Inkcazo yoLwazi loomatshini nguAnebon

Ulwazi ngoomatshini kukukwazi ukuqonda nokusebenzisa iikhonsepthi ezahlukeneyo zoomatshini, imigaqo kunye nezenzo. Ulwazi ngoomatshini lubandakanya ukuqonda koomatshini, izixhobo kunye nemathiriyeli kunye nezixhobo kunye neenkqubo. Oku kubandakanya ulwazi lwemigaqo yomatshini, njengamandla kunye nokushukuma, amandla kunye neenkqubo zeegiya kunye neepulleys. Ulwazi lobunjineli boomatshini lubandakanya uyilo, ugcino kunye neendlela zokusombulula iingxaki, kunye nemigaqo yobunjineli boomatshini. Ulwazi lweMechanical lubalulekile kwiingcali ezininzi kunye namashishini asebenza ngeenkqubo zoomatshini. Ezi ziquka ubunjineli, ukwenziwa kunye nokwakha.

1. Zeziphi iindlela zokusilela kwamalungu oomatshini?

(1) Ukuqhekeka ngokupheleleyo

(2) Ukugqwetheka ngokugqithisileyo okusisigxina

(3) Ukonakala kwendawo

(4) Ukungasebenzi kakuhle ngenxa yokuphazamiseka kweemeko zokusebenza rhoqo

Ithini ingqiqo emva kwemfuno ethe gqolo ye-anti-unscrew kwimidibaniso enemisonto?

Ithini ingqikelelo engundoqo yokuchasana nokukhulula?

Zeziphi iindlela ezahlukeneyo ezikhoyo zokuthintela ukukhulula?

Impendulo:

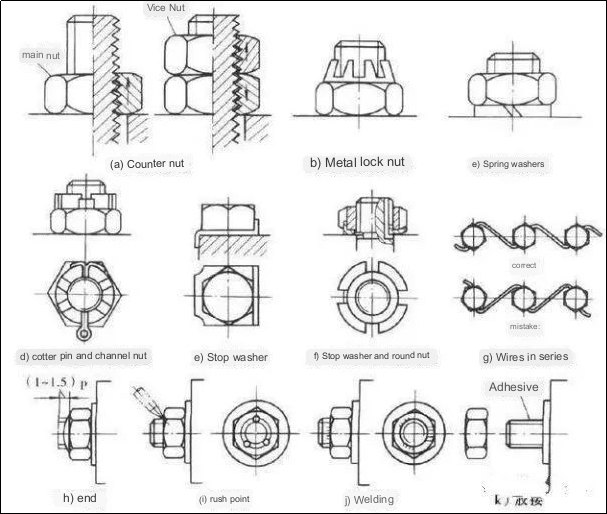

Ngokuqhelekileyo, uxhulumaniso olunentambo lunokuzalisekisa imilinganiselo yokuzivalela kwaye aluyi kukhululeka ngokuzenzekelayo. Nangona kunjalo, kwiimeko ezibandakanya ukungcangcazela, imithwalo yempembelelo, okanye ukuguquguquka okukhulu kwamaqondo obushushu, kukho into enokwenzeka yokuba i-nut edibanisayo ithekeleleke kancinci kancinci. Oyena nobangela wokukhulula umsonto usekujikelezweni kobudlelwane phakathi kwezibini zemisonto. Ngenxa yoko, kunyanzelekile ukuba kufakwe amanyathelo achasene nokukhulula kuyilo lokwenene.

Iindlela ezisetyenziswa ngokuqhelekileyo ziquka:

1. I-friction-based anti-loosening - ukugcinwa kwe-friction phakathi kwezibini zentambo ukuthintela ukukhulula, njengokusebenzisa i-spring washers kunye namandongomane aphindwe kabini kwicala eliphezulu;

2. Mechanical anti-loosening - utilizing obstructiveamacandelo oomatshiniukuqinisekisa ukunqanda ukukhulula, ngokufuthi besebenzisa amandongomane afakwe slotted kunye nezikhonkwane zecotter, phakathi kwabanye;

3. Ukuphazamiseka-okusekelwe kwi-anti-loosening of pairs of thread pairs - ukuguqula kunye nokuguqula ubudlelwane phakathi kweebini zentambo, njengokusetyenziswa kobuchule obusekelwe kwimpembelelo.

Yintoni injongo yokuqinisa imidibaniso enemisonto?

Pibonelela ngeendlela ezininzi zokulawula amandla asetyenziswayo.

Impendulo:

Injongo yokuqinisa uqhagamshelo oluthungelweyo kukuvumela iibholithi ukuba zenze amandla okuqinisa kwangaphambili. Le nkqubo yokuqinisa kwangaphambili izama ukunyusa ukuthembeka kunye nokuqina koqhagamshelwano ukukhusela naziphi na izikhewu okanye intshukumo ehambelanayo phakathi kweendawo ezidibeneyo phantsi kweemeko zokulayisha. Iindlela ezimbini ezisebenzayo zokulawula amandla okuqinisa zisebenzisa i-torque wrench okanye i-torque wrench engaguqukiyo. Nje ukuba i-torque efunekayo ifikelelwe, inokutshixwa kwindawo. Kungenjalo, ukunyuswa kwebholithi kunokulinganiswa ukulawula amandla okuqinisa kwangaphambili.

Ngaba ukutyibilika okulastiki kwahluke njani ekutyibilikeni kwiidrive zebhanti?

Kwi-design ye-V-belt drive, kutheni kukho umda kumlinganiselo omncinci we-pulley encinci?

Impendulo:

I-Elastic sliding imele uphawu lwendalo lokuqhuba ibhanti elingenako ukuphetshwa. Kwenzeka xa kukho ukungafani koxinzelelo kunye nempahla yebhanti ngokwayo i-elastomer. Ngakolunye uhlangothi, ukutyibilika luhlobo lokungaphumeleli oluvela ngenxa yomthwalo ogqithiseleyo kwaye kufuneka luthintelwe kuzo zonke iindleko.

Ngokukodwa, ukutyibilika kwenzeka kwipuli encinci. Ukunyuka kwemithwalo yangaphandle kukhokelela kumahluko omkhulu kuxinzelelo phakathi kwamacala amabini, nto leyo ebangela ukwandiswa kwendawo apho i-elastic sliding iyenzeka. I-Elastic sliding ibonisa utshintsho lobungakanani, ngelixa ukutyibilika kubonisa utshintsho lomgangatho. Ngenxa yoko, ukuthintela ukutyibilika, kukho umda kubukhulu obuncinci bedayamitha yepuli encinci, njengoko iidayamitha zepuli ezincinci zikhokelela kwii-angles zokusonga ezincinci kunye neendawo zokunxibelelana ezincitshisiweyo, okwenza ukutyibilika kwenzeke ngakumbi.

Ingaba isantya sokutyibilika somphezulu wamazinyo sinxulumana njani noxinzelelo oluvunyiweyo loqhagamshelo lwentsimbi engwevu kunye neeinjini ze-aluminiyam zobhedu?

Impendulo:

Uxinzelelo loqhagamshelwano oluvumelekileyo lwentsimbi engwevu kunye neeinjini zobhedu ze-aluminiyam ziphenjelelwa sisantya sokutyibilika kwindawo yezinyo ngenxa yemowudi yokusilela eyaziwa ngokuba kukuncamathela komphezulu wezinyo. Ukubambelela ngokuthe ngqo kuchaphazeleka ngesantya sokutyibilika, ngaloo ndlela kuchaphazela uxinzelelo oluvumelekileyo lokunxibelelana. Kwelinye icala, eyona ndlela iphambili yokungaphumeleli kwee turbines zetin zobhedu yimingxuma yamazinyo, ebangelwa luxinzelelo loqhagamshelwano. Ngoko ke, uxinzelelo loqhagamshelwano oluvumelekileyo aluhambelani nesantya sokuslayida.

Enumchaza imithetho eqhelekileyo yentshukumo, iimpawu zempembelelo, kunye neemeko ezifanelekileyo kumlandeli wendlela yeekhamera.

Impendulo:

Imithetho eshukumayo yomlandeli wekhamera ibandakanya isindululo sesantya esingaguqukiyo, imithetho eyahlukeneyo yesindululo sokunciphisa, kunye nesindululo esilula se-harmonic (umthetho wokunyuswa kwe-cosine). Umthetho wentshukumo yesantya esingaguqukiyo ubonisa impembelelo engqongqo kwaye ufumana ukusetyenziswa kwisantya esisezantsi kunye neemeko zomthwalo wokukhanya.

Imithetho yesindululo sokunciphisa, kubandakanywa nokukhawuleza rhoqo, impembelelo eguquguqukayo kwaye ifanelekile kwiimeko zesantya esiphakathi ukuya kwisantya esiphantsi. Isindululo esilula se-harmonic (i-cosine 4-chord yomthetho wentshukumo yokunyusa isantya) inika impembelelo ethambileyo xa kukho ikhefu lokunqumama, iyenza ibe luncedo kwiimeko zesantya esiphakathi ukuya kwisantya esisezantsi. Kwiimeko zesantya esiphezulu ngaphandle kwezithuba zokuphumla, akukho mpembelelo eguquguqukayo, eyenza ukuba ifaneleke kwezo meko.

Shwankathela imigaqo esisiseko elawula iprofayili yezinyo.

Impendulo:

Kungakhathaliseki ukuba iiprofayili zezinyo zenza uqhagamshelwano, umgca oqhelekileyo oqhelekileyo odlula kwindawo yokudibanisa kufuneka udibanise indawo ethile kumgca ophakathi. Le meko iqinisekisa ukuba umlinganiselo wothumelo ugcinwa.

Zeziphi iindlela ezahlukeneyo zokulungisa iinxalenye kwi-shaft? (bonelela ngeendlela ezingaphezu kwezine)

Impendulo:

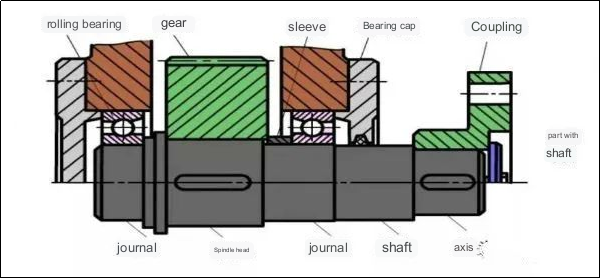

Amathuba okulungiswa kwe-circumferential abandakanya ukusetyenziswa koqhagamshelo oluneqhosha, uqhagamshelo olunabileyo, uqhagamshelo lwe-interference fit, i-set screw, i-pin ye-pin, kunye ne-joint yokwandisa.

Ziziphi iintlobo eziphambili zeendlela zokulungisa i-axial yokufaka iinxalenye kwi-shaft?

Zeziphi iimpawu ezahlulayo nganye? (khankanya ngaphezu kwesine)

Impendulo:

Iindlela zokulungisa i-Axial zokuncamathisela iinxalenye kwi-shaft zibandakanya iindidi ezininzi eziphambili, nganye ineempawu ezahlukileyo. Oku kubandakanya ukulungiswa kwekhola, ukulungiswa kwentambo, ukulungiswa kwe-hydraulic, kunye nokulungiswa kwe-flange. Ukulungiswa kwekhola kubandakanya ukusetyenziswa kwekhola okanye i-clamp eqiniswe malunga ne-shaft ukukhusela inxalenye ye-axially. Ukulungiswa komsonto kubandakanya ukusetyenziswa kwemisonto kwi-shaft okanye inxalenye ukuyidibanisa ngokuqinileyo kunye. Ukulungiswa kweHydraulic kusebenzisa uxinzelelo lwe-hydraulic ukudala uxhulumaniso oluqinileyo phakathi kwenxalenye kunye ne-shaft. Ukulungiswa kwe-flange kubandakanya ukusetyenziswa kwe-flange eboshiweyo okanye i-welded ukuyacnc iindawo zomatshinikunye ne-shaft, eqinisekisa i-axial attachment ekhuselekileyo.

Kutheni kuyimfuneko ukwenza izibalo ezilinganayo zobushushu kwiidridi zeentshulube ezivaliweyo?

Phendula:

Iidridi zeentshulube ezivalelweyo zibonisa ukutyibilika okuhambelanayo kunye namanqanaba aphezulu okukhuhlane. Ngenxa yokunqongophala kwamandla abo okunciphisa ubushushu kunye nokuthambekela kwimiba yokubambelela, ukubala ukulinganisa ubushushu kubaluleka.

Zeziphi iithiyori zokubala zamandla ezimbini eziqeshwe kwizibalo zamandla egiya?

Ziziphi iintsilelo abajolise kuzo?

Ukuba ukuhanjiswa kwegiya kuqeshe indawo yezinyo elithambileyo elivaliweyo, ithini inqobo yokuyila yayo?

Impendulo:

Ubalo lwamandla egiya lubandakanya ukumisela amandla okudinwa komfowunelwa kumphezulu wezinyo kunye nokugoba amandla okudinwa kweengcambu zezinyo. Amandla okudibana nokudinwa ajolise ekuthinteleni ukudinwa kokusilela kwimingxuma kwindawo yezinyo, ngelixa ukugoba ukudinwa amandla kujongana nokudinwa ukwaphuka kwingcambu yezinyo. Ukuhanjiswa kwegiya osebenzisa indawo yezinyo elithambileyo elivaliweyo lilandela inqobo yoyilo lokuqwalasela amandla okudinwa komphezulu wezinyo kunye nokuqinisekisa ukugoba amandla okudinwa kweengcambu zezinyo.

Yeyiphi imisebenzi eyahlukeneyo ye-couplings kunye ne-clutches?

Zahluke njani enye kwenye?

Impendulo:

Zombini i-couplings kunye ne-clutch zisebenza ngenjongo yokudibanisa i-shafts ezimbini ukwenzela ukuba ukuhanjiswa kwe-torque kunye nokujikeleza okuhambelanayo. Nangona kunjalo, ziyahluka ngokwamandla abo okukhutshwa ngexesha lokusebenza. Cii-ouplings zidibanisa i-shafts ezingenako ukwahlukana ngelixa zisetyenziswa; ukuqhawulwa kwabo kunokwenzeka kuphela ngokuqhawula iiindawo eziguqukayoemva kokuvalwa. Kwelinye icala, ii-clutches zibonelela ngokukwazi ukubandakanya okanye ukukhupha iishafti ezimbini nangawuphi na umzuzu ngexesha lokusebenza komatshini.

Chaza izinto ezifunekayo ezifunekayo ukuze iibheringi zeefilimu zeoyile zisebenze ngokufanelekileyo.

Impendulo:

Imiphezulu emibini ehamba intshukumo ehambelanayo kufuneka iseke umsantsa omise okwe wedge; isantya sokutyibilika phakathi komgangatho kufuneka siqinisekise ukungena kweoyile yokuthambisa ukusuka kwizibuko elikhulu kwaye uphume kwizibuko elincinane; ioli yokuthambisa kufuneka ibe ne-viscosity ethile, kwaye i-oyile eyaneleyo iyimfuneko.

Nika ingcaciso emfutshane malunga neziphumo, iimpawu ezahlukileyo, kunye nokusetyenziswa okuqhelekileyo kwemodeli yokuthwala 7310.

Impendulo:

Ikhowudi yokutolikwa: Ikhowudi "7" imele ibhola yoqhagamshelwano oluyi-angular. Igama elithi “(0)” libhekisa kububanzi obuqhelekileyo, kunye no-“0″ ozikhethelayo. Inani "3" libonisa uluhlu oluphakathi ngokobubanzi. Okokugqibela, "10" ihambelana nedayamitha engaphakathi ye-50mm.

Iimpawu kunye nezicelo:

Lo mzekelo wokuthwala unokunyamezela ngaxeshanye imithwalo ye-radial kunye ne-axial kwicala elinye. Ibonelela ngesantya esiphezulu somda kwaye ngokuqhelekileyo isetyenziswa ngababini.

Ngaphakathi kwenkqubo yothumelo ebandakanya ukuhanjiswa kwegiya, ukuhanjiswa kwebhanti, kunye nokuhanjiswa kwekhonkco, loluphi uhlobo losasazo oluhlala lubekwe kwinqanaba eliphezulu lesantya?

Ngokuchaseneyo, leliphi icandelo lothumelo elicwangciswe kweyona ndawo isezantsi yegiya?

Cacisa isizathu sokuba eli lungiselelo.

Impendulo:

Ngokubanzi, i-belt drive ibekwe kwinqanaba eliphezulu lesantya, ngelixa i-chain drive ibekwe kwindawo ephantsi yegiya. Ibhanti yokuqhuba ineempawu ezifana nokuhanjiswa okuzinzile, ukuthoba, kunye nokufunxa ukothuka, kuyenza ibe luncedo kwimoto ngesantya esiphezulu. Kwelinye icala, iidrive zamatsheyini zikholisa ukwenza ingxolo ngexesha lokusebenza kwaye zifaneleka ngcono iimeko ezinesantya esiphantsi, ngaloo ndlela zabelwa inqanaba legiya elisezantsi.

Yintoni ebangela isantya esingafaniyo sothumelo lwetsheyini?

Ngabaphi oothunywashe abaphambili abayiphembelelayo?

Kuphantsi kwaziphi iimeko apho umlinganiselo wosulelo olukhawulezileyo unokuhlala ungaguquguquki?

Impendulo:

I-1) Isantya esingaqhelekanga kwi-chain transmission ngokuyinhloko sibangelwa yi-polygonal effect ehambelana ne-chain mechanism; I-2) Izinto eziphambili ezichaphazelayo ziquka isantya se-chain, i-chain pitch, kunye ne-sprocket tooth count; 3) Xa inani lamazinyo kuzo zombini ii-sprockets ezinkulu kunye ezincinci zilingana (okt, z1 = z2) kunye nomgama ophakathi phakathi kwawo yi-multiple ngokuchanekileyo ye-pitch (p), umlinganiselo wokudluliselwa ngokukhawuleza uhlala uhleli kwi-1.

Kutheni ububanzi bezinyo (b1) bephiko bukhulu kancinane kunobubanzi bezinyo (b2) begiya enkulu kunciphiso lwegiya yesilinda?

Xa ubala amandla, ngaba i-coefficient yobubanzi bezinyo (ψd) isekelwe kwi-b1 okanye i-b2? Ngoba?

Impendulo:

I-1) Ukuthintela ukungahambi kakuhle kwe-axial yeegesi ngenxa yeempazamo zendibano, ububanzi bezinyo lwe-meshing buyancitshiswa, okukhokelela ekunyuseni komsebenzi wokusebenza. Ke ngoko, ububanzi bezinyo (b1) begiya encinci kufuneka bube bukhulu kancinci kune-b2 yegiya enkulu. Ubalo lwamandla kufuneka lusekwe kububanzi bezinyo (b2) kwigiya enkulu kuba imele obona bubanzi boqhagamshelwano xa iperi yegiya yecylindrical ibandakanyeka.

Kutheni kufuneka i-diameter ye-pulley encinci (d1) ilingane okanye ibe nkulu kunobuncinane bedayamitha (dmin) kunye ne-engile yokusonga yevili lokuqhuba (α1) ilingane okanye ibe nkulu kuno-120° kwi-deceleration belt drive?

Ngokuqhelekileyo, isantya sebhanti esicetyiswayo siphakathi kwe-5 ukuya kwi-25 m / s.

Ziziphi ii-cUkuqala ukuba isantya sebhanti singaphezulu kolu luhlu?

Impendulo:

I-1) I-diameter encinci ye-pulley encinci ikhokelela kuxinzelelo oluphezulu lokugoba kwibhanti. Ukuthintela uxinzelelo olugqithisileyo lokugoba, ubuncinci be-diameter ye-pulley encinci kufuneka igcinwe.

I-2) I-angle yokugoqa (α1) yevili lokuqhuba ichaphazela ubuninzi boxinzelelo olusebenzayo lwebhanti. I-α1 encinci iphumela kumandla asezantsi asebenzayo okutsala. Ukuphucula amandla okutsala asebenzayo kunye nokuthintela ukutyibilika, i-engile yokusonga ye-α1≥120° iyacetyiswa ngokubanzi.

3) Ukuba isantya sebhanti siwela ngaphandle koluhlu lwe-5 ukuya kwi-25 m / s, kunokubakho imiphumo. Isantya esingaphantsi koluhlu sinokufuna amandla amakhulu okutsala (Fe), okukhokelela ekwandeni kwenani lamabhanti (z) kunye nesakhiwo esikhulu sokuqhuba ibhanti. Ngokwahlukileyo, isantya esiphezulu sebhanti siya kubangela amandla aphezulu e-centrifugal (Fc), efuna isilumkiso.

Iinzuzo kunye neengozi ze-helical rolling.

Impendulo:

Iingenelo

I-1) Ibonisa ukunxiba okuncinci, kwaye indlela yokulungelelanisa ingasetyenziselwa ukuphelisa imvume kwaye ibangele inqanaba elithile le-deformation yangaphambili, ngaloo ndlela iphucula ukuqina kunye nokufezekisa ukuchaneka kokuhanjiswa okuphezulu.

2) Ngokungafaniyo neenkqubo zokuzivalela, iyakwazi ukuguqula intshukumo yomgca kwintshukumo ejikelezayo.

Iingxaki

I-1) Ulwakhiwo luyinkimbinkimbi kwaye lubeka imingeni kwimveliso.

2) Iindlela ezithile zingafuna indlela eyongezelelweyo yokuzitshixa ukuthintela ukuguqulwa.

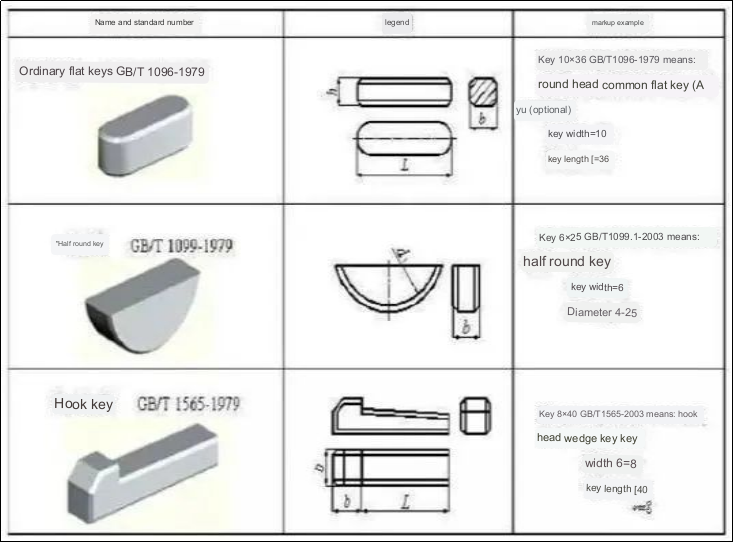

Ngowuphi umgaqo osisiseko wokukhetha izitshixo?

Impendulo:

Xa ukhetha izitshixo, kukho izinto ezimbini eziphambili zokuqwalaselwa: uhlobo kunye nobukhulu. Ukukhethwa kohlobo kuxhomekeke kwizinto ezifana neempawu zesakhiwo soqhagamshelwano oluphambili, iimfuno zokusetyenziswa, kunye neemeko zokusebenza.

Ngakolunye uhlangothi, ukhetho lobungakanani kufuneka luhambelane nemilinganiselo esemgangathweni kunye neemfuno zamandla. Ubungakanani besitshixo buqulathe imilinganiselo enqamlezileyo (ububanzi besitshixo b * ukuphakama kwesitshixo h) kunye nobude L. Ukukhethwa kwemilinganiselo yecandelo elinqamlezileyo b*h kugqitywa yi-shaft diameter d, ngelixa ubude beqhosha L bungakwazi. ngokubanzi kumiselwa ngokusekelwe kubude be hub, okuthetha ukuba ubude besitshixo L akufunekanga bugqithe ubude be hub. Ukongeza, kwizitshixo ezisicaba ezikhokelayo, ubude be hub L' buqhelekile ukujikeleza (1.5-2) amaxesha eshaft idayamitha d, kuthathelwa ingqalelo ubude be hub kunye nomgama wokutyibilika.

I-Anebon ixhomekeke kubuchule bayo obuqinileyo kwaye ngokuqhubekayo iphuhlisa itekhnoloji ephezulu ukuhlangabezana neemfuno zokusetyenzwa kwentsimbi ye-CNC,I-5 axis cnc milling, kunye nokuphosa imoto. Sizixabisa kakhulu zonke iingcebiso kunye nengxelo. Ngentsebenziswano elungileyo, sinokufikelela ekuphuhliseni kunye nokuphucula.

Njengomvelisi we-ODM e-China, i-Anebon igxile ekwenzeni iindawo zesitampu se-aluminiyam kunye nezixhobo zoomatshini bokwenza. Okwangoku, iimveliso zethu zithunyelwe kumazwe angaphezu kwamashumi amathandathu kunye nemimandla eyahlukeneyo kwihlabathi liphela, kubandakanya uMzantsi-mpuma Asia, iMelika, iAfrika, iMpuma Yurophu, iRussia, kunye neCanada. I-Anebon izibophelele ekusekeni unxibelelwano olubanzi nabathengi abanokubakho eTshayina nakwezinye iindawo zehlabathi.

Ixesha lokuposa: Aug-16-2023