Ukusebenza kakuhle kwesixhobo somatshini we-CNC kuhambelana ngokusondeleyo nokuchaneka kwayo, okwenza kube yinto ephambili ephambili kwiinkampani xa zithenga okanye ziphuhlisa izixhobo ezinjalo. Nangona kunjalo, ukuchaneka kwezona zixhobo zitsha zoomatshini zihlala zisilela kwimigangatho efunekayo xa ushiya umzi-mveliso. Ukongezelela, ukwenzeka komatshini wokugijima kunye nokunxiba ngexesha lokusetyenziswa ixesha elide kugxininisa imfuneko ebalulekileyo yokulungelelanisa ukuchaneka kwezixhobo zoomatshini be-CNC ukuqinisekisa ukusebenza kakuhle kwemveliso.

1. Imbuyekezo yasemva

Ukunciphisa i-BacklashNgaphakathi kwezixhobo zoomatshini be-CNC, iimpazamo ezivela kwiindawo ezifileyo ezibuyela umva zamacandelo okuqhuba kwitsheyini yokuhanjiswa kwesondlo kwi-axis yolungelelwaniso nganye kunye nokucocwa ngasemva kweperisi nganye yokuhambisa intshukumo yomatshini kukhokelela ekuphambukeni njengoko nganye ilungelelanisa uguqulo lwe-axis ukusuka phambili ukuya umva intshukumo. Oku kunxaxha, okwakwaziwa njengokususwa umva okanye ukulahleka komfutho, kunokuba nefuthe elibonakalayo ekuchanekeni kwendawo kunye nokuphinda-phinda ukuchaneka kokuma kwesixhobo somatshini xa kusetyenziswa iinkqubo ze-servo ezinesiqingatha-ezivaliweyo. Ngaphaya koko, ukunyuka okuthe chu kwi-kinematic pair clearances ngenxa yokuguga ngokuhamba kwexesha kukhokelela ekunyukeni okuhambelanayo kokutenxa umva. Ngoko ke, umlinganiselo oqhelekileyo kunye nembuyekezo yokuphambuka okubuyela umva kwi-axis yokulungelelanisa nganye yesixhobo somatshini kuyimfuneko.

Ukulinganisa Ukubuyela emva

Ukuvavanya ukutenxa umva, qalisa phakathi koluhlu lokuhamba lwe-coordinate axis. Okokuqala, misela indawo yereferensi ngokuhambisa umgama obekiweyo ukuya phambili okanye umva. Ukulandela oku, khupha umyalelo wentshukumo ethile kwicala elinye ukugubungela umgama othile. Emva koko, qhubela phambili ukuhambisa umgama ofanayo kwicala elichaseneyo kwaye unqume umahluko phakathi kwereferensi kunye nezikhundla zokumisa. Ngokuqhelekileyo, imilinganiselo emininzi (ehlala isixhenxe) iqhutyelwa kwiindawo ezintathu kufuphi nendawo ephakathi kunye nokugqithiswa koluhlu lokuhamba. I-avareji yexabiso ibalwa kwindawo nganye, kunye nobona bukhulu phakathi kwale miyinge isetyenziswe njengomlinganiselo wokutenxa umva. Kubalulekile ukuhambisa umgama othile ngexesha lemilinganiselo ukumisela ngokuchanekileyo ixabiso lokutenxa umva.

Xa uvavanya ukutenxa ngasemva kwe-axis yentshukumo yomgca, kuqhelekile ukusebenzisa isalathisi sokudayela okanye igeyiji yokudayela njengesixhobo sokulinganisa. Ukuba iimeko ziyavuma, i-dual-frequency laser interferometer nayo ingasetyenziselwa le njongo. Xa usebenzisa isalathisi sokudayela imilinganiselo, kubalulekile ukuqinisekisa ukuba isiseko semitha kunye nesiqu asikwandisi ngokugqithiseleyo, njengoko i-cantilever ende ngexesha lokulinganisa inokubangela ukuba isiseko semitha sihambe ngenxa yokunyanzeliswa, okukhokelela ekufundweni okungachanekanga kunye nexabiso lembuyekezo elingenangqiqo.

Ukuphumeza indlela yeprogram yokulinganisa kunokuphucula ukukhululeka kunye nokuchaneka kwenkqubo. Umzekelo, ukuvavanya ukutenxa ngasemva kwe-X-axis kwisixhobo somatshini esilungelelanisiweyo esimithathu, inkqubo inokuqala ngokucinezela imitha ngokubhekiselele kumphezulu we-cylindrical we-spindle, ilandelwa ngokuqhuba inkqubo ekhethiweyo yokulinganisa.

N10G91G01X50F1000; hambisa ibhentshi ekunene

N20X-50;i-worktable ishukuthela ekhohlo ukuphelisa umsantsa wothumelo

N30G04X5; nqumama ukuze uqwalasele

N40Z50; I-Z-axis iphakanyisiwe kwaye iphuma endleleni

N50X-50: Ibhentshi yokusebenzela iya ngasekhohlo

N60X50: I-Workbench ihamba ngasekunene kwaye iphinda ilungise

I-N70Z-50: Ukusetha kwakhona umgca we-Z

N80G04X5: Misa ujonge

N90M99;

Kubalulekile ukuba uqaphele ukuba iziphumo ezilinganisiweyo zinokuhluka ngokusekelwe kwizantya ezahlukeneyo zokusebenza zebhentshi yokusebenza. Ngokuqhelekileyo, ixabiso elilinganisiweyo kwisantya esiphantsi likhulu kunelo lihamba ngesantya esiphezulu, ngakumbi xa umbane we-axis wesixhobo somatshini kunye nokumelana nokunyakaza kukhulu. Ngezantya ezisezantsi, i-worktable ihamba ngesantya esicothayo, okukhokelela kumathuba amancinci okudubula okugqithisileyo kunye nokuhamba ngaphezulu, kungoko inika ixabiso elilinganisiweyo eliphezulu. Ngakolunye uhlangothi, kwizantya eziphezulu, ukudubuleka kunye nokugqithiswa kakhulu kunokwenzeka ngenxa yesantya esisebenzayo esisebenzayo, okukhokelela kwixabiso elincinci elilinganisiweyo. Indlela yokulinganisa ukutenxa ngasemva kwe-axis ye-rotary motion ilandela inkqubo efanayo naleyo ye-axis yomgca, umahluko kuphela sisixhobo esisetyenziselwa ukukhangela.

Ukuhlawulela uBacklash

Uninzi lwezixhobo zoomatshini be-CNC ezenziwe kweli lizwe zibonisa ukuchaneka kokubeka ngaphezulu kwe-0.02mm, ukanti ziswele amandla embuyekezo. Kwiimeko ezithile, iindlela zokucwangcisa zinokuqeshwa ukufezekisa ukubeka ngendlela enye kunye nokuphelisa umva wezixhobo zoomatshini. Logama nje icandelo lomatshini lihlala lingatshintshi, ukuqalisa ukusetyenzwa kwe-interpolation kunokwenzeka nje ukuba isantya esisezantsi, ukubekwa kwendlela enye kufikelele kwindawo yokuqala yofakelo. Xa udibana nesalathiso esibuya umva ngexesha lesondlo sofakelo, ukudibanisa ngokusesikweni ixabiso lokubuyela umva linamandla okuphucula ukuchaneka kokucutshungulwa kunye nokuhlangabezana ngokufanelekileyocnc inxalenye egayiweyoiimfuno zonyamezelo.

Kwezinye iindidi zezixhobo zoomatshini be-CNC, iidilesi ezininzi zeememori kwisixhobo se-CNC ziqhele ukumiselwa ukugcina ixabiso lomva we-axis nganye. Xa i-axis yesixhobo somatshini iqondiswe ekutshintsheni isalathiso sayo sokuhamba, isixhobo se-CNC siya kubuyisela ngokuzenzekelayo ixabiso le-backlash ye-axis, ehlawulela kwaye ilungise ixabiso lomyalelo we-coordinate. Oku kuqinisekisa ukuba isixhobo somatshini sinokubekwa ngokuchanekileyo kwindawo yomyalelo kwaye sinciphise impembelelo embi yokuphambuka okubuyela umva ekuchanekeni kwesixhobo somatshini.

Ngokuqhelekileyo, iinkqubo ze-CNC zixhotyiswe ngexabiso elilodwa elikhoyo lembuyekezo yokubuyela umva. Ukulinganisa ukuchaneka kwentshukumo ephezulu kunye nesezantsi, kunye nokujongana nokuphuculwa koomatshini, kuba ngumngeni. Ngaphezu koko, ixabiso lokutenxa umva elilinganisiweyo ngexesha lentshukumo ekhawulezayo linokusetyenziswa kuphela njengexabiso lembuyekezo yegalelo. Ngenxa yoko, ukufezekisa ukulingana phakathi kokuchaneka kokumisa ngokukhawuleza kunye nokuchaneka kwe-interpolation ngexesha lokusika kubonakala kunzima.

Kwiinkqubo ze-CNC ezifana ne-FANUC0i kunye ne-FANUC18i, kukho iindlela ezimbini ezikhoyo zembuyekezo ye-backlash yokuhamba ngokukhawuleza (G00) kunye ne-speed-speed cut feed motion (G01). Ngokuxhomekeke kwindlela yokutya ekhethiweyo, inkqubo ye-CNC ikhetha ngokuzenzekelayo kwaye isebenzise amaxabiso embuyekezo awohlukileyo ukuphumeza ukuchaneka okuphuculweyo.

Ixabiso le-backlash A, elifunyenwe kwi-G01 yokusika i-feed motion, kufuneka lifakwe kwi-parameter NO11851 (isantya sovavanyo lwe-G01 kufuneka sinqunywe ngokusekelwe kwisantya sokutya esisetyenziswa ngokuqhelekileyo kunye neempawu zesixhobo somatshini), ngelixa ixabiso le-backlash B ukusuka kwi-G00 kufuneka lifakwe. kwi parameter NO11852. Kubalulekile ukuqaphela ukuba ukuba inkqubo ye-CNC ifuna ukuphumeza imbuyekezo ye-reverse backlash echazwe ngokwahlukileyo, idijithi yesine (RBK) yenombolo yepharamitha ye-1800 kufuneka imiselwe kwi-1; ngenye indlela, imbuyekezo yomqolo echaziweyo ngokwahlukeneyo ayizukwenziwa. Imbuyekezo yesikhewu. I-G02, G03, JOG, kunye ne-G01 zonke zisebenzisa ixabiso lembuyekezo elifanayo.

Imbuyekezo yeempazamo zePitch

Ukubekwa ngokuchanekileyo kwezixhobo zomatshini we-CNC kubandakanya ukuvavanywa kokuchaneka apho amacandelo ashukumayo omatshini anokufikelela phantsi komyalelo wenkqubo ye-CNC. Oku kuchanekileyo kudlala indima ebalulekileyo ekwahluleni izixhobo zoomatshini be-CNC kweziqhelekileyo. Ukulungelelaniswa nokuchaneka kwejometri yesixhobo somatshini, kuchaphazela kakhulu ukuchaneka kokusika, ngokukodwa kwi-machining yomgodi. Impazamo yokugrumba umngxuma inempembelelo enkulu. Ukukwazi kwesixhobo somatshini we-CNC ukuvavanya ukuchaneka kwayo kuxhomekeke ekufumaneni ukuchaneka kokumisa. Ke ngoko, ukubonwa kunye nokulungiswa kokuchaneka kokubeka izixhobo zoomatshini be-CNC ngamanyathelo abalulekileyo okuqinisekisa umgangatho wokuqhuba.

Inkqubo yokulinganisa iPitch

Okwangoku, eyona ndlela iphambili yokuvavanya kunye nokuphatha izixhobo zoomatshini kukusetyenziswa kwee-interferometers ze-laser eziphindwe kabini. Ezi interferometers zisebenza kwimigaqo ye-laser interferometry kwaye zisebenzisa i-real-time laser wavelength njengereferensi yokulinganisa, ngaloo ndlela iphucula ukuchaneka komlinganiselo kunye nokwandisa uluhlu lwezicelo.

Inkqubo yokubona isandi selizwi ihamba ngolu hlobo lulandelayo:

- Faka i-laser interferometer ephindwe kabini.

- Misa isixhobo sokulinganisa ukukhanya ecaleni kwe-axis yesixhobo somatshini esifuna umlinganiselo.

- Ukulungelelanisa intloko ye-laser ukuqinisekisa ukuba i-axis yokulinganisa ihambelana okanye i-collinear kunye ne-axis yokunyakaza yesixhobo somatshini, ngaloo ndlela ulungelelanisa kwangaphambili indlela yokubona.

- Faka iiparameters zokulinganisa xa i-laser ifikelela kwiqondo lokushisa layo lokusebenza.

- Yenza iinkqubo zokulinganisa ezimiselweyo ngokuhambisa isixhobo somatshini.

- Yenza idatha kwaye uvelise iziphumo.

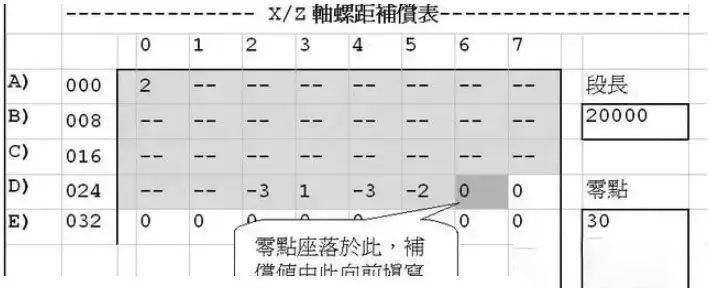

Imbuyekezo yemposiso ye-Pitch kunye noLungiso oluzenzekelayo

Xa impazamo yokubeka elinganisiweyo yesixhobo somatshini we-CNC idlula uluhlu oluvumelekileyo, kukho imfuneko yokulungisa impazamo. Enye indlela exhaphakileyo ibandakanya ukubala itafile yembuyekezo yempazamo yepitch kwaye uyifake ngesandla kwisistim yeCNC yesixhobo somatshini ukulungisa impazamo yokubeka. Nangona kunjalo, imbuyekezo yesandla inokuthatha ixesha kwaye ithande ukuba neempazamo, ngakumbi xa ujongene namanqaku amaninzi embuyekezo kwii-axes ezintathu okanye ezine zesixhobo somatshini we-CNC.

Ukulungelelanisa le nkqubo, isisombululo senziwe. Ngokudibanisa ikhompyuter kunye nomlawuli weCNC wesixhobo somatshini ngokusebenzisa ujongano lweRS232 kunye nesoftware yokulinganisa ngokuzenzekelayo eyenziwe kwiVB, kunokwenzeka ukuvumelanisa i-laser interferometer kunye nesixhobo somatshini weCNC. Olu ngqamaniso luvumela ubhaqo oluzenzekelayo lokuchaneka kokubeka isixhobo somatshini we-CNC kunye nokuphunyezwa kwembuyekezo yempazamo ye-pitch ngokuzenzekelayo. Indlela yembuyekezo ibandakanya:

- Ukudala i-backup yeeparamitha zembuyekezo ezikhoyo kwinkqubo yokulawula ye-CNC.

- Ukuvelisa isixhobo somatshini inkqubo ye-CNC yokulinganisa ukuchaneka kwendawo-by-point usebenzisa ikhompyutha, ethi ke idluliselwe kwisistim ye-CNC.

- Ukulinganisa ngokuzenzekelayo impazamo yokubeka indawo nganye.

- Ukuvelisa iseti entsha yeeparamitha zembuyekezo esekelwe kumanqaku embuyekezo esele imisiwe kwaye iwadlulisele kwinkqubo ye-CNC yembuyekezo ye-pitch ngokuzenzekelayo.

- Ukuqinisekisa ukuchaneka ngokuphindaphindiweyo.

Ezi zisombululo ezithile zijolise ekuphuculeni ukuchaneka kwezixhobo zoomatshini be-CNC. Nangona kunjalo, kubalulekile ukuqaphela ukuba ukuchaneka kwezixhobo ezahlukeneyo zoomatshini be-CNC kunokwahluka. Ngenxa yoko, izixhobo zoomatshini kufuneka zilinganiswe ngokweemeko zabo.

Ukuba imbuyekezo yempazamo ayenziwanga kwisixhobo somatshini, iya kuba nayiphi impembelelo kumacandelo e-CNC avelisiweyo?

Ukuba imbuyekezo yempazamo ayihoywanga kwisixhobo somatshini, inokubangela ukungangqinelani kwiAmalungu e-CNCyenziwe. Ngokomzekelo, ukuba isixhobo somatshini sinempazamo yokumisa engalungiswanga, indawo eyinyani yesixhobo okanye i-workpiece inokwahlukana ukusuka kwindawo ecwangcisiweyo echazwe kwiprogram ye-CNC, ekhokelela ekungalungi kwe-dimensional kunye neempazamo zejometri kwiindawo eziveliswayo.

Umzekelo, ukuba umatshini wokugaya we-CNC unempazamo yokumisa engalungiswanga kwi-X-axis, i-slots egayiweyo okanye imingxuma kwindawo yokusebenza inokungahambelani kakuhle okanye ibe nemilinganiselo engalunganga. Ngokufanayo, kwi-lathe operation, iimpazamo zokumisa ezingalungiswanga zingabangela ukungachaneki kububanzi okanye ubude bamalungu ajikiweyo. Oku kungangqinelani kunokukhokelela ekubeni amalungu angangqinelaniyo angaphumeleliyo

I-Anebon iya kwenza umsebenzi ngamnye onzima ukuba ube ngogqwesileyo kwaye ugqwese, kwaye ikhawulezise imilinganiselo yethu yokuma ukusuka kwinqanaba lenqanaba eliphezulu le-intercontinental kunye namashishini aphezulu e-China uMboneleli weGolide we-OEM, isiko.cnc inkonzo yomatshini, I-Sheet yenkonzo yokwenziwa kwesinyithi, iinkonzo zokugaya. I-Anebon iya kwenza ukuthenga kwakho ukuze uhlangabezane nokwanelisayo kwakho! Ishishini le-Anebon limisela amasebe amaninzi, kubandakanywa isebe lemveliso, isebe lengeniso, isebe lolawulo olugqwesileyo kunye neziko lenkonzo, njl.

Factory Supply ChinaInxalenye echanekileyo kunye nenxalenye yeAluminiyam, Unokwenza i-Anebon yazi ingcamango yakho yokuphuhlisa uyilo olulodwa lwemodeli yakho ukukhusela iindawo ezifanayo kakhulu kwimarike! Siza kunika inkonzo yethu engcono ukwanelisa zonke iimfuno zakho! Khumbula ukuqhagamshelana neAnebon ngoko nangoko!

Ixesha lokuposa: Jan-09-2024