ye-machining process kunye nokuthintela ukuchithwa kwendawo yokusebenza kunye nomonakalo wesixhobo ngenxa yokushisa okugqithisileyo.

(4) Gcina incakuba ibukhali; izixhobo ezibuthuntu zibangela ukwakha ubushushu kunye nokunxiba, ngokukhawuleza okukhokelela ekungaphumeleli kwesixhobo.

(5) Ukucoca kwimeko ethambileyo ye-titanium alloy kangangoko kunokwenzeka ngenxa yokuba izinto ziba nzima kakhulu kumatshini emva kokuqina, kunye nonyango lobushushu kwandisa amandla ezinto kunye nokunxiba kokufakwa.

(6) Sebenzisa i-radius yempumlo enkulu okanye i-chamfer ukusika kangangoko kunokwenzeka kwi-edge yokusika. Oku kunciphisa amandla okusika kunye nobushushu kwindawo nganye kwaye kuthintela ukuphuka kwendawo. Xa i-alloys ye-titanium yokugaya, phakathi kweeparitha zokusika, isantya sokusika sinempembelelo ebalulekileyo kwisixhobo sobomi vc, kulandelwa ukubandakanyeka kwe-radial (ubunzulu bokugaya) ae.

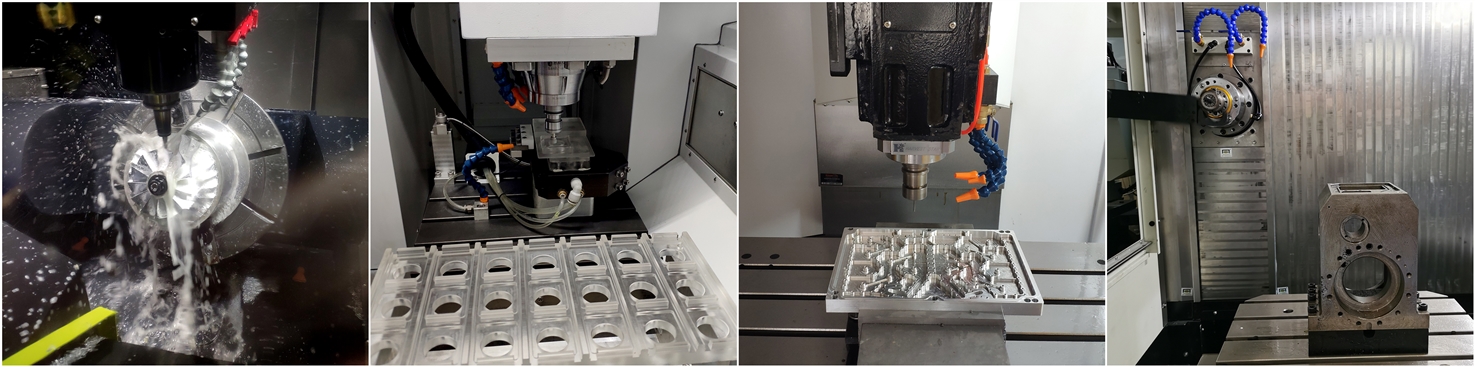

3. Qala nge-blade ukusombulula ingxaki ye-titanium processing

Ukunxitywa kwe-groove yokufaka ngexesha lokulungiswa kwee-alloys ze-titanium kukunxitywa kwendawo yangasemva nangaphambili kwicala lobunzulu bokusikwa, okuhlala kubangelwa ngumaleko olukhuni oshiywe yinkqubo yangaphambili. Ukusabela kweekhemikhali kunye nokusasazwa kwesixhobo kunye nezinto zokusebenza kwiqondo lokushisa elingaphezulu kwe-800 °C nazo zizizathu zokubunjwa kwe-groove wear. Ngenxa yokuba ngexesha lenkqubo yomatshini, iimolekyuli ze-titanium ze-workpiece ziqokelela phambi kwe-blade kwaye "zifakwe kwi-welded" kwi-blade edge phantsi koxinzelelo oluphezulu kunye nobushushu obuphezulu, zenza umda owenziweyo. Xa i-edge eyakhelweyo ikhupha umgca wokusika, ithatha i-carbide yokufaka i-insert, ngoko ke i-titanium machining ifuna izinto ezikhethekileyo zokufaka kunye neejometri.cCustomprecision machining

4. Ulwakhiwo lwesixhobo esifanelekileyo kwi-titanium machining

Ugxininiso lwe-titanium alloy processing lubushushu, kwaye inani elikhulu le-high-pressure cutting fluid kufuneka litshizwe kwi-cut cut edge ngokukhawuleza nangokuchanekileyo ukususa ukushisa ngokukhawuleza. Kukho ulungelelwaniso olulodwa lwabasiki be-milling ngokukodwa kwi-machining titanium.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Jan-18-2022