Isebenza ngokubanzi kangakanani inkqubo yomatshini wokwenza umngxuma onzulu owaziwayo kwinkqubo yethu yomatshini?

Imipu yompu kunye neenkqubo zezixhobo:

Ukugrumba okunzulu kudlala indima ebalulekileyo ekuvelisweni kwemibhobho yompu, ukuqinisekisa ukuchaneka kunye nokuchaneka kobukhulu bemibhobho, ukudubula, kunye nokwakheka komphezulu.

Ishishini le-Aerospace:

Kusetyenziswa oomatshini bokwenza izixhobo zokumisa iinqwelo-moya, iinxalenye zeenjini zejethi, i-helicopter rotor shafts, kunye nezinye izinto ezibalulekileyo ezifuna ukuchaneka okukhethekileyo kunye nokuqina.

Ishishini leoli negesi:

Ukugrumba umngxuma onzulu kusetyenziswa ekwenziweni kwezixhobo ezisetyenziswa kuphononongo lweoyile nerhasi, kubandakanywa izixhobo zokomba, iintloko zemithombo, kunye netyhubhu yokuvelisa.

Umzi mveliso weemoto:

Ukwenziwa kwezixhobo ze-injini ezifana neecrankshafts, iicamshafts, iirodi zokuqhagamshela, kunye neendawo zokutofa ngamafutha kufuna ukufakwa kwemingxuma enzulu.

Ukhathalelo lwezonyango kunye nezempilo:

Ukwenziwa komngxuma onzulu kubalulekile ekuveliseni izixhobo zotyando, ukufakelwa, kunye nezixhobo zonyango ezifuna iimpawu zangaphakathi ezenziwe ngokuchanekileyo kunye nokugqitywa komphezulu.

Ishishini lokungunda kunye nokufa:

Ukugrumba umngxuma onzulu kufumanisa ukusetyenziswa ekwenziweni kwesitofu sokungunda, i-extrusion iyafa, kunye nezinye izixhobo zokusebenza ezifuna amajelo okupholisa antsonkothileyo ukuze akhuphe ubushushu ngokufanelekileyo.

Ukufa kunye nokulungiswa kokungunda:

Iinkqubo zomatshini wokwenza imingxunya enzulu zikwasetyenziselwa ukulungisa okanye uhlengahlengiso lwezibumba ezikhoyo kwaye ziyafa, zivumela ukugrunjwa kwamajelo okupholisa, imingxunya ye-ejector pin, okanye ezinye iimpawu eziyimfuneko.

Iinkqubo zokulungisa umngxuma onzulu: iimodeli ezintandathu ezisetyenziswa ngokuqhelekileyo

Yintoni ukusetyenzwa komngxuma onzulu?

Umngxuma onzulu ngulowo umlinganiselo wobude ukuya kwidayamitha mkhulu kune-10. Ubungakanani bobunzulu ukuya kwidayamitha yemingxuma enzulu ngokubanzi idla ngokuba yi-L/d>=100. Oku kubandakanya imingxunya yesilinda kunye ne-oyile ye-axial shaft, i-hollow spindle, kunye neevalvu zehydraulic. Le mingxuma isoloko ifuna ukuchaneka okuphezulu kunye nomgangatho womphezulu, ngelixa ezinye izinto kunzima ukuzisebenzisa, ezinokuba yingxaki kwimveliso. Zeziphi ezinye iindlela onokucinga ngazo ukwenza imingxuma enzulu?

1. UKwemba ngokweMveli

I-twist drill, eyasungulwa ngabantu baseMelika, yimvelaphi yokulungiswa komngxuma onzulu. Le bit drill inesakhiwo esilula, kwaye kulula ukwazisa ulwelo lokusika, okuvumela ukuba i-drill bits yenziwe kwiidamitha ezahlukeneyo kunye nobukhulu.

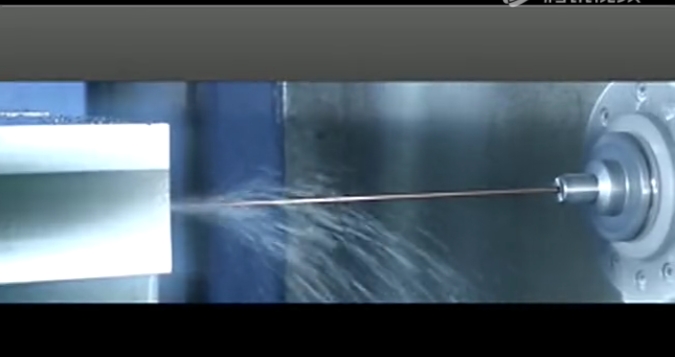

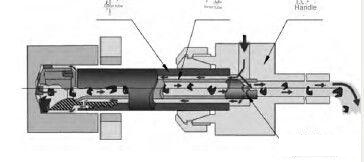

2. Ukudubula umpu

Ityhubhu yomngxuma enzulu yaqala yasetyenziswa ukwenza imigqomo yompu, ekwaziwa njengeityhubhu ezinzulu. I-gun drill yathiywa njalo ngenxa yokuba imigqomo yayingeyiyo iityhubhu ezichanekileyo ezingenamthungo kwaye inkqubo yokuvelisa ityhubhu echanekileyo ayinakuhlangabezana nemfuneko yokuchaneka. Ukucutshungulwa komngxuma onzulu ngoku kuyindlela ethandwayo nesebenzayo yokulungisa ngenxa yophuhliso lwenzululwazi kunye nobuchwepheshe kunye nemizamo yabavelisi beenkqubo zomngxuma onzulu. Zisetyenziselwa kwiinkalo ezininzi, kubandakanywa: imboni yemoto, i-aerospace, ukwakhiwa kwesakhiwo, izixhobo zonyango, i-mold / tool / jig, i-hydraulic kunye ne-pressure industry.

Ukugrumba imipu sisisombululo esihle sokwenziwa komngxuma onzulu. Ukugrumba imipu yindlela elungileyo yokufumana iziphumo ezichanekileyo. Ukugrumba imipu kunokufikelela kwiziphumo ezichanekileyo zokusetyenzwa. Iyakwazi ukucubungula iindidi zemingxuma enzulu kunye nemingxuma ekhethekileyo ekhethekileyo njengemingxuma eyimfama kunye nemingxuma enqamlezileyo.

Imipu yokomba amacandelo

Imipu yobhola

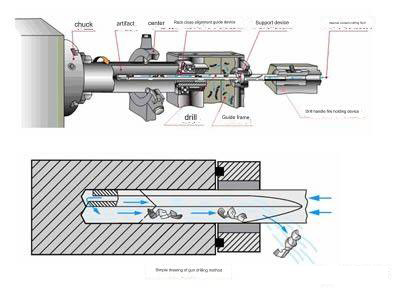

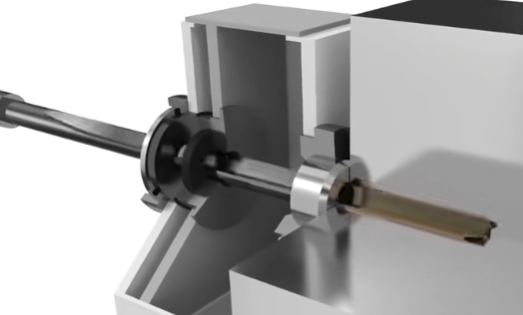

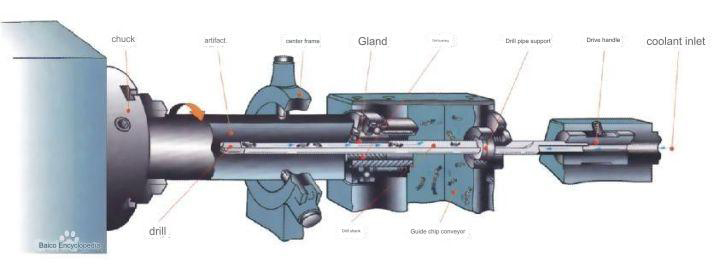

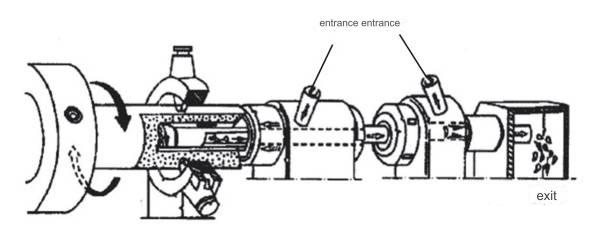

3. Inkqubo ye-BTA

I-International Hole Processing Association yaqulunqa i-drill enzulu ekhupha iitshiphusi ngaphakathi. Inkqubo ye-BTA isebenzisa iisilinda ezingenanto kwi-drill rod kunye nebit. Oku kuphucula ukuqina kwesixhobo kwaye kuvumela ukudibanisa ngokukhawuleza kunye nokuqhaqha. Umzobo ubonisa umgaqo wayo wokusebenza. I-oyile ye-oyile izaliswe ngamanzi okusika phantsi koxinzelelo.

I-fluid yokusika ke idlula kwindawo ye-annular eyenziwe ngumbhobho we-drill, udonga lomngxuma kwaye lugeleza kwindawo yokusika ukupholisa kunye ne-lubrication. Ikwacinezela itshiphu kwiitshiphusi zentwana ye-drill. Umbhobho wangaphakathi wombhobho kulapho iitshiphusi zikhutshwa khona. Inkqubo ye-BTA ingasetyenziselwa imingxuma enzulu enobubanzi obungaphezulu kwe-12mm.

Ukwakhiwa kwenkqubo ye-BAT↑

BAT drill bit↑

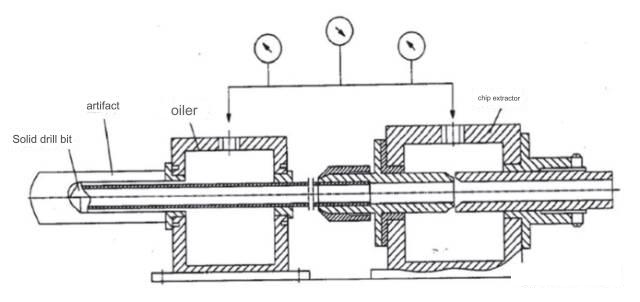

4. Isitofu kunye neNkqubo yokuDla iSifo

I-Jet Suction Drilling System bubuchule bokomba obunzulu obusebenzisa ityhubhu ephindwe kabini esekelwe kumgaqo wokufunxa ijethi womatshini wolwelo. Inkqubo yokufunxa isitshizi isekelwe kwisixhobo setyhubhu enamaleko amabini. Emva koxinzelelo, i-fluid yokusika ifakwe kwi-inlet. I-2/3 yolwelo olusikwayo olungena kwisithuba phakathi kwemivalo yangaphandle kunye nengaphakathi yokubhobhoza ingenacnc isiko lokusika inxalenyeukuyipholisa nokuyithambisa.

Iitshiphusi zityhalelwa kumqolo ongaphakathi. I-1/3 eseleyo yolwelo lokusika lutshizwe ngesantya esiphezulu kumbhobho ongaphakathi ngokusebenzisa i-crescent shaped nozzle. Oku kudala indawo yoxinzelelo oluphantsi ngaphakathi kombhobho wangaphakathi, ukufunxa ulwelo lokusika oluthwele iichips. Iitshiphusi zikhutshwa ngokukhawuleza kwindawo yokuphuma phantsi kweentshukumo ezimbini zokutshiza kunye nokufunxa. Iisistim zokugrumba ukufunxa i-Jet zisetyenziswa ikakhulu ukusetyenzwa kwemingxuma enzulu, enobubanzi obungaphezulu kwe-18mm.

Umgaqo-nkqubo wokomba wokufunxa ijethi↑

I-Jet suction drill bit↑

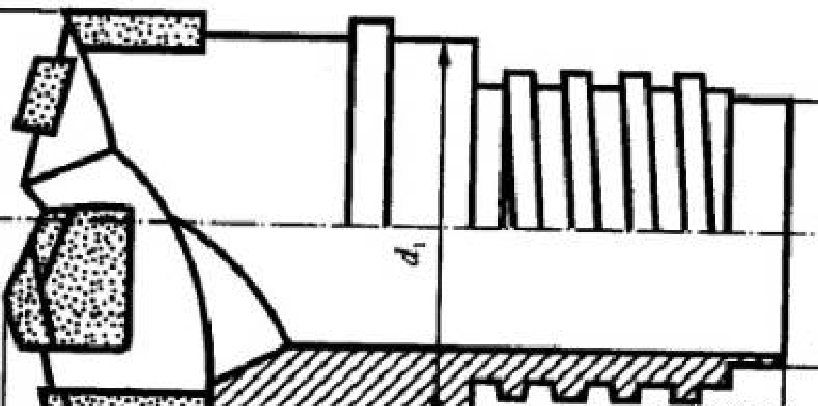

Inkqubo ye-5.DF

Inkqubo ye-DF yinkqubo ye-double-inlet single-tube yokususwa kwe-chip yangaphakathi eyenziwe yi-Nippon Metallurgical Co., Ltd. I-fluid yokusika ihlulwe ibe ngamasebe amabini angaphambili nasemva, angena kwii-inlets ezimbini ngokulandelanayo. I-2/3 yolwelo lokusika kwindawo yokuqala igeleza ukuyacnc intsimbi yokusika inxalenyengommandla we-annular owenziwe ngumbhobho we-drill kunye nodonga lomngxuma owenziweyo, kwaye utyhale iitshiphusi kwi-chip outlet kwi-drill bit, ingena kumbhobho wokubhobhoza, kwaye igeleza kwi-chip extractor; le yokugqibela i-1/3 yolwelo lokusika ingena ngqo kwi-extractor yetshiphu kwaye ikhawuleziswe ngomsantsa omxinwa weconical phakathi kwemilomo yangaphambili nangasemva, idala ifuthe elibi lokufunxa uxinzelelo ukuze kuphunyezwe injongo yokukhawulezisa ukususwa kwetshiphu.

Ubume besiqingatha sokuqala senkqubo ye-DF edlala indima "yokutyhala" iyafana nenkqubo ye-BTA, kwaye ulwakhiwo lwesiqingatha sesibini esidlala indima "yokufunxa" lufana nelo bhola lokufunxa ijethi. inkqubo. Ekubeni inkqubo ye-DF isebenzisa izixhobo ezimbini zokungena kwe-oyile, isebenzisa kuphela umbhobho wokubhobhoza omnye. Indlela yokutyhalela itshiphu kunye nokufunxa igqityiwe, ngoko ke ubukhulu bentonga yokomba inokwenziwa ibe mincinci kakhulu kwaye imingxunya emincinci ingalungiswa. Okwangoku, ubuncinci bokucutshungulwa kwedayimitha yenkqubo yeDF inokufikelela kwi-6mm.

Isebenza njani inkqubo yeDF↑

DF umngxuma onzulu drill bit↑

6. Inkqubo ye-SIED

IYunivesithi yaseNyakatho yeChina yaqulunqa inkqubo ye-SIED, inkqubo enye yokukhupha i-chip kunye ne-suction drill system. Le teknoloji isekelwe kwiiteknoloji ezintathu zangaphakathi zokususwa kwetshiphu: i-BTA (i-jet-suction drill), inkqubo ye-DF, kunye ne-DF System. Inkqubo yongeza isixhobo sokutsalwa kwetshiphu esilungelelaniswa ngokuzimeleyo esiqhutywa ngumbane wokulawula ukupholisa kunye nokuhamba kolwelo lokususwa kwetshiphu ngokuzimeleyo. Njengoko kuboniswe kumzobo, lo ngumgaqo osisiseko. Ipompo ye-hydraulic ikhupha ulwelo lokusika, oluthi ke luhlulwe lube yimijelo emibini: i-fluid yokuqala yokusika ingena kwisixhobo sokuhambisa ioyile kwaye iqukuqele isithuba se-annular phakathi kodonga lombhobho we-drill kunye nomngxuma ukufikelela kwindawo yokusika, ukususa iitshiphusi.

Ulwelo lokuqala lokusika lutyhalelwa kwindawo yokuphuma yomngxuma we-drill bit. Ulwelo lwesibini lokusika lungena ngesithuba phakathi kweeperi ze-conical nozzle kwaye luqukuqela kwisixhobo sokutsalwa kwetshiphu. Oku kudala ijethi enesantya esiphezulu kunye noxinzelelo olubi. I-SIED ixhotyiswe ngeevalvu ezimbini ezizimeleyo zokulawula uxinzelelo, enye yeyokuhamba kolwelo ngalunye. Ezi zinokuhlengahlengiswa ngokwezona zipholileyo okanye iimeko zokutsalwa kwetshiphu. I-SlED yinkqubo ekhuthazwa ngokuthe ngcembe. Yinkqubo ephucuke ngakumbi. Inkqubo ye-SlED okwangoku iyakwazi ukunciphisa ubukhulu obuncinci bomngxuma wokugaya ukuya ngaphantsi kwe-5mm.

Isebenza njani inkqubo ye-SIED↑

Ukusetyenziswa kwenkqubo yomngxuma onzulu kwi-CNC

Ukwenziwa kwemipu nezixhobo:

Ukwemba imingxunya enzulu kusetyenziswa ukwenza imipu kunye neenkqubo zezixhobo. Iqinisekisa imilinganiselo echanekileyo, ukudubula kunye nokugqitywa komphezulu womsebenzi ochanekileyo kunye nothembekileyo wompu.

Ishishini le-Aerospace:

Inkqubo yokwenza oomatshini bomngxuma onzulu isetyenziselwa ukwenza iinxalenye zezixhobo zokumisa zenqwelomoya kwakunye neenxalenye zeinjini yomoya womoya kunye namanye amacandelo abalulekileyo asemajukujukwini afuna umgangatho ophezulu kunye nokuchaneka.

Uphononongo lweoyile negesi:

Ukugrunjwa kwemingxunya enzulu kusetyenziselwa ukuveliswa kwezixhobo ezifana nokugrumba, imibhobho, njengeentloko zemithombo, eziyimfuneko ekuhloleni i-oyile negesi. Imingxuma enzulu ivumela ukutsalwa kwemithombo yobutyebi evaleleke kumadama angaphantsi komhlaba.

Umzi mveliso weemoto:

Ukusetyenzwa kwemingxuma enzulu kubalulekile ekudalweni kwamalungu e-injini afana neecrankshafts, iicamshafts kwakunye neerodi zokuqhagamshela. La macandelo afuna ukuchaneka kwiimpawu zawo zangaphakathi kunye nokugqiba ukusebenza kakuhle.

Ukhathalelo lwempilo kunye nonyango:

Inkqubo ye-machining enzulu isetyenziselwa ukwenza izixhobo zotyando, ukufakelwa kwezonyango kunye nezixhobo zonyango ezahlukeneyo. Ezi zixhobo zifuna iimpawu ezichanekileyo zangaphakathi kunye nokugqiba ukuqinisekisa ukusebenza okuphezulu kunye nokuhambelana.

Ishishini lokungunda kunye nokufa:

Umngxuma onzulu we-drill udlala indima ebalulekileyo ekudaleni ukungunda kunye nokufa. Ukungunda kunye nokufa kufuna imijelo yokupholisa ukuqinisekisa ukutshatyalaliswa kobushushu ngokufanelekileyo xa usebenzisa iinkqubo ezifana nokubumba inaliti okanye iinkqubo ezahlukeneyo zokuvelisa.

Ishishini lamandla:

Ukusetyenzwa komngxuma onzulu kusetyenziselwa ukwenziwa kwamalungu anxulumene namandla, anje ngencakuba zeinjini yomoya, oomatshini bokutshintsha ubushushu kunye namalungu othumelo lwamandla. La macandelo afuna iinkcukacha ezichanekileyo zangaphakathi kunye nokugqiba ukuqinisekisa ukusebenza kakuhle ekudaleni amandla.

Ishishini loKhuselo:

Ukwemba imingxunya enzulu kusetyenziselwa ukwenziwa kwezinto ezinxulumene nokhuseloiindawo ezigayiweyo zecncnjengeesistim zesikhokelo somjukujelwa kunye neepleyiti zesikrweqe kunye nezixhobo zemoto ye-aerospace. Ezicnc amacandelo oomatshinizifuna ukuchaneka okuphezulu kunye nokuqina okuhlala ixesha elide ukuqinisekisa ukusebenza kunye nokhuseleko lwabo.

I-Anebon iyakwazi ukubonelela ngemveliso ekumgangatho ophezulu, ixabiso lokuthengisa elikhuphisanayo kunye nenkxaso egqwesileyo yabathengi. Indawo yokufikela i-Anebon ithi “Uza apha ngobunzima kwaye sikunika uncumo ukuze uhambe” ngenkonzo yesiko lesitampu sesinyithi. Ngoku i-Anebon ithathele ingqalelo kuzo zonke iinkcukacha zokuqinisekisa imveliso nganye okanye inkonzo equlethwe ngabathengi bethu.

Sikwabonelela ngenkonzo yesinyithi ye-OEM anodized kunye ne-lazer yokusika ebonelela kwiimfuno zakho kunye neemfuno zakho. Ngeqela elinamandla leenjineli ezinamava kuyilo lwe-hose kunye nophuhliso, i-Anebon ixabisa ngononophelo lonke ithuba lokubonelela ngeemveliso ezingcono kunye nezisombululo kubathengi bethu.

Ukuba ufuna ukwazi ngakumbi, nceda uqhagamshelane nomntu osemthethweni ophethe i-Anebon nge info@anebon.com, ifowuni+86-769-89802722

Ixesha lokuposa: Oct-27-2023