Umsonto yi-helix esikwe kwi-workpiece nokuba ivela ngaphandle okanye ngaphakathi kwaye isebenza imisebenzi emininzi ebalulekileyo. Okokuqala, iintambo zenza uxhulumaniso lomatshini ngokudibanisa imveliso edibeneyo yangaphakathi kunye nemveliso yangaphandle. Olu nxibelelwano luqinisekisa ukuba iindawo ezahlukeneyo ze-workpiece zinokudibaniswa ngokuqinileyo omnye komnye.

Ngaphezu koko, imisonto idlala indima ebalulekileyo ekuhambiseni intshukumo. Bangakwazi ukuguqula isindululo esijikelezayo sibe sisindululo somgca kwaye ngokuphambeneyo. Esi sixhobo siluncedo kakhulu kwizicelo ezininzi, ezinje ngoomatshini abafuna isindululo somgca ukwenza imisebenzi ethile.

Ukongeza, iintambo zibonelela ngeenzuzo zoomatshini. Ngokusebenzisa iintambo, ukusebenza okuphezulu koomatshini kunokufezekiswa kuzo zonke iinkalo. Oku kuquka ukwanda komthamo wokuthwala umthwalo, ukuxhathisa okongeziweyo ekuhleni okanye ukungcangcazela, kunye nokuphuculwa kokuhanjiswa kwamandla.

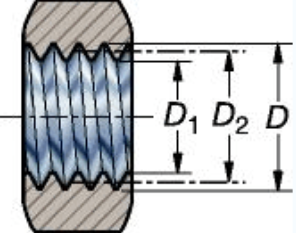

Kukho iifom ezahlukeneyo zentambo, nganye kuzo imisela ijometri yomsonto. Inkalo ebalulekileyo yeprofayili yentambo yidayamitha yomsebenzi. Oku kubandakanya idiameter enkulu (eyona dayamitha inkulu yomsonto) kunye nedayamitha yepitshi (idayamitha kwindawo yentelekelelo apho ububanzi bentambo bunguziro). Le milinganiselo ibalulekile ekuqinisekiseni ukuba imisonto ingena ngokufanelekileyo kwaye isebenza ngokufanelekileyo.

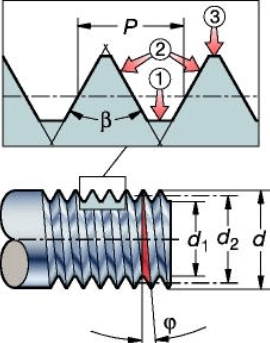

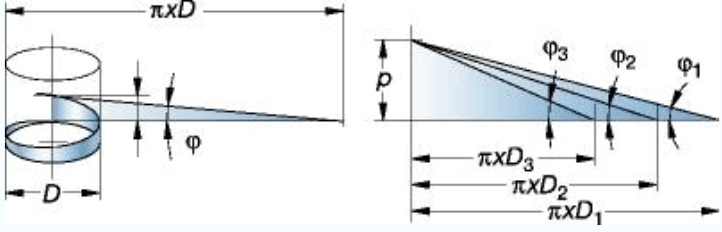

Ukuqonda isigama somsonto kubalulekile ekusebenziseni imisonto ngokufanelekileyo. Amanye amagama angundoqo aquka ilothe (umgama ohamba nge-axial umsonto ohamba kwi-revolution enye epheleleyo) kunye ne-pitch (umgama phakathi kwamanqaku ahambelanayo kwimisonto ekufutshane). Umlinganiselo ochanekileyo welothe kunye nepitch kubalulekile ukuqinisekisa uyilo oluchanekileyo lwentambo kunye nokuhambelana.

Isishwankathelo, iintambo zisebenza imisebenzi emininzi ebalulekileyo kumashishini ahlukeneyo. Baququzelela ukudityaniswa koomatshini, ukuhambisa intshukumo kunye nokubonelela ngeenzuzo zoomatshini. Ukuqonda iiprofayili zemisonto kunye nesigama esihambelanayo kubalulekile ekusebenziseni imisonto ngempumelelo kunye nokuqinisekisa ukusebenza kakuhle.

Ukusombulula iMystery of Pitch: Ukuphonononga intsingiselo yayo kunye nendlela yokubala

I-thread pitch yinto ephambili kwintsimi yokuvelisa kunye nomatshini. Ukuqonda ukuba kuthetha ukuthini kunye nokubala ngokuchanekileyo kubalulekile ekwenzeni iindawo ezinomatshini ezikumgangatho ophezulu. Kweli nqaku, siza kuntywila kwiintsonkotha zepitch yentambo, ijometri yayo, kunye nendlela yokuyifumanisa ngokuchanekileyo. Ukongeza, siza kwazisa i-Anebon, inkampani ekhethekileyo kwiinkonzo zomatshini ze-CNC kunye nesiko lokugaya i-CNC, inikezela ngeekowuti ezikhawulezayo nezithembekileyo ze-intanethi kumatshini we-CNC.

Ijometri yomsonto isekelwe kwidayamitha yepitch yentambo (d, D) kunye nepitch (P): umgama we-axial ecaleni komsonto kwi-workpiece ukusuka kwindawo enye kwiprofayili ukuya kwinqanaba elilandelayo elihambelanayo. Yicinge njengonxantathu ojikeleza i-workpiece. Esi sakhiwo esingunxantathu simisela ukusebenza kunye nokusebenza kwamacandelo anemisonto. Ubalo oluchanekileyo lwepitch yentambo ibalulekile ukuze kuqinisekiswe ukufaneleka okuchanekileyo, ukuhanjiswa komthwalo ofanelekileyo kunye nokusebenza ngokufanelekileyo kwamalungu omatshini.

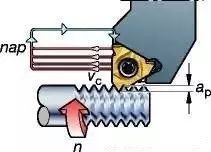

Ukuze uqonde ngokuchanekileyo i-pitch, umenzi usebenzisa itekhnoloji yomatshini ephucukileyo ye-CNC. I-CNC machining, okanye ikhompyuter yolawulo lwamanani machining, yinkqubo yokuvelisa esebenzisa izixhobo zoomatshini ezilawulwa ngekhompuyutha ukususa ngokuchanekileyo izinto ezivela kwizinto eziluhlaza ukwenza iindawo ezinomatshini. I-CNC Machining Online Quoting yinkonzo enikezelwa ziinkampani ezininzi zobuchwephesha ezivumela abathengi ukuba bakhawuleze kwaye bafumane uqikelelo lwamaxabiso ngokwesiko labo.CNC Machining iindawo.

I-Anebon yinkampani ekhokelayo kwishishini le-hardware, ibonelela ngeenkonzo ze-prototype ze-CNC ze-machining kunye ne-custom CNC milling ukususela ekuqaleni kwayo kwi-2010. Ngeqela leengcali kunye nezixhobo zanamhlanje, i-Anebon inikeza iimveliso ezisebenzayo, ezikumgangatho ophezulu. . Oomatshini abasemgangathweni abasuka eJapan. Izixhobo zabo zokusila ze-CNC kunye neeleyile kwakunye nezisila ezingaphezulu zibenza bakwazi ukunikezela ngokuchaneka kwemveliso kunye nomgangatho obalaseleyo. Ukongezelela, i-Anebon yi-ISO 9001: i-2015 eqinisekisiweyo, ebonisa ukuzibophezela kwabo ekugcineni imigangatho ephezulu yokuvelisa kunye nokwaneliseka kwabathengi.

Xa kubalwa inowuthi, idla ngokubonakaliswa ngemisonto nge-intshi nganye (TPI) okanye iimilimitha. Kwimisonto yemetriki, i-pitch ichazwa njengomgama weemilimitha phakathi kwemigca emibini emeleneyo yomsonto. Ngokuchaseneyo, kwiinkqubo zemisonto ezisekelwe kwi-intshi, i-TPI imele iintambo nge-intshi nganye. Ukulinganisa ngokuchanekileyo i-pitch yentambo ibalulekile ekuqinisekiseni ukuhambelana phakathi kweendawo ezinemisonto kunye nokuphepha iingxaki ezinokubakho njengokukhululeka, ukonakala okanye ukungonelanga kokusasazwa komthwalo.

CNC machiningidlala indima ebalulekileyo ekuphumezeni umlinganiselo ochanekileyo welizwi. Ngokusebenzisa itekhnoloji yokusika kunye nezixhobo ezichanekileyo, iinxalenye zoomatshini beCNC zinokuhlangabezana nezona mfuno zingqongqo kunye neenkcukacha. Iiprogram zesoftware eziphucukileyo zenza ukuba oomatshini be-CNC benze izibalo zemisonto entsonkothileyo, beqinisekisa ukuba i-pitch yentambo echanekileyo iphunyeziwe kwisicelo ngasinye esisodwa.

Ngamafutshane, ukuqonda ubucukubhede bepitch kunye nokubala ngokuchanekileyo kubalulekile ekwenzeni iindawo ezinomatshini ezikumgangatho ophezulu. Ngokusebenzisa iprototype yeenkonzo zomatshini zeCNC kunye nokusebenzisa isikoCNC milling, abavelisi banokufikelela ukuchaneka okungaqhelekanga kunye nomgangatho kwiimveliso zabo. Uzibophelele ekugqweseni kunye nezixhobo zanamhlanje, iinkampani ezifana ne-Anebon zikhokela indlela yokubonelela ngeenkonzo ezithembekileyo, ezisebenzayo zeCNC zokucaphula i-intanethi. Ngolwazi oluchanekileyo lwe-thread pitch, abavelisi banokwenza iinxalenye ezinemisonto ezihlangabezana nemigangatho ephezulu yokusebenza kunye nokusebenza.

1. Ukubalwa kunye nokunyamezelana kwe-pitch diameter ye-60 ° intambo yangaphandle emile okwezinyo (umgangatho wesizwe we-GB197/196)

a.Ukubalwa kwedayamitha yepitch ubukhulu obusisiseko

Ubungakanani obusisiseko bobubanzi be-pitch yentambo = ubukhulu obukhulu bentambo - i-pitch × ixabiso le-coefficient.

Ukumelwa kwefomula: d/DP×0.6495

Umzekelo: Ukubalwa komthamo wepitch yomsonto wangaphandle we-M8

8-1.25×0.6495=8-0.8119≈7.188

b. Ngokuqhelekileyo kusetyenziswa i-6h yangaphandle ye-pitch pitch diameter tolerance (esekelwe kwi-pitch pitch)

Ixabiso lomda ophezulu ngu "0"

Umda osezantsi ngu-P0.8-0.095P1.00-0.112P1.25-0.118

P1.5-0.132P1.75-0.150P2.0-0.16

P2.5-0.17

Ifomyula yobalo lomda ophezulu yisayizi esisiseko, kwaye umlinganiselo osezantsi wokubala ifomula d2-hes-Td2 yi pitch idayamitha esisiseko-ukutenxa-ukutenxa okuvumelekileyo.

Ixabiso lokunyamezela kwe-6h yebanga le-pitch ye-M8: ixabiso elilinganiselweyo eliphezulu 7.188 ixabiso eliphantsi lomda: 7.188-0.118 = 7.07.

C. Ngokuqhelekileyo kusetyenziswa i-6g yebanga langaphandle pitch pitch idayamitha yokutenxa okusisiseko: (ngokusekwe kwipitch yentambo)

P0.80-0.024P1.00-0.026P1.25-0.028P1.5-0.032

P1.75-0.034P2-0.038P2.5-0.042

Umda ophezulu wokubala ifomula i-d2-ges yisiseko sokutenxa kwisayizi

Umda osezantsi wokubala ifomula i-d2-ges-Td2 sisiseko sokunyamezela ukutenxa ubungakanani

Ngokomzekelo, i-6g ye-grade pitch diameter tolerance value ye-M8: ixabiso lomda ophezulu 7.188-0.028 = 7.16 ixabiso eliphantsi lomda: 7.188-0.028-0.118 = 7.042.

Phawula:

①Ukunyamezelwa kwentambo engentla kusekelwe kwimicu enqabileyo, kwaye ukunyamezelwa kweentambo zemisonto emihle kuyatshintshwa ngokufanelekileyo, kodwa ukunyamezela kwandiswa kuphela, ngoko ke ulawulo aluyi kudlula umda oqhelekileyo, ngoko ke aziphawulwanga etafileni. Umphezulu waphuma.

②Kwimveliso yokwenyani, ngokokuchaneka okufunekayo kuyilo kunye namandla okukhutshwa kwesixhobo sokulungisa umsonto, idiameter yentonga epholisiweyo yonyuswa ngo-0.04-0.08 xa kuthelekiswa nodayamitha oyiliweyo, obuyidayamitha yentambo epholisiweyo. intonga. Umzekelo, ububanzi benkampani yethu ye-M8 yangaphandle intambo ye-6g intonga epholisiweyo yi-7.08-7.13, engaphakathi kolu luhlu.

③Ukuthathela ingqalelo iimfuno zenkqubo yemveliso, umda wolawulo olusezantsi lwedayamitha yepitsi yomsonto wangaphandle ngaphandle konyango lobushushu kunye nonyango lomphezulu kwimveliso eyiyo kufuneka igcinwe kwinqanaba le-6h kangangoko kunokwenzeka.

2. Ukubalwa kunye nokunyamezela kwe-pitch diameter ye-60 ° intambo yangaphakathi (GB197/196)

inqanaba le-a.6H lemisonto yepitch yokunyamezelana kwedayamitha (ngokusekwe kwipitch yentambo)

umda ophezulu:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Ixabiso elisezantsi lomda ngu “0”,

Umlinganiselo ophezulu wokubala ifomula 2+TD2 ubungakanani obusisiseko + ukunyamezela.

Ngokomzekelo, i-pitch diameter ye-M8-6H intambo yangaphakathi: 7.188 + 0.160 = 7.348 umda ophezulu: 7.188 ngumda ophantsi.

b. Ifomula yokubala i-pitch diameter yentambo yangaphakathi iyafana naleyo yomsonto wangaphandle

Oko kukuthi, i-D2 = DP × 0.6495, oko kukuthi, i-pitch diameter yentambo yangaphakathi ilingana ne-pitch diameter× ixabiso le-coefficient.

c.6G iklasi ye-pitch pitch yeklasi ukutenxa isiseko se-E1 (esekelwe kwi-pitch pitch)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

Umzekelo: Umda ophezulu we-pitch diameter ye-M86G intambo yangaphakathi: 7.188+0.026+0.16=7.374

Umda osezantsi: 7.188 + 0.026 = 7.214

Ifomyula yomda ophezulu 2+GE1+TD2 yisayizi esisiseko yepitch idayamitha+enxantathu+ukunyamezela

Ifomula yexabiso lomda osezantsi 2+GE1 bubungakanani bepitch idayamitha+enxamnye

3. Ukubalwa kunye nokunyamezela kwedayimitha enkulu yomsonto wangaphandle (GB197/196)

a.Upper umda we-6h ubukhulu obukhulu bomsonto wangaphandle

Oko kukuthi, umzekelo wexabiso ledayamitha yentambo i-M8 yi-φ8.00, kwaye ukunyamezela umda ophezulu ngu "0".

b. Ukunyamezela komda ophantsi we-diameter enkulu yeklasi yangaphandle ye-6h intambo (esekelwe kwi-pitch pitch)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Ifomula yokubala yomda osezantsi wedayamitha enkulu: i-d-Td yeyona nto isisiseko sokunyamezela idimension ye-diameter enkulu yomsonto.

Umzekelo: Intambo ye-M8 yangaphandle 6h ubukhulu obukhulu bedayamitha: umda ophezulu ngu-φ8, umda osezantsi ngu-φ8-0.212=φ7.788

c.Ukubalwa kunye noNyamezelo lweDayamitha eNkulu 6g yoMsonto waNgaphandle

I-6g ireferensi yomsonto wangaphandle (ngokusekwe kwipitch yentambo)

P0.8-0.024P1.00-0.026P1.25-0.028P1.5-0.032P1.25-0.024P1.75–0.034

P2.0-0.038P2.5-0.042

Ifomyula yobalo lomda ophezulu i-d-ges ngumlinganiselo osisiseko womsonto omkhulu wedayamitha-yereferensi yokutenxa

Ifomula yobalo lomda osezantsi d-ges-Td ngumlinganiselo osisiseko womsonto omkhulu wedayamitha-isiseko sokutenxa-unyamezelo.

Umzekelo: i-M8 intambo yangaphandle 6g iklasi enkulu yedayamitha engaphezulu umda φ8-0.028=φ7.972.

Umda osezantsi φ8-0.028-0.212=φ7.76

Qaphela: ①Idayamitha enkulu yomsonto imiselwa ngokwedayamitha yentonga epolishiweyo kunye neqondo lokuguga kwepleyiti eqengqelekayo/iprofayile yezinyo eliqengqelekayo, kwaye ixabiso layo lithelekiseka ngokungafaniyo nedayamitha engaphezulu nephakathi yomsonto. Kwisiseko sesixhobo esifanayo esingenanto kunye nesithunga, esincinci i-diameter ephakathi, inkulu i-diameter enkulu, kwaye ngokuphambeneyo, inkulu i-diameter ephakathi, encinci i-diameter enkulu.

② Kwiindawo ezifuna unyango lobushushu kunye nonyango lwangaphezulu, ngokuqwalasela ubudlelwane phakathi kobugcisa bokucubungula kunye nemveliso yangempela, ububanzi obukhulu bomsonto kufuneka ilawulwe kumda ophantsi weklasi ye-6h kunye ne-0.04mm okanye ngaphezulu. Ngokomzekelo, kwintambo yangaphandle ye-M8, ububanzi obukhulu be-rubbing (rolling) intambo kufuneka iqinisekiswe ukuba ingaphezulu kwe-7.83 nangaphantsi kwe-7.95.

4. Ukubala kunye nokunyamezela kwe-diameter encinci yentambo yangaphakathi

a.Ukubalwa kobungakanani obusisiseko bobubanzi obuncinci bomsonto wangaphakathi (D1)

Ubungakanani obusisiseko bentambo encinci ye-diameter = ubungakanani obusisiseko bentambo yangaphakathi - i-pitch × i-coefficient

Umzekelo: Ubungakanani obusisiseko bobubanzi obuncinci bentambo yangaphakathi ye-M8 yi-8-1.25 × 1.0825 = 6.646875≈6.647

b. Ukubalwa kwentambo yangaphakathi 6H ukunyamezelana kwedayamitha encinci (esekelwe kwi-pitch pitch) kunye nexabiso elincinci le-diameter

P0.8+0.2P1.0+0.236P1.25+0.265P1.5+0.3P1.75+0.335

P2.0+0.375P2.5+0.48

Umda osezantsi ukutenxa ifomula D1 + HE1 intambo yangaphakathi 6H iklasi ubukhulu esisiseko intambo yangaphakathi ububanzi encinane + ukutenxa.

Qaphela: Ixabiso le-bias “0″ kwinqanaba le-6H

Ifomula yokubala umda ophezulu wezinga le-6H lentambo yangaphakathi = D1 + HE1 + TD1, oko kukuthi, ubungakanani obusisiseko bobubanzi obuncinci bentambo yangaphakathi + ukuphambuka + ukunyamezela.

Umzekelo: Umda ophezulu we-diameter encinci ye-6H grade M8 intambo yangaphakathi yi-6.647 + 0 = 6.647

Umda ophantsi we-diameter encinci ye-6H grade M8 intambo yangaphakathi yi-6.647 + 0 + 0.265 = 6.912

c.Ukubalwa kokutenxa okusisiseko kwedayamitha encinci ye-6G yangaphakathi (esekelwe kwi-pitch) kunye nexabiso le-diameter encinci.

P0.8+0.024P1.0+0.026P1.25+0.028P1.5+0.032P1.75+0.034

P2.0+0.038P2.5+0.042

Ifomula yokubala kumda ophantsi we-diameter encinci yentambo yangaphakathi 6G = D1 + GE1 ubungakanani obusisiseko bentambo yangaphakathi + ukuphambuka.

Umzekelo: Umda ophantsi we-diameter encinci ye-6G grade M8 intambo yangaphakathi yi-6.647 + 0.028 = 6.675

Ifomula ye-D1 + GE1 + TD1 yexabiso eliphezulu lomda we-diameter encinci ye-6G yebakala le-M8 intambo yangaphakathi yisayizi esisiseko somsonto wangaphakathi + ukuphambuka + ukunyamezela.

Umzekelo: Umda ophezulu we-diameter encinci ye-6G grade M8 intambo yangaphakathi yi-6.647 + 0.028 + 0.265 = 6.94

Phawula:

① Ukuphakama kwezinyo kwintambo yangaphakathi kuhambelana ngokuthe ngqo nomzuzu wokuthwala wentambo yangaphakathi, ngoko ke into engenanto kufuneka ibe ngaphakathi komda ophezulu weklasi ye-6H kangangoko kunokwenzeka.

②Ngexesha lokulungisa intambo yangaphakathi, incinci i-diameter encinci ye-thread yangaphakathi, iyancipha ukusebenza kakuhle kwesixhobo sokucubungula-impompo. Ngokombono wokusetyenziswa, i-diameter encinci encinci, ingcono, kodwa ingqalelo ebanzi, i-diameter encinci isetyenziswa ngokubanzi phakathi komda ophakathi kunye nomda ophezulu, ukuba intsimbi okanye i-aluminium, kufuneka isetyenziswe phakathi umda osezantsi kunye nomda ophakathi we-diameter encinci.

③Xa i-diameter encinci yomsonto wangaphakathi iyi-6G, inokuqondwa njenge-6H. Inqanaba lokuchaneka liqwalasela ubukhulu becala ukugquma komthamo we-pitch wentambo. Ngoko ke, kuphela i-pitch diameter yempompo iqwalaselwa ngexesha lokucubungula intambo, kwaye i-diameter encinci ayiqwalaselwa. Ubukhulu bomngxuma wokukhanya.

5. Ifomula yokubala yendlela yokwahlula intloko enye

Ifomula yokubala yecandelo elinye: n=40/Z

n: inani lezangqa ekufuneka intloko eyahlulayo ijike

Z: inxalenye elinganayo yomsebenzi

40: inombolo yentloko yesalathiso esisigxina

Umzekelo: Ukubalwa kokugaya ihexagon

Faka endaweni yefomula: n=40/6

Ukubala: ① Yenza lula amaqhezu: fumana esona sahluli sincinci 2 kwaye wahlule nge, oko kukuthi, yahlule inani kunye nedinomineyitha ngo-2 ngaxeshanye ukufumana 20/3. Ngelixa ukunciphisa amanqaku, ulwahlulo lwalo olulinganayo luhlala lufana.

② Ukubalwa kwamaqhezu: Kweli nqanaba, kuxhomekeke kumaxabiso amanani kunye nedinomineyitha; ukuba inani kunye nedinomineyitha zinkulu, ubalo lwenziwa.

20÷3=6(2/3) lixabiso lika-n, oko kukuthi, intloko eyahlulayo kufuneka ijike 6(2/3) isangqa. Ngeli xesha, iqhezu libe liqhezu; inxalenye egqibeleleyo yesi-6 yintloko yolwahlulo kufuneka ijike izangqa ezi-6 ezipheleleyo. Iqhezu 2/3 elineqhezu linokuba yi-2/3 kuphela yesangqa kwaye kufuneka libalwe kwakhona kweli nqanaba.

③ Ukukhethwa kunye nokubala kwe-indexing plate: ukubalwa okungaphantsi kwesangqa esinye kufuneka kuphunyezwe ngoncedo lwe-indexing plate yentloko yesalathiso. Inyathelo lokuqala ekubaleni kukwandisa ngaxeshanye iqhezu ngo-2/3. Umzekelo: ukuba amanqaku anyuswe ngamaxesha angama-14 ngexesha elinye, ngu-28/42; ukuba inyuswe ngamaxesha angama-10 ngexesha elinye, inqaku ngu-20/30; ukuba yenziwe nkulu amaxesha ali-13 ngaxeshanye, amanqaku ngu-26/39…Isikali esandisiweyo kufuneka sibe ngokokudayalo Khetha inani lemingxuma kuyo.

Kweli nqanaba kufuneka ingqalelo:

①Inani lemingxuma yesalathiso sepleyiti ekhethiweyo kufuneka yahlulwe yidinomineyitha 3. Umzekelo, kulo mzekelo ungentla, imingxuma engama-42 ngamaxesha angama-14 ka-3, imingxuma engama-30 amaxesha ayi-10 ku-3, kwaye imingxuma engama-39 amaxesha ayi-13 ku-3. .

② Ukwandiswa kwamaqhezu kufuneka ukuba inani kunye nedinomineyitha zandiswe ngaxeshanye, kwaye ulwahlulo olulinganayo luhlala lungatshintshi, umzekelo.

28/42=2/3×14=(2×14)/(3×14); 20/30=2/3×10=(2×10)/(3×10);

26/39=2/3×13=(2×13)/(3×13)

28/42 Idinomineyitha 42 kukusebenzisa imingxunya engama-42 yenombolo yesalathiso; I-numerator 28 iqhubela phambili kumngxunya wokumisa wevili eliphezulu, ize ijike phezu komngxuma 28, oko kukuthi, umngxuma 29 ngumngxuma wokumisa wevili langoku, 20/30 yimingxuma eli-10 phambili kwindawo ejikelezayo yevili langoku. Isalathiso sesalathisi se-30-hole, kunye nomngxuma we-11 kanye umngxuma wokumisa welivili. I-26/39 ngumngxuma wokumisa kweli vili kwi-index plate ye-39-hole, kwaye imingxuma engama-26 yemingxuma ye-27 ijikelezwe phambili.

Xa usila ihexagon (isithandathu), imingxuma enjengemingxuma engama-42, imingxuma engama-30, kunye nemingxuma engama-39 enokwahlulwa ngo-3 isetyenziswa njengezikali: umsebenzi kukujikelezisa isiphatho izihlandlo ezi-6, uze uqhubele phambili kumngxunya wokumisa ukuya. ibe livili eliphezulu ngokulandelelanayo. Jika 28+1/10+1/26+ kwakhona! Umngxuma ongasentla 29/11/27 umngxuma usetyenziswa njengomngxuma wokumisa ivili.

Umzekelo 2: Ukubalwa kokugaya igiya elinamazinyo ali-15.

Faka endaweni yefomula: n=40/15

Bala n=2(2/3)

Kukujika i-2 izangqa ezipheleleyo, kwaye emva koko ukhethe imingxuma yesalathiso enokwahlulwa ngo-3, njengo 24, 30, 39, 42.51. Yongeza umngxuma omnye, oko kukuthi 17, 21, 27, 29, 35, 37, 39, 45 imingxuma, njengomngxuma wokumisa elivili.

Umzekelo 3: Ukubalwa kwesalathiso sokusila amazinyo angama-82.

Faka endaweni yefomula: n=40/82

Bala n=20/41

Oko kukuthi: nje ukuba i-index plate enemingxuma engama-41 ikhethiwe, jika i-20 + 1 kwindawo yokubeka isondo eliphezulu, oko kukuthi, imingxuma engama-21 isetyenziswe njengembobo yokumisa ivili langoku.

Umzekelo 4: Ukubalwa kwesalathiso sokusila amazinyo angama-51

Ukutshintsha i-formula n = 40/51, ekubeni amanqaku akanakubalwa ngeli xesha, unokukhetha ngokuthe ngqo umngxuma, oko kukuthi, khetha i-index plate enemingxuma engama-51, uze ujike i-51 + 1 ivili eliphezulu kwindawo yokubeka. umngxuma, oko kukuthi, imingxuma engama-52, njengevili langoku. Ukubeka imingxunya okt.

Umzekelo 5: Ukubalwa kwesalathiso sokugaya amazinyo ayi-100.

Faka endaweni yefomula n=40/100

Bala n=4/10=12/30

Khetha ipleyiti yesalathiso enemingxuma engama-30 ngexesha, kwaye emva koko ubeke i-12+1 okanye imingxuma eyi-13 kumngxunya wokumisa ivili elingasentla njengomngxuma wokumisa ivili langoku.

Ukuba zonke iidiski zesalathisi azifikeleli kwinani lemingxuma efunekayo ekubaleni, indlela yokulinganisa i-compound kufuneka isetyenziswe ekubaleni, engabandakanywanga kule ndlela yokubala. Kwimveliso yokwenyani, i-gear hobbing isetyenziswa ngokubanzi, kuba owona msebenzi emva kokubala i-compound indexing akulula kakhulu.

6. Ifomula yokubala yehexagon ebhalwe kwisangqa

① Fumana icala elichasene nehexagon (S umphezulu) wesangqa D

S=0.866D ubukhulu×0.866 (i-coefficient)

② Bala i-diameter (D) yesangqa ukusuka kwelinye icala lehexagon (S surface)

D=1.1547S icala elichaseneyo×1.1547 (i-coefficient)

7. Ifomula yokubala yecala elichaseneyo kunye nomgca we-diagonal we-hexagon kwinkqubo yesihloko esibandayo

① Fumana i-engile echaseneyo yecala elichaseneyo (S) lehexagon yangaphandle

e=1.13s Icala elichasayo×1.13

② Fumana i-engile echaseneyo (e) ukusuka kwelinye icala (s) le-hexagon yangaphakathi

e=1.14s Icala elichaseneyo×1.14 (i-coefficient)

③ Fumana i-diagonal ye-diagonal yentloko (D) kumacala achaseneyo we-hexagon yangaphandle

I-diameter (D) yesangqa kufuneka ibalwe ngokwecala elichaseneyo (s plane) ye-hexagon (ifomula yesibini kwi-6), kunye nexabiso le-offset center kufuneka linyuswe ngokufanelekileyo, oko kukuthi, i-D≥1.1547s. Isixa se-offset ukusuka kwiziko sinokuqikelelwa kuphela.

8. Ifomula yokubala yesikwere ebhalwe kwisangqa

① Zoba isangqa (D) ukufumana icala elichasene nesikwere (S umphezulu)

S=0.7071D ubukhulu×0.7071

② Fumana isangqa (D) ukusuka kwelinye icala lesikwere (S umphezulu)

D=1.414S icala elichaseneyo×1.414

9. Iifomula zokubala zesikwere kumacala achaseneyo kunye nee-engile ezichaseneyo kwinkqubo yesihloko esibandayo

① Fumana i-engile echaseneyo (e) ukusuka kwelinye icala (S) lesikwere esingaphandle

e=1.4s licala elichaseneyo (ama)×1.4 iparamitha

② Fumana i-engile echaseneyo (e) yecala elichaseneyo (s) lesikwere esingaphakathi

e=1.45s licala elichaseneyo (s)×1.45 i-coefficient

10. Ifomula yokubala umthamo weHexagon

s20.866×H/m/k lithetha icala elichaseneyo×elichaseneyo×0.866×ubude okanye ubukhulu.

11. Ifomula yokubala yevolumu enqunyuliweyo (cone).

I-0.262H (D2+d2+D×d) yi-0.262×ubude×(idayamitha yentloko enkulu×idayamitha yentloko enkulu+idayamitha yentloko encinci×intloko encinci+intloko+intloko enkulu×idayamitha yentloko encinci).

12. Ifomula yokubala yomthamo wengqukuva (enjengentloko engemisetyhula)

3.1416h2(Rh/3) yi 3.1416×ubude×ubude×(radius-height÷3).

13. Ifomula yokubala yemilinganiselo yomatshini yeetephu zangaphakathi zomsonto

1. Ukubalwa kwetaphu enkulu yedayamitha D0

D0=D+(0.866025P/8)×(0.5~1.3) yisayizi esisiseko yempompo yediamitha yentambo enkulu + 0.866025 pitch÷8×0.5~1.3.

Qaphela: Ukukhethwa kwe-0.5~1.3 kufuneka kugqitywe ngokobungakanani besandi. Ixabiso le-pitch likhulu, i-coefficient encinci kufuneka isetyenziswe. Ngokuchaseneyo, incinci ixabiso le-pitch, inkulu i-coefficient ehambelanayo kufuneka ibe.

2. Ukubalwa komthamo wempompo yepitshi (D2)

D2=(3×0.866025P)/8, oko kukuthi, tap diameter=3×0.866025×pitch÷8

3. Ukubalwa komthamo wempompo (D1)

D1=(5×0.866025P)/8 yimpompo yediameter=5×0.866025×pitch÷8

Shumi elinane,

Ifomula yokubala yobude besixhobo sokwenziwa kwesihloko esibandayo seemilo ezahlukeneyo

Ifomula yomthamo wesangqa esaziwayo yi-diameter×i-diameter×0.7854×ubude okanye iradiyasi×3.1416×ubude. Oko kukuthi, d2×0.7854×L okanye R2×3.1416×L

Xa ubala, umthamo we-X÷diameter÷diameter÷0.7854 okanye i-X÷radius÷radius÷3.1416 yezinto ezifunekayo ubude bezinto eziphathekayo.

Ifomyula yeKholam = X/(3.1416R2) okanye X/0.7854d2

Kwifomula, u-X umele ixabiso lomthamo wezinto ezifunekayo;

L imele ubude bexabiso lokondliwa kwangempela;

I-R/d imele iradiyasi yokwenyani yokutya okanye i-diameter.

Injongo ye-Anebon kukuqonda ukonakala okugqwesileyo okuvela kwimveliso kunye nokubonelela ngenkxaso ephezulu kubathengi basekhaya nabaphesheya ngentliziyo epheleleyo ngo-2022 Umgangatho ophakamileyo wentsimbi yeAluminiyam ekumgangatho oPhezulu oPhakamileyo oCwangcisiweyo weCNC oGuqulela iMilling Machining Spare Part yeAerospace, Ukuze kwandiswe imakethi yethu yamazwe aphesheya, iAnebon. ubukhulu becala unikezelo lwabathengi bethu baphesheya kolwandle Umgangatho ophezulu wokusebenza kwamalungu oomatshini, iinxalenye ezigayiweyo kunye nenkonzo yokuguqula i-cnc.

I-China i-wholesale yase-China iCandelo loomatshini kunye ne-CNC Machining Service, i-Anebon iphakamisa umoya "wokutsha, ukuhambelana, umsebenzi weqela kunye nokwabelana, iindlela, inkqubela phambili yepragmatic". Sinike ithuba kwaye siza kubonakalisa amandla ethu. Ngoncedo lwakho olunobubele, i-Anebon ikholelwa ukuba singadala ikamva eliqaqambileyo kunye nawe kunye.

Ixesha lokuposa: Jul-10-2023