Kwii-injini, amacandelo e-shaft afana ne-crankshafts, i-camshafts, kunye ne-cylinder liners zisebenzisa ii-chucks kwinkqubo nganye yokucubungula. Ngexesha lokucubungula, iziko le-chucks, libambe kwaye liqhube i-workpiece. Ngokwesakhono sechuck ukubamba i-workpiece kunye nokugcina iziko, yahlulwe yaba yi-chuck eqinile kunye ne-chuck edadayo. Eli nqaku lixoxa ikakhulu le migaqo yokukhetha iichucks ezimbini kunye namanqaku okugcina imihla ngemihla.5aixs CNC amacandelo machining

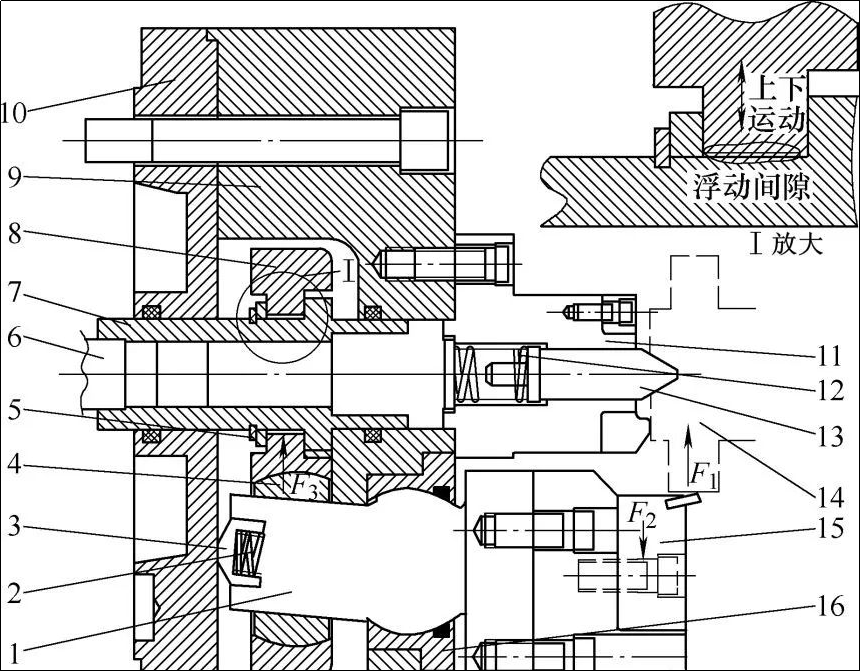

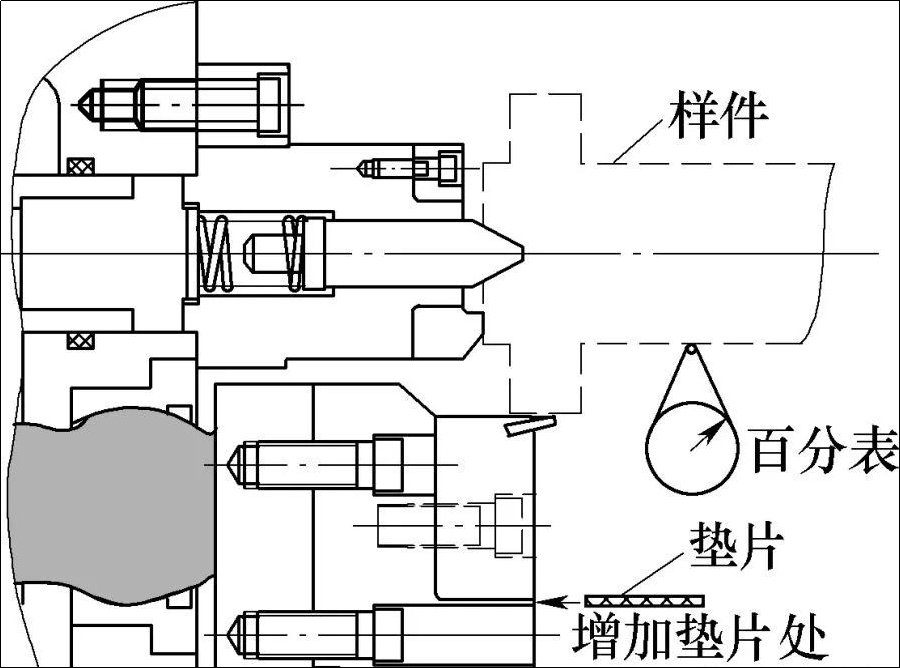

Iichucks eziqinileyo kunye neechucks ezidadayo zahluke kakhulu kwisakhiwo kunye neendlela zohlengahlengiso. Ukuthatha uluhlu lwee-chucks ze-brand yaseJapan njengomzekelo, uMzobo 1 ubonisa inkqubo yesenzo se-chuck edadayo: i-workpiece iphantsi kwesenzo sebhloko yenkxaso yokumisa kunye nephezulu. I-axial kunye ne-radial positioning kunye ne-clamping iyenziwa. Emva koko, i-chuck cylinder iqhuba intonga yeqhina le-chuck, ipleyiti yokulungelelanisa i-gap, ipleyiti yenkxaso yengalo yomhlathi, i-spherical joint, kunye nengalo yomhlathi kwi-tie rod, ekugqibeleni uqonde umhlathi we-chuck ukuze ubambe i-workpiece.

Xa kukho ukutenxa okubalulekileyo kwe-coaxially phakathi kumbindi wemihlathi emithathu ye-chuck kunye nombindi we-workpiece, umhlathi we-chuck odibanisa i-workpiece kuqala uya kuthotyelwa phantsi kwe-F2, ethi idluliselwe emhlathini. ipleyiti yokuxhasa ingalo kwingalo yomhlathi kunye nelungu elingqukuva. I-F3 isebenza kwipleyiti yenkxaso yengalo yozipho. Kwi-chuck edadayo, kukho umsantsa phakathi kwentonga yokutsala esembindini kunye nepleyiti yokuxhasa ingalo yozipho. Phantsi kwentshukumo yamandla F3, ipleyiti yenkxaso yengalo yozipho isebenzisa umsantsa odadayo (ipleyiti yokulungelelanisa isithuba, intonga esembindini yokutsalwa kwechuck, kunye nepleyiti yenkxaso yengalo yomhlathi kunye yenze indlela edadayo yechuck), eya kuthi idibane. hambisa kwicala lamandla de imihlathi emithathu ibambe i-workpiece ngokupheleleyo.

Umzobo 1 Isakhiwo se-chuck esidadayo

1. Ingalo yozipho

2. Intwasahlobo exande

3. Isigqubuthelo esingaphezulu esingqukuva

4. Umdibaniso weSpherical

5. Ipleyiti yohlengahlengiso yokucoca

6. Isilinda intonga yokutsala

7. Chuck iziko tsala intonga

8. Ipleyiti yokuxhasa ingalo yozipho

9. Umzimba kaChuck 10. Isigqubuthelo sokugqibela sikaChuck

10. Ibhloko yenkxaso yokubeka

12. Umsebenzi oza kwenziwa

13. Chuck Jaws 16. Ibhola inkxaso

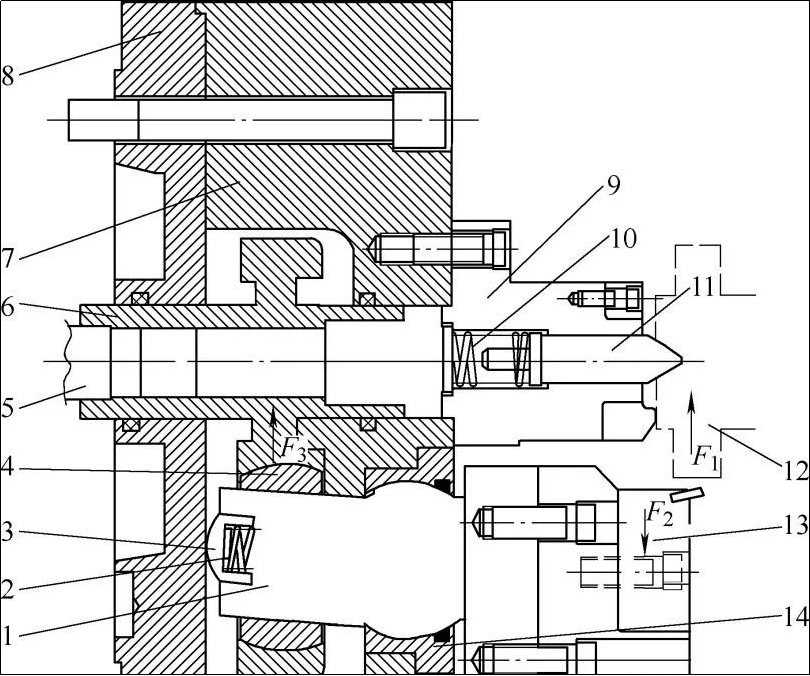

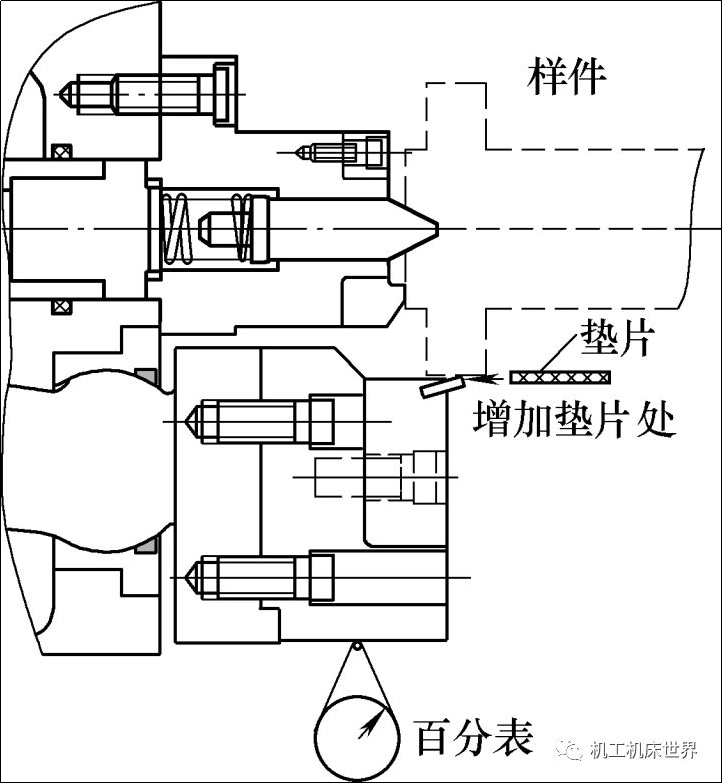

Umzobo 2 ubonisa inkqubo yesenzo se-chuck eqinile

Ngaphantsi kwentshukumo yebhloko yenkxaso yokumisa kunye nomphezulu, i-workpiece ibekwe kwaye ibotshwe nge-axially kunye ne-radially, kwaye emva koko i-cylinder yeoli ye-chuck iqhuba intonga yokutsala esembindini, i-spherical joint kunye nomhlathi we-chuck ngokusebenzisa intonga yokutsala. Ingalo iyashukuma, kwaye ekugqibeleni, imihlathi ye-chuck ibambe i-workpiece. Ekubeni iziko lokutsala intonga ye-chuck lidityaniswe ngokungqongqo kunye ne-spherical joint kunye nengalo yomhlathi, emva kokuba i-chuck imihlathi (imihlathi emithathu) ibambekile, iziko lokubamba liya kwenziwa. Iziko lokubamba elenziwe phezulu alidibanisi, kwaye i-workpiece iya kuba ne-deformation ecacileyo ye-clamping emva kokuba i-chuck ibambekile. Ngaphambi kokuba i-chuck isetyenziswe, kuyimfuneko ukulungisa ukugqithela phakathi kombindi we-chuck kunye nombindi weziko ukuqinisekisa ukuba i-chuck ayiyi kubonakala i-virtual after clamping. Imeko ebambelweyo.

Umzobo 2 Isakhiwo se-chuck esiqinileyo

1. Ingalo yozipho

2. 10. Intwasahlobo exande

3. Isigqubuthelo esingaphezulu esingqukuva

4. Umdibaniso weSpherical

5. Intonga ye-cylinder tie

6. Chuck iziko tie intonga

7. Umzimba kaChuck

8. Ikhava yangasemva ye-Chuck

9. Ibhloko yenkxaso yokubeka

10. Phezulu

11. Umsebenzi oza kwenziwa

12. Imihlathi kaChuck

13. Inkxaso engqukuva

Ukususela kuhlalutyo lwendlela ye-chuck kwi-Figure 1 kunye ne-Figure 2, i-chuck edadayo kunye ne-chuck eqinile inomahluko olandelayo.

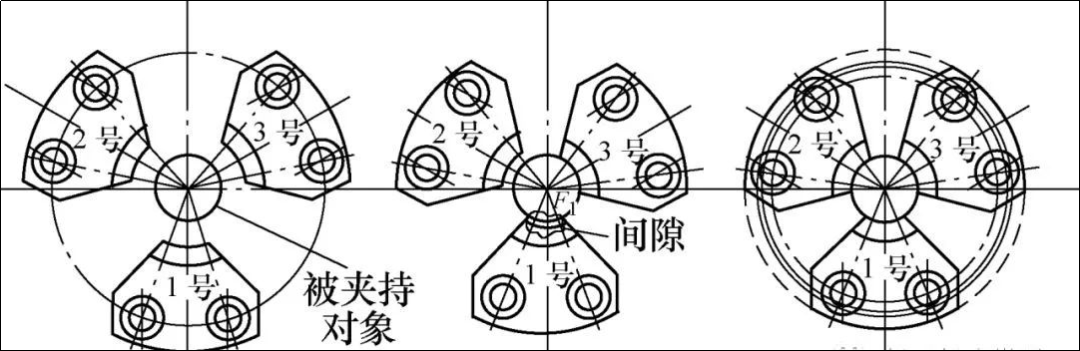

I-chuck edadayo: Njengoko kubonisiwe kuMzobo 3, kwinkqubo yokucinezela i-workpiece, ngenxa yokuphakama okwahlukeneyo kwendawo engenanto okanye ukunyamezela okukhulu okujikelezayo kwendawo engenanto, i-3 yomhlathi iya kudibana nomphezulu womsebenzi kwaye iNombolo yoku-1 neyesi-2 iya kuvela imihlathi. Ukuba i-workpiece ayizange ichukunyiswe okwangoku, ngeli xesha, indlela edadayo ye-chuck edadayo isebenza, isebenzisa umphezulu we-workpiece njengenkxaso yokudada umhlathi we-3. Ngethuba nje isixa esidadayo sanele, i-No. I-workpiece inefuthe elincinci kumbindi we-workpiece.

Umfanekiso wesi-3 Inkqubo yokubamba imihlathi yechuck edadayo

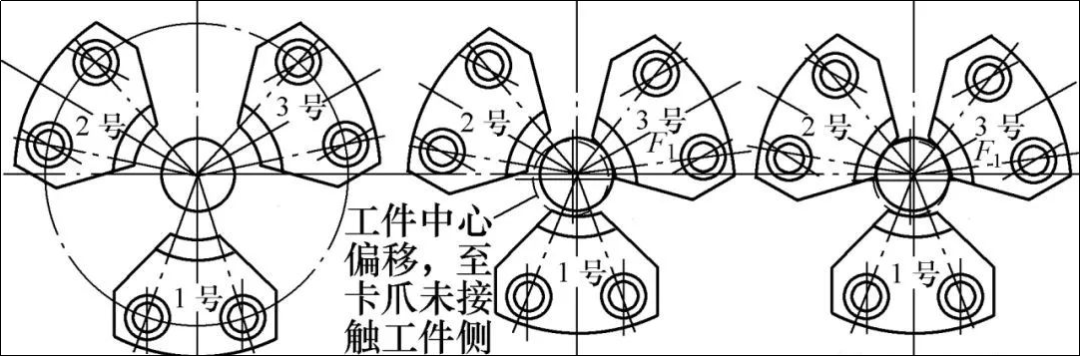

I-chuck engqongqo: Njengoko kubonisiwe kuMfanekiso 4, ngexesha lenkqubo yokudibanisa, ukuba i-concentricity phakathi kwe-chuck kunye ne-workpiece ayilungiswanga ngokufanelekileyo, i-No. qhagamshelana nomsebenzisi. , emva koko i-chuck clamping force F1 iya kusebenza kwindawo yokusebenza. Ukuba i-force inkulu ngokwaneleyo, i-workpiece iya kulungiswa ukusuka kwiziko elinqunywe kwangaphambili, ukunyanzelisa i-workpiece ukuya kumbindi we-chuck; xa i-clamping force ye-chuck incinci, ezinye iimeko ziya kwenzeka. Xa imihlathi ayikwazi ukudibanisa ngokupheleleyo i-workpiece, i-vibration iyenzeka ngexesha lomatshini.cnc isidibanisi sokugaya

Umfanekiso wesi-4 Inkqubo yokubambelela kwemihlathi eqinile

Iimfuno zohlengahlengiso ngaphambi kokuba i-chuck isetyenziswe: I-chuck eqinile iya kwenza i-clamping center ye-chuck ngokwayo emva kokudibanisa. Xa usebenzisa i-chuck eqinile, kuyimfuneko ukulungelelanisa i-clamping center ye-chuck ukuze ihambelane ne-clamping kunye ne-positioning center ye-workpiece, njengoko kuboniswe kumfanekiso wesi-5.cnc machining aluminiyam inxalenye

Umzobo 5 Uhlengahlengiso lweziko le-chuck eliqinileyo

Ngokutsho kolu hlalutyo lwesakhiwo esingentla, kucetyiswa ukuba ulandele le migaqo ilandelayo ekuhlengahlengisweni nasekugcinweni kwe-chuck: I-lubrication kunye negrisi yeendawo ezihambayo ngaphakathi kwe-chuck zihlala zitshintshwa. Ukuhamba phakathi kweendawo ezihambayo ngaphakathi kwe-chuck ngokusisiseko kukuslayida. Kuyimfuneko ukongeza kunye nokutshintsha rhoqo ibakala elichaziweyo lokuthambisa ioli / igrisi ngokweemfuno zokugcinwa kwe-chuck. Xa ufaka igrisi, kuyimfuneko ukukhama yonke igrisi esetyenzisiweyo kwixesha elidlulileyo, kwaye emva koko uvale i-oyile yokukhupha izibuko emva kokubamba i-chuck ukukhusela umgodi wangaphakathi we-chuck ukuba ungabanjwa.

Ukuhlolwa rhoqo kunye nohlengahlengiso lweziko lokubambelela kwi-chuck eqinile kunye nombindi we-workpiece: I-chuck eqinile idinga ukulinganisa ngamaxesha ukuba umbindi we-chuck kunye nombindi we-spindle yomsebenzi uyahambelana. Ukulinganisa ukuphuma kwediski. Ukuba idlula uluhlu olufunekayo, yongeza i-spacers ngokufanelekileyo kwimihlathi enye okanye emibini ehambelana nomgangatho ophezulu, kwaye uphinde uphinde ulandele amanyathelo angasentla de iimfuno zifezekiswe.

Ukuhlolwa kwamaxesha ngamaxesha omthamo odadayo wechuck edadayo (jonga uMfanekiso 6). Kulondolozo lwemihla ngemihla lwe-chuck, kuyimfuneko ukulinganisa rhoqo isixa esidadayo kunye nokuchaneka okudadayo kwe-chuck edadayo, kunye nokubonelela ngesikhokelo sokugcinwa kwangaphakathi kwe-chuck kwinqanaba lamva. Indlela yokulinganisa yokuchaneka okudadayo: emva kokuba i-chuck ibambe isampuli, beka i-chuck ukuze ilinganiswe. Jikelezisa uzipho kwindawo efanelekileyo yokulinganisa, linganisa isalathisi sokucofa (imfuno yokuncamathelisa isiseko semitha yemagnethi kwishafti eshukumayo), kwaye umaka indawo yomlinganiselo njengendawo yenqaku elinguziro. Emva koko lawula i-axis ye-servo ukuhambisa isalathisi sokudayela, vula i-chuck, ubeke i-gasket enobunzima be-Amm phakathi kwemihlathi ukuze ilinganiswe kunye nesampuli, cinezela isampuli kwi-chuck, uhambise isalathisi sokudayela kwindawo ye-zero point, kwaye uqinisekise ukuba idatha ecinezelwe sisalathisi sokudayela malunga no-Amm. Ukuba kunjalo, oko kuthetha ukuba ukuchaneka okudadayo kulungile. Ukuba idatha yahluka kakhulu, oko kuthetha ukuba kukho ingxaki kwindlela edadayo ye-chuck. Umlinganiselo weminye imihlathi uyafana nongasentla.

Umfanekiso wesi-6 Ukuhlolwa komthamo odadayo wechuck edadayo

Ukutshintshwa rhoqo kweendawo ezinje ngetywina, iigaskets, kunye nemithombo ngaphakathi kwe-chuck: imithombo exande, umzimba we-chuck, isigqubuthelo sangasemva se-chuck, imithombo exande, kunye netywina kunye nemithombo ekwizixhaso ezingqukuva kufuneka zenziwe ngokuhambelana nokuphindaphindwa kokusetyenziswa kunye noku kungasentla. iziphumo zovavanyo. Faka endaweni yakho rhoqo. Ngaphandle koko, ukudinwa kuya kuyonakalisa, kubangele isixa esidadayo kunye nokuphuma kwe-chuck eqinile.

Ngolu hlalutyo lungentla lwamanqaku e-criticaly yohlengahlengiso lwesakhiwo se-chuck kunye nokugcinwa, nikela ingqalelo kule migaqo ilandelayo ekukhethweni kwee-chucks: ukuba i-chuck clamping inxalenye yecandelo elicwangcisiweyo yindawo engenanto, i-chuck edadayo iyakhethwa, kunye ne-chuck eqinile. isetyenziswa kwisixhobo sokusebenza. I-chuck clamping surface yecandelo lomatshini ngumphezulu emva kokurhabaxa, ukugqiba / ukugqiba. Emva kokulandela le migaqo ingentla apha, ukukhetha okuchanekileyo ngokweemeko ezahlukeneyo zokusebenza kuyimfuneko.

Ukukhetha i-chuck eqinile:

① Iimeko zomatshini zifuna inani elikhulu lokusika kunye namandla amakhulu okusika. Emva kokunyanzeliswa yi-workpiece ukuba iqhutywe kwaye ixhaswe yifreyimu yeziko, i-muscular workpiece rigidity, kunye ne-workpiece enkulu yokujikeleza amandla okuqhuba kufuneka.

②Xa kungekho sixhobo sexesha elinye, njengendawo ephezulu, uyilo lwe-chuck centering luyafuneka.

Ukhetho lwechuck edadayo:

①Iimfuno eziphezulu zokubeka embindini wesixhobo sokusonta. Emva kokuba i-chuck ibotshiwe, ukudada kwayo akuyi kuphazamisa indawo ephambili ye-spindle yomsebenzi.

②Ixabiso lokusika alikho likhulu, kwaye kuyimfuneko kuphela ukuqhuba i-spindle yomsebenzi ukujikeleza kunye nokwandisa ukuqina komsebenzi.

Oku kungasentla kuchaza umahluko wesakhiwo kunye nokugcinwa kunye neemfuno zokhetho lwee-chucks ezidadayo kunye neziqinileyo, eziluncedo ekusetyenzisweni nasekugcinweni. Ufuna ukuqonda okunzulu kunye nokusetyenziswa okuguquguqukayo; kufuneka uhlale ushwankathela amava kusetyenziso kunye nokugcinwa kwendawo.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Mar-31-2022