1. Ukusetyenziswa kwee-calipers

I-caliper inokulinganisa i-diameter yangaphakathi, i-diameter yangaphandle, ubude, ububanzi, ubukhulu, umehluko wesinyathelo, ubude kunye nobunzulu bento; i-caliper yeyona nto isetyenziswa ngokuqhelekileyo kwaye iluncedo kakhulu kwaye isetyenziswa rhoqo isixhobo sokulinganisa kwindawo yokucubungula.

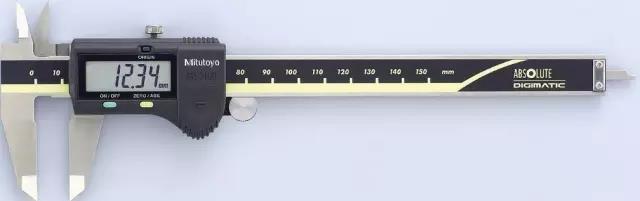

I-Digital Caliper: Isigqibo se-0.01mm, esetyenziselwa ukulinganisa ubungakanani kunye nokunyamezela okuncinci (ukuchaneka okuphezulu).

Ikhadi letafile: isisombululo se-0.02mm, sisetyenziselwa ukulinganisa ubungakanani obuqhelekileyo.

I-Vernier caliper: isisombululo se-0.02mm, esetyenziselwa ukulinganisa ukulinganisa.

Ngaphambi kokusebenzisa i-caliper, susa uthuli kunye nokungcola ngephepha elimhlophe elicocekileyo (sebenzisa indawo yangaphandle ye-caliper ukubamba iphepha elimhlophe kwaye ulikhuphe ngokwemvelo; phinda amaxesha angama-2-3)

Xa ulinganisa nge-caliper, umgangatho wokulinganisa we-caliper kufuneka ube njenge-parallel okanye i-perpendicular kumgangatho wokulinganisa into elinganisiweyo ngokusemandleni;

Xa usebenzisa umlinganiselo wobunzulu, ukuba into elinganisiweyo ine-angle engu-R, kuyimfuneko ukuphepha i-angle ye-R kodwa isondele kwi-angle ye-R, kwaye umgaqo onzulu kufuneka ube ngokuthe nkqo kangangoko kunokwenzeka kubude obulinganisiweyo;

Xa i-caliper ilinganisa i-cylinder, kufuneka ijikelezwe, kwaye ixabiso eliphezulu lilinganiswe kumacandelo:CNC machining inxalenye.

Ngenxa yokuphindaphinda okuphezulu kokusetyenziswa kwee-calipers, umsebenzi wokulondoloza kufuneka ube ngowona ungcono. Emva kosuku ngalunye lokusetyenziswa, kufuneka kusulwe kwaye kufakwe kwibhokisi. Ngaphambi kokusetyenziswa, ibhloko iyafuneka ukujonga ukuchaneka kwe-caliper.

2. Ukusetyenziswa kwe-micrometer

Ngaphambi kokusebenzisa i-micrometer, susa uthuli kunye nokungcola ngephepha elimhlophe elicocekileyo (sebenzisa i-micrometer ukulinganisa indawo yoqhagamshelwano kunye ne-screw surface kunye nephepha elimhlophe linamathele kwaye likhuphe ngokwemvelo, phinda amaxesha angama-2-3), uze ujije. iqhoshana lokulinganisa umfowunelwa Xa umphezulu udibana ngokukhawuleza kunye ne-screw surface, ukulungiswa okulungileyo kusetyenziswa, kwaye xa iindawo ezimbini zidibene ngokupheleleyo, ukulungiswa kwe-zero kunokwenziwa ukulinganisa.inxalenye yomatshini

Xa ulinganisa i-hardware nge-micrometer, hambisa i-knob, kwaye xa idibana nomsebenzi, sebenzisa iqhosha lokulungisa kakuhle ukuze ujike. Yima kwaye ufunde idatha evela kumboniso okanye isikali xa usiva ukucofa kathathu.

Xa ulinganisa iimveliso zeplastiki, umphezulu woqhagamshelwano womlinganiselo kunye nesikrufu sichukumisa kancinci imveliso.

Xa ulinganisa ububanzi beeshafu nge-micrometer, linganisa ubuncinci beendlela ezimbini kwaye ulinganise i-micrometer kwimilinganiselo ephezulu kumacandelo. Imiphezulu emibini yokudibanisa kufuneka ihlale icocekile ukunciphisa iimpazamo zomlinganiselo.

3. Ukusetyenziswa kwerula yobude

Igeyiji yobude isetyenziswa ikakhulu ukulinganisa ubude, ubunzulu, umcaba, ukuthe nkqo, ukujula, ukuhlangana, ukungcangcazela komphezulu, ukungcangcazela kwamazinyo, ubunzulu kunye nobude. Xa ulinganisa, qala ujonge i-probe kunye neendawo zokudibanisa ukukhululeka.

4. Isixhobo sokulinganisa ngokuchanekileyo: into yesibini

Isixhobo sesibini sisixhobo sokulinganisa esingadibananga kunye nokusebenza okuphezulu kunye nokuchaneka. Into yokuva isixhobo sokulinganisa ayihambelani ngokuthe ngqo nomphezulu wecandelo elilinganisiweyo, ngoko akukho mandla okulinganisa oomatshini; into yesibini idlulisela umfanekiso othathiweyo ngomgca wedatha kwikhadi lokufumana idatha yekhompyuter ngendlela yokubonisa. Ifotwe kwikhompyuter yisoftware: izinto ezahlukeneyo zejometri (amanqaku, imigca, izangqa, ii-arcs, ii-ellipses, uxande), imigama, ii-engile, ukuhlangana, ukunyamezelana kwejometri (ukujikeleza, ukuthe tye, ukufana, nkqo) Isidanga, ukuthambekela, indawo, ukugxila. , i-symmetry), kunye nemveliso ye-CAD yokuzoba umzobo we-2D. Icontour yeworkpiece inokujongwa, kwaye ukumila komphezulu we-opaque workpiece kunokulinganiswa.CNC

5. Izixhobo zokulinganisa ngokuchanekileyo: ezintathu-dimensional

Iimpawu zezinto ezintathu-ntathu zichanekile eziphezulu (ukuya kwinqanaba le-μm), indawo yonke (inokuthi ithathe indawo yezixhobo ezahlukeneyo zokulinganisa ubude), ingasetyenziselwa ukulinganisa imiba yejometri (ukongeza kwizinto ezinokulinganiswa yinto yesibini; inokulinganisa iisilinda kunye neecones), ukumila kunye nokunyamezela indawo (ukongeza kwimilo kunye nokunyamezela indawo enokuthi ilinganiswe yinto yesibini, kuquka i-cylindricity, flatness, iprofayili yomgca, umphezulu iprofayili, i-coaxial, i-complex surface, ixesha elide i-probe ye-three-dimensional apho inokuchukunyiswa khona, ubukhulu bayo bejometri, indawo ehlangeneyo, iphrofayili yomphezulu inokulinganiswa kunye nokugqitywa kwedatha kusetyenziswa ikhompyutha ngokuchaneka kwayo okuphezulu; ukuguquguquka, kunye nezakhono ezibalaseleyo zedijithali, iye yaba yinxalenye ebalulekileyo yokulungiswa komngundo kunye nokuveliswa kunye nokuqinisekiswa komgangatho, izixhobo ezisebenzayo.

We are a reliable supplier and professional in CNC service. If you need our assistance, please get in touch with me at info@anebon.com.

I-Anebon Metal Products Limited inokubonelela ngomatshini we-CNC, ukuphosa ukufa, iinkonzo zomatshini wesinyithi, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Ixesha lokuposa: Epreli-13-2020