Ukuchaneka kweeparamitha zejiyometri zamalungu oomatshini kuphenjelelwa zizo zombini impazamo yobukhulu kunye nempazamo yokumila. Uyilo lwecandelo loomatshini luhlala luchaza ukunyamezelwa kwe-dimensional kunye nokunyamezela kwejometri ngaxeshanye. Nangona kukho iiyantlukwano kunye nokudibanisa phakathi kwezi zimbini, iimfuno zokuchaneka kweeparamitha zejometri zigqiba ubudlelwane phakathi kokunyamezela kwejometri kunye nokunyamezela kwe-dimensional, ngokuxhomekeke kwiimeko zokusetyenziswa kwecandelo lomatshini.

1. Imigaqo emininzi yonyamezelo malunga nobudlelwane phakathi konyamezelo lwedimensional kunye nokunyamezelana kwejometri.

Imigaqo yokunyamezelana yimigaqo emisela ukuba ukunyamezela kwe-dimensional kunye nokunyamezela kwejometri kunokusetyenziswa ngokutshintshisanayo okanye cha. Ukuba oku kunyamezelana akukwazi ukuguqulwa komnye nomnye, kuthathwa njengemigaqo ezimeleyo. Ngakolunye uhlangothi, ukuba ukuguqulwa kuvunyelwe, ngumgaqo ohambelanayo. Le mithetho-siseko iphinda ihlelwe ngokweemfuno ezibandakanyayo, ezona mfuno ziphezulu zequmrhu, ubuncinane beemfuno zequmrhu, kunye neemfuneko ezinokubuyiselwa umva.

2. Isigama esisisiseko

1) Ubungakanani bendawo yokwenyani D al, d al

Umgama olinganiselwa phakathi kwamanqaku amabini ahambelanayo kulo naliphi na icandelo eliqhelekileyo lophawu lokwenyani.

2) Ubungakanani besenzo sangaphandle D fe, d fe

Le nkcazo ibhekiselele kububanzi okanye ububanzi bowona mphezulu mkhulu ofanelekileyo odityaniswe ngaphandle kowona mgangatho wangaphakathi okanye owona mphezulu omncinci ofanelekileyo odityaniswe ngaphandle kumphezulu wenene wangaphandle kubude obunikiweyo bophawu olulinganiswayo. Kwiimpawu ezihambelanayo, i-axis okanye iplani ephakathi yendawo efanelekileyo kufuneka igcine ubudlelwane bejometri obunikwe ngumzobo kunye nedatum.

3) Ubungakanani besenzo se-vivo D fi, d fi

Idayamitha okanye ububanzi bowona mphezulu umncinci ufanelekileyo kunxibelelwano lomzimba nowona mgangatho wangaphakathi wokwenene okanye owona mphezulu mkhulu ufanelekileyo kuqhagamshelo lomzimba kunye nomphandle wenene ongaphandle kubude obunikiweyo bophawu olulinganiswayo.

4) Ubungakanani obukhulu obusebenzayo bomzimba we-MMVS

Ubukhulu besayizi obusebenzayo bomzimba bubhekisa kubungakanani besiphumo sangaphandle kwimeko apho busebenza kakhulu ngokwasemzimbeni. Xa kuziwa kumphezulu wangaphakathi, ubungakanani obukhulu obuqinileyo obusebenzayo bubalwa ngokukhupha ixabiso lokunyamezela kwejometri (eboniswe ngesimboli) ukusuka kubukhulu obukhulu obuqinileyo. Ngakolunye uhlangothi, kumphezulu wangaphandle, ubukhulu becala obuqinileyo obusebenzayo bubalwa ngokongeza ixabiso lokunyamezela kwejometri (kwakhona kuboniswe ngesimboli) kubukhulu obuqinileyo.

MMVS= MMS± T-shape

Kwifomula, umphezulu wangaphandle umelwe ngumqondiso "+", kwaye umgangatho wangaphakathi umelwe ngumqondiso "-".

5) Ubuncinci bobungakanani obusebenzayo bomzimba LMVS

Ubuncinane bobungakanani obusebenzayo bequmrhu bubhekisa kubungakanani bomzimba xa ukwimeko esebenzayo. Xa kubhekiselwa kumphezulu wangaphakathi, ubuncinci besayizi obusebenzayo bomzimba bubalwa ngokongeza ixabiso lokunyamezela kwejometri kubungakanani obuncinci bomzimba (njengoko kuboniswe ngesimboli kumfanekiso). Ngakolunye uhlangothi, xa ubhekisela kumphezulu wangaphandle, ubungakanani obuncinci bomzimba obusebenzayo bubalwa ngokukhupha ixabiso lokunyamezela kwejometri ukusuka kubukhulu obuncinane bomzimba (nabo buboniswa ngumqondiso kumfanekiso).

LMVS= LMS ±t-shape

Kwifomula, indawo yangaphakathi ithatha uphawu "+", kwaye indawo yangaphandle ithatha uphawu "-".

3. Umgaqo wokuzimela

Umgaqo wokuzimela ngumgaqo wokunyamezela osetyenziswa kuyilo lobunjineli. Oku kuthetha ukuba ukunyamezela kwejometri kunye nokunyamezela kwe-dimensional kuchazwe kumzobo kwahlukile kwaye akukho nxu lumano omnye komnye. Zombini ukunyamezelana kufuneka zihlangabezane neemfuno zazo ezithile ngokuzimeleyo. Ukuba ukunyamezela imilo kunye nokunyamezela kwe-dimensional kulandela umgaqo wokuzimela, ixabiso labo lamanani kufuneka liphawulwe kumzobo ngokwahlukileyo ngaphandle kweempawu ezongezelelweyo.

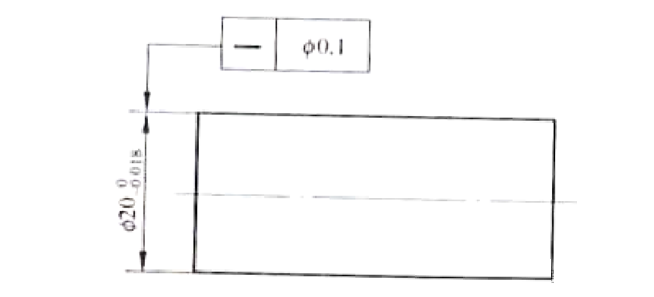

Ukuze kuqinisekiswe umgangatho weengxenye ezivezwe kumfanekiso, kubalulekile ukuqwalasela ukunyamezela kwe-dimensional ye-shaft diameter Ф20 -0.018 kunye nokunyamezela ngokuthe tye kwe-axis Ф0.1 ngokuzimeleyo. Oku kuthetha ukuba imilinganiselo nganye kufuneka ihlangabezane neemfuno zoyilo ngokwayo, kwaye ke ngoko kufuneka ihlolwe ngokwahlukeneyo.

Ububanzi be-shaft kufuneka buwele phakathi koluhlu lwe-Ф19.982 ukuya kwi-20, kunye nephutha elivumelekileyo lokuchaneka phakathi koluhlu lwe-Ф0 ukuya kwi-0.1. Nangona elona xabiso liphezulu lobungakanani bedayamitha ye-shaft yokwenyani inokwandisa ukuya kwiФ20.1, ayifuni kulawulwa. Umgaqo wokuzimela uyasebenza, oku kuthetha ukuba i-diameter ayihlolisiswa ngokupheleleyo.

4. Umgaqo wokunyamezelana

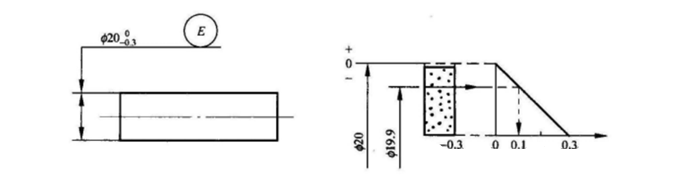

Xa umfanekiso wesimboli ubonakala emva kokutenxa komda wedimensional okanye ikhowudi yendawo yokunyamezela yento enye kumzobo, oko kuthetha ukuba into enye ineemfuno zokunyamezelana. Ukuhlangabezana neemfuno zokuqulatha, olona phawu kufuneka luhambelane nowona mda womzimba uphezulu. Ngamanye amazwi, ubungakanani obubambeleyo bangaphandle bophawu akufunekanga bugqithe kumda walo ophezulu womzimba, kwaye ubungakanani bendawo obuyinyani akufunekanga bube buncinci kunobungakanani bomzimba obusezantsi.

Inani libonisa ukuba ixabiso le-dfe kufuneka libe ngaphantsi okanye lilingane ne-20mm, ngelixa ixabiso le-dal kufuneka libe likhulu okanye lilingane ne-19.70mm. Ngexesha lokuhlolwa, i-cylindrical surface iya kuthathwa ifanelekile ukuba inokudlula kwi-gauge ye-shape-shape kunye nobubanzi be-20mm kwaye ukuba ubungakanani bendawo bendawo bulinganiswe kumanqaku amabini bukhulu okanye bulingana ne-19.70mm.

Imfuno yonyamezelo yimfuneko yonyamezelo elawula ngaxeshanye ubungakanani obububo kunye neempazamo zemilo ngaphakathi koluhlu lonyamezelo lwe-dimensional.

5. Ezona mfuno ziphezulu zequmrhu kunye neemfuno zabo zokubuyela umva

Kumzobo, xa umfanekiso wesimboli ulandela ixabiso lonyamezelo kwibhokisi yokunyamezela yejometri okanye ileta yereferensi, oko kuthetha ukuba into elinganisiweyo kunye nesalathiso sesalathisi samkele iimfuno eziphezulu zomzimba. Masithi umfanekiso ubhalwe emva komfanekiso wesimboli emva kwexabiso lokunyamezela kwejometri yento elinganisiweyo. Kwimeko apho, kuthetha ukuba imfuneko ebuyiselwa umva isetyenziselwa eyona mfuno iqinileyo.

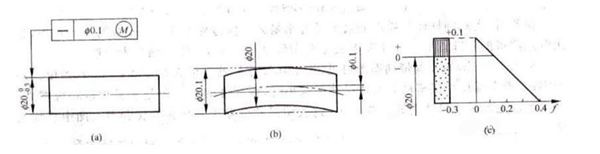

I-1) Ubuninzi obufunekayo bequmrhu busebenza kwizinto ezilinganisiweyo

Xa ulinganisa uphawu, ukuba ubuninzi bemfuno yokuqina buyasetyenziswa, ixabiso lonyamezelo lwejiyometri yefitsha liya kunikwa kuphela xa ifitsha ikubume obuqinileyo obuphezulu. Nangona kunjalo, ukuba i-contour yokwenyani yophawu iyatenxa kubume bayo obuqinileyo obuphezulu, okuthetha ukuba ubungakanani bendawo obuyinyani bohlukile kubungakanani bobungakanani obuqinileyo, ubume kunye nexabiso lempazamo lendawo linokugqithisa ixabiso lonyamezelo elinikiweyo kubume obuphezulu obuqinileyo, kwaye ubuninzi bemali egqithileyo iyakulingana nobona mgangatho uqinileyo. Kubalulekile ukuqaphela ukuba ukunyamezela kwedimensional ye-elementi elinganisiweyo kufuneka kube ngaphakathi kobukhulu bayo kunye nobukhulu bomzimba obuncinane, kwaye ubukhulu bayo bendawo abufanele bugqithise ubukhulu bayo bomzimba.

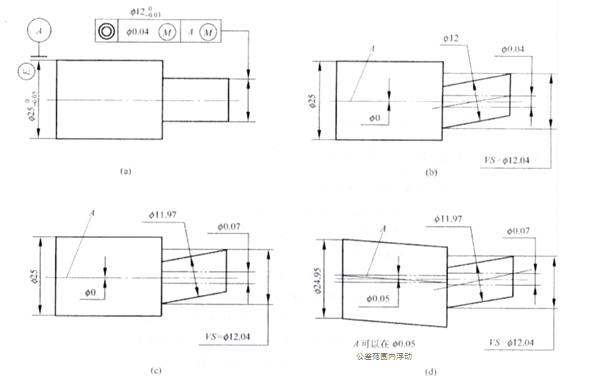

Umzobo ubonisa ukunyamezela okuthe tye kwe-axis, ehambelana neyona mfuno iphezulu yomzimba. Xa i-shaft ikwisimo sayo esiphezulu esiqinileyo, ukunyamezela okuthe tye kwe-axis yayo yi-Ф0.1mm (Umfanekiso b). Nangona kunjalo, ukuba ubungakanani bokwenyani be-shaft butenxa kubume bayo obuqinileyo, impazamo evumelekileyo yokuthi tye kwe-axis yayo inokunyuswa ngokufanelekileyo. Umzobo wezowuni yokunyamezela onikwe kuMfanekiso C ubonisa ubudlelwane obuhambelanayo.

Ububanzi be-shaft kufuneka bube phakathi koluhlu lwe-Ф19.7mm ukuya kwi-Ф20mm, kunye nomda ophezulu we-Ф20.1mm. Ukujonga umgangatho we-shaft, qala ulinganise ulwandlalo lwe-cylindrical ngokuchasene negeyiji yendawo ehambelana nobona bungakanani bomda obusebenzayo bomzimba obuphezulu be-Ф20.1mm. Emva koko, sebenzisa indlela yamanqaku amabini ukulinganisa ubukhulu bendawo bendawo ye-shaft kwaye uqinisekise ukuba iwela ngaphakathi kwemilinganiselo eyamkelekileyo yomzimba. Ukuba imilinganiselo ihlangabezana nale migaqo, i-shaft inokuthathwa ifanelekile.

Umzobo oguquguqukayo wendawo yokunyamezela ubonisa ukuba ukuba ubungakanani bokwenene buyancipha ukusuka kwimo eqinileyo ephezulu nge Ф20mm, impazamo evumelekileyo yobulungisa ixabiso le-f livumelekile ukuba linyuke ngokufanelekileyo. Nangona kunjalo, ukonyuka okuphezulu akufuneki kudlule ukunyamezela kwe-dimensional. Oku kuvumela ukuguqulwa konyamezelo lwe-dimensional kwimilo kunye nokunyamezela isikhundla.

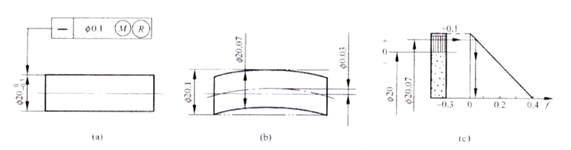

2) Iimfuno ezibuyiselwa umva zisetyenziselwa iimfuno eziphezulu zequmrhu

Xa imfuno yokubuyisela umva isetyenziswa kowona mgangatho wokuqina uphezulu, eyona contour yophawu olulinganiswayo kufuneka ihambelane nomda wayo wokuqina osebenzayo. Ukuba ubungakanani bokwenene buphambuka kubukhulu obuqinileyo obuqinileyo, impazamo yejometri ivumelekile ukuba idlule ixabiso lokunyamezela kwejometri elinikeziweyo. Ukongeza, ukuba impazamo yejiyometri ingaphantsi kwexabiso elinikiweyo lomahluko wejometri kwimeko eqinileyo ephezulu, ubungakanani bokwenyani bunokugqithisa ubungakanani bemilinganiselo yesimo esiqinileyo, kodwa ubuninzi obuvumelekileyo obugqithisiweyo bubume obuqhelekileyo bobume bejiyometri kunye nonyamezelo olunikiweyo. kuba yokugqibela.

Umzobo A ngumzekeliso wokusetyenziswa kweemfuno ezibuyiselwa umva kwimfuno ephezulu eqinileyo. I-axis kufuneka yanelise i-d fe ≤ Ф20.1mm, Ф19.7 ≤ d al ≤ Ф20.1mm.

Ifomyula engezantsi ichaza ukuba ukuba ubungakanani bokwenene be-shaft buyatenxa ukusuka kubukhulu bemeko eqinileyo ukuya kwelona xesha lincinci liqinileyo, impazamo yokuma kwe-axis inokufikelela kwixabiso eliphezulu, elilingana nexabiso lokunyamezela okuthe tye kwe-0.1mm enikwe kumzobo kunye nokudibanisa. ukunyamezela ubungakanani be-shaft ye-0.3mm. Oku kubangela ukuba Ф0.4mm iyonke (njengoko kubonisiwe kuMfanekiso c). Ukuba ixabiso lephutha le-axis lingaphantsi kwexabiso lokunyamezela kwe-0.1mm elinikezelwe kumzobo, yi-Ф0.03mm, kwaye ubungakanani bayo bokwenene bunokuba bukhulu kunobukhulu bomzimba, bufikelele kwi-Ф20.07mm (njengoko kubonisiwe kuMfanekiso b). Xa impazamo yokuthe tye ingu-zero, ubungakanani bayo bokwenene bunokufikelela kwixabiso eliphezulu, elilingana nobukhulu bomda walo womzimba osebenzayo we-Ф20.1mm, ngaloo ndlela uhlangabezana nemfuneko yokuguqula ukunyamezela kwejometri ibe yinyamezelo ye-dimensional. Umzobo c ngumzobo oguquguqukayo obonisa indawo yokunyamezela yobudlelwane obuchazwe ngasentla.

Ngexesha lokuhlolwa, i-shaft ye-diameter yokwenyani ithelekiswa ne-gauge yendawo ebanzi, eyilwe ngokusekelwe kubukhulu bomda obusebenzayo bomzimba obuyi-20.1mm. Ukongezelela, ukuba ubukhulu bokwenene be-shaft, njengoko kulinganiswe kusetyenziswa indlela yamanqaku amabini, bukhulu kunobukhulu obuncinane bomzimba we-19.7mm, ngoko inxalenye ithathwa njengefanelekileyo.

3) Ubuninzi beemfuno zequmrhu ziyasebenza kwiifitsha zedatum

Xa usebenzisa iimfuno eziphezulu zokuqina kwiimpawu zedatha, idatha kufuneka ihambelane nemida ehambelanayo. Oku kuthetha ukuba xa ubungakanani besenzo sangaphandle sophawu lwedatum buhluka kubungakanani bomda obuhambelanayo, i-element yedatum ivumelekile ukuba ihambe ngaphakathi koluhlu oluthile. Uluhlu oludadayo lulingana nomahluko phakathi kobungakanani besenzo sangaphandle sedatum kunye nobungakanani bomda obuhambelanayo. Njengoko isiqalelo sedatum siyatenxa kubuncinane bemeko yequmrhu, uluhlu lwayo oludadayo luyanyuka lude lufike kowona mgangatho uphezulu.

Umzobo A ubonisa ukunyamezelana kwe-coaxiality ye-axis yesangqa sangaphandle kwi-axis yesangqa sangaphandle. Izinto ezilinganisiweyo kunye nezinto zedatum zamkela ezona mfuno ziphezulu zomzimba ngaxeshanye.

Xa i-element ikwimeko eqinile, ukunyamezelana kwe-coaxiality ye-axis yayo kwi-datum A yi-Ф0.04mm, njengoko kuboniswe kuMfanekiso B. I-axis elinganisiweyo kufuneka yanelise d fe≤Ф12.04mm, Ф11.97≤d al≤Ф12mm .

Xa into encinci ilinganiswa, ivumelekile ukuba impazamo ye-coaxiality ye-axis yayo ifikelele kwixabiso eliphezulu. Eli xabiso lilingana nenani lezinto ezimbini zokunyamezela: ukunyamezela kwe-coaxiality ye-0.04mm echazwe kumzobo kunye nokunyamezela kwe-dimensional ye-axis, eyi-Ф0.07mm (njengoko kuboniswe kuMzobo c).

Xa i-axis ye-datum ikumda ophezulu womzimba, kunye nobukhulu bangaphandle be-Ф25mm, ukunyamezela kokubambisana okunikiweyo kumzobo kunokuba yi-Ф0.04mm. Ukuba ubungakanani bangaphandle bedatum bunciphisa kubungakanani bomzimba obuncinci be-Ф24.95mm, i-axis ye-datum inokudada ngaphakathi kokunyamezela kwe-dimensional ye-Ф0.05mm. Xa i-axis ikwimo edadayo kakhulu, ukunyamezelana kwe-coaxiality kuyanda ukuya kwixabiso lonyamezelo lwedatum ye-Ф0.05mm. Ngenxa yoko, xa izinto ezilinganisiweyo kunye ne-datum zikwisimo esincinci esiqinileyo ngexesha elinye, impazamo enkulu ye-coaxiality inokufikelela kwi-Ф0.12mm (Figure d), eyisamba se-0.04mm yokunyamezela i-coaxiality, i-0.03mm kunyamezelo lwedatum dimensional kunye ne-0.05mm ye-datum unyamezelo oludadayo.

6. Ubuncinane beemfuno zequmrhu kunye neemfuno zabo zokubuyela umva

Ukuba ubona umfanekiso wesimboli ophawulwe emva kwexabiso lonyamezelo okanye unobumba we-datum kwibhokisi yokunyamezela yejometri kumzobo, kubonisa ukuba into elinganisiweyo okanye i-datum element kufuneka ihlangabezane neemfuno ezincinci zomzimba, ngokulandelanayo. Ngakolunye uhlangothi, ukuba kukho isimboli emva kwexabiso lokunyamezela kwejometri yento elinganisiweyo, kuthetha ukuba imfuno eguqulwayo isetyenziselwa imfuno encinci yequmrhu.

1) Ubuncinci beemfuno zequmrhu zisebenza kwiimfuno phantsi kovavanyo

Xa usebenzisa eyona mfuno isezantsi yequmrhu kwi-elementi elinganisiweyo, eyona nkcazo yesiqalelo mayingagqithi kumda wayo osebenzayo nakubuphi na ubude obunikiweyo. Ukongeza, ubungakanani bendawo yokwenyani yesiqalelo akufuneki bugqithise ubukhulu bayo okanye ubuncinci besayizi yeziko.

Ukuba ubuncinci obufunekayo obuqinileyo busetyenziswa kuphawu olulinganisiweyo, ixabiso lonyamezelo lwejiyometri linikezelwa xa uphawu lukwimeko eqinileyo esezantsi. Nangona kunjalo, ukuba eyona contour yophawu iyatenxa kubungakanani bayo obuncinane obuqinileyo, ubume kunye nexabiso lempazamo yendawo inokugqithisa ixabiso lonyamezelo elinikiweyo kubume obuncinane obuqinileyo. Kwiimeko ezinjalo, ubungakanani obusebenzayo bophawu olulinganisiweyo akufunekanga budlule ubuncinci balo obuqinileyo, ubungakanani bomda obusebenzayo.

2) Iimfuno ezibuyiselwa umva zisetyenziselwa ubuncinci beemfuno zequmrhu

Xa usebenzisa imfuneko enokujikwa kowona mgangatho uphantsi wemfuno eqinileyo, uphawu olulinganisiweyo lolona lwandlalo alufanelanga ukuba lugqithise umda walo oqinileyo, osebenzayo nakubuphi na ubude obunikiweyo. Ukongezelela, ubukhulu bayo bendawo yokwenene akufanele bugqithise ubukhulu obuqinileyo. Phantsi kwezi meko, kungekuphela nje imposiso yejiyometri evumelekileyo ukuba idlule kwixabiso lonyamezelo lwejometri enikwe kubume obuncinane bomzimba xa ubungakanani bokwenene bento elinganisiweyo itenxa kubungakanani bomzimba obusezantsi, kodwa ikwavumelekile ukuba igqithe ubungakanani bomzimba obusezantsi xa ubungakanani bokwenyani bohlukile, ngaphandle kokuba impazamo yejiyometri incinci kunexabiso elinikiweyo lonyamezelo lwejometri.

Icnc yenziwe ngoomatshiniiimfuno zokuqina okuncinci kunye nokuguqulwa kwayo kufuneka kusetyenziswe kuphela xa unyamezelo lwejometri lusetyenziselwa ukulawula uphawu olunxulumene nombindi. Nangona kunjalo, ukuba ukusetyenziswa kwezi mfuno okanye akunjalo kuxhomekeke kwiimfuno ezithile zokusebenza zento.

Xa ixabiso elinikeziweyo lokunyamezela kwejometri liyi-zero, ubuninzi (ubuncinci) beemfuno eziqinileyo kunye neemfuno zabo eziguqulwayo zibizwa ngokuba yi-zero yokunyamezela kwejometri. Ngeli xesha, imida ehambelanayo iya kutshintsha ngelixa ezinye iinkcazo zihlala zingatshintshi.

7. Ukumiselwa kwamaxabiso okunyamezela kwejometri

I-1) Ukumiselwa kobume benaliti kunye namaxabiso okunyamezela isikhundla

Ngokubanzi, kucetyiswa ukuba amaxabiso okunyamezela kufuneka alandele ubudlelwane obuthile, kunye nokunyamezela imilo kuncinci kunokunyamezela isikhundla kunye nokunyamezela kwe-dimensional. Nangona kunjalo, kubalulekile ukuba uqaphele ukuba kwiimeko ezingaqhelekanga, ukunyamezela okuthe tye kwe-axis ye-shaft e-slender kunokuba kukhulu kunokunyamezela kwe-dimensional. Ukunyamezela indawo kufuneka kufane nokunyamezela kwe-dimensional kwaye kudla ngokuthelekiswa nokunyamezela kwe-symmetry.

Kubalulekile ukuqinisekisa ukuba ukunyamezela kokubeka kuhlala kukhulu kunonyamezelo lwe-orientation. Ukunyamezela indawo kunokubandakanya iimfuno zokunyamezela uqhelaniso, kodwa okuchaseneyo akuyonyani.

Ngaphaya koko, unyamezelo olubanzi kufuneka lube lukhulu kunonyamezelwano lomntu ngamnye. Ngokomzekelo, ukunyamezela kwe-cylindricity ye-cylinder surface kunokuba mkhulu okanye kulingane nokunyamezela okuthe tye kokujikeleza, umgca wokuqala kunye ne-axis. Ngokufanayo, ukunyamezela ukunyanzeliswa kwendiza kufuneka kube kukhulu okanye kulingane nokunyamezela okuthe tye kwendiza. Ekugqibeleni, ukunyamezela okupheleleyo kufuneka kube kukhulu kune-radial circular runout, ukujikeleza, i-cylindricity, ukuchaneka kwe-prime line kunye ne-axis, kunye ne-coaxiality tolerance ehambelanayo.

2) Ukumiselwa kwamaxabiso angabonakaliyo okunyamezela ijometri

Ukuze wenze imizobo yobunjineli ibe mfutshane kwaye icace, kuyakhethwa ukubonisa ukunyamezela kwejometri kwimizobo yokuchaneka kwejometri ekulula ukuyiqinisekisa ngokulungiswa kwesixhobo somatshini jikelele. Kwizinto ezineemfuno zokunyamezela iifom ezingachazwanga ngokuthe ngqo kumzobo, ifom kunye nokuchaneka kwendawo kuyafuneka. Nceda ubhekisele kwimimiselo yokuphunyezwa kwe-GB/T 1184. Ukuzoba iinkcazo ngaphandle kwamaxabiso okunyamezela kufuneka kubhalwe kwi-title block attachment okanye kwiimfuno zobugcisa kunye namaxwebhu obugcisa.

Izixhobo ezikumgangatho ophezulu ezisecaleni,iindawo zokusila, kwayeiinxalenye zentsimbizenziwa e China, Anebon. Iimveliso zeAnebon ziye zafumana ukuqondwa ngakumbi nangakumbi kubathengi bamanye amazwe kwaye zaseka ubudlelwane bexesha elide kunye nentsebenziswano kunye nabo. I-Anebon iya kubonelela ngeyona nkonzo ilungileyo kuye wonke umthengi kwaye yamkele ngokunyanisekileyo abahlobo ukuba basebenze ne-Anebon kwaye baseke izibonelelo ezifanayo kunye.

Ixesha lokuposa: Apr-16-2024