Isishwankathelo seendlela ezisibhozo zokusetyenzwa komsonto ekufuneka uyazi xa usenziwa ngomatshini.

.Igama lesiNgesi elihambelana ne-Screw is Screw. Intsingiselo yeli gama itshintshe kakhulu kumakhulu eminyaka yakutshanje. Ubuncinci ngo-1725, lithetha "ukukhwelana".

Ukusetyenziswa komgaqo womsonto kunokulandwa umva kwisixhobo sokuphakamisa amanzi esijikelezayo esenziwe ngumphengululi ongumGrike uArchimedes ngowama-220 BC.

Ngenkulungwane ye-4 AD, amazwe aseMeditera aqala ukusebenzisa umgaqo weebholiti kunye namandongomane koomatshini bokushicilela abasetyenziswa ekwenzeni iwayini. Ngelo xesha, umsonto ongaphandle wawubotshwa ngentambo ukuya kwicylindrical bar uze ukrolwe ngokwalo phawu, ngoxa umsonto wangaphakathi wawudla ngokuyilwa ngokubethelela umsonto ongaphandle ngento ethambileyo.

Malunga ne-1500, kumzobo wesixhobo sokulungisa intambo esizotywe ngu-Leonardo da Vinci wase-Italiya, kwakukho umbono wokusebenzisa i-Screw yabasetyhini kunye negiya yokutshintshiselana ukucubungula imisonto ngeepitshi ezahlukeneyo. Ukususela ngoko, indlela yokusika imisonto ngoomatshini iye yaphuhliswa kwishishini laseYurophu lokwenza iiwotshi.

Ngowe-1760, abazalwana baseBritani uJ. Wyatt noW. Wyatt bafumana ilungelo elilodwa lomenzi wechiza lokusika izikrufu zomthi ngesixhobo esithile. Ngomnyaka we-1778, iBritish J. Ramsden yakha yenza isixhobo sokusika intambo esiqhutywa yiperi yegiya yeentshulube, esikwaziyo ukucubungula imisonto emide ngokuchaneka okuphezulu. Ngomnyaka we-1797, iNgesi uH. Maudsley wasebenzisa i-Screw yabasetyhini kunye nezixhobo zokutshintshiselana ukujika imisonto yentsimbi yeepitshi ezahlukeneyo kwi-lathe yakhe ephuculweyo, eyabeka indlela yokuqala yokujika imisonto.

Ngeminyaka yee-1820, uMaudsley wavelisa iimpompo zokuqala kwaye wafa ngenxa yokuthunga.

Ekuqaleni kwenkulungwane yama-20, uphuhliso lweshishini leemoto lwakhuthaza ngakumbi ukubekwa emgangathweni kwemisonto kunye nophuhliso lweendlela ezahlukeneyo ezichanekileyo nezisebenzayo zokucombulula intambo. Iintloko ezahlukeneyo zokuvula ezizenzekelayo zokuvula kunye neetephu ezizenzekelayo ezicuthekayo zayilwa enye emva kwenye, kwaye kwaqala ukusetyenziswa imisonto yokusila.

Ekuqaleni kweminyaka yee-1930, kwavela ukucola intambo.

Nangona iteknoloji yokuqengqeleka intambo yayinelungelo elilodwa lomenzi ekuqaleni kwenkulungwane ye-19, ngenxa yobunzima bokwenziwa komngundo, uphuhliso lwandiswa de kwayiMfazwe Yehlabathi yesiBini (1942-1945) ngenxa yesidingo sokuvelisa izixhobo kunye nophuhliso lobugcisa bokusila intambo. Ingxaki echanekileyo yokwenziwa kokungunda ikhule ngokukhawuleza.CNC ukujika inxalenye

Imisonto yahlulahlulwe kakhulu ibe yimisonto edibanisayo kunye nemisonto yokuhambisa.

Iindlela zokucubungula eziphambili zokudibanisa imisonto kukucofa, ukuthunga, ukuthunga, ukuqengqeleka, ukuqengqeleka kwentambo, njl.

Iindlela ezisembindini zokusetyenzwa kweentambo zothumelo zirhabaxa kwaye zijikajika kakuhle---ukusila, ukuguba---kurhabaxa kunye nokujika kakuhle, njl.

Udidi lokuqala kukusika intambo

Ngokubanzi ibhekisa kumatshini wokwenza imisonto yokwenza okanye izixhobo ezirhawukayo, ikakhulu ezibandakanya ukujika, ukungqusha, ukucofa kunye nokusila intambo, ukusila, kunye nokusika okujikelezayo. Xa ujika, ukugaya, kunye nokusila imisonto, ikhonkco lokuqhuba lesixhobo somatshini liqinisekisa ukuba isixhobo sokujika, isisiki sokusila, okanye ivili lokusila lihamba ngokuchanekileyo nangokulungeleleneyo ilothe enye ecaleni kweasi yesixhobo sokusebenza kwirevolution nganye yesixhobo sokusebenza. Xa ucofa okanye ukuthunga, isixhobo (itephu okanye ufe) kunye ne-workpiece ejikelezayo malunga nomnye, kunye ne-groove yentambo eyenziwe ngaphambili ikhokela isixhobo (okanye i-workpiece) ukuhamba nge-axially.

1. Ukujika imisonto

Ukuguqula intambo kwi-lathe kunokwenziwa ngesixhobo sokuguqula okanye i-thread comb. Ukuguqula imicu kunye nesixhobo sokuguqula isicatshulwa yindlela eqhelekileyo yecandelo elilodwa kunye nokuveliswa kwebhetshi encinci ye-workpieces edibeneyo ngenxa yesakhiwo esilula sesixhobo; ukuguqula imisonto ngesixhobo sokudibanisa intambo kunomgangatho ophezulu wemveliso, kodwa isakhiwo sesixhobo sinzima, sifanelekile kuphela kwimveliso yebhetshi ephakathi kunye nenkulu. Bajika imisonto emifutshane yokusebenzela enenowuti entle. Ukuchaneka kwe-pitch ye-lathes eqhelekileyo yokuguqula imicu ye-trapezoidal inokufikelela ngokubanzi kuphela kwi-8 ukuya kwi-9 amabakala (JB2886-81, efanayo ngezantsi); iintambo zoomatshini kwiileyile zemisonto ezikhethekileyo kunokuphucula kakhulu imveliso okanye ukuchaneka.

2. Ukugaya imisonto

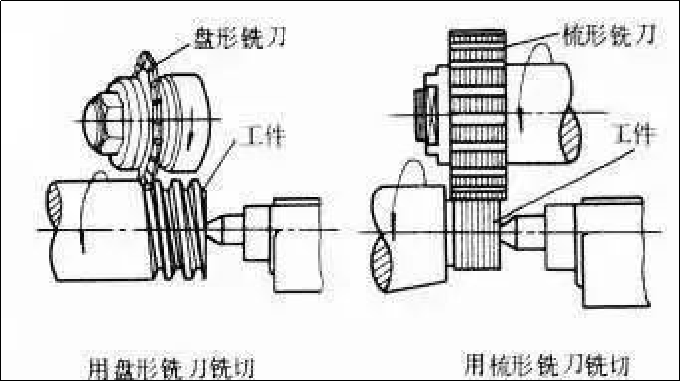

Bendisila ngedisc okanye icomb cutter kumsonto.

Disc milling cutters zisetyenziswa ikakhulu kwi milling trapezoidal imisonto yangaphandle kwi workpieces ezifana nezikrufu kunye neentshulube comb-ezimilise yokusila cutter isetyenziselwa lokusila yangaphakathi nangaphandle imisonto eqhelekileyo kunye nemisonto tapered. Ekubeni ixutywe nge-multi-blade milling cutter kunye nobude becandelo layo lokusebenza likhulu kunobude bomsonto, i-workpiece kufuneka ijikelezwe kuphela i-1.25 ukuya kwi-1.5 ijika ukuba iqhutywe kwaye yenziwe ngemveliso ephezulu. Ukuchaneka kwe-pitch yokugaya imisonto ngokubanzi kunokufikelela kumabanga esi-8 ukuya kwa-9, kwaye uburhabaxa bomphezulu yi-R5 ukuya kwi-0.63 ye-microns. Le ndlela ifanelekile kwimisonto yokusebenza enemisonto yokuchaneka ngokubanzi okanye ukurhaxa phambi kokusila.

Umsiki wokugaya umsonto wokwenza imisonto yangaphakathi

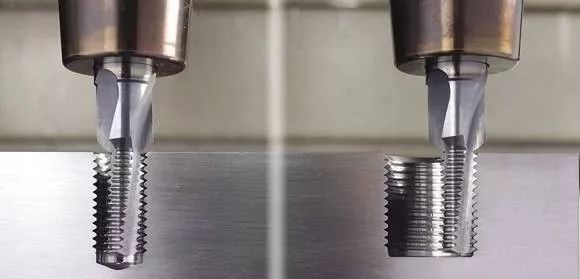

3. Ukusila imisonto

Isetyenziselwa ikakhulu ukucubungula imisonto echanekileyo yezixhobo zokusebenza eziqinisiweyo kumatshini wokusila intambo. Ubume becandelo lomnqamlezo wevili lokugaya lunokwahlulwa lube ziindidi ezimbini: ivili lokugaya umgca omnye kunye nevili lokugaya i-multi-line. Ukuchaneka kwe-pitch okuphunyezwa ngokusila ivili lomgca omnye ngamabakala ama-5 ukuya kwa-6, kwaye uburhabaxa bomphezulu yi-R1.25 ukuya kwi-0.08 microns, ekulungele ngakumbi ukugquma isondo. Le ndlela ilungele ukusila izikrufu ezichanekileyo, iigeyiji zemisonto, iintshulube, iibhetshi ezincinci zemisonto ephothiweyo, kunye neendawo zokusila ezichanekileyo. Ukugaya ivili lokusila ngemigca emininzi yahlulwe ngokweendlela zokusila zelongitudinal kunye ne-plunge. Kwindlela yokugaya i-longitudinal, ububanzi bevili lokusila buncinane kunobude bomsonto oza kucolwa, kwaye ivili lokusila lihamba ngobude kube kanye okanye izihlandlo ezininzi ukuze licole umsonto ukuya kumlinganiselo wokugqibela. Ububanzi bevili lokusila lendlela yokugaya i-plunge inkulu kunobude bomsonto oza kwenziwa. Ivili lokusila lisikwa ngokukhawuleza kumphezulu we-workpiece, kwaye i-workpiece inokucolwa kakuhle emva kokuguqulwa kwe-1.25. Imveliso iphezulu, kodwa ukuchaneka kuphantsi kancinci, kwaye isondo lokugaya linzima ngakumbi. I-Plunge grinding ilungele ukukhulula ukucola iibhetshi ezinkulu zeetephu kunye nokusila imisonto ethile yokuqinisa.iinxalenye ze-aluminium extrusion

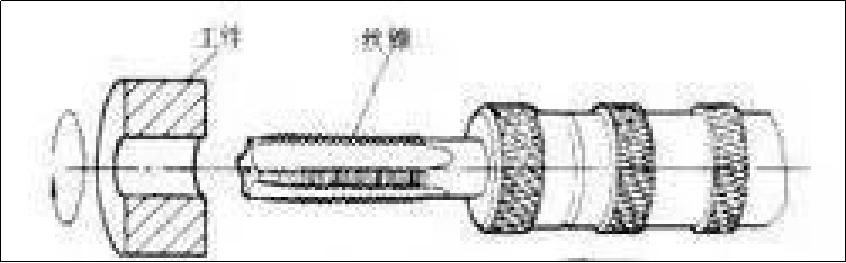

4. Ukusila imisonto

I-nut-type okanye i-screw-type thread grinder yenziwe ngezinto ezithambileyo ezifana nentsimbi etyhidiweyo, kwaye iindawo apho intambo inempazamo ye-pitch kwi-workpiece ixhomekeke phambili kwaye iguqule ukujikeleza ukujikeleza ukuphucula ukuchaneka kwe-pitch. Iintambo zangaphakathi eziqiniweyo zihlala ziphantsi ukuphelisa i-deformation kunye nokuphucula ukuchaneka.

5. Ukucofa kunye nokuthunga

Ukucofa

Kukukrukra impompo kumngxuma ongaphantsi ogrunjwe kwangaphambili kwisixhobo sokusebenza kunye netorque ethile ukucubungula umsonto wangaphakathi.

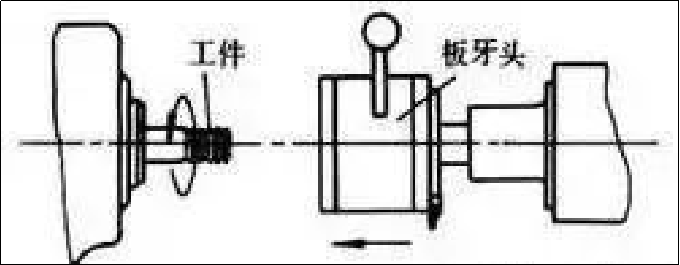

Umsonto

Sika intambo yangaphandle kwi-bar (okanye umbhobho) i-workpiece kunye ne-die. Ukuchaneka komatshini wokucofa okanye ukuthunga kuxhomekeke ekuchanekeni kompompo okanye kufa.amalungu aluminiyam

Nangona kukho iindlela ezininzi zokucutshungulwa kwangaphakathi nangaphandle, iintambo zangaphakathi ezinobubanzi obuncinci zinokucutshungulwa kuphela ngeetephu. Ukucofa nokuthunga kunokwenziwa ngesandla, nangeentambo, ngoomatshini bomatshini bokucofa, noomatshini bokuthunga.

Udidi lwesibini: Ukuqengqeleka kwemisonto

Indlela yokucubungula yeplastiki yokuguqula i-workpiece kunye ne-forming rolling die ukuze ufumane intambo. Ukuqengqeleka komsonto ngokuqhelekileyo kwenziwa kumatshini wokuqengqeleka komsonto okanye i-lathe ezenzekelayo enokuvulwa nokuvala i-Tread rolling head, intambo yangaphandle yokuvelisa ngobuninzi beziqhoboshi ezisemgangathweni, kunye nolunye udibaniso olunentambo. I-diameter yangaphandle ye-Thread rolled isThreadally ayikho ngaphezu kwe-25 mm, ubude abukho ngaphezu kwe-100 mm, ukuchaneka kwentambo kunokufikelela kwinqanaba le-2 (GB197-63), kwaye ububanzi bendawo engenanto esetyenzisiweyo ilingana ngokulinganayo nobubanzi bepitch. yoMtya ogqityiweyo. I-RTthread ngokubanzi ayikwazi ukwenza imisonto yangaphakathi, kodwa kwizinto zokusebenza ezinemathiriyeli ethambileyo, itephu ye-extrusion engenamsele ingasetyenziselwa ukukhupha imisonto yangaphakathi ebandayo (ubukhulu bedayamitha inokufikelela malunga ne-30 mm). Umgaqo wokusebenza ufana nowokucofa. I-torque efunekayo kwi-extrusion ebandayo yeentambo zangaphakathi malunga namaxesha angama-1 amakhulu kunokokucofa, kwaye ukuchaneka kwe-machining kunye nomgangatho womhlaba uphezulu kancinane kunezo zokucofa.

Izinto eziluncedo zokuqengqeleka komsonto:

① Uburhabaxa bomphezulu buncinci kunobo bujikajika, bungqusha, kunye nokusila;

②Umphezulu we-Thread afThreadlling ungaphucula amandla kunye nobunzima ngenxa yomsebenzi obandayo wokuqina;

③Ireyithi yokusetyenziswa kwezinto iphezulu;

④Imveliso iphindwe kabini xa kuthelekiswa nokusikwa, kwaye kulula ukuyiqonda i-automation;

⑤ Ubomi bomqengqelezi bude kakhulu. Nangona kunjalo, i-rolling Thread reThread ukuba ubulukhuni besixhobo sokusebenza abudluli HRC40; ukuchaneka kwe-dimensional ye-blank iphezulu; ukuchaneka kunye nobunzima bokufa okuqengqelekayo nako kuphezulu, kwaye kunzima ukwenza idiyizi; ayifanelekanga ukuqengqeleka kwemicu ene-asymmetric tooth shape.

Ngokufa kokuqengqeleka okwahlukileyo, Umsonto unokwahlulwa ube ziindidi ezimbini: Ukuqengqeleka komsonto kunye ne-Threadthreadd.

6. Ukuqengqeleka komsonto

Iipleyiti ezimbini zokuqengqeleka ezinemisonto yamazinyo zicwangciswe ngokuchaseneyo kunye ne-1/2 pitch; ipleyiti engatshintshiyo ilungisiwe, kwaye ipleyiti eshukumayo ihamba kwi-reciprocating linear motion parallel kwipleyiti engatshintshiyo. Xa i-workpiece ithunyelwa phakathi kwamacwecwe amabini, ipleyiti eshukumayo iqhubela phambili kwaye ikhuhle i-workpiece ukuze i-plastic ikhubaze umphezulu ukwenza intambo (Umfanekiso 6 [Screwing]).

7. Ukuqengqeleka komsonto

Kukho iintlobo ezintathu ze-radial Thread roThread, tangential Thread roThread, kunye nentloko eqengqelekayo.

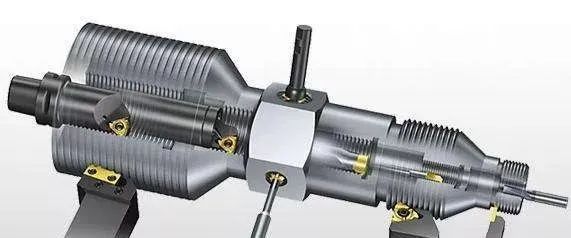

①I-Radial Threathreadad 2 (okanye 3) amavili aqengqelekayo anemisonto yeprofayile afakelwe kwishafti ezinxuseneyo; i-workpiece ifakwe kwinkxaso phakathi kwamavili amabini, kwaye amavili amabini ajikeleza ngendlela efanayo nangesantya esifanayo (Umfanekiso 7). [I-Radial Thread rolling]), enye yemijikelo, yenza intshukumo yokutya kweradial. Ivili elijikelezayo lijikeleza i-workpiece, kwaye umphezulu we-radially extruded ukwenza imisonto. Kwezinye izikrufu ezikhokelayo ezingadingi kuchaneka okuphezulu, indlela efanayo ingasetyenziselwa ukwenza umqulu.

②Tangential Thread roThread Eyaziwa ngokuba yiplanetary Thread roThread, isixhobo esiqengqelekayo sinevili elijikelezayo elijikelezayo eliphakathi kunye neepleyiti ezintathu ezilungisiweyo ezimile okwearc (umzobo 8 [I-Tangential Thread rolling]). Umsebenzi wokusebenza unokondliwa ngokuqhubekayo ngexesha lomsonto, ngoko ke imveliso iphezulu kunaleyo ye-Thread roThreadand radial Thread thread.

③ Umsonto uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uwafunde umsonto: Wenziwa kwileyile ezenzekelayo kwaye ngokuqhelekileyo isetyenziselwa ukusetyenzwa kwemisonto emifutshane kwisixhobo sokusebenza. Kukho i-3 ukuya kwe-4 yamavili ajikelezayo asasazwa ngokulinganayo kwi-periphery yangaphandle ye-workpiece kwintloko eqengqelekayo (Umfanekiso we-9 [Umsonto owenziwe ngokutsha]). Ngexesha lokuqengqeleka kwentambo, i-workpiece ijikeleza, kwaye intloko eqengqelekayo itya i-axially ukuze ikhuphe i-workpiece ngaphandle kweThread.

Ukuthunga imisonto

Ukusetyenzwa kwemicu eqhelekileyo ngokuqhelekileyo isebenzisa amaziko omatshini okanye izixhobo zokucofa kunye nezixhobo; ngamanye amaxesha, ukucofa ngesandla kuyenzeka. Nangona kunjalo, kwezinye iimeko ezikhethekileyo, le ndlela ingasentla ayilulanga ukufumana iziphumo ezilungileyo zokucwangcisa, ezifana nesidingo somatshini wemisonto emva kokunyangwa kobushushu bamalungu ngenxa yokungakhathali okanye ngenxa yezithintelo zezinto eziphathekayo, ezifana nesidingo sokucofa ngokuthe ngqo kwi-carbide workpieces. . Ngeli xesha, kuyimfuneko ukuqwalasela indlela yokucubungula i-pEDM.

Xa kuthelekiswa nendlela yokwenza, inkqubo ye-EDM ikwindlela efanayo: umngxuma ongezantsi kufuneka uqhutywe kuqala, kwaye ububanzi bomngxuma ongezantsi kufuneka bunqunywe ngokwemiqathango yokusebenza. I-electrode kufuneka ifakwe kwimilo yentambo, kwaye i-electrode idinga ukukwazi ukujikeleza ngexesha lenkqubo yokucoca.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Apr-15-2022