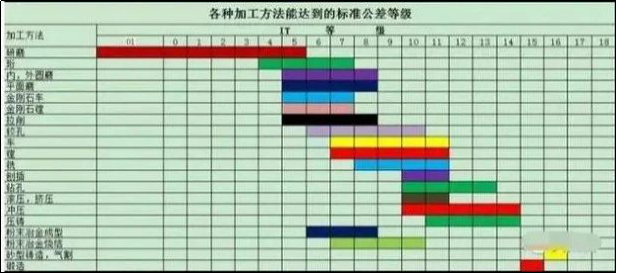

Ukuguqula, ukugaya, ukucwangcisa, ukugaya, ukubhola, ukudinwa, ukuchaneka okuphezulu kwezi zixhobo zoomatshini kunye namanqanaba okunyamezela ukuba iindlela ezahlukeneyo zokucwangcisa zinokufikelela zonke zilapha.

Ukujika

Inkqubo yokusika apho i-workpiece ijikeleza kwaye isixhobo sokuguqula sihamba ngendlela echanekileyo okanye i-curve kwindiza. Ukujika ngokuqhelekileyo kuqhutyelwa kwi-lathe, esetyenziselwa ukucubungula iindawo zangaphakathi kunye nezangaphandle ze-cylindrical, ubuso bokugqibela, i-conical surfaces, ukwenza iindawo kunye nemicu yezinto zokusebenza.

Ukuchaneka kokujika ngokuqhelekileyo yi-IT8-IT7, kwaye uburhabaxa bomphezulu yi-1.6~0.8 μ m.

I-1) Ukuguquka ngokukrakra kuya kwamkela ubunzulu obukhulu bokusika kunye nesantya esikhulu sokutya ukuze kuphuculwe ukusebenza kakuhle ngaphandle kokunciphisa isantya sokusika, kodwa ukuchaneka komatshini kunokufikelela kuphela kwi-IT11 kunye nobukhulu bomhlaba ngu-R α 20 ~ 10 μ m.

2) Isantya esiphezulu kunye nesantya somxhesho omncinci kunye nobunzulu bokusika kuya kwamkelwa kangangoko kunokwenzeka ukugqiba ukujika kunye nokugqiba ukujika. Ukuchaneka komatshini kunokufikelela kwi-IT10~IT7, kwaye uburhabaxa bomphezulu yi-R α 10~0.16 μ m.

3) Isantya esiphezuluukujika okuchanekileyo kwamalungu esinyithi angenamvubelongesixhobo sedayimani esijikayo sigudiswe ngokucokisekileyo kwi-lathe ephezulu echanekileyo inokwenza ukuchaneka komatshini ukufikelela kwi-IT7~IT5, kunye noburhabaxa bomphezulu yi-R α 0.04 ~ 0.01 μ m. Olu hlobo lokujika lubizwa ngokuba "yimirror turning".

Ukugaya

I-Milling ibhekisa kusetyenziso lwezixhobo ezijikelezayo zomphetho omninzi ukusika ii-workpieces, eyindlela esebenza kakhulu yokusebenza. Ifanelekile kwi-plane yomatshini, i-groove, iindawo ezahlukeneyo zokubumba (ezifana ne-spline, i-gear kunye nentambo) kunye nomgangatho okhethekileyo wokufa. Ngokwendlela enye okanye echaseneyo yesantya esiphambili sentshukumo kunye nesalathiso sokutya kwesixhobo sokusebenza ngexesha lokusila, inokwahlulwa ibe yi-milling eya phambili kunye ne-reverse milling.

Ukuchaneka komatshini wokungqusha kunokufikelela ngokubanzi kwi-IT8~IT7, kwaye uburhabaxa bomphezulu yi-6.3 ~ 1.6 μ m.

1) Ukuchaneka komatshini ngexesha lokugaya i-IT11 ~ IT13, kwaye uburhabaxa bomphezulu yi-5 ~ 20 μ m.

2) Ukuchaneka komatshini IT8~IT11 kunye noburhabaxa bomphezulu 2.5 ~ 10 kwi-semi precision milling μ m.

3) Ukuchaneka komatshini ngexesha lokusila ngokuchanekileyo yi-IT16 ~ IT8, kwaye uburhabaxa bomphezulu yi-0.63 ~ 5 μ m.

Ukucwangcisa

Ukucwangciswa yindlela yokusika esebenzisa isicwangcisi ukwenza intshukumo ethe tyaba yesalamane ehambelanayo kwisixhobo sokusebenza, esisetyenziswa kakhulu ekusetyenzweni kwecontour yamalungu.

Ukuchaneka komatshini wokucwangcisa ngokubanzi kunokufikelela kwi-IT9~IT7, kwaye uburhabaxa bomphezulu yiRa6.3 ~ 1.6 μ m.

1) Ukuchaneka komatshini wokuchaneka kunokufikelela kwi-IT12~IT11, kwaye uburhabaxa bomphezulu yi-25 ~ 12.5 μ m.

2) Ukuchaneka kwe-semi final machining kunokufikelela kwi-IT10 ~ IT9, kwaye uburhabaxa bomphezulu yi-6.2 ~ 3.2 μ m.

3) Ukuchaneka kokugqiba ukucwangciswa kunokufikelela kwi-IT8 ~ IT7, kwaye uburhabaxa bomphezulu yi-3.2 ~ 1.6 μ m.

Ukusila

Ukugaya kubhekisela kwindlela yokucubungula yokususa izinto ezingaphezulu kwi-workpiece kunye nezixhobo ezixubileyo kunye ne-abrasive. Yeyokugqibezela kwaye isetyenziswa kakhulu kwishishini lokwenziwa koomatshini.

Ukusila ngokuqhelekileyo kusetyenziselwa ukugqiba isiqingatha kunye nokugqiba, ngokuchaneka kwe-IT8~IT5 okanye nangaphezulu, kunye noburhabaxa bomphezulu ngokuqhelekileyo yi-1.25 ~ 0.16 μ m.

1) Uburhabaxa bomphezulu bokusila ngokuchanekileyo yi-0.16~0.04 μ m.

2) Uburhabaxa bomhlaba wokusila obuchanekileyo yi-0.04-0.01 μ m.

3) Uburhabaxa bomphezulu bokugaya isibuko bunokufikelela kwi-0.01 μ M ngaphantsi.

Ukugrumba

Ukugrumba yindlela esisiseko yokucutshungulwa komngxuma. Ukugrumba kuhlala kuqhutywa koomatshini bokomba kunye neentambo, okanye koomatshini abadikayo okanye oomatshini bokusila.

Ukuchaneka komatshini wokugaya kuphantsi, ngokuqhelekileyo kufikelela kwi-IT10, kwaye uburhabaxa bomphezulu ngokuqhelekileyo yi-12.5 ~ 6.3 μ m. Emva kokugrumba, ukubuyisela kwakhona kunye nokuphinda kusetyenziswe rhoqo ukugqiba isiqingatha kunye nokugqiba.

Kuyadika

Ukudika luhlobo lwenkqubo yokusika i-diameter yangaphakathi esebenzisa isixhobo sokwandisa umngxuma okanye enye i-contour ejikelezayo. Uluhlu lwesicelo ngokuqhelekileyo lusuka kwi-semi rough machining ukuya ekugqibeleni. Isixhobo esisetyenziswayo siqhele ukuba sisixhobo esikruqulayo somphetho omnye (esibizwa ngokuba yibhar ekruqulayo).

1) Ukuchaneka okudidayo kwezinto zetsimbi kunokufikelela ngokubanzi kwi-IT9 ~ IT7, kwaye uburhabaxa bomhlaba yi-2.5 ~ 0.16 μ m.

2) Ukuchaneka komatshini wokuchaneka kokuchaneka kunokufikelela kwi-IT7 ~ IT6, kwaye uburhabaxa bomhlaba yi-0.63 ~ 0.08 μ m.

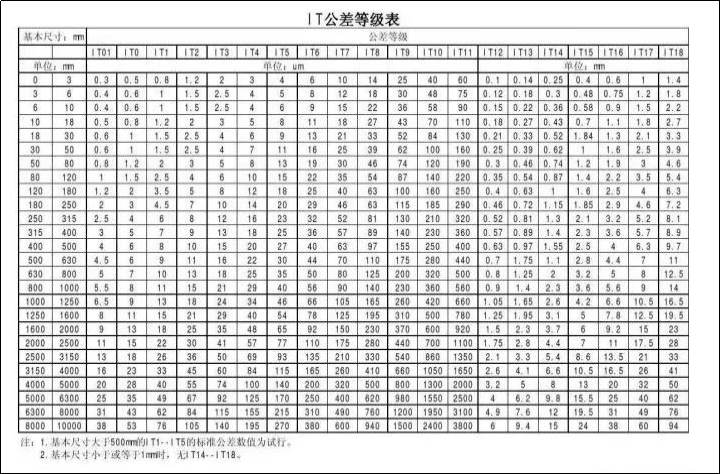

Phawula:Ukuchaneka okuphezulu koMatshiniisetyenziswa ikakhulu ukubonisa ukucoleka kweemveliso, kwaye ligama elisetyenziselwa ukuvavanya iiparamitha zejometri zomgangatho owenziwe ngoomatshini. Umgangatho wokulinganisa ukuchaneka komatshini libakala lokunyamezelana. Kukho imigangatho ye-20 esuka kwi-IT01, i-IT0, i-IT1, i-IT2, i-IT3 ukuya kwi-IT18, phakathi kwayo i-IT01 ibonisa ukuchaneka kwe-machining ephezulu yecandelo, i-IT18 imele ukuchaneka komatshini ophantsi kwenxalenye. Oomatshini ngokubanzi bemigodi ngabakwa-IT7, kwaye oomatshini bolimo ngokubanzi ngabakwa-IT8. Ngokwemisebenzi eyahlukeneyo yamacandelo emveliso, ukuchaneka komatshini okufunekayo ukuba kuphunyezwe kuyahluka, kwaye ifom yokucubungula kunye nenkqubo ekhethiweyo nayo yahlukile.

Ixesha lokuposa: Nov-07-2022