Progressive die stamping

Progressive die presses sebenzisa intshukumo nkqo xa processing Slit coil metal. Imisebenzi yokugoba kunye nokusika yenziwa ngaxeshanye kwi-mold ukugqiba ubuncinane inxalenye enye kwi-stroke nganye yomatshini. Izinto ezidibeneyo zondliwa ngokubumba kwaye zicutshungulwe ngesinyathelo ngesinyathelo. Ngokuxhomekeke kubunzima benxalenye, i-progressive die dies inokuba mbalwa njengenyathelo elinye okanye amanyathelo angama-40 amaninzi. Ngenxa yokuba ubume benkqubo bufuna ukuba izinto eziphathekayo zityhalelwe kwisikhululo esilandelayo ngexesha lokubetha kwesixhobo ngasinye, ukufa okuqhubekileyo kufuneka kuqala kukukhokele izinto eziphathekayo ukuze kubekwe izinto eziphathekayo ngaphakathi kwefa ngaphambi kokusika kunye nokwenza. Isidingo semingxuma yokulinga kwimicu yemathiriyeli eqhubekayo ngamanye amaxesha ikhokelela kwinkunkuma eninzi kakhulu kwinkqubo.isitampu inxalenye

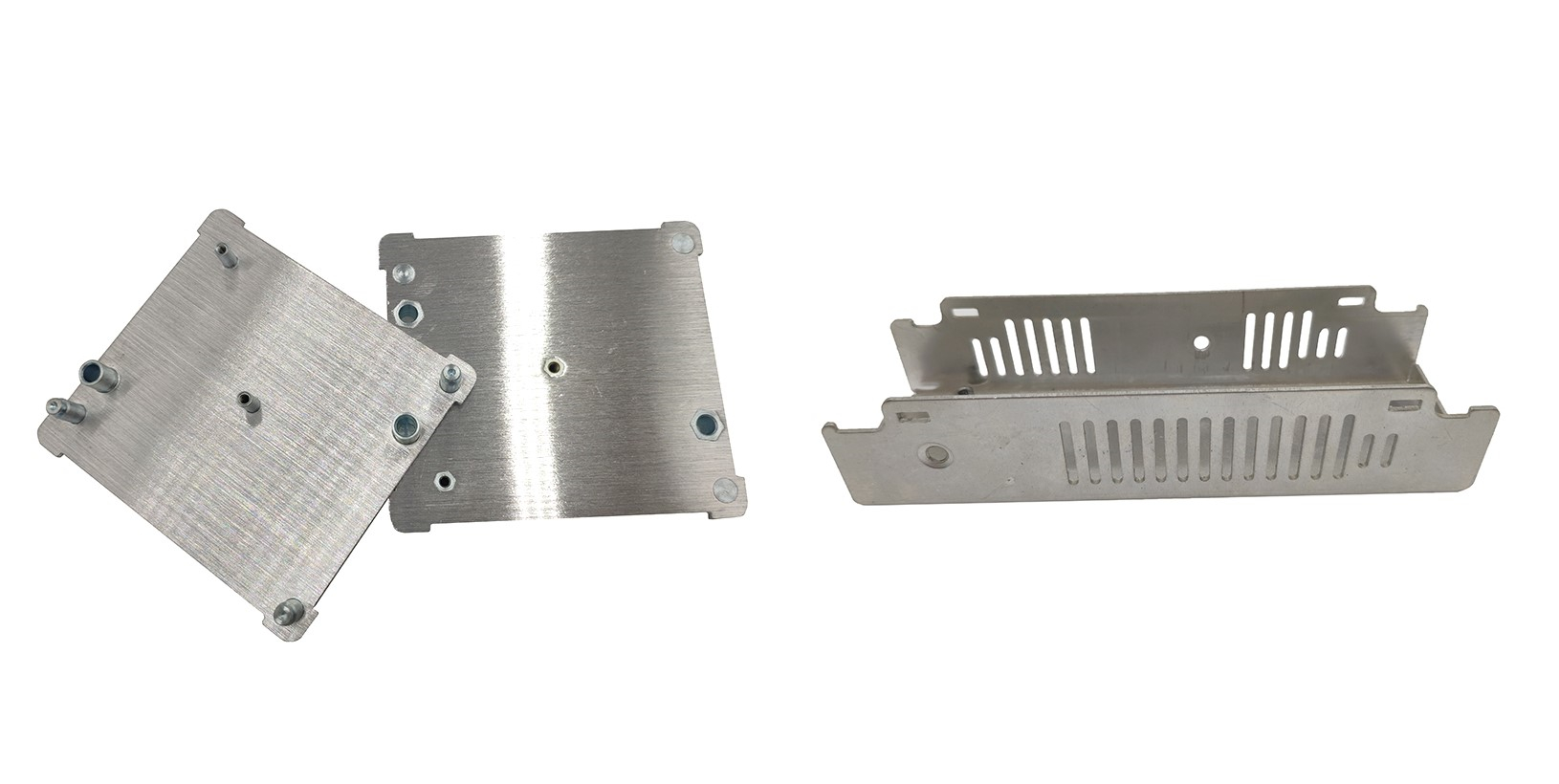

Nangona kunjalo, ixesha lofakelo lokufa kwe-progressive lincitshiswe ngama-38% xa kuthelekiswa ne-4-slide die okanye i-multi-slide die. Oku kuvumela abavelisi ukuba bavelise iibhetshi ezincinci kunye nokuguquguquka ngakumbi kwizicwangciso zemveliso, ukuvelisa kuphela iimveliso abazidingayo xa zifuneka. Umgaqo oqaliswe yinjineli yaseJapan yaseJapan uShigeo Shingo: I-SMED (utshintsho lokufa lomzuzu omnye) lunokusetyenziswa kumatshini wokushicilela oqhubekayo, nto leyo iyindlela eqhelekileyo kaKeats. Ukufa okuqhubekekayo kunokuvelisa iindawo ezininzi nge-stroke, zizenze zilungele imveliso yobuninzi:

pier

izibiyeli

Isakhelo esikhokelayo

Ibhasi

Ikhaka

Isilayidi esine / isitampu esinezilayidi ezininzi

Njengoko igama lisitsho, umatshini wesitampu wentsimbi onezilayidi ezine uneebhodi ezine ezishukumayo zokutyibilika. Ngokwahlukileyo, umatshini wokucofa izilayidi ezininzi unokuba neziliphu ezine ezihambayo ezifayo. Izitampu zetsimbi ezine-slide okanye ezininzi zisebenza kwii-angles ezichanekileyo ngokuthe tye, kunye nezilayidi (iinkunzi) kumatshini zichaphazela izinto zekhoyili ukuvelisa imveliso egqityiweyo.isitampu sentsimbi

Iinjini zeServo okanye iikhamera eziqhutywa ngoomatshini ezisebenza kwisilayidi zinokuvelisa iingqiniba ezintsonkothileyo kunye neemilo. Ngolu hlobo lomatshini, iintambo, ukufakwa kwe-screw, i-riveting, kunye neminye imisebenzi yendibano yexabiso elongeziweyo inokongezwa.ukugoba inxalenye

Xa kuthelekiswa nenkqubela-phambili yokunyathela, isilayidi esine kunye nezityibilizi ezininzi kunciphisa inkunkuma ngomyinge wama-31%. Oku kuphunyezwa ngokuphelisa isidingo somngxuma wesikhokelo kunye nokutshintsha umsebenzi wesikhokelo kunye nomnini ongenanto ofakiweyo, ovumela inxalenye ukuba itshintshe ukusuka ekubetheni ukuya ekubunjweni ngaphandle kwemfuneko yesikhokelo. Iikethi nazo zinokuthenga izinto eziluhlaza ngokusekwe kububanzi obuchanekileyo benxalenye kwaye ziphelise ukucheba. Kuba imveliso yesilayidi ezine ivumela ukusetyenziswa kwenani elingenamkhawulo leenqwelomoya kunye namazembe, inokuvelisa ukuya kuthi ga kwi-375 iinxalenye ngomzuzu, iyenze ilungele ukuveliswa kobuninzi beendawo ezintsonkothileyo ezifana:

Ifilimu emfutshane

ibamba

Isiqhoboshi

ukubhuqa

umhlathi

Idyokhwe

I-Anebon Metal Products Limited inokubonelela ngomatshini we-CNC, ukuphosa ukufa, iinkonzo zomatshini wesinyithi, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Ixesha lokuposa: Jan-15-2020