Ucinga ukuba yintoni ubudlelwane phakathi kwesantya sokusika, ukusebenzisana kwesixhobo, kunye nesantya sokutya kwi-CNC machining?

Ukusebenza kakuhle, kubalulekile ukuqonda ubudlelwane phakathi kwesantya sokutya, ukusika isantya kunye nokuzibandakanya kwesixhobo kwi-CNC machining.

Isantya sokusika:

Isantya sokusika sisantya sokujikeleza okanye ukunyakaza kwizinto eziphathekayo. Isantya siqhele ukulinganiswa ngeenyawo zomhlaba ngemizuzu (SFM) okanye iimitha/umzuzu (m/min). Isantya sokusika sichongwa ngezinto eziza kwenziwa ngoomatshini, isixhobo sokusika, kunye nokugqitywa komhlaba ofunekayo.

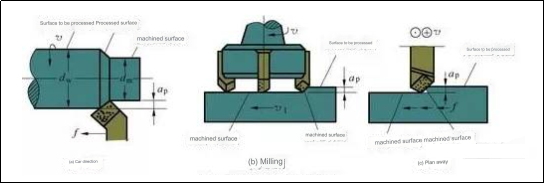

Isixhobo sokuthethathethana

Isixhobo sokusebenzisana bubunzulu apho isixhobo sokusika singena kwi-workpiece ngexesha lomatshini. Ukuzibandakanya kwesixhobo kuchatshazelwa yimiba efana nejiyometri yokusika isixhobo kunye nokutya kunye nezantya kunye nomgangatho ofunekayo womphezulu kunye nesantya sokususwa kwezinto. Ngokukhetha ubungakanani besixhobo esifanelekileyo, ubunzulu bokusikwa kunye nokuzibandakanya kweradial, unokulungelelanisa ukubandakanyeka kwesixhobo.

Isantya sokutya

Isantya sokutya sikwabizwa ngokuba yireyithi yokutya okanye isondlo ngezinyo ngalinye. Ngumlinganiselo wokuba isixhobo sokusika siqhubela phambili ngenguqu nganye kwizinto zesixhobo sokusebenza. Isantya silinganiswa ngeemilimitha okanye i-intshi ngomzuzu. Izinga lokutya lichaphazela ngqo ubomi besixhobo, umgangatho womphezulu, kunye nokusebenza komatshini ngokubanzi.

Ngokubanzi, isantya esiphezulu sokusika sikhokelela kumazinga aphezulu okususwa kwezinto. Nangona kunjalo, zikwavelisa ubushushu obuninzi. Isakhono sesixhobo sokusika sokuphatha isantya esiphezulu, kunye nokusebenza kakuhle kwesipholisi ekukhupheni ubushushu zizinto ezibalulekileyo.

Ukubandakanyeka kwesixhobo kufuneka kulungiswe ngokwezinto eziphathekayo ze-workpiece, ijometri yezixhobo zokusika, kunye nokugqiba okufunwayo. Ukudibana kwesixhobo esifanelekileyo kuya kuqinisekisa ukukhutshwa kwetshiphu okusebenzayo kunye nokunciphisa ukuphambuka kwesixhobo. Kwakhona kuya kuphucula ukusebenza kokusika.

Isantya sokutya kufuneka sikhethwe ukufezekisa izinga elifunwayo lokususwa kwezinto kunye nokugqiba, ngaphandle kokulayisha ngaphezulu isixhobo. Izinga eliphezulu lokutya linokubangela ukunxitywa kwezixhobo ezigqithisileyo. Nangona kunjalo, isantya sokutya esisezantsi siya kukhokelela ekugqityweni okungalunganga komphezulu kunye nomatshini ongasebenziyo.

Umdwelisi weprogram kufuneka abhale imiyalelo kwiprogram ye-CNC ukugqiba inani lokusika inkqubo nganye. Isantya sokusika, isixa sokusika umva, isantya sokutya njalo njalo zonke ziyinxalenye yokusetyenziswa kokusika. Izixa ezahlukeneyo zokusika ziyafuneka kwiindlela ezahlukeneyo zokusetyenzwa.

1. Umgaqo wokukhethwa kwexabiso lokusika

Xa i-roughing, eyona nto iphambili kugxilwe ekuphuculeni imveliso, kodwa uqoqosho kunye neendleko zokulungisa kufuneka ziqwalaselwe; xa i-semi-finishing kunye nokugqiba, ukusika ukusebenza kakuhle, uqoqosho, kunye neendleko zokucubungula kufuneka zithathelwe ingqalelo ngelixa uqinisekisa umgangatho wokucubungula. Amaxabiso athile kufuneka amiselwe ngokwencwadi yesixhobo somatshini, incwadi yokusetyenziswa kokusika, kunye namava.

Ukuqala ngokuhlala kwesixhobo, umyalelo wokukhethwa kwexabiso lokusika: kuqala unqume inani lokusika umva, emva koko unqume inani lokutya, kwaye ekugqibeleni unqume isantya sokusika.

2. Ukumiselwa kwenani lemela ngasemva

Ubungakanani bokusika umva bunqunywe ngokuqina kwesixhobo somatshini, i-workpiece kunye nesixhobo. Ukuba ubunzima buvumela, ubungakanani bokusika umva kufuneka bulingane nesibonelelo somatshini we-workpiece kangangoko kunokwenzeka. Oku kunokunciphisa inani lokupasa kwesixhobo kunye nokuphucula ukusebenza kakuhle kwemveliso.

Imigaqo yokumisela ubungakanani bemela ngasemva:

1)

Xa umgangatho woburhabaxa bomphezulu womsebenzi kufuneka ube yiRa12.5μm~25μm, ukuba isibonelelo somatshiniCNC machiningingaphantsi kwe-5mm ~ 6mm, isondlo esinye somatshini obunzima sinokuhlangabezana neemfuno. Nangona kunjalo, xa umda ukhulu, ukuqina kwenkqubo yenkqubo ihlwempuzekileyo, okanye amandla omatshini womatshini awanelanga, unokugqitywa kwisondlo ezininzi.

2)

Xa umgangatho woburhabaxa bomphezulu womsebenzi kufuneka ube yiRa3.2μm~12.5μm, unokwahlulwa ube ngamanyathelo amabini: ukurhabaxa kunye nokugqiba. Ukukhethwa kwexabiso lokusika ngasemva ngexesha lomatshini olukhuni kuyafana nangaphambili. Shiya umda we-0.5mm ukuya kwi-1.0mm emva komatshini orhabaxa kwaye uwususe ngexesha lokugqitywa kwesiqingatha sokugqibela.

3)

Xa umgangatho woburhabaxa bomphezulu womsebenzi kufuneka ube nguRa0.8μm~3.2μm, unokwahlulwa ube ngamanyathelo amathathu: ukurhabaxa, ukugqiba ukugqiba nokugqiba. Isixa sokusika umva ngexesha lokugqiba i-semi-finishing yi-1.5mm ~ 2mm. Ngexesha lokugqiba, inani lokusika umva kufuneka libe yi-0.3mm ~ 0.5mm.

3. Ukubalwa kwesixa sesondlo

Ubungakanani bokutya buchongwa ngokuchaneka kwenxalenye kunye noburhabaxa bomhlaba obufunekayo, kunye nakwizinto ezikhethiweyo zesixhobo kunye nomsebenzi. Ubuninzi bezinga lokutya kuxhomekeke kubungqongqo bomatshini kunye nenqanaba lokusebenza kwenkqubo yokutya.

Imigaqo yokumisela isantya sokutya:

I-1) Ukuba umgangatho we-workpiece unokuqinisekiswa, kwaye ufuna ukunyusa ukusebenza kwemveliso, ngoko isantya sokutya esikhawulezayo siyacetyiswa. Ngokubanzi, isantya sokutya sibekwe phakathi kwe-100m / min kunye ne-200m / min.

2) Ukuba usika okanye ulungisa imingxuma enzulu, okanye usebenzisa i-steel-speed steels, kungcono ukusebenzisa isantya sokutya esicothayo. Oku kufuneka kube phakathi kwe-20 kunye ne-50m / min.

Xa imfuno yokuchaneka kwi-machining kunye noburhabaxa bomphezulu buphezulu, kungcono ukhethe isantya esincinci sokutya, ngokuqhelekileyo phakathi kwe-20m / min kunye ne-50m / min.

Unokukhetha izinga eliphezulu lokutya elibekwe yinkqubo yesixhobo somatshini we-CNC xa isixhobo singasebenzi, kwaye ngokukodwa "ukubuyisela i-zero" kumgama.

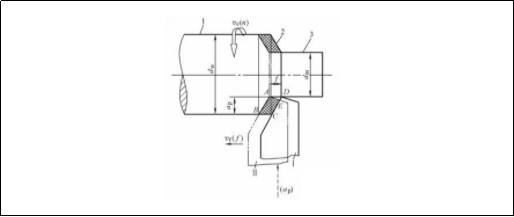

4. Ukuzimisela kwesantya se-Spindle

I-spindle kufuneka ikhethwe ngokusekelwe kwisantya esiphezulu sokusika esivumelekileyo kunye nobubanzi bomsebenzi wakho okanye isixhobo. Ifomula yokubala yesantya sokusonta yile:

n=1000v/pD

Ukuqina kwesixhobo kugqiba isantya.

Isantya somjikelo silinganiswa nge-r/min.

D —- Idayamitha yesixhobo sokusetyenzwa okanye ubungakanani besixhobo, esilinganiswa nge-mm.

Isantya sokugqibela sokuphotha sibalwa ngokukhetha isantya isixhobo somatshini esinokufikelela kuso okanye sisondele, ngokutsho kwencwadana yayo.

Kungekudala, ixabiso lexabiso lokusika lingabalwa ngokufanisa, ngokusekelwe ekusebenzeni komatshini, iincwadana, kunye namava obomi bokwenene. Isantya se-spindle kunye nobunzulu bokusika bunokulungelelaniswa kwisantya sokutya ukwenza elona nani lilungileyo lokusika.

1) Ukusika umva inani (ukusika ubunzulu) ap

Isixa sokusika umva ngumgama othe nkqo phakathi komphezulu ukuya kumatshini kunye nomgangatho owenziwe ngoomatshini. Ukusika umva yimali yokusika elinganiswe nge-perpendicularly ukuya kwindiza yomsebenzi ngokusebenzisa indawo yesiseko. Ubunzulu bokusika bubuninzi bokusika ukuba isixhobo sokuguqula senze i-workpiece kunye nokutya ngalunye. Isixa sokusikwa ngasemva kwisangqa sangaphandle singabalwa kusetyenziswa le fomula ingezantsi:

ap = ( dw — dm ) /2

Kwifomula, ap——ubungakanani bemela ngasemva (mm);

dw——Ububanzi bomphezulu oza kucutshungulwa kwisixhobo sokusebenza (mm);

dm - i-diameter yomhlaba owenziwe ngomatshini we-workpiece (mm).

Umzekelo 1:Kuyaziwa ukuba i-diameter yomphezulu we-workpiece eza kusetyenzwa yi-Φ95mm; ngoku i-diameter yi-Φ90mm kwisondlo esinye, kwaye inani lokusika umva lifunyenwe.

Isisombululo: ap = (dw — dm) /2= (95 —90) /2=2.5mm

2) Imali yokutya f

Ukufuduswa kwesalamane kwesixhobo kunye ne-workpiece kwicala le-feed motion kwi-revolution nganye ye-workpiece okanye isixhobo.

Ngokwezalathiso ezahlukeneyo zokuxheshisela, yahlulwe ngokwenani lesondlo sexesha elide kunye nesixa sesondlo esinqamlezileyo. Isixa sesondlo sexesha elide sibhekisa kwisixa sesondlo ecaleni kwendlela kaloliwe wesalathiso sebhedi, kwaye isixa sesondlo esinqamlezileyo sibhekiselele kulwalathiso oluthe ngqo kumzila kaloliwe wesalathiso sebhedi. Izinga lokutya.

Phawula:Isantya sokutya i-vf sibhekisa kwisantya esikhawulezileyo sendawo ekhethiweyo kumda wokusika ngokunxulumene nentshukumo yokutya kwesixhobo sokusebenza.

vf=fn

apho vf——isantya sokutya (mm/s);

n——Isantya sokujikeleza (r/s);

f——imali yokutya (mm/s).

3) Ukusika isantya vc

Isantya esikhawulezayo kwintshukumo ephambili kwindawo ethile kwi-blade yokusika ngokumalunga nomsebenzi. Kubalwe ngu:

vc=(pdwn)/1000

Apho vc —-ukusika izantya (m/s);

dw = ububanzi bomphezulu oza kunyangwa (mm);

—- Isantya sokujikeleza sesixhobo sokusebenza (r/min).

Ubalo kufuneka lwenziwe ngokusekelwe kwisantya esiphezulu sokusika. Ubalo kufuneka, umzekelo, lwenziwe ngokusekelwe kubukhulu kunye nesantya sokuguga komphezulu owenziwe ngoomatshini.

Fumana vc. Umzekelo 2: Xa ujika isangqa esingaphandle sento enobubanzi obuyi-Ph60mm kwilathe, isantya sokusonta esikhethiweyo yi-600r/min.

Isisombululo:vc=( pdwn)/1000 = 3.14x60x600/1000 = 113 m/min

Kwimveliso yangempela, kuqhelekile ukwazi ububanzi beqhekeza. Isantya sokusika sichongwa yimiba efana nesixhobo somsebenzi, izixhobo zesixhobo kunye neemfuno zokusetyenzwa. Ukulungelelanisa i-lathe, isantya sokusika siguqulelwa kwisantya se-spindle se-lathe. Le fomula inokufumaneka:

n=(1000vc)/pdw

Umzekelo 3: Khetha i-vc ukuya ku-90m/min uze ufumane u-n.

Isisombululo: n=(1000v c)/ pdw=(1000×90)/ (3.14×260) =110r/min

Emva kokubala izantya zokuphotha i-lathe, khetha ixabiso elikufutshane ne-numberplate, umzekelo, n=100r/min njengesona santya se-lathe.

3. Isishwankathelo:

Ukunciphisa inani

1. Isixa semela ngasemva ap (mm) ap= (dw – dm) / 2 (mm)

2. Imali yokutya f (mm/r)

3. Ukusika isantya vc (m/min). Vc=dn/1000 (m/min).

n=1000vc/d(r/min)

Ngokubhekiselele kwisiqhelo sethuCNC iinxalenye aluminiyambaxhalabile, zeziphi iindlela zokunciphisa ukuguqulwa kokulungiswa kwamalungu e-aluminium?

Ukulungiswa okufanelekileyo:

Ukulungisa i-workpiece ngokuchanekileyo kubalulekile ekunciphiseni ukugqwetheka ngexesha lomatshini. Ngokuqinisekisa ukuba ii-workpieces ziboshwe ngokukhuselekileyo endaweni, ukungcangcazela kunye neentshukumo zingancitshiswa.

Ukuziqhelanisa noMatshini

Impendulo ye-Sensor isetyenziselwa ukulungelelanisa iiparamitha zokusika ngokukhawuleza. Oku kuhlawulela ukwahluka kwezinto, kwaye kunciphisa i-deformation.

Ukusika iiParameters zokuPhuculwa

Utshintsho lunokuncitshiswa ngokulungiselela iiparamitha ezinje ngesantya sokusika, i-feedrate, kunye nokusika ubunzulu. Ngokunciphisa amandla okusika kunye nokuveliswa kobushushu ngokusebenzisa iiparitha ezifanelekileyo zokusika, ukuphazamiseka kunokunciphisa.

Ukunciphisa isiZukulwana soBubushushu:

Ubushushu obuveliswe ngexesha lomatshini bunokukhokelela ekuguqulweni kwe-thermal kunye nokwandiswa. Ukunciphisa imveliso yobushushu, sebenzisa isipholile okanye izithambisi. Nciphisa isantya sokusika. Sebenzisa iidyasi zesixhobo eziphezulu.

UkuCwangcisa ngokuthe ngcembe

Kungcono ukwenza iipasi ezininzi xa usenza ialuminiyam kunesisiki esinzima esinye. Umatshini ngokuthe ngcembe kunciphisa ukuguquka ngokunciphisa ubushushu kunye namandla okusika.

Ukufudumeza kwangaphambili:

Ukufudumala i-aluminium phambi komatshini kunokunciphisa umngcipheko wokuphazamiseka kwiimeko ezithile. Ukushisa kwangaphambili kuzinzisa izinto kwaye zenze ukuba zixhathise ngakumbi ukugqwetheka xa umatshini.

Ukuphelisa Uxinzelelo

Ukunciphisa uxinzelelo loxinzelelo kunokwenziwa emva komatshini ukunciphisa uxinzelelo olushiyekileyo. Inxalenye inokuzinziswa ngokuyifudumeza kwiqondo elithile lobushushu, emva koko ipholise kancinci.

Ukukhetha iSixhobo esiLungileyo

Ukuze kuncitshiswe i-deformation, kubalulekile ukukhetha izixhobo ezifanelekileyo zokusika, kunye neengubo ezifanelekileyo kunye neejometri. Izixhobo ezikhethekileyo ezenzelwe i-aluminium machining zinciphisa amandla okusika, ziphucula ukugqitywa kwendawo, kwaye zithintele ukubunjwa kwemiphetho eyakhiweyo.

Umatshini ngokwamanqanaba:

Imisebenzi emininzi yomatshini okanye izigaba zingasetyenziselwa ukuhambisa amandla okusika kwizinto ezinzimaiindawo ze-aluminiyam ze-cnckunye nokunciphisa deformation. Le ndlela ikhusela uxinzelelo lwendawo kwaye inciphisa ukuphazamiseka.

Ukusukela i-Anebon kunye nenjongo yenkampani ihlala "ihlala isanelisa iimfuno zethu zabathengi". I-Anebon qhubeka nokufumana kunye nesimbo kunye nokuyila iimveliso ezikumgangatho ophezulu ezikumgangatho ophezulu kuye ngamnye abathengi bethu abaphelelwe lixesha kunye nabatsha kwaye ufikelele kwithemba lokuphumelela kubathengi be-Anebon kunye nathi kwiProfayili yoMzimveliso we-Original extrusions aluminium,cnc yajika inxalenye, cnc yokugaya inayiloni. Samkela ngokunyanisekileyo abahlobo ukuba bathengise ishishini kwaye baqalise intsebenziswano nathi. I-Anebon inethemba lokubamba izandla nabahlobo abasenyongweni kumashishini ahlukeneyo ukuvelisa ixesha elide eliqaqambileyo.

China Manufacturer for China High Precision and Metal Stainless Steel Foundry, Anebon ifuna amathuba ukudibana bonke abahlobo abavela zombini ekhaya nakwamanye amazwe ukuze win-win intsebenziswano. I-Anebon inethemba elinyanisekileyo lokuba nentsebenziswano yexesha elide kunye nani nonke kwiziseko zenzuzo efanayo kunye nophuhliso olufanayo.

Ukuba ufuna ukwazi ngakumbi, nceda uqhagamshelane neqela le-Anebon kuinfo@anebon.com.

Ixesha lokuposa: Nov-03-2023