Umahluko kunye nokusetyenziswa kweebholiti zamandla aphezulu kunye neebholiti eziqhelekileyo

Iibholiti eziphezulu kunye neebholiti eziqhelekileyo zimbini iintlobo ze-fasteners ezisetyenziswa kwizicelo ezahlukeneyo.

Nalu uthelekiso lweeyantlukwano zabo kunye nezicelo eziqhelekileyo:

Amandla: Iibholiti eziphakamileyo zenzelwe ukuba zibe namandla aphezulu kakhulu kunye namandla okucheba xa kuthelekiswa neebholiti eziqhelekileyo. Zenziwe ngentsimbi ye-alloy kwaye zingena kwiinkqubo ezikhethekileyo zonyango lobushushu ukunyusa amandla azo. Ngakolunye uhlangothi, iibholiti eziqhelekileyo zinamandla aphantsi kwaye zenziwe ngekhabhonimachining steel.

Iimpawu: Iibholithi eziqinileyo zihlala zineempawu entloko ukubonisa ibakala okanye udidi lwamandla. Olu phawu lunceda ekuchongeni iinkcukacha zebholithi, njengamandla ayo okuqina kunye nezinto eziphathekayo. Iibholiti eziqhelekileyo azinamanqaku athile anxulumene namandla.

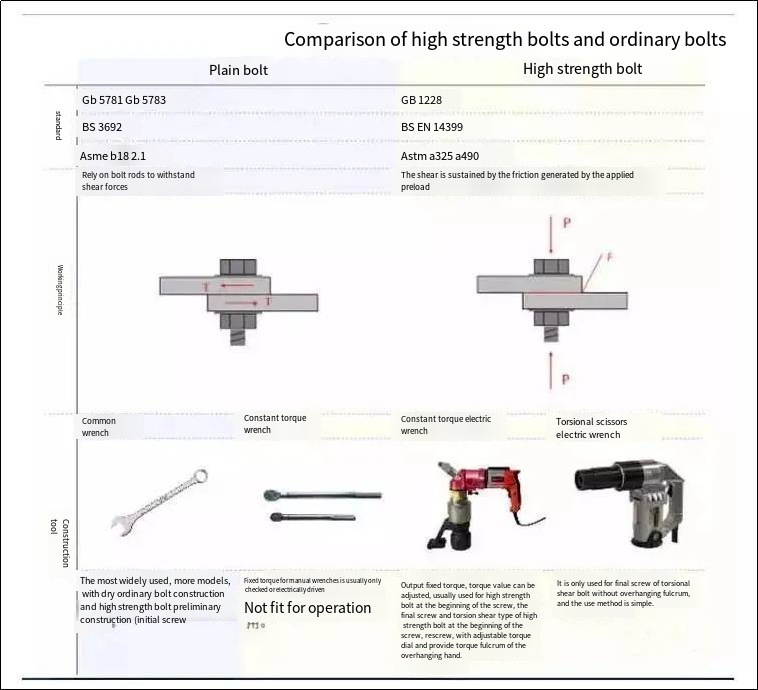

Ukuhlohla: Iibholiti zamandla aphezulu zifuna iinkqubo zokufakela ezichanekileyo ukufezekisa amandla afunekayo kunye nokusebenza. Zihlala zisetyenziswa kwizicelo apho ukuthembeka kwesakhiwo kunye nomthamo wokuthwala umthwalo ubalulekile. Iindlela zokufakela iibholiti zokuqina okuphezulu ngokuqhelekileyo zibandakanya ukusebenzisa i-calibrated torque wrenches okanye izixhobo ze-hydraulic tensioning ukuphumeza ukulayisha kwangaphambili okuchaziweyo. Iibholiti eziqhelekileyo zilula ukuzifaka kwaye azifuni izixhobo ezikhethekileyo okanye ulawulo lwetorque.

Usetyenziso: Iibholiti eziphakamileyo zisetyenziswa ngokuqhelekileyo ekwakheni, iiprojekthi zeziseko zophuhliso, iibhulorho, izakhiwo, kunye nezinye izicelo apho imithwalo enzima okanye amanqanaba aphezulu oxinzelelo kulindeleke. Ziyimfuneko ekudibaniseni amalungu entsimbi yesakhiwo, njengemiqadi, iikholomu, kunye neetrasi. Iibholiti eziqhelekileyo zifumana ukusetyenziswa kwizicelo ezingafuneki kangako, kubandakanyaiindawo zoomatshini be-cncindibano yefenitshala, amacandelo eemoto, udibaniso olungelulo olwakhiwo, kunye nokuqiniswa kwenjongo ngokubanzi.

Imigangatho: Iibholiti zamandla aphezulu zihlala zenziwe kwaye zichazwe ngokwemigangatho yoshishino, njenge-ASTM A325 kunye ne-ASTM A490 e-United States. Le migangatho ichaza iimfuno zezinto eziphathekayo, iimpawu zomatshini, imilinganiselo, kunye neenkqubo zokufakela iibholiti eziphezulu. Iibholiti eziqhelekileyo zilandela imigangatho eqhelekileyo ngakumbi, efana ne-ASTM A307, egubungela uluhlu olubanzi lwezicelo kunye neemfuno zamandla asezantsi.

Zeziphi iibholithi zamandla aphezulu?

I-High-Strength Friction Grip Bolt , i-English literal translation is: high-strength friction pre-tightening bolt, isishunqulelo sesiNgesi: HSFG. Ingabonwa ukuba iibholiti eziphakamileyo ezikhankanywe kulwakhiwo lwethu lwaseTshayina zizifinyezo zebholithi zokulayisha kwangaphambili zokhuhlane. Kunxibelelwano lwemihla ngemihla, amagama athi "Friction" kunye ne "Grip" akhankanywe ngokufutshane nje, kodwa ezininzi iinjineli kunye neechwephesha aziyiqondi kakuhle inkcazo eyisiseko yeebholiti zamandla aphezulu.

Ukungaqondi enye:

Iibholiti ezinomgangatho wezinto eziphathekayo ezingaphezu kwe-8.8 "ziibholithi eziphezulu"?

Umahluko ongundoqo phakathi kweebholiti eziphezulu kunye neebholiti eziqhelekileyo azikho amandla ezinto ezisetyenzisiweyo, kodwa uhlobo lwamandla. Undoqo kukufaka ukufaka ukulayisha kwangaphambili kwaye usebenzise ukukhuhlana okumileyo ukuxhathisa ukucheba.

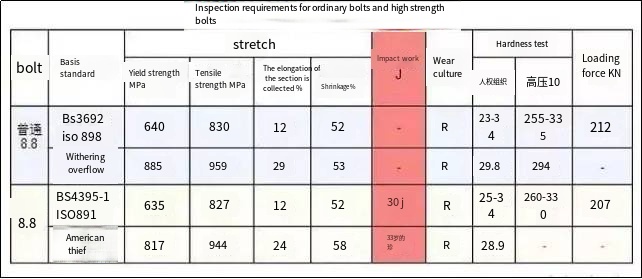

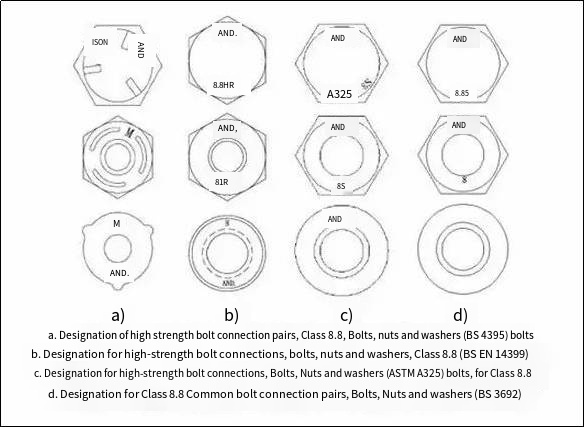

Enyanisweni, i-bolts yamandla aphezulu (HSFG BOLT) ekhankanywe kumgangatho waseBrithani kunye nomgangatho waseMelika kuphela i-8.8 kunye ne-10.9 (BS EN 14399 / ASTM-A325 & ASTM-490), ngelixa iibholiti eziqhelekileyo ziquka i-4.6, 5.6, 8.8, 10.9, 12.9, njl. (BS 3692 11 Itheyibhile 2); kunokubonwa ukuba amandla ezinto eziphathekayo ayisitshixo sokuhlukanisa iibholiti eziphezulu ezivela kwiibhotshi eziqhelekileyo.

Ukuqonda ngokuchanekileyo "amandla aphezulu", aphi amandla

Ngokutsho kwe-GB50017, ukubala amandla okuqina kunye nokucheba kwebholithi eyodwa eqhelekileyo (Uhlobo B) ibakala le-8.8 kunye nenqanaba eliphezulu lamandla 8.8.

Ngokubala, sinokubona ukuba phantsi kwebakala elifanayo, uyilo kunyeinkonzo aluminiyam cncixabiso lamandla okuqina kunye namandla okucheba eebholiti eziqhelekileyo aphezulu kuneebholiti zokuqina.

Ngoko ke uphi "ukuqina" kweebholiti eziphezulu?

Ukuze uphendule lo mbuzo, kuyimfuneko ukuqalisa ngemeko yokusebenza yoyilo lweebholiti ezimbini, ufunde umthetho we-elastic-plastic deformation, kwaye uqonde umda womda ngexesha lokungaphumeleli koyilo.

I-Stress-strain curves ye-bolts eziqhelekileyo kunye ne-high-power bolts phantsi kweemeko zokusebenza

Imeko yokunciphisa ukusilela koyilo

Iibholiti eziqhelekileyo: I-deformation yeplastiki yesikrufu ngokwayo idlula isibonelelo soyilo, kwaye isikrufu sonakaliswe kukucheba.

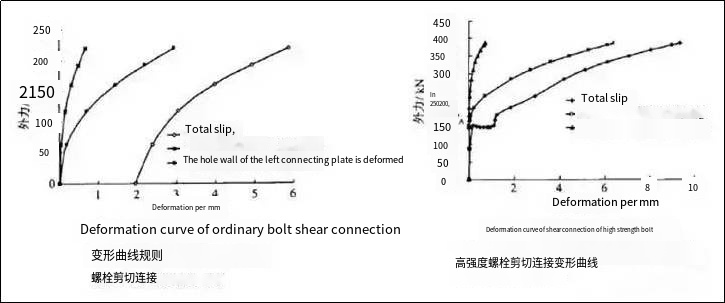

Uqhagamshelo lwebholithi oluqhelekileyo, ukutyibilika kwesalamane kuya kwenzeka phakathi kwamacwecwe okudibanisa phambi kokuba amandla okucheba aqale ukuthwala, emva koko intonga yebholiti kunye noqhagamshelwano lweplate yokudibanisa, i-elastic-plastic deformation iyenzeka, kwaye i-shear force iyanyamezeleka.

Iibholiti zamandla aphezulu: I-static friction phakathi kweendawo ezithintekayo ezisebenzayo ziyanqotshwa, kwaye ukufuduka okuhambelanayo kwamacwecwe amabini ensimbi kwenzeka, okubhekwa njengowonakalisiweyo kwingqwalasela yoyilo.

Kudibaniso lwebholithi ephezulu, amandla okukhuhlana kuqala athwala amandla okucheba. Xa umthwalo unyuka ukuya kwindawo apho amandla okubetha akwanelanga ukuxhathisa amandla okucheba, i-static force force force iyoyiswa, kwaye ukutyibilika kweplate yokudibanisa kwenzeka (imeko elinganiselweyo). Nangona kunjalo, nangona yonakele ngeli xesha, intonga yebholithi inxibelelana nepleyiti yokudibanisa, kwaye isenokuthi isebenzise eyayo i-elastic-plastic deformation ukumelana ne-shear force.

Ukungaqondi 2:

Umthamo wokuthwala i-bolts-high-high-power iphezulu kuneebhotshi eziqhelekileyo. Ngaba “ngamandla amakhulu”?

Inokubonwa ekubalweni kwebholithi enye ukuba amandla oyilo lweebholiti eziphezulu zokuqina kwi-tension kunye ne-shear iphantsi kuneebholiti eziqhelekileyo. I-essence yayo yamandla aphezulu kukuba: ngexesha lokusebenza okuqhelekileyo, iinqununu azivumelekanga ukuba zibe ne-slippage ehambelanayo, oko kukuthi, i-deformation elastic-plastic deformation incinci, kwaye ukuqina kwe-node kukhulu.

Kuyabonakala ukuba kwimeko yomthwalo owenziweyo woyilo lwe-node, i-node eyenzelwe i-bolts yamandla aphezulu ayinako ukugcina inani leebhotshi ezisetyenzisiweyo, kodwa ine-deformation encinci, ukuqina okuphezulu, kunye nokugcinwa kokhuseleko oluphezulu. Kuyafaneleka kwiinqununu eziphambili kunye nezinye iindawo ezifuna ukuqina kwe-node ephezulu, kwaye ihambelana nomgaqo osisiseko woyilo lwe-seismic "i-nodes eqinile, amalungu abuthathaka".

Amandla ee-bolts zamandla aphezulu akakho kwixabiso loyilo lomthamo walo wokuthwala, kodwa kubunzima obuphezulu beendawo zokuyila, ukusebenza okuphezulu kokhuseleko, kunye nokuchasana okunamandla kumonakalo.

Ukuthelekiswa kweebholiti zamandla aphezulu kunye neebholiti eziqhelekileyo

Iibholiti eziqhelekileyo kunye neebhotshi eziphakamileyo zihluke kakhulu kwiindlela zokuhlola ukwakhiwa ngenxa yemigaqo yazo eyahlukileyo yoyilo.

Iimfuno zokusebenza komatshini zeebholiti eziqhelekileyo zebakala elifanayo ziphezulu kancinane kuneebholiti zamandla aphezulu, kodwa iibholiti zamandla aphezulu zinemfuno enye yokwamkelwa kwamandla empembelelo kuneebholiti eziqhelekileyo.

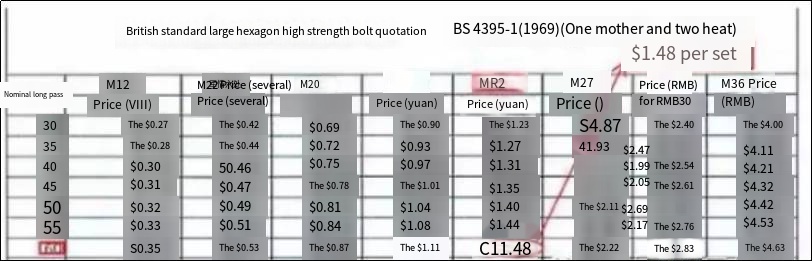

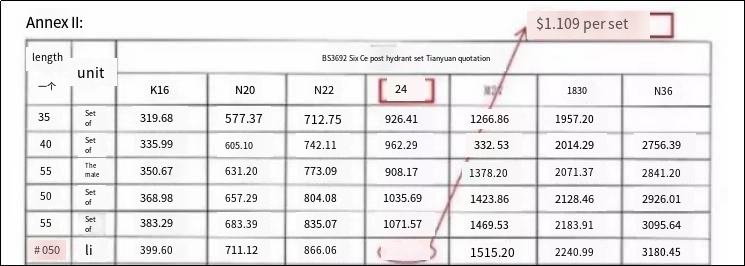

Ukumakishwa kweebholithi eziqhelekileyo kunye ne-high-strength bolts yindlela esisiseko yokuchongwa kwendawo yeebholithi zebakala elifanayo. Ekubeni ixabiso elibalwe kwixabiso le-torque ye-bolts-high-power bolts kwimigangatho yaseBrithani naseMelika ayifani, kuyafuneka kwakhona ukuchonga iibholiti zemigangatho emibini.

Iibholithi zokuqina okuphezulu: (M24, L60, ibakala 8.8)

Iibholiti eziqhelekileyo: (M24, L60, ibakala 8.8)

Ingabonwa ukuba iibholiti eziqhelekileyo zimalunga ne-70% yexabiso leebhotshi eziphezulu. Ukudibanisa nokuthelekisa iimfuno zabo zokwamkelwa, kunokugqitywa ukuba inxalenye yeprimiyamu kufuneka iqinisekise ukusebenza kwempembelelo yamandla (ukuqina) kwezinto.

Shwankathela

Kwingxaki ebonakala ilula, asingomcimbi ulula ukuba nokuqonda okunzulu, okubanzi nokuchanekileyo ngondoqo wayo. Inkcazo, intsingiselo kunye nokwahlukana okunzulu phakathi kweebhotshi eziphezulu kunye neebholiti eziqhelekileyo ziyisiseko esisisiseko sokuba siqonde ngokuchanekileyo, sisebenzise iibholiti eziphezulu, kwaye siqhube ulawulo lokwakha.

Jonga:

I-1) Ngokuqinisekileyo kuchazwe kwezinye iincwadi zesakhiwo sensimbi ukuba iibholiti eziphakamileyo zibhekisela kwiibholiti ezinamandla angaphezu kwama-8.8. Kulo mbono, okokuqala, imigangatho ye-Anglo-American ayixhasi, kwaye akukho nkcazo "yomelele" kunye "nobuthakathaka" kwinqanaba elithile lamandla. Okwesibini, ayihambelani "neebholiti eziphezulu" ezikhankanywe kumsebenzi wethu.

2) Ukuze kube lula ukuthelekisa, uxinzelelo lwamaqela e-bolt anzima aluqwalaselwa apha.

I-3) Ukunyanzeliswa koxinzelelo lwe-screw kuqwalaselwa kwakhona kwi-design ye-bolt-high-high-strength bolt, eya kwaziswa ngokubanzi ngokulandelayo "Ukuthelekiswa koxinzelelo kunye nohlobo lwe-friction-high-strength bolts".

Wazi kangakanani malunga neebholiti eziphezulu?

Igama elipheleleyo lee-bolts zamandla aphezulu kwimveliso libizwa ngokuba yi-high-strength bolt connection pair, kwaye ngokuqhelekileyo ayibhekiselwanga njengeebholiti zamandla amafutshane.

Ngokweempawu zokufakela, yahlulwe ibe: iibholiti ezinkulu zehexagon kunye neebholiti zokucheba. Phakathi kwabo, uhlobo lwe-torsional shear lusetyenziswa kuphela kwinqanaba le-10.9.

Ngokomgangatho wokusebenza kweebholiti eziphezulu, zahlulwe zibe: 8.8 kunye ne-10.9. Phakathi kwazo, kukho kuphela iibholiti ezinkulu ezine-hexagonal zokuqina okuphezulu kwibanga lesi-8.8. Kwindlela yokumakisha, inani eliphambi kwedesimali libonisa amandla okuqina emva kokunyangwa kobushushu; inani emva kwedesimali libonisa umlinganiselo wesivuno, oko kukuthi, umlinganiselo wexabiso elilinganisiweyo lamandla esivuno ukuya kwixabiso elilinganiselweyo lokomelela kokugqibela. . IBanga lesi-8.8 lithetha ukuba amandla okuqina eshaft yebholithi ayikho ngaphantsi kwe-800MPa, kwaye umlinganiselo wesivuno ngu-0.8; IBanga le-10.9 lithetha ukuba ukomelela kwe-bolt shaft akukho ngaphantsi kwe-1000MPa, kwaye umlinganiselo wesivuno ngu-0.9.

I-diameters of high-high-power bolts in design structure generally include M16/M20/M22/M24/M27/M30, but M22/M27 is the second choice series, kunye ne-M16/M20/M24/M30 iyona nto ikhethayo phantsi kweemeko eziqhelekileyo.

Ngokubhekiselele kwi-design ye-shear, iibholiti eziphakamileyo zihlulwe zibe: i-bolt-high-power-high-high-high-high-high-high-high-high-high-high-high-power type friction bolt ngokweemfuno zoyilo.

Umthamo wokuthwala uhlobo lwe-friction luxhomekeke kwi-anti-slip coefficient ye-force transmission surface ye-friction kunye nenani leendawo zokukhuhla. I-coefficient ye-friction ye-rust ebomvu emva kwe-sandblasting (i-shot) iyona nto iphezulu, kodwa ichaphazeleka kakhulu kumgangatho wokwakha ngokwemigaqo yokusebenza kwangempela. Iiyunithi ezininzi zokubeka iliso Bonke baphakamisa ukuba umgangatho unokuthotywa ukuqinisekisa umgangatho weprojekthi.

Umthamo wokuthwala imithwalo yohlobo loxinzelelo oluxhomekeke kwixabiso elincinci lomthamo we-shear we-bolt kunye noxinzelelo lwe-bolt. Kwimeko yendawo enye kuphela yokudibanisa, umthamo wokucheba we-M16 uhlobo lwe-friction yi-21.6-45.0 kN, ngelixa umthamo we-shear we-M16 yoxinzelelo lwe-39.2-48.6 kN, kwaye ukusebenza kungcono kunoko uhlobo lwengxabano.

Ngokufakela, inkqubo yoxinzelelo lwengcinezelo ilula, kwaye indawo yokudibanisa ifuna ukucocwa kuphela ngeoli kunye ne-rust ejikelezayo. Umthamo wokuthwala i-tensile ecaleni kolwalathiso lwe-shaft unomdla kakhulu kwikhowudi yesakhiwo sensimbi. Ixabiso loyilo lohlobo lwe-friction lilingana namaxesha angama-0.8 amandla angaphambili, kwaye ixabiso loyilo lohlobo loxinzelelo lilingana nommandla osebenzayo we-screw yanda ngexabiso loyilo lwamandla obunzima bezinto eziphathekayo. Kubonakala ngathi kukho umahluko omkhulu, enyanisweni, amaxabiso amabini ayafana.

Xa uthwala amandla okucheba kunye namandla okuzibamba kwicala le-axis yentonga ngaxeshanye, uhlobo lokukhuhlana lufuna ukuba umlinganiselo wamandla okucheba athwalwe yibholithi ukuya kumthamo wokucheba kunye nesimbuku somlinganiselo woxinzelelo lwamandla e-axial athwalwayo. Ngesikrufu kumthamo we-tensile ungaphantsi kwe-1.0, kwaye uhlobo loxinzelelo lufuna Sisimbuku sesikwere somlinganiselo wamandla okucheba kumthamo wokucheba webholithi kunye nesikwere se Umlinganiselo we-axial force kumthamo we-tensile we-screw ungaphantsi kwe-1.0, oko kukuthi, phantsi kwendibaniselwano yomthwalo ofanayo, i-diameter efanayo yokuthwala Ugcino lokhuseleko loyilo lweebholiti zamandla aphezulu luphezulu kunelo iibholithi zokuqina kohlobo lwefriction.

Ukuqwalasela ukuba phantsi kwesenzo esiphindaphindiweyo seenyikima ezinamandla, umphezulu wokudibanisa ukudibanisa unokusilela, kwaye umthamo wokucheba ngeli xesha usaxhomekeke kumthamo wokucheba webholithi kunye noxinzelelo lwamandla epleyiti. Ke ngoko, ikhowudi yenyikima ichaza elona qondo liphezulu lokucheba iibholiti zokuqina.

Nangona uhlobo oluthwele uxinzelelo lunenzuzo kwixabiso loyilo, kuba lolohlobo lokusilela koxinzelelo lwe-shear-compression, imingxuma yebholidi yimingxuma yebholithi ye-pore efana neebholiti eziqhelekileyo, kwaye ukuguqulwa phantsi komthwalo kukhulu kakhulu kunoko. uhlobo lokukhuhlana, ngoko ke iibholiti eziphezulu-zomelele zithwele uxinzelelo. imidibaniso yecandelo.

Umda wenkonzo eqhelekileyo uthi ezi ntlobo zimbini nazo zahlukile:

Uxhulumaniso lohlobo lwefriction lubhekiselele kwisalamane sokutyibilika komphezulu womdibaniso wonxibelelwano phantsi kodibaniso olusisiseko lwemithwalo;

Uxhulumaniso olujongene noxinzelelo lubhekiselele kwi-slippage ehambelanayo phakathi kweendawo zokudibanisa phantsi komgangatho womgangatho womthwalo;

Ibholithi eqhelekileyo

1. Iibholiti eziqhelekileyo zihlulwe zibe ziintlobo ezintathu: A, B, kunye no-C. Ezokuqala ezimbini zi-bolts eziphuculweyo, ezisetyenziswa ngaphantsi. Ngokuqhelekileyo, iibholiti eziqhelekileyo zibhekisa kwi-C-level bolts eziqhelekileyo.

2. Kwezinye iziqhagamshelo zexeshana kunye nodibaniso olufuna ukuchithwa, iibholiti eziqhelekileyo ze-C-level zisetyenziswa ngokuqhelekileyo. Iibholiti eziqhelekileyo ezisetyenziswa ngokuqhelekileyo kwizakhiwo zokwakha ziyi-M16, M20, M24. Ezinye iibholiti ezirhabaxa kwishishini lomatshini zinokuba nobukhulu obukhulu kwaye zisetyenziselwa iinjongo ezizodwa.

Iibholiti zamandla aphezulu

3. Izinto eziphathekayo zeebholiti eziphezulu zihluke kwiibhotshi eziqhelekileyo. Iibholiti zamandla aphezulu zisetyenziselwa ukudibanisa okusisigxina. Ngokuqhelekileyo zisetyenziswa yi-M16 ~ M30. Ukusebenza kwee-bolts ezigqithisiweyo eziphezulu zokuqina azinzanga kwaye kufuneka zisetyenziswe ngokuqaphela.

4. Ukudityaniswa kwebholidi yamacandelo aphambili esakhiwo sokwakha ngokuqhelekileyo kudityaniswe ngamabholiti aphezulu.

5. Iibholiti eziphezulu ezihanjiswa yifektri azihlelwanga zibe yi-pressure-bearing okanye i-friction-type.

6. Ngaba luhlobo lwe-friction-high-forth bolts okanye iibholiti ezinoxinzelelo oluphezulu? Enyanisweni, kukho umahluko kwindlela yokubala yoyilo:

I-1) Kuhlobo lwe-friction-high-high-power bolts, i-sliding phakathi kwamacwecwe ithathwa njengelizwe elilinganiselweyo lomthamo wokuthwala.

I-2) Kwimibhobho ephezulu yoxinzelelo, i-sliding phakathi kwamacwecwe ithathwa njengelizwe elilinganiselweyo lokusetyenziswa ngokuqhelekileyo, kwaye ukungaphumeleli kokudibanisa kuthathwa njengelizwe elilinganiselweyo lokuthwala amandla.

7. Iibholithi zohlobo lwefriction azikwazi ukunika umdlalo opheleleyo kwisakhono seebholithi. Kwizicelo ezisebenzayo, uhlobo lwe-friction-high-high-forth bolts kufuneka lusetyenziswe kwizakhiwo ezibaluleke kakhulu okanye izakhiwo ezixhomekeke kwimithwalo eguquguqukayo, ngakumbi xa umthwalo ubangela uxinzelelo olubuyela umva. Ngeli xesha, amandla ebholithi angasetyenziswanga angasetyenziswa njengendawo yokugcina ukhuseleko. Kwezinye iindawo, iibholiti ezinoxinzelelo oluphezulu kufuneka zisetyenziswe ukunciphisa iindleko.

Umahluko phakathi kweebholiti eziqhelekileyo kunye neebholiti zamandla aphezulu

8. Iibholiti eziqhelekileyo zingaphinda zisetyenziswe, kodwa iibholiti eziphakamileyo azinakuphinda zisetyenziswe.

9. Iibholiti eziphakamileyo ngokuqhelekileyo zenziwe ngentsimbi ephezulu (iNombolo ye-45 yensimbi (8.8s), i-20MmTiB (10.9S), i-bolts e-prestressed bolts. uhlobo loxinzelelo lukhulula intloko yeentyatyambo zeplum eziqhelekileyo zenziwe ngentsimbi eqhelekileyo (Q235) kwaye kuphela kufuneka iqiniswe.

10. Iibholiti eziqhelekileyo zibakala 4.4, ibakala 4.8, ibakala 5.6 nebakala 8.8. Iibholithi zokuqina okuphezulu ngokubanzi zibakala 8.8 kunye nebakala 10.9, apho ibakala 10.9 lelona lininzi.

. Ngapha koko, iibholiti eziqhelekileyo zinemingxuma emincinci yezikrufu.

12. Imingxunya ejijwayo yamabakala A no-B eebholithi eziqhelekileyo ngokubanzi nje 0.3~0.5mm makhulu kuneebholiti. Imingxunya yesijivu yodidi C iba yi-1.0~1.5mm ubukhulu kuneebholiti.

13. I-friction-type-high-power bolts ihambisa imithwalo nge-friction, ngoko ke umahluko phakathi kwe-screw rod kunye ne-screw hole inokufikelela kwi-1.5-2.0mm.

14. Iimpawu zokuhanjiswa kwamandla okunyanzeliswa koxinzelelo lwe-bolts-high-power bolts kukuqinisekisa ukuba phantsi kokusetyenziswa ngokuqhelekileyo, i-shear force ayigqithisi i-friction force, efana ne-friction-type high-strength bolts. Xa umthwalo unyuka kwakhona, ukutyibilika kwesalamane kuya kwenzeka phakathi kwamacwecwe okudibanisa, kwaye uqhagamshelo luxhomekeke kuxhathiso lokucheba lwe-screw kunye noxinzelelo lodonga lomngxuma ukuhambisa amandla, afana nalawo eebholiti eziqhelekileyo, Umahluko phakathi kwe-screw kunye ne-screw hole incinci kancinane, 1.0-1.5mm.

I-Anebon ibambelela kumgaqo othi “Inyanisekile, ikhuthele, ingenisa izinto ezintsha” ukufumana izisombululo ezitsha ngokuqhubekayo. I-Anebon ijonga amathemba, impumelelo njengempumelelo yobuqu. Vumela i-Anebon yakhe ikamva elinempumelelo kwisandla somatshini wobhedu kunye neengxenye ze-CNC ze-titanium / izincedisi zesitampu. I-Anebon ngoku inobonelelo lwempahla olubanzi kunye nexabiso lokuthengisa lilungelo lethu. Wamkelekile ukubuza malunga neemveliso ze-Anebon.

IiMveliso ezihamba phambili eTshayina iCNC yokuMaching iNdawo kunye neNqanaba eliChanekile, ngokwenene kufuneka nayiphi na kwezi zinto ibe nomdla kuwe, nceda usazise. I-Anebon iya kukuvuyela ukukunika ikowuti yakuba ifumene iinkcukacha zomntu. I-Anebon ineenjineli zethu zobuqu ze-R&D ukuhlangabezana nazo naziphi na iimfuno. I-Anebon ijonge phambili ekufumaneni imibuzo yakho kungekudala kwaye ndiyathemba ukuba nethuba lokusebenza kunye nawe kwixesha elizayo. Wamkelekile ukujonga umbutho we-Anebon.

Ixesha lokuposa: Jun-01-2023