Kutheni le nto izixhobo zoomatshini ezichanekileyo kufuneka zikhutywe ngesandla?

Ukukrwela yinkqubo engumceli-mngeni kakhulu eyodlula ukukrolwa komthi ngokuntsokothileyo. Isebenza njengesiseko esisisiseko semisebenzi yesixhobo esichanekileyo ngokuqinisekisa ukugqitywa ngokuchanekileyo komphezulu. Ukukrazula kuphelisa ukuthembela kwethu kwezinye izixhobo zoomatshini kwaye kunokususa ngokufanelekileyo ukutenxa okubangelwa ngamandla okubamba kunye namandla obushushu.

Iireyile ezikhutshiweyo azikwazi ukunxiba, ngokuyintloko ngenxa yempembelelo yazo ephezulu yokuthambisa. Umchwephesha we-scraping kufuneka azi kakuhle kwiindlela ezahlukeneyo, kodwa ubuchule babo bunokulungiswa kuphela ngamava ngamava, okwenza ukuba bafezekise ukuvakalelwa okuchanekileyo kunye nokugudileyo okufunekayo.

Ukukhuhla yindlela entsonkothileyo kunye nomngeni obandakanya ukususwa kwentsimbi kumphezulu. Yinkqubo esisiseko esetyenziswa kwimisebenzi yesixhobo esichanekileyo, ukuqinisekisa ukugqitywa ngokuchanekileyo komphezulu. Ukukrazula kuphelisa imfuno yezinye izixhobo zoomatshini kwaye kunokususa ngokufanelekileyo ukutenxa okubangelwa ngamandla okubamba kunye namandla obushushu.

Iireyile eziye zakhuhla zibonisa iimpawu eziphuculweyo zokuthambisa, ezikhokelela ekunciphiseni ukuguga nokukrazuka. Ukuba ligcisa lokukrala elinobuchule kufuna ukuqonda okunzulu kweendlela ezahlukeneyo, ezinokuhonjiswa kuphela ngamava ngamava. Ibenza ukuba bafezekise ukuziva okuchanekileyo kunye nokugudileyo okufunekayo ekusebenzeni kakuhle. Xa udlula kumzi-mveliso wokwenza izixhobo zoomatshini uze ubone amagcisa ekhuhla yaye esila ngesandla, akukwazi kuzibamba uzibuze: “Ngaba ngokwenene banokuwuphucula umgangatho olungiswa ngoomatshini ngokukhuhla nokusila?” (Abantu baya kuthi Ngaba unamandla ngakumbi kunomatshini?)”

Ukuba ubhekisa kuphela kwinkangeleko yayo, ke impendulo yethu ithi “hayi”, asiyi kuyenza ibe ntle ngakumbi, kodwa kutheni uyikrwela? Kukho izizathu zalo, ngokuqinisekileyo, kwaye enye yazo yinto yomntu: injongo yesixhobo somatshini kukwenza ezinye izixhobo zomatshini, kodwa ayinakuze iphinde ikhuphe imveliso ngokuchanekileyo kuneyokuqala. Ngoko ke, ukuba sifuna ukwenza umatshini ochane ngakumbi kunoomatshini bokuqala, kufuneka sibe nesiqalo esitsha, oko kukuthi, simele siqale ngemigudu yabantu. Kule meko, imigudu yabantu ibhekisela ekukhuhleni nasekusileni ngesandla.

Ukukrwela kunye nokusila ayisiyo "freehand" okanye "freehand" yokusebenza. Ngokwenyani yindlela yokukopa ephantse iphindaphinde ngokugqibeleleyo imatrix. Le matrix yinqwelomoya eqhelekileyo kwaye yenziwa ngesandla.

Nangona ukukhuhla kunye nokusila kunzima kwaye kunzima, bubuchule (ubugcisa bezinga lobugcisa); kusenokuba nzima ngakumbi ukuqeqesha ingcibi yokukrwela nokusila kunokuqeqesha igcisa lokuchwela. Azikho iincwadi ezininzi emarikeni ezixoxa ngesi sihloko. Ngokukodwa, kukho ulwazi oluncinci oluxubusha "kutheni ukukhuhla kuyimfuneko". Oku kusenokuba kutheni ukukrwela kuthathwa njengobugcisa.

Kwinkqubo yokuvelisa, kubalulekile ukugcina ukuchaneka kwiindawo eziveliswayo. Indlela esetyenzisiweyo ekufezekiseni oku kuchanekileyo ibaluleke kakhulu, njengoko ichaphazela ngokuthe ngqo umgangatho wemveliso yokugqibela. Ngokomzekelo, ukuba umenzi ukhetha ukusila ngesixhobo sokusila endaweni yokukhuhla, iintsimbi ezikwisixhobo sokusila “zomzali” zimele zicace ngakumbi kunezo zikwisixhobo sokusila esitsha.

Umbuzo ke uthi, ukuchaneka koomatshini bokuqala kwavela phi? Imele ukuba ivela kumatshini ochane ngakumbi okanye ixhomekeke kwenye indlela yokuvelisa umphezulu othe tyaba ngokwenene okanye mhlawumbi ikhutshelwe kumphezulu osele wenziwe kakuhle.

Ukubonisa ingcamango yokudalwa komhlaba, sinokusebenzisa iindlela ezintathu zokuzoba izangqa. Nangona izangqa ziyimigca ingeyiyo imiphezulu, zinokunceda ekuchazeni umbono. Umchweli onobuchule unokuzoba isangqa esipheleleyo ngekhampasi eqhelekileyo. Nangona kunjalo, ukuba balandelela ipensile emngxunyeni kwitemplate yeplastiki, baya kuphinda baphindaphinde zonke izinto ezingachanekanga emngxunyeni. Ukuba bazama ukuyizoba ngokukhululekileyo, ukuchaneka kwesangqa kuxhomekeke kwizakhono zabo ezilinganiselweyo.

Ukuba umenzi ugqiba kwelokuba asile ngesixhobo sokusila endaweni yokukhuhla, iintsimbi ezikwisixhobo sokusila “zomzali” wakhe kufuneka zichane ngakumbi kunomatshini omtsha wokugaya.

Ngoko kwavela phi ukuchaneka koomatshini bokuqala?

Imele ukuba ivela kumatshini ochane ngakumbi okanye ixhomekeke kwenye indlela yokuvelisa umphezulu othe tyaba ngokwenene okanye mhlawumbi ikhutshelwe kumphezulu osele wenziwe kakuhle.

Singasebenzisa iindlela ezintathu zokuzoba izangqa ukubonisa inkqubo yokudala umphezulu (nangona izangqa ziyimigca kwaye ingeyiyo imiphezulu, zinokucatshulwa ukubonisa ingcamango). Umchwephesha unokuzoba isangqa esipheleleyo ngekhampasi eqhelekileyo; ukuba ulandelela ipensile emngxunyeni kwi-template yeplastiki, uya kuphinda aphindaphinde zonke izinto ezingachanekanga emngxunyeni; ukuba uyayitsala freehand, Ngokubhekiselele kwisangqa, ukuchaneka kwesangqa kuxhomekeke kwizakhono zakhe ezilinganiselweyo.

Ngokwethiyori, umphezulu othe tyaba ogqibeleleyo unokuveliswa ngokutshintshana kwe-friction (i-lapping) yemigangatho emithathu. Ukuze kube lula, makhe sibonise ngamatye amathathu, ngalinye linomphezulu othe tyaba. Ukuba uhlikihla le miphezulu mithathu ngokutshintshanayo ngokulandelelana, uya kusila imiphezulu emithathu imtyibilizi kwaye imtyibilizi. Ukuba uhlikihla amatye amabini nje kunye, uya kuphelela ngokudibana kweqhuma elinye kunye neqhuma elinye. Ngokwesiqhelo, ukongeza ekusebenziseni i-scraping endaweni yokunxiba (Lapping), kuya kulandelwa ulandelelwano olucacileyo lokudibanisa. Abaphathi be-scraping ngokubanzi basebenzisa lo mgaqo ukwenza i-jig esemgangathweni (i-gauge echanekileyo okanye i-flat plate) abafuna ukuyisebenzisa.

Xa usebenzisa, i-scraper master iya kuqala ifake umthuthukisi wombala kwi-jig eqhelekileyo, kwaye emva koko isilayidi phezu kwendawo yokusebenza ukuze ibonise iindawo ezifuna ukuchithwa. Uqhubeka ephindaphinda esi senzo, kwaye umphezulu we-workpiece uya kusondela kwaye usondele kwi-jig eqhelekileyo, kwaye ekugqibeleni, unokukopisha ngokugqibeleleyo umsebenzi ofana ne-jig eqhelekileyo.

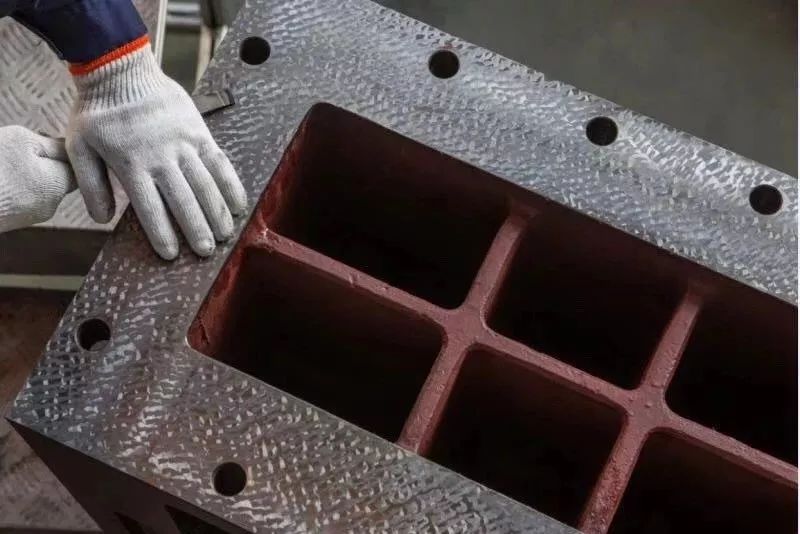

Iicastings ezifuna ukugqitywa ziyacolwa ukuba zibe nkulu kancinane kunobungakanani bokugqibela, kwaye emva koko zithunyelwe kunyango lobushushu ukukhulula uxinzelelo olushiyekileyo. Emva koko, ii-castings ziphantsi kokugqiba ukucolwa komhlaba ngaphambi kokuba kukhuhlwe. Nangona inkqubo ye-scraping ifuna ubuninzi bexesha, abasebenzi kunye neendleko, inokuthi ithathe indawo yesidingo sezixhobo eziphezulu, eziza kunye nexabiso eliphezulu. Ukuba i-scraping ayisetyenziswanga, i-workpiece kufuneka igqitywe ngokusebenzisa umatshini obiza kakhulu, ochanekileyo, okanye uhambe ngokulungiswa kweendleko.

Kwinkqubo yokugqiba iinxalenye, ngokukodwa ii-castings ezinkulu, ukusetyenziswa kwezenzo zokubethelwa komxhuzulane kudla ngokuyimfuneko. I-clamping force, xa ukuqhutyelwa phambili kufikelela kumawaka ambalwa okuchaneka okuphezulu, nangona kunjalo, kunokubangela ukuphazamiseka komsebenzi, ukubeka engozini ukuchaneka komsebenzi emva kokukhulula amandla okubamba. Ukongeza, ubushushu obuveliswe ngexesha lokucutshungulwa bunokubangela ukuphazamiseka komsebenzi. I-scraping, kunye neenzuzo zayo, iza luncedo kwiimeko ezinjalo. Akukho mandla okubamba, kwaye ubushushu obuveliswa kukukhuhla buphantse bungabikho. Izixhobo zokusebenza ezinkulu zixhaswa kumanqaku amathathu ukuqinisekisa ukuba azikhubeki ngenxa yobunzima bazo.

Xa i-scraping track yesixhobo somatshini igugile, inokuphinda ilungiswe ngokukhuhla. Le yinzuzo ebalulekileyo xa kuthelekiswa nenye indlela yokulahla umatshini okanye ukuyithumela kumzi-mveliso ukuze idityaniswe kwaye iphinde ilungiswe. Abasebenzi bokulungisa umzi-mveliso okanye iingcali zasekuhlaleni zinokwenza umsebenzi wokukhuhla nokusila.

Kwezinye iimeko, i-manual scraping kunye ne-power scraping ingasetyenziswaed ukuphumeza ukuchaneka kokugqibela kwejiyometri okufunekayo. I-master scraping master enokugqiba olu hlobo lolungiso ngexesha elifutshane elimangalisayo. Nangona le ndlela ifuna iteknoloji yezakhono, ixabisa ngakumbi kunokusebenza inani elikhulu lamacandelo ukuba ichaneke kakhulu, okanye ukwenza uyilo oluthembekileyo okanye oluhlengahlengisiweyo ukuthintela iimpazamo zolungelelwaniso. Nangona kunjalo, kubalulekile ukuqaphela ukuba esi sisombululo akufanele sisetyenziswe njengendlela yokulungisa iimpazamo ezibalulekileyo zokulungelelanisa, njengoko kwakungeyona injongo yayo yokuqala.

Ukuphuculwa kokuthambisa

Kwinkqubo yokwenziwa kwecastings, ukugqiba kufuna ukugawula iicastings zibe nkulu kancinane kunobukhulu bazo bokugqibela, kulandele unyango lobushushu ukukhulula uxinzelelo olushiyekileyo. Iicastings ke ziphantsi kokugqiba ukugrumba kunye nokukhuhla. Nangona inkqubo ye-scraping ichitha ixesha kwaye iyabiza, inokuthi ithathe indawo yesidingo sezixhobo eziphezulu eziza kunye nexabiso eliphezulu. Ngaphandle kokukrazula, ukugqiba i-workpiece kufuna umatshini obiza kakhulu, ochanekileyo ophezulu okanye ukulungiswa kweendleko.

Amanyathelo okubamba umxhuzulane asoloko efuneka xa kugqitywa iinxalenye, ingakumbi iicastings ezinkulu. Nangona kunjalo, amandla okubamba anokubangela ukugqwetheka kwesixhobo sokusebenza, kubeka emngciphekweni ukuchaneka emva kokukhulula amandla okubamba. I-scraping iza luncedo kwiimeko ezinjalo, njengoko kungekho mandla okubamba, kwaye ubushushu obuveliswa ngokukhuhla buphantse bungabikho. Izixhobo zokusebenza ezinkulu zixhaswa kumanqaku amathathu ukukhusela ukuguqulwa ngenxa yobunzima babo.

Xa i-scraping track yesixhobo somatshini igugile, inokulungiswa ngokutsha ngokukrazula, eyona nto ibiza kakhulu kunokulahla umatshini okanye ukuyithumela kumzi-mveliso ukuchithwa kunye nokulungiswa kwakhona. Ukukrwela ngesandla kunye namandla kungasetyenziswa ukufezekisa ukuchaneka kokugqibela kwejometri efunekayo. Nangona le ndlela ifuna iteknoloji enezakhono, ineendleko-esebenzayo ngaphezu processing inani elikhuluiindawo zomatshiniukuchaneka kakhulu okanye ukwenza uyilo oluthembekileyo okanye olulungelelanisiweyo ukunqanda iimpazamo zolungelelwaniso. Nangona kunjalo, kubalulekile ukuqaphela ukuba esi sisombululo akufanele sisetyenziswe ukulungisa iimpazamo ezibalulekileyo zokulungelelanisa, njengoko kwakungeyona injongo yayo yokuqala. Ukuphuculwa kokuthambisa

Amava asebenzayo abonise ukuba ukukrazula iileyili kunokunciphisa ukungqubana ngokuthambisa umgangatho ongcono, kodwa akukho mvumelwano malunga nokuba kutheni. Olona luvo luxhaphakileyo kukuba amabala akhutshiweyo asezantsi (okanye ngakumbi, iidimples ezigrunjiweyo, iipokotho zeoyile ezongezelelweyo zokuthambisa) zibonelela ngeepokotho ezininzi zeoyile, ezifunxwa ziindawo ezininzi ezincinci ezingqongileyo. Yikhuphe.

Enye indlela yokubeka ingqiqo kukuba ivumela ukuba siqhubeke sigcina ifilimu yeoli apho iindawo ezihambayo zihambayo, eyona njongo yazo zonke i-lubrication. Isizathu esona sizathu sokuba oku kwenzeke kukuba ezi pokotho zeoli ezingaqhelekanga zenza indawo eninzi yokuhlala kweoli, okwenza kube nzima ukuba ioli ibaleke ngokulula. Imeko efanelekileyo yokuthambisa kukugcina ifilimu yeoli phakathi kweendawo ezimbini ezigudileyo ngokugqibeleleyo, kodwa ke kufuneka ujongane nokuthintela i-oyile ukuba ingaphumi, okanye ifune ukuyizalisa ngokukhawuleza. (Kungakhathaliseki ukuba kukho ukukrazula kumphezulu womzila okanye akunjalo, i-oil grooves idla ngokuncedisa ukuhanjiswa kweoli).

Ingxelo enjalo iya kwenza abantu bathandabuze umphumo wendawo yoqhagamshelwano. Ukukrwela kunciphisa indawo yoqhagamshelwano kodwa kudala usasazo olulinganayo, kwaye ukusabalalisa yinto ebalulekileyo. I-flatterer ezimbini ezihambelanayo, iindawo zokudibanisa ziya kusasazeka ngokulinganayo. Kodwa kukho umgaqo kumatshini wokuba “ingxabano ayinanto yakwenza nommandla.” Esi sivakalisi sithetha ukuba ingaba indawo yoqhagamshelwano i-10 okanye i-100 intshi yesikwere, amandla afanayo afunekayo ukuhambisa i-workbench. (Ukunxiba ngomnye umcimbi. Incinci indawo ephantsi komthwalo ofanayo, kokukhona ukunxiba ngokukhawuleza.)

Inqaku endifuna ukulenza kukuba into esiyijongayo kukuthambisa okungcono, hayi ngaphezulu okanye ngaphantsi kwendawo yoqhagamshelwano. Ukuba i-lubrication ayinasiphako, umphezulu womzila awusoze uguge. Ukuba itheyibhile inobunzima bokuhamba njengoko iguga, oku kunokuhambelana nokuthambisa, kungekhona indawo yoqhagamshelwano.

Kwenziwa njani ukukrwela?

Ngaphambi kokufumana iindawo eziphakamileyo ekufuneka zikhutshiwe, sebenzisa kuqala umphuhlisi wombala kwi-jig esemgangathweni (i-flat plate okanye i-jig eqondileyo xa ukhuhla iileyili ezibunjwa ngu-V), uze ubeke umphuhlisi wombala kwi-jig eqhelekileyo. Ngokuhlikihla kumzila womkhondo oza kuhlatywa ngefosholo, umphuhlisi wombala uya kudluliselwa kwiindawo eziphakamileyo zomkhondo womkhondo, kwaye ke isixhobo esikhethekileyo sokukrala sisetyenziselwa ukususa amanqaku aphezulu ophuhliso lombala. Esi senzo kufuneka siphindwe de kube umphezulu womzila ubonisa ukuhanjiswa okufanayo.

Ngokuqinisekileyo, i-scraping master kufuneka ikwazi iindlela ezahlukeneyo. Makhe ndithethe ngezimbini zazo apha:

Kwinkqubo yokwenziwa kwecastings, ukugqiba kufuna ukugawula iicastings ezinkulu kancinci kunobukhulu bazo bokugqibela, kulandelwa lunyango lobushushu ukukhulula uxinzelelo olushiyekileyo. Iicastings ke ziphantsi kokugqiba umphezulu wokusila kunye nokukhuhla. Nangona inkqubo ye-scraping ichitha ixesha kwaye iyabiza, inokuthi ithathe indawo yesidingo sezixhobo eziphezulu eziza kunye nexabiso eliphezulu. Ngaphandle kokukrazula, ukugqiba i-workpiece kufuna umatshini obiza kakhulu, ochanekileyo ophezulu okanye ukulungiswa kweendleko.

Xa ugqibezela iinxalenye, ingakumbi iicastings ezinkulu, iintshukumo zomxhuzulane zisoloko zifuneka. Nangona kunjalo, amandla okubamba anokubangela ukugqwetheka kwesixhobo sokusebenza, kubeka emngciphekweni ukuchaneka emva kokukhulula amandla okubamba. I-scraping iza luncedo kwiimeko ezinjalo, njengoko kungekho mandla okubamba, kwaye ubushushu obuveliswa ngokukhuhla buphantse bungabikho. Izixhobo zokusebenza ezinkulu zixhaswa kumanqaku amathathu ukukhusela ukuguqulwa ngenxa yobunzima babo.

Xa i-scraping track yesixhobo somatshini igugile, inokulungiswa ngokutsha ngokukrazula, eyona nto ibiza kakhulu kunokulahla umatshini okanye ukuyithumela kumzi-mveliso ukuchithwa kunye nokulungiswa kwakhona. Ukukrwela ngesandla kunye namandla kungasetyenziswa ukufezekisa ukuchaneka kokugqibela kwejometri efunekayo. Nangona le ndlela ifuna iteknoloji enezakhono, ineendleko-esebenzayo ngaphezu processing inani elikhuluiindawo zecncukuchaneka kakhulu okanye ukwenza uyilo oluthembekileyo okanye olulungelelanisiweyo ukunqanda iimpazamo zolungelelwaniso. Nangona kunjalo, kubalulekile ukuqaphela ukuba esi sisombululo akufanele sisetyenziswe ukulungisa iimpazamo ezibalulekileyo zokulungelelanisa, njengoko kwakungeyona injongo yayo yokuqala.

Amava asebenzayo abonise ukuba ukukrazula iileyili kunokunciphisa ukungqubana ngokuthambisa umgangatho ongcono, kodwa akukho mvumelwano malunga nokuba kutheni. Olona luvo luxhaphakileyo kukuba amabala akhutshiweyo asezantsi (okanye ngakumbi, iidimples ezigrunjiweyo, iipokotho zeoyile ezongezelelweyo zokuthambisa) zibonelela ngeepokotho ezininzi zeoyile, ezifunxwa ziindawo ezininzi ezincinci ezingqongileyo. Ukukrwela kunciphisa indawo yoqhagamshelwano kodwa kudala usasazo olulinganayo, kwaye ukusabalalisa yinto ebalulekileyo. I-flatterer ezimbini ezihambelanayo, iindawo zokudibanisa ziya kusasazeka ngokulinganayo. Kodwa kukho umgaqo kumatshini wokuba “ingxabano ayinanto yakwenza nommandla.” Esi sivakalisi sithetha ukuba ingaba indawo yoqhagamshelwano i-10 okanye i-100 intshi yesikwere, amandla afanayo afunekayo ukuhambisa i-workbench. (Ukunxiba ngomnye umcimbi. Incinci indawo ephantsi komthwalo ofanayo, kokukhona ukunxiba ngokukhawuleza.)

Inqaku lelokuba into esiyifunayo kukuthambisa okungcono, hayi ngaphezulu okanye ngaphantsi kwendawo yoqhagamshelwano. Ukuba i-lubrication ayinasiphako, umphezulu womzila awusoze uguge. Ukuba itheyibhile inobunzima bokuhamba njengoko iguga, oku kunokuthi kunxulumene nokuthambisa, kungekhona indawo yoqhagamshelwano.Okokuqala, ngaphambi kokuba senze uphuhliso lombala, ngokuqhelekileyo sisebenzisa ifayile engabonakaliyo ukuze sihlikihle ngobunono phezu kwendawo yokusebenza ukuze susa i-burrs.

Okwesibini, sula umphezulu ngebrashi okanye izandla zakho, ungalokothi ube ne-rag. Ukuba usebenzisa ilaphu ukosula, imigca emihle eshiywe lilaphu iya kubangela amanqaku alahlekisayo kwixesha elizayo xa usenza uphuhliso lombala ophezulu.

Inkosi ye-scraping ngokwayo iya kujonga umsebenzi wayo ngokuthelekisa i-jig esemgangathweni kunye nomphezulu womzila. Umhloli ufuna kuphela ukuxelela inkosi ye-scraping xa imisa umsebenzi, kwaye akukho mfuneko yokukhathazeka malunga nenkqubo yokukrazula. (Inkosi yokukrwela inokuba noxanduva lomgangatho womsebenzi wayo)

Sasihlala sinemigangatho yemigangatho echaza ukuba mangaphi amabala aphakamileyo kufuneka abe ne-intshi nganye yesikwere, kwaye yiyiphi ipesenti yendawo yonke ekufuneka idibene nayo; kodwa siye safumanisa ukuba ukujonga indawo yoqhagamshelwano phantse akunakwenzeka, kwaye ngoku konke kwenziwa ngokukhuhla I master grinder imisela inani lamachaphaza nge-intshi nganye yesikwere. Ngamafutshane, iinkosi zokukrwela ngokubanzi zizama ukufikelela umgangatho wama-20 ukuya kuma-30 amachaphaza nge-intshi nganye yesikwere.

Kwinkqubo ye-scraping yangoku, oomatshini bokutshiza bombane basetyenziselwa imisebenzi ethile yokulinganisa. Zikwaluhlobo lokukhuhla ngesandla, kodwa zinokuphelisa umsebenzi onzima kwaye zenze umsebenzi wokukhuhla ungadinwa. Akukabikho nto ithatha indawo yemvakalelo yokukhuhla ngesandla xa usenza owona msebenzi ubuthathaka.

I-Anebon ixhomekeke kumandla obugcisa owomeleleyo kwaye ngokuqhubekayo idala itekhnoloji ephucukileyo ukuhlangabezana nemfunoCNC metal machining, i-5-axis ye-CNC yokugaya, kunye neemoto zokuphosa. Zonke izimvo kunye neengcebiso ziya kuthakazelelwa kakhulu! Intsebenziswano elungileyo ingasiphucula sobabini kuphuhliso olungcono!

ODM ManufacturerChina Customized aluminiyam iiNdawo zokusilakunye namalungu oomatshini okwenza, Okwangoku, izinto ze-Anebon zithunyelwe kumazwe angaphezu kwamashumi amathandathu kunye nemimandla eyahlukeneyo, njengaseMzantsi-mpuma Asia, eMelika, eAfrika, eMpuma Yurophu, eRashiya, eKhanada, njl njl. abathengi zombini e China kunye nenxalenye yehlabathi.

Ixesha lokuposa: Mar-05-2024