Ukususwa kwe-chip esebenzayo kuthintela ukukrwela umphezulu owenziwe ngoomatshini kwaye kuthintele iitshiphusi ukuba zingabambeki kwindawo kunye nesixhobo ngaphambi kokusikwa kwesibini, ngoko ke iitshiphusi zentsimbi kufuneka ziphulwe kangangoko ukuze imveliso ibe mpuluswa kwaye izinzile. Ke kufuneka ndenze ntoni xa ndiqhubeka ne-chip?cnc machining inxalenye

Kukho izisombululo ezithathu:

1. Yandisa ubunzulu cut Ap

2. Yandisa ukondla F

3. Sebenzisa iblade yoqhawulo lwetshiphu ebukhali

Ukwandisa ubunzulu bokunqunyulwa kunye nokunyusa ukutya kuyafana, oko kukuthi, amandla okufakwa kwentsimbi anyuswa, ukwenzela ukuba xa kusetyenziswe i-curvature efanayo, iifayili zentsimbi zingaphulwa.

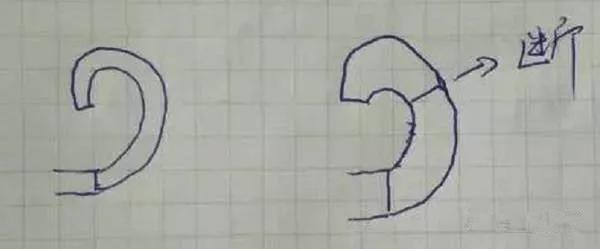

Umzobo ubonisa imeko yokuba iifayili zentsimbi ziphukile kwi-curvature efanayo emva kobunzulu bokusika. Ukunyuka kwesondlo kukwandisa ubunzulu bokusikwa kwinqanaba le-axial, ngoko ke isizathu esifanayo, andiyi kutsala.

Ngokuqinisekileyo, ixesha elininzi, ubunzulu bokusika abukwazi ukulungiswa, ngokukodwa ukulungelelanisa ukutya (ngokukhethekileyo ukunciphisa isantya, i-F ayitshintshi, i-F inyuka, enokuthi iphucule ubomi besixhobo). Nangona kunjalo, ukwandisa ukutya kuya kuzisa iingxaki ezihambelanayo.

Ingxaki yoku-1: Amandla okusika abe mkhulu, imfuno yamandla yenkqubo yonke yokucubungula iyanda, kwaye i-vibration ingenzeka. Ukuba ukungcangcazela akwanelanga, ezinye iindlela ziyafuneka.

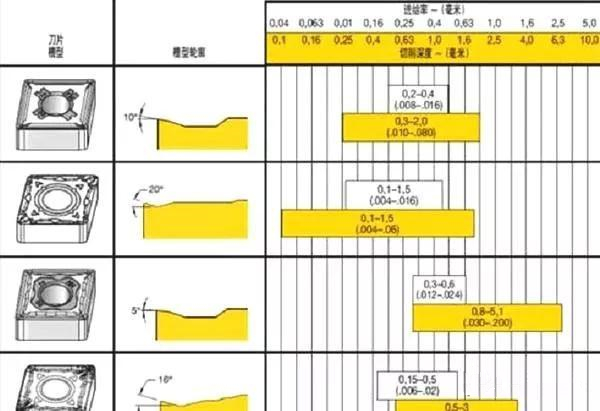

Ingxaki 2: Ukugqiba kuncitshisiwe. Kwimeko yeekona ezijikelezileyo ezifanayo, ukongezwa kokutya okunyusiweyo kuya kuncipha ngokuqinisekileyo, ngoko nikela ingqalelo ekugqityweni komsebenzi. (Ubudlelwane phakathi kwefillet kunye nefidi inefomula yobungqina: Ra = (f * f ** 50) / re, eyona feed inkulu, incinci ikona yesixhobo sencam yesixhobo, kokukhona ixabiso elirhabaxa lomphezulu lifunyenwe) Makhe ndithethe. malunga nokutshintsha uhlobo lwegroove. Yintoni umkhombe? Enyanisweni, isampuli nganye yesixhobo inentshayelelo kwi-chipbreaker phambi kwayo. Umzekelo, oku kulandelayo.

I-chipbreaker ijonge ubukhulu becala i-rake angle kunye nobubanzi be-blade, njenge-angle ephawulwe "kwiprofayili yegroove" ngasentla. Inkulu i-engile, inkulu i-engile yeefayili zentsimbi. Ukuncipha kweefayili zentsimbi, kunokwenzeka ngakumbi. Ukuqhekeka kwe-Chip, ngoko xa uqhubeka uguqa, kuyimfuneko ukujonga i-engile yangaphambili ye-blade oyisebenzisayo ngoku, kwaye utshintshe i-blade ye-engile enkulu yangaphambili yokucubungula, imeko yokuphulwa kwe-chip iya kuba ngcono.

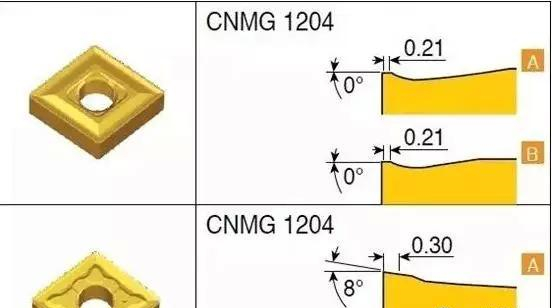

Kukho ububanzi be-blade, ububanzi be-blade abubonakali kulo mfanekiso ungasentla, kodwa bubonakaliswa bunzulu bokusikwa, bhetele, oko kukuthi, ubunzulu be-blade bufanelekile ukucutshungulwa, ukuba usebenzisa i-blade ngokuqhubekayo, emva koko uya kubona Jonga ezinye iincakuba ezinokusika kancinci. Ezinye zibonisa ububanzi be-blade njengoko kuboniswe ngezantsi.inxalenye yeplastiki

Kulo mfanekiso ungentla, ububanzi be-blade (obufana ne-0.21) buphawulwe. Kuqondwa kakuhle ukuba incinci ububanzi be-blade, i-shallower inganqunyulwa. Nangona kunjalo, ubunzulu bokunqunyulwa kufuneka bube malunga nobubanzi be-blade, ngaphandle koko akuyi kusika kodwa ukugaya. Ngamafutshane, i-scraping eqhubekayo, khetha ububanzi obuncinci be-blade, inokunqumla, kwaye i-chip breaking situation ingcono.

Nangona kunjalo, ukukhetha i-angle enkulu yerake kunye nobubanzi beblade encinci kuya kubangela iingxaki. Amandla e-blade awanele, kwaye isixhobo siyanelisa ngakumbi. Ke ngoko, ukuba ukhetha iblade ebukhali kwaye uzame kwakhona, ungakhetha ethambileyo kancinci. Kunokwenzeka ukunciphisa inqaku kuqala (ukuba ukusebenza akufuneki).inxalenye yealuminiyam

Ithegi eshushu:I-CNC yokuguqula iiNdawo eziChanekileyo eziPhezulu,Izahlulo ze-CNC zokugaya ezichanekileyo zombane, iiNdawo ze-CNC ze-Stainless Steel,Izixhobo ze-CNC zokuguqula i-Aluminiyam

I-Anebon Metal Products Limited inokubonelela ngomatshini we-CNC, ukuphosa ukufa, iinkonzo zomatshini wesinyithi, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Ixesha lokuposa: Aug-31-2019