Ukusika umsonto omnye

Ngokubanzi, kubhekiselele kumatshini wokwenza intambo kwisixhobo sokubumba okanye sokusila, ikakhulu kubandakanywa ukujika, ukugaya, ukucofa nokucofa ukucola, ukugaya, ukusika isivunguvungu, njl njl. isixhobo somatshini siqinisekisa ukuba isixhobo sokujika, isisiki sokusila, okanye ivili lokugaya lihambisa ilothe ngokuchanekileyo nangokulungeleleneyo kwicala leaxial yesixhobo sokusebenza zonke. ukujikeleza. Xa ucofa okanye ukuthunga, isixhobo (itephu okanye ufe) ujikeleza ngokumalunga nomsebenzi, kwaye i-groove yokuqala eyenziwe ngentambo ikhokela isixhobo (okanye i-workpiece) ukuhamba nge-axially.

Ukujika kwemisonto emibini

Izixhobo zekhadi zingasetyenziselwa ukujika okanye ukudibanisa intambo kwi-lathe (jonga isixhobo sokucubungula intambo). Ukuguqula intambo kunye nokwenza isixhobo sokuguqula indlela eqhelekileyo yesiqwenga esisodwa kunye nokuveliswa kwebhetshi encinci ye-workpiece yentambo ngenxa yesakhiwo sayo esilula; ukujika intambo ngesixhobo sokuhlanganisa intambo inomgangatho ophezulu wemveliso, kodwa ubume bayo buntsonkothile, ngoko ke ilungele kuphela ukuguqula umsonto omfutshane wokusebenza kunye namazinyo amahle kwimveliso yebhetshi ephakathi kunye nenkulu. Ukuchaneka kwe-pitch yokuguqula intambo ye-trapezoidal kunye ne-lathe jikelele inokufikelela kuphela kumanqanaba e-8-9 (jb2886-81, efanayo ngezantsi); imveliso okanye ukuchaneka kunokuphuculwa kakhulu xa umatshini wokwenza intambo kwilathe ekhethekileyo.

Imisonto emithathu yokusila

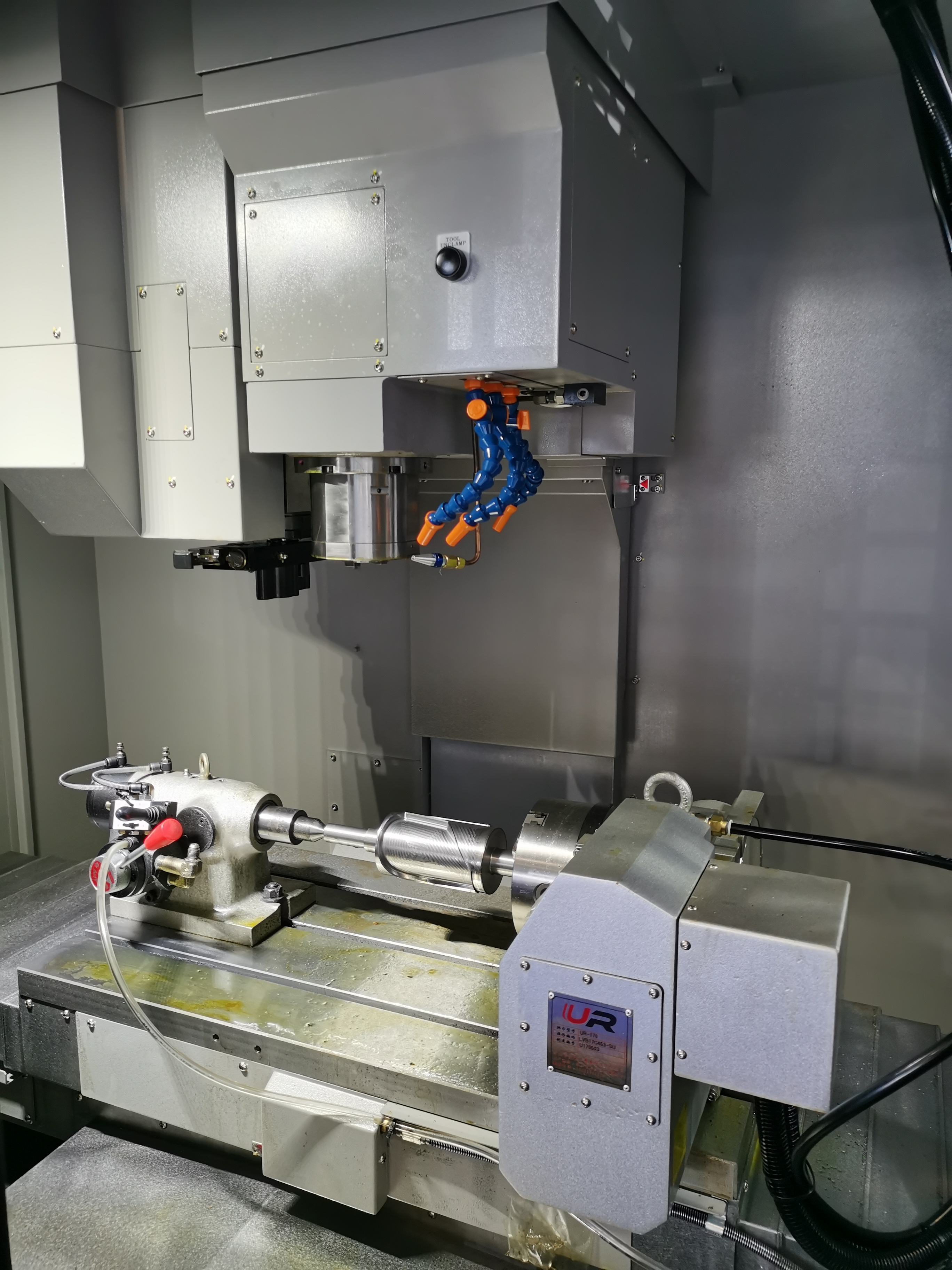

Umsiki wokusila idisc okanye umsiki wekama wokusila usetyenziselwa ukugaya kumatshini wokusila intambo. I-disc milling cutter isetyenziselwa ikakhulu ukucola imisonto yetrapezoid yangaphandle ye-screw rods, iintshulube, kunye nezinye izixhobo zokusebenza. I-combo milling cutter mill yangaphakathi nangaphandle intambo eqhelekileyo kunye nentambo ye-taper. Ngenxa yokuba inxalenye yayo yokusebenza ide kunobude bomsonto oza kuqhutyelwa yi-multi-edge milling cutter, i-workpiece inokucutshungulwa kuphela ngokujikeleza i-1.25-1.5 revolutions, kunye nemveliso ephezulu. Ukuchaneka kwe-pitch yokugaya intambo kunokufikelela kumabakala angama-8-9, kwaye uburhabaxa bomphezulu yi-r5-0.63 μ M. Le ndlela ifanelekile kwimveliso yobuninzi bemisonto echanekileyo yokuchaneka ngokubanzi okanye umatshini olukhuni phambi kokugaya.

Isineukucola intambo

Isetyenziselwa ikakhulu ukucubungula intambo echanekileyo ye-workpiece eqinile kwi-grinder yentambo. Ngokweemilo ezinqamlezayo ezinqamlezayo zevili lokusila, linokwahlulwa libe ziindidi ezimbini: ivili lokusila lomgca omnye kunye nevili lokusila lemigca emininzi. Ukuchaneka kwe-pitch yomgca omnye wokugaya isondo ngamabakala angama-5-6, kunye nobunzima bomhlaba ngu-r1.25-0.08 μ m, ngoko kulungele ukugqiba ivili lokugaya. Le ndlela ifanelekile ekusileni izikrufu ezichanekileyo, iigeyiji zentambo, iintshulube, iibhetshi ezincinci zemisonto yokusebenza, kunye ne-hob echanekileyo Iindidi ezimbini zokusila zazikhona: ukucola okude kunye nokusikwa kokusila. Ububanzi bevili lokusila kunye nendlela yokugaya i-longitudinal ingaphantsi kobude bomsonto oza kucolwa, kwaye intambo inokucolwa ukuya kubukhulu bokugqibela emva kokuba ivili lokusila lihamba ngobude kanye okanye amaxesha amaninzi. Ububanzi bevili lokugaya lendlela yokugaya i-cut-in bukhulu kunobude bomsonto oza kwenziwa. Ivili lokusila linqumla kumphezulu we-workpiece radially, kwaye i-workpiece inomhlaba emva kokujika malunga ne-1.25 revolutions. Imveliso iphezulu, kodwa ukuchaneka kuncinci, kwaye ukugqoka ivili lokugaya kunzima ngakumbi. Indlela yokusila yokusika ilungele ukuhlatywa izixa ezikhulu zeetephu kunye nokusila imisonto ethile. Ukulungiswa kwesinyithi kufanelekile ukuqwalaselwa!

Imisonto emihlanu yokusila

Uhlobo lwe-nut okanye i-screw-type-thread-lapping tool yenziwe ngezinto ezithambileyo ezifana nentsimbi. Amalungu omsonto ogqityiweyo kwi-workpiece enempazamo ye-pitch aphantsi ngokujikeleza phambili kunye nokubuyisela umva ukuphucula ukuchaneka kwe-pitch. Intambo yangaphakathi eqinile idla ngokuchithwa ngokusila ukuphucula ukuchaneka.

Ukucofa okuthandathu kunye nokuthunga

Ukucofa kukusebenzisa itorque ethile ukujija impompo kumngxuma osezantsi ogrunjiweyo kwisixhobo sokusebenza ukuqhubekekisa umsonto wangaphakathi.

I-threading kukusika intambo yangaphandle kwi-bar (okanye ityhubhu) i-workpiece kunye ne-die. Ukuchaneka komatshini wokucofa okanye ukuthunga kuxhomekeke ekuchanekeni kompompo okanye kufa. Nangona kukho iindlela ezininzi zokucutshungulwa kwangaphakathi nangaphandle, iintambo zangaphakathi ezinobubanzi obuncinci zinokucutshungulwa kuphela ngeetephu. Ukucofa nokuthunga kunokwenziwa ngesandla okanye ngelathe, umatshini wokomba, umatshini wokucofa, kunye noomatshini bokuthunga.

Sixhengxeukuqengqeleka komsonto

Indlela yokucubungula yokwenza kunye nokuqengqeleka kwefa ukuvelisa i-deformation yeplastiki ye-workpiece ukufumana ukuqengqeleka kwentambo ngokuqhelekileyo kuqhutyelwa kumatshini wokugubungela intambo okanye i-lathe ezenzekelayo edityaniswe nentloko yokuvula kunye nokuvala intambo, efanelekileyo kwimveliso yobuninzi. ipateni yomsonto yangaphandle yeziqhoboshi ezisemgangathweni kunye namanye amalunga adityanisiweyo. Ngokuqhelekileyo, i-diameter yangaphandle yentambo yokujikeleza ayikho ngaphezu kwe-25 mm, ubude abukho ngaphezu kwe-100 mm, kwaye ukuchaneka kwentambo kunokufikelela kwinqanaba le-2 (gb197-63). Idayamitha yesithuba esingenanto esetyenzisiweyo ilingana ngokulinganayo nobubanzi bepitshi yomsonto oza kucutshungulwa. Ngokuqhelekileyo, intambo yangaphakathi ayinakucutshungulwa ngokuqengqeleka. Sekunjalo, kwi-workpiece ethambileyo, intambo yangaphakathi ebandayo ye-extrusion ingasetyenziselwa ngaphandle kwempompo ye-slot extrusion (ubukhulu bobukhulu bunokufikelela malunga ne-30mm), kwaye umgaqo wokusebenza ufana nokucofa. I-torque efunekayo kwi-extrusion ebandayo yentambo yangaphakathi imalunga namaxesha angama-1 amakhulu kunokokucofa, kwaye ukuchaneka komatshini kunye nomgangatho womphezulu uphezulu kancinci kunoko wokucofa.

Iinzuzo zokuqengqeleka komsonto zezi zilandelayo:

① Uburhabaxa bomphezulu bungaphantsi kunokujika, ukungqusha, kunye nokusila;

② Umphezulu wentambo emva kokuqengqeleka unokuphucula amandla kunye nobunzima ngenxa yokuqina komsebenzi obandayo;

③ izinga lokusetyenziswa kwezinto liphezulu;

④ imveliso iphindwe kabini xa ithelekiswa nenkqubo yokusika, kwaye kulula ukuyiqonda i-automation;

⑤ ubomi benkonzo ye-rolling die bude kakhulu. Nangona kunjalo, ubunzima bomsebenzi we-workpiece abukho ngaphezu kwe-hrc40, ukuchaneka kobukhulu obungenanto bufunekayo ukuba buphakame, kwaye ukuchaneka kunye nobunzima be-rolling die nabo buphezulu, ngoko kunzima ukuvelisa ukufa. Ayifanelekanga kwimicu eneprofayili yokuqengqeleka eyi-asymmetric.

Ngokutsho kwee-dies ezahlukeneyo zokuqengqeleka, ukuqengqeleka komsonto kunokohlulwa kube ziindidi ezimbini: ukuqengqeleka komsonto kunye nokuqengqeleka kwentambo.

Iipleyiti ezimbini eziqengqelekayo ezinemisonto yeeprofayili ziyagxadazwa ngu-1/2 pitch, ipleyiti engatshintshiyo ilungisiwe, kwaye ipleyiti eshukumayo ihamba kumgca obuyelayo othe tye onxusene nepleyiti emileyo. Ukuba ufuna ukufunda inkqubo ye-UG kwiqela le-565120797, inokukunceda xa i-workpiece ifakwe kwiipleyiti ezimbini, uhambisa ipleyiti phambili ukuze uhlikihle kwaye ucinezele i-workpiece, ukwenza i-deformation yayo yeplastiki ibe ngumsonto.

Zintathu iindidi zokuqengqeleka: iradial, tangential, kunye nentloko eqengqelekayo.

① Ukuqengqeleka komsonto:Amavili amabini (okanye amathathu) afakwe kwimisonto yokuqengqeleka emise okwemisonto kwishafti ezinxuseneyo, i-workpiece ibekwe kwinkxaso phakathi kwamavili amabini, kwaye amavili amabini ajikeleza ngesantya esifanayo kwicala elinye, enye nayo yenza i-radial. intshukumo feed. Ivili elijikelezayo liqhuba i-workpiece ukuba ijikeleze, kwaye umphezulu ukhutshwe nge-radially ukwenza intambo. Indlela efanayo yokuqengqeleka ingasetyenziselwa ezinye izikrufu ezineemfuno ezichanekileyo ezisezantsi.

②ukuqengqeleka komsonto:ikwabizwa ngokuba kukuqengqeleka komsonto weplanethi. Isixhobo sokuqengqeleka siquka ivili elijikelezayo elijikelezayo eliphakathi kunye neepleyiti ezintathu ezizinzileyo ezimile okwearc. I-workpiece inokondliwa ngokuqhubekayo ngexesha lokuqengqeleka, ngoko ke imveliso iphezulu kunokuba i-thread rubbing kunye ne-radial rolling.

③ Ukuqengqeleka kwentloko yomsonto:iqhutyelwa kwi-lathe ezenzekelayo kwaye isetyenziselwa ngokubanzi ukucubungula intambo emfutshane kwi-workpiece. Kukho ii-roller ezi-3-4 ezisasazwa ngokufanayo kwi-workpiece. Xa uqengqeleka, i-workpiece ijikeleza, kwaye intloko eqengqelekayo itya i-axially ukuze ikhuphe i-workpiece ngaphandle kwentambo.

| CNC Machining Components | Okumangalisayo kweCNC Machining | Inkonzo ye-Intanethi ye-Cnc |

| Machining Aluminiyam iinxalenye | Izahlulo zeenqwelomoya zoomatshini | Ukwenziwa kweNsimbi yesiko |

| CNC Ukuqhubekeka | Iinxalenye zoomatshini bobhedu | I-CNC yobhedu iguqule iinxalenye |

www.anebon.com

I-Anebon Metal Products Limited inokubonelela ngomatshini we-CNC, ukuphosa ukufa, iinkonzo zomatshini wesinyithi, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Ixesha lokuposa: Oct-04-2019