1. Ingqikelelo yoburhabaxa bomphezulu wesinyithi

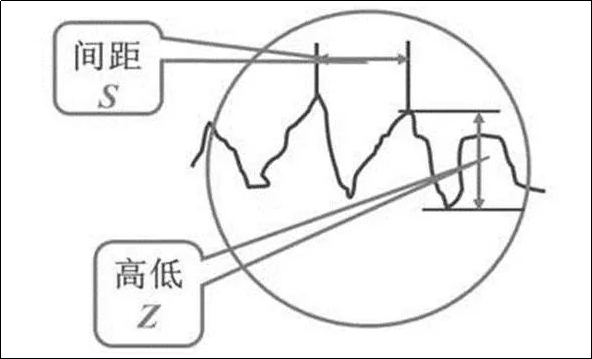

Uburhabaxa bomphezulu bubhekiselele ekungalinganini kweepatshi ezincinci kunye neencopho ezingephi kunye neentlambo ezinomphezulu womatshini. Umgama (umgama wamaza) phakathi kweencopho ezimbini okanye iinqanawa ezimbini zincinci kakhulu (ngaphantsi kwe-1mm), eyempazamo yemilo yejiyometri emincinci.

Ngokukodwa, ibhekisa kwiqondo lobude kunye nomgama S weencopho ezincinci kunye neentlambo. Ngokubanzi yahlulwe ngu-S:

-

S<1mm buburhabaxa bomphezulu;

- 1≤S≤10mm kukuphaphazela;

- S>10mm yimilo kaf.

2. VDI3400, Ra, itheyibhile yokuthelekisa iRmax

Umgangatho wesizwe umisela ukuba izalathi ezithathu ziqhele ukusetyenziswa ukuvavanya uburhabaxa bomphezulu (iyunithi yi-μm): umyinge we-arithmetic deviation Ra yeprofayili, umyinge wokuphakama kwe-Rz yokungalingani kunye nobude obuphezulu be-Ry. Isalathisi seRa sisoloko sisetyenziswa kwimveliso yangempela. Ubukhulu be-micro-height deviation Ry yeprofayili idla ngokubonakaliswa ngumqondiso we-Rmax eJapan nakwamanye amazwe, kwaye isalathisi se-VDI sisetyenziswa ngokuqhelekileyo eYurophu nase-United States. Ngezantsi i-VDI3400, i-Ra, i-Rmax yokuthelekisa itafile.

VDI3400, Ra, itheyibhile yokuthelekisa iRmax

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

3. Izinto ezenza uburhabaxa bomphezulu

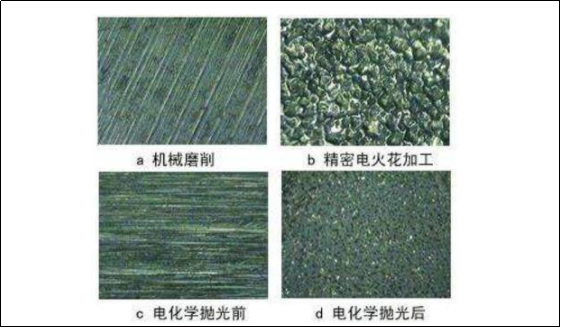

Uburhabaxa bomphezulu ngokuqhelekileyo bubunjwa yindlela yokucubungula esetyenziswayo kunye nezinye izinto, ezifana nokukhuhlana phakathi kwesixhobo kunye nomphezulu wesixhobo.cnc machining inxalenyengexesha lokucutshungulwa, ukuguqulwa kweplastiki yentsimbi yomphezulu xa i-chip yahluliwe, kunye ne-vibration ephezulu kwiinkqubo zenkqubo, imigodi yokukhupha umbane, njl. kunye nokuthungwa kwemikhondo eshiywe kwindawo ecutshungulwayo yahlukile.

4. Iimpawu eziphambili zempembelelo yobunzima bomphezulu kwiindawo

I-1) Ukuchaphazela ukuxhathisa ukunxiba. Okukhona umphezulu urhabaxa, incinci indawo yoqhagamshelwano esebenzayo phakathi kweendawo zokukhwelana, kokukhona uxinzelelo olukhulu, kokukhona uxhathiso olukhulu, kunye nokukhawuleza ukunxiba.

2) Ukuchaphazela ukuzinza kokulungelelaniswa. Ukulungelelaniswa kwe-clean, i-rougher surface, kulula ukuyinxiba, ukwenzela ukuba i-gap ikhule ngokuthe ngcembe ngexesha lenkqubo yokusebenza; amandla oqhagamshelwano.

3) Ukuchaphazela amandla okukhathala. Kukho imijelo emikhulu kumphezulu weendawo ezirhabaxa, ezinochuku kuxinzelelo loxinzelelo njengenotshi ezibukhali kunye neentanda, oko kuchaphazela amandla okudinwa.iindawo ezichanekileyo.

4) Ukuchaphazela ukuxhathisa ukubola. Iindawo ezirhabaxa ezingaphezulu zinokubangela ukuba irhasi edlayo okanye ulwelo lungene kumaleko angaphakathi esinyithi kwiintlambo ezincinane ezikumphezulu, nto leyo edala ukuhlwa komphezulu.

5) Ukuchaphazela ukuqina. Imiphezulu erhabaxa ayinakulingana ngokuqinileyo, kwaye irhasi okanye ulwelo luvuza kwizikhewu phakathi kwemiphezulu yoqhagamshelwano.

6) Ichaphazela ukuqina koqhagamshelwano. Ukuqina koqhagamshelwano kukukwazi komphezulu odibeneyo wamacandelo ukuchasana nokuguqulwa koqhagamshelwano phantsi kwesenzo samandla angaphandle. Ukuqina komatshini kunqunywe ubukhulu becala ngokuqina koqhagamshelwano phakathi kweiindawo ze-cnc lathe.

7) Ukuchaphazela ukuchaneka komlinganiselo. Ubunzima obuphezulu bomgangatho olinganisiweyo wenxalenye kunye nomgangatho wokulinganisa wesixhobo sokulinganisa buya kuchaphazela ngokuthe ngqo ukuchaneka komlinganiselo, ngokukodwa kwimilinganiselo echanekileyo.

Ukongeza, uburhabaxa bomphezulu buya kuba namanqanaba ahlukeneyo empembelelo kwi-plating coating, i-thermal conductivity kunye nokumelana nokunxibelelana, ukubonakaliswa kunye nokusebenza kweradiation yamalungu, ukuchasana nolwelo kunye nokuhamba kwegesi, kunye nokuhamba kwangoku kumphezulu wee-conductor.

5. isiseko sovavanyo loburhabaxa

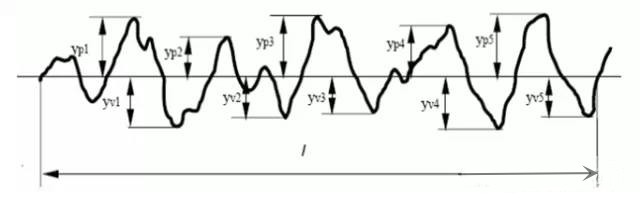

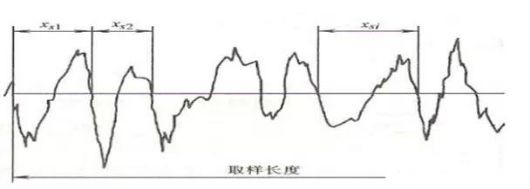

1. Ubude besampulu

Ubude besampulu bubude bomgca wereferensi ochazwe kuvavanyo lokurhabaxa komphezulu. Ngokokwakheka kunye neempawu zokuthungwa komphezulu wokwenene wenxalenye, ubude obunokubonisa iimpawu zobunzima bomphezulu kufuneka bukhethwe, kwaye ubude besampulu kufuneka bulinganiswe ngokwendlela eqhelekileyo yokwenyani umphezulu wecontour. Injongo yokuchaza kunye nokukhetha ubude besampulu kukucutha kunye nokwenza buthathaka impembelelo yobuso be-waviness kunye neempazamo zemilo kwiziphumo zokulinganisa uburhabaxa bomphezulu.

2. Ubude bovavanyo

Ubude bovavanyo bubude obuyimfuneko ekuvavanyeni iprofayili, kwaye inokubandakanya ubude besampulu enye okanye ezininzi. Kuba uburhabaxa bomphezulu bendawo nganye yomphezulu wenxalenye ayifani ngokuyimfuneko, indawo ethile yoburhabaxa bomphezulu ayinakubonakaliswa ngokufanelekileyo kubude besampulu enye, ngoko ke kuyimfuneko ukuthatha ubude besampulu eliqela kumphezulu ukuvavanya uburhabaxa bomphezulu. Ubude bovavanyo ngokubanzi buba nobude besampulu ezi-5.

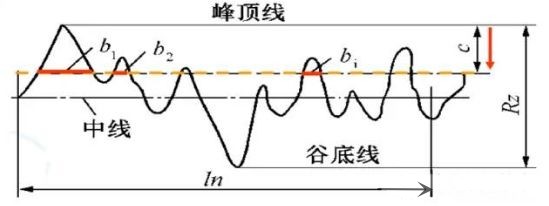

3. Isiseko

Umgca wereferensi ngumgca ophakathi weprofayili esetyenziselwa ukuvavanya iiparamitha zobunzima bomhlaba. Kukho iindidi ezimbini zemigca yereferensi: owona mgca umncinci wesikwere somdiba wecontour: ngaphakathi kobude besampulu, isimbuku sezikwere zecontour offset imigama kwindawo nganye kumgca wecontour yeyona incinci, kwaye inemilo yecontour yejiyometri. . I-arithmetic ithetha umgca ophakathi wecontour: ngaphakathi kobude besampulu, iindawo zeekhontolo ezingaphezulu nangaphantsi komgca ophakathi ziyalingana. Ngokwethiyori, umgca we-median owona mgangatho uphantsi ngowona mgaqo ufanelekileyo, kodwa kunzima ukuwufumana kwizicelo ezibonakalayo, ngoko ke uthatyathelwa indawo yi-arithmetic mean median line yecontour, kunye nomgca othe tye onendawo eqikelelweyo ingasetyenziselwa yitshintshe ngexesha lokulinganisa.

6. Iiparamitha zokuvavanya uburhabaxa bomphezulu

1. Iimpawu zeempawu zobude

I-Ra profile arithmetic ithetha ukutenxa: i-arithmetic mean yexabiso elipheleleyo lokutenxa kwiprofayili ngaphakathi kobude besampulu (lr). Kwimilinganiselo yokwenyani, kokukhona inani lamanqaku omlinganiselo, kokukhona ichaneka ngakumbi iRa.

Ubude beprofayili ye-Rz: umgama phakathi komgca wencopho yeprofayile kunye nomgca osezantsi wentlambo.

I-Ra ikhethwa kuluhlu oluqhelekileyo lweeparamitha ze-amplitude. Kumgangatho wesizwe ngaphambi kwe-2006, kwakukho enye iparameter yokuvavanya "ubude be-10-point of micro-roughness" echazwe ngu-Rz, kunye nobude obuphezulu be-contour bubonakaliswe ngu-Ry. Emva kuka-2006, umgangatho wesizwe warhoxisa ukuphakama kwamanqaku alishumi obunzima obuncinci, kwaye i-Rz yasetyenziswa. Ibonisa ubude bobude beprofayile.

2. Iiparamitha zeempawu zesithuba

RsmI-avareji yobubanzi bezinto zecontour. Ngaphakathi kobude besampulu, ixabiso eliqhelekileyo lomgama phakathi kwezinto ezitenxileyo ze-microscopic zeprofayili. I-micro-roughness spacing ibhekisela kubude bencopho yeprofayili kunye nentlambo yeprofayili ekufutshane kumgca ophakathi. Kwimeko yexabiso elifanayo le-Ra, ixabiso le-Rsm alifani, ngoko ukuthungwa okubonakalisiweyo kuya kwahluka. Imibuso enika ingqalelo kwi-texture idla ngokuqwalasela izikhombisi ezimbini zeRa kunye ne-Rsm.

IUMnuiparameter yefitsha yemilo imelwe yireyishiyo yobude benkxaso yecontour, engumlinganiselo wobude benkxaso yecontour ukuya kubude besampulu. Ubude benkxaso yeprofayili yisixa sobude bemigca yecandelo efunyenwe ngokunqumla iphrofayili kunye nomgca ochanekileyo ohambelana nomgca ophakathi kunye nomgama we-c ukusuka kumgca wencopho yeprofayili ngaphakathi kobude besampulu.

7. Indlela yokulinganisa uburhabaxa bomphezulu

1. Indlela yokuthelekisa

Isetyenziselwa ukulinganisa indawo kwindawo yokusebenzela, kwaye isoloko isetyenziselwa umlinganiselo wemigangatho ephakathi okanye erhabaxa. Indlela yokuthelekisa umphezulu olinganisiweyo kunye nesampulu yoburhabaxa ephawulwe ngexabiso elithile ukumisela ixabiso lobunzima obulinganisiweyo bomgangatho.

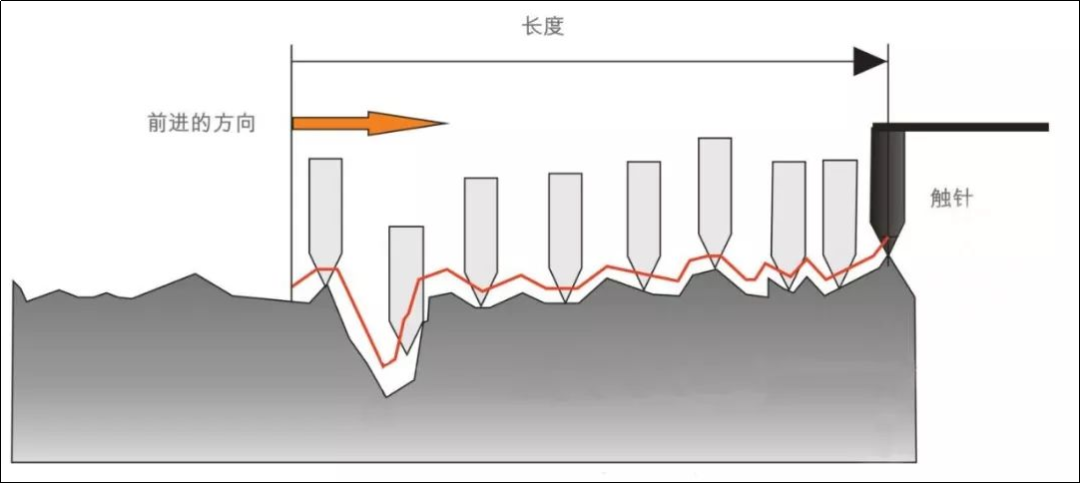

2. Indlela yeStylus

Uburhabaxa bomphezulu busebenzisa istylus yedayimane enencam yeradiyasi egophe malunga neemicrons ezi-2 ukutyibilika kancinane kumphezulu olinganisiweyo. I-up and down displacement ye-diamond stylus iguqulwa ibe ngumqondiso wombane ngenzwa yobude bombane, kwaye ibonakaliswe ngesixhobo sokubonisa emva kokukhulisa, ukuhluza, kunye nokubala. Ixabiso lobunzima bomphezulu lingafumaneka, kwaye irekhoda ingasetyenziselwa ukurekhoda ijika leprofayili yecandelo elilinganisiweyo. Ngokubanzi, isixhobo somlinganiselo esinokubonisa kuphela ixabiso loburhabaxa bomphezulu sibizwa ngokuba sisixhobo sokulinganisa uburhabaxa bomphezulu, kwaye eso sinokurekhodisha ijiko lenkangeleko yomphezulu sibizwa ngokuba yiprofayili yoburhabaxa bomphezulu. Ezi zixhobo zibini zokulinganisa zineesekethe zokubala ze-elektroniki okanye iikhompyutha ze-elektroniki, ezinokubala ngokuzenzekelayo i-arithmetic ithetha ukutenxa i-Ra ye-contour, ukuphakama kwamanqaku alishumi e-Rz yokungalingani kwe-microscopic, ubude obuphezulu be-Ry ye-contour kunye nezinye iiparameters zokuvavanya, kunye nokuphakama okuphezulu. ukulinganisa ukusebenza kakuhle kwaye ifanelekile Uburhabaxa bomphezulu weRa yi-0.025-6.3 microns ilinganiswa.

Usukelo lukanaphakade lwe-Anebon sisimo sengqondo “sokujonga imarike, sijonge isiko, sithathele ingqalelo inzululwazi” kunye nethiyori “yomgangatho osisiseko, themba owokuqala nolawulo oluphambili” kwintengiso eshushu Factory OEM Service High Precision CNC Machining parts for automation. industrial, Anebon quote kumbuzo wakho. Ngolwazi oluthe kratya, nceda uqhagamshelane nathi, i-Anebon iya kukuphendula ngokukhawuleza!

Intengiso eshushu Factory China 5 axis cnc machining iinxalenye, CNC wajika iinxalenye kunyeinxalenye yobhedu yokusila. Wamkelekile ukuba undwendwele inkampani yethu, umzi-mveliso kunye negumbi lethu lokubonisa apho libonisa iimpahla ezahlukeneyo zeenwele eziza kuhlangabezana nolindelo lwakho. Okwangoku, kulungele ukutyelela iwebhusayithi ye-Anebon, kwaye abasebenzi be-Anebon abathengisayo baya kuzama konke okusemandleni abo ukukuzisa eyona nkonzo ilungileyo. Nceda uqhagamshelane ne-Anebon ukuba kufuneka ube nolwazi oluthe kratya. Injongo yeAnebon kukunceda abathengi baqonde iinjongo zabo. I-Anebon iye yenza iinzame ezinkulu zokuphumeza le meko yokuphumelela.

Ixesha lokuposa: Mar-25-2023