Ibakala lokusebenza kweebholiti ezisetyenziselwa ukudibanisa isakhiwo sensimbi yi-3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9 njalo njalo. Iibholiti zebanga le-8.8 nangaphezulu zenziwe ngentsimbi ephantsi ye-carbon alloy okanye i-medium carbon steel kunye ne-heat-treated (icinyiwe, inomsindo), ebizwa ngokuba yi-bolts yamandla aphezulu kwaye ezinye zibizwa ngokuba ziibholiti eziqhelekileyo.Umsonto wokuchaneka okuphezulu ngundoqo wokwenzaumgangatho ophezulu CNC amacandelo machining.

Ileyibhile yomgangatho wokusebenza webholithi yenziwe ngamacandelo amabini, ngokulandelelanayo amele ixabiso lamandla okuqina kunye nomyinge webuckling wemathiriyeli yebholithi. Njenge:

Kwiibholiti zeklasi ye-4.6, intsingiselo yile:

Amandla okuqina okuqhelekileyo okwenziwa kwebholithi ukuya kuthi ga kwi-400MPa;

Umlinganiselo wamandla we-bolt material ngu-0.6;

Amandla emveliso yegama lesixhobo sebholithi yi-400×0.6=240MPa.

Ibanga lokusebenza 10.9 bolt amandla aphezulu, izinto zayo emva unyango ubushushu, inokufikelela:

Amandla okuqina okuqhelekileyo ezinto zebholithi afikelela kwi-1000MPa;

Umlinganiselo wamandla we-bolt material ngu-0.9;

Amandla emveliso yesiqhelo yi-1000×0.9=900MPa.

Intsingiselo yomgangatho wokusebenza kwebholithi ngumgangatho wamazwe ngamazwe. Iibholiti zebakala elifanayo lentsebenzo, kungakhathaliseki ukuba umehluko phakathi kwezinto zabo kunye nemvelaphi, zisebenza ngokufanayo, kwaye kuphela ibakala lokusebenza elinokukhethwa kuyilo.

Amanqaku anamandla e-8.8 kunye ne-10.9 abhekisela kumabakala okumelana noxinzelelo lwe-shear yeebholithi 8.8GPa kunye ne-10.9GPa

8.8 Amandla okuqina okuqhelekileyo 800N/MM2 amandla emveliso yesiqhelo 640N/MM2

Ngokubanzi, “x. Y” isetyenziselwa ukubonisa amandla ebholithi, X*100= amandla okuqina ebholithi, X*100* (Y/10) = amandla esivuno sebholithi (kuba ngokweleyibhile: isivuno samandla/i-tensile amandla =Y/10)

Njenge 4.8, amandla okuqina ebholithi: 400MPa; Amandla esivuno yi 400*8/10=320MPa.

Ukongeza: iibholiti zensimbi ezingenasici zihlala zibhalwe njenge-A4-70, A2-70, intsingiselo yolunye utoliko.

Ukulinganisa i

Iyunithi yokulinganisa ubude kwihlabathi namhlanje kukho iindidi ezimbini eziphambili, enye yemetric system, iyunithi yokulinganisa iimitha (m), iisentimitha (cm), iimilimitha (mm), njl., eYurophu, eChina naseJapan nakwamanye asezantsi-mpuma. Ukusetyenziswa kwe-Asia kuninzi, enye isiNgesi, iyunithi yokulinganisa ubukhulu becala i-intshi (intshi), ilingana nesixeko esidala "kwilizwe lethu, isetyenziswa kakhulu eUnited States, eBritani nakwamanye aseYurophu. kunye namazwe aseMelika.

Umlinganiselo wemitha: (isiseko se-10) 1m =100 cm=1000 mm

Inkqubo yobukhosi: (isiseko 8) 1 intshi =8 imizuzu 1 intshi =25.4 mm 3/8 x 25.4 =9.52

Iimveliso ezingezantsi kwe-1/4 zisebenzisa inombolo yobizo ukumela ubungakanani bedilesi yazo, ezinje: 4#, 5#, 6#, 7#, 8#, 10#, 12#

Intambo yesijivu

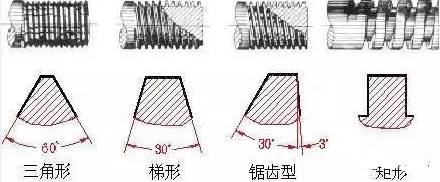

Umsonto yimilo enemigca efanayo engqukuva kwicandelo lomphandle ongaphandle okanye ongaphakathi wento eqinileyo. Ngokweempawu zayo zesakhiwo kunye nokusetyenziswa kwayo kunokwahlulwa ngokweendidi ezintathu:

Umsonto oqhelekileyo: imilo yezinyo elingunxantathu, esetyenziselwa ukudibanisa okanye ukuqinisa iindawo. Umsonto oqhelekileyo wohlulwe ube ziindidi ezimbini zemisonto erhabaxa kunye nentambo ecolekileyo ngokwepitshi, kwaye intambo ecolekileyo inamandla aphezulu onxibelelwano.

Intambo yokuhanjiswa: i-trapezoid yezinyo, uxande, isarha kunye nonxantathu, njl.

Intambo yokutywina: Isetyenziselwa ukudityaniswa kwetywina, ikakhulu intambo yombhobho, intambo yetaper kunye nentambo yombhobho wetaper.

Ukuhlelwa ngokwemilo:

Ibakala elilingana nomsonto

Imisonto echanekileyo iyinxalenye ebalulekileyo yokwenzaumgangatho ophezulu CNC Machining iinxalenye.

Ukulingana sisixa sokucotha okanye ukuxinana phakathi kwemisonto ye-screw, kwaye ibakala elifanelekileyo yindibaniselwano echaziweyo yokunxaxha kunye nokunyamezelana okusebenzayo kwimisonto yangaphakathi nangaphandle.

1. Kwimisonto ye-intshi efanayo, kukho amabakala amathathu kwintambo yangaphandle: 1A, 2A kunye ne-3A, kunye namabakala amathathu kwintambo yangaphakathi: 1B, 2B kunye ne-3B, zonke ziyi-gap fit. Okukhona liphezulu inani lerenki, kokukhona ilingana. Nge-inch THREADS, UKUtenxa kucaciswe kuphela kumabakala 1A no-2A, UKUtenxa kwibakala 3A ngu-ziro, yaye UKUtenxa kwibakala 1A no-2A kuyalingana. Okukhona liba likhulu inani lamabanga, kokukhona lincinci ukunyamezelana.

Iklasi ye-1A kunye ne-1B, amabakala okunyamezela kakhulu, afanelekileyo ukunyamezela ukunyamezela imicu yangaphakathi nangaphandle.

Iiklasi 2A kunye ne-2B zezona klasi zixhaphakileyo zokunyamezela intambo ezimiselweyo kuthotho lwaseBritani lwezibophelelo zoomatshini.

I-Class 3A kunye ne-3B, i-screw ukwenza eyona nto ifanelekileyo, ifanelekile kwiifasteners ezinokunyamezela okuqinileyo, kuyilo olubalulekileyo lokhuseleko.

Kwimisonto yangaphandle, i-CLASS 1A kunye ne-2A inokunyamezelana, i-CLASS 3A ayinayo. Ukunyamezela kwe-Class 1A yi-50% enkulu kunokunyamezela kweklasi ye-2A, i-75% inkulu kuneklasi ye-3A yokunyamezela, kwiintambo zangaphakathi, ukunyamezela kweklasi ye-2B yi-30% enkulu kunokunyamezela kwe-2A. Iklasi 1B yi-50% enkulu kuneklasi 2B kunye ne-75% enkulu kuneklasi 3B.

2. Intambo ye-Metric, intambo yangaphandle inamabakala amathathu entambo: 4h, 6h kunye ne-6g, intambo yangaphakathi inamabakala amathathu entambo: 5H, 6H, 7H. (Amabanga achanekileyo emisonto yemihla ngemihla i-I, II, III, kwaye ngokuqhelekileyo i-II.) Kwimisonto ye-metric, ukutenxa okusisiseko kwe-H kunye no-h ngu-zero. Ukutenxa okusisiseko ku-G kulungile, kwaye ukutenxa okusisiseko kuka-E, F kunye no-G kubi.

H yindawo eqhelekileyo yokunyamezela indawo yentambo yangaphakathi, engasetyenziswanga njengendawo yokugquma umphezulu, okanye umaleko obhityileyo wephosphating. Isikhundla sika-G sokutenxa okusisiseko kwizihlandlo ezikhethekileyo, ezifana nokwaleka okutyebileyo, okuxhaphake ngokunqabileyo ukusetyenziswa.

g iqhele ukusetyenziselwa ukugquma i-6-9um yokwaleka obhityileyo, ukuba iimfuno zomzobo wemveliso zizibholiti ze-6h, umsonto ojijwayo phambi kokwaleka wamkele ibhendi yokunyamezelana ye-6g.

Inhlanganisela engcono kakhulu yokudibanisa intambo i-H / g, i-H / h okanye i-G / h, i-bolts, i-nuts kunye nezinye iintambo ze-fastener ecocekileyo, umgangatho onconywayo we-6H / 6g.

3. Ukumakishwa kwemisonto

Iiparameters eziphambili zejometri zokuzibamba kunye ne-self-drilling threads

1. Idayimitha enkulu/idayamitha yangaphandle (d1) : Idayamitha yesilinda esicingelwayo esinemiqhele edityanisiweyo enemisonto. Idayamitha yomsonto imele ubukhulu becala ubukhulu bomsonto.

2. Indlela yeenyawo/idayamitha esezantsi (d2) : Idayamitha yesilinda esicingelwayo apho umzantsi womsonto uwelana khona.

3. Isithuba samazinyo (p) : sibhekisa kumgama we-axial phakathi kweendawo ezimbini ezihambelanayo zamazinyo akufutshane kumgca ophakathi. Kwinkqubo yobukhosi, umgama phakathi kwamazinyo uboniswa ngenani lamazinyo nge-intshi nganye (25.4mm).

Oku kulandelayo kudwelisa iinkcukacha eziqhelekileyo zomgama wamazinyo (metric) Inani lamazinyo (i-intshi)

1) Ukuzicofa ngokweMetric:

Iinkcukacha: ST 1.5, S T1.9, S T2.2, S T2.6, S T2.9, S T3.3, S T3.5, S T3.9, S T4.2, S T4.8, S T5.5, S T6.3, S T8.0, S T9.5

Umgama wamazinyo: 0.5, 0.6, 0.8, 0.9, 1.1, 1.3, 1.3, 1.3, 1.4, 1.6, 1.8, 1.8, 2.1, 2.1

2) Amazinyo aseBritane azibethayo:

Iinkcukacha: 4#, 5#, 6#, 7#, 8#, 10#, 12#, 14#

Inani lamazinyo: AB amazinyo 24, 20, 20, 19, 18, 16, 14, 14

Izinyo A 24, 20, 18, 16, 15, 12, 11, 10

Ixesha lokuposa: Oct-08-2022