Ngaba uyazi ukuba zingaphi iindlela ezikhoyo zokuseta isixhobo esichanekileyo kwiileyile ze-CNC?

Indlela yokucofa iProbe: - Le ndlela isebenzisa iprobe echukumisa isixhobo ukulinganisa indawo yaso malunga nendawo yesalathiso yomatshini. Inika idatha echanekileyo kwidayamitha yesixhobo kunye nobude.

Isixhobo sokuSeta kwangaphambili:Isixhobo sokusetha kwangaphambili sisetyenziselwa ukulinganisa imilinganiselo yesixhobo ngaphandle komatshini. Le ndlela ivumela ukusekwa ngokukhawuleza nangokuchanekileyo kwesixhobo.

Indlela yokuSetyenziswa kwesixhobo:- Ngale ndlela, umqhubi ulinganisa ubude kunye nobubanzi besixhobo usebenzisa izixhobo ezifana ne-calipers kunye ne-micrometers. Amaxabiso ke angeniswa kwinkqubo yolawulo lomatshini.

Umlinganiselo wesixhobo seLaser:Iinkqubo zeLaser zisetyenziselwa ukuseta nokulinganisa imilinganiselo yesixhobo. Ngokubonisa ukukhanya kwelaser kumda wokusika wesixhobo, babonelela ngedatha yesixhobo esichanekileyo kunye nesikhawulezayo.

Indlela yokuqaphela umfanekiso:Iinkqubo zekhompyuter ezikwinqanaba eliphezulu zinokusebenzisa itekhnoloji yokuqaphela umfanekiso ukubala ngokuzenzekelayo imilinganiselo yesixhobo. Bakwenza oku ngokuthatha imifanekiso yesixhobo, bahlalutye iimpawu zaso baze babale imilinganiselo.

Eli linqaku eliluncedo kakhulu. Inqaku lazisa kuqala imigaqo kunye neengcamango emva "kwendlela yokumisela isixhobo sokulinga" esetyenziswa ngokuqhelekileyo ngeelayile ze-CNC. Emva koko yazisa iindlela ezine zezandla zokucwangcisa isixhobo sokusika isilingo kwiinkqubo zokuguqula i-CNC. Ukuphucula ukuchaneka kwezicwangciso zayo zesixhobo, inkqubo elawulwa ngokuzenzekelayo indlela yokusika isilingo esekelwe "kwi-automatic cutting - measuring - error compensation" yaphuhliswa. Iindlela ezine ezichanekileyo zokuseta izixhobo nazo ziye zashwankathelwa.

1. Umgaqo kunye neengcamango emva kwesixhobo-setting method for CNC lathes

Ukuqonda imigaqo ye-CNC ye-lathe-setting tool-setting kubalulekile kubaqhubi abafuna ukugcina iingcamango ezicacileyo malunga nokusetwa kwesixhobo, ukuseta izixhobo zokusebenza, kunye nokucebisa iindlela ezintsha. Ukusetwa kwesixhobo kukumisela indawo yemvelaphi yenkqubo yolungelelwaniso lwesixhobo sokusebenza, esitshintsha xa kusenziwa inkqubo isixhobo somatshini silungelelanisa inkqubo. Ukusetwa kwesixhobo kubandakanya ukufumana ulungelelwaniso lomatshini kwindawo yokuqala yenkqubo yesixhobo sereferensi, kunye nokumisela isixhobo sokujongana neso sixhobo.

Le migaqo ilandelayo isetyenziselwa ukubonisa iikhonsepthi kunye neengcamango emva kokusetwa kwesixhobo usebenzisa indlela yokusika isilingo. Sebenzisa i-Hua Medieval Star Teaching Turning System (inombolo ye-5.30 ye-software yesicelo); sebenzisa embindini wobuso besiphelo sasekunene kumsebenzi wemvelaphi yenkqubo kwaye uyimise ngomyalelo weG92. Iprogram ye-Diameter, i-workpiece yokulungelelanisa indawo yokuqala yeprogram H (100,50); fakela izixhobo ezine kwisibambi sesixhobo. Isixhobo esingu-No.1 sisixhobo sokuguqula i-90deg kunye ne-No. imela, iNombolo. Imela yesi-4 imela enemisonto engunxantathu ene-angle ye-60deg (imizekelo kwinqaku iyafana).

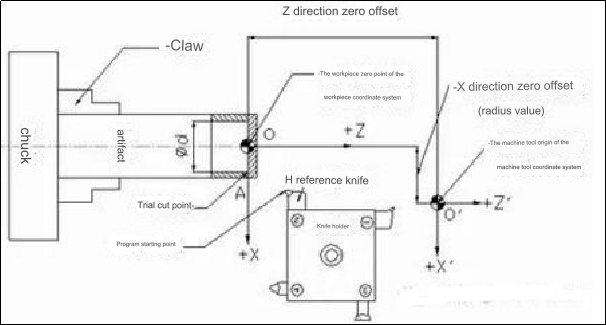

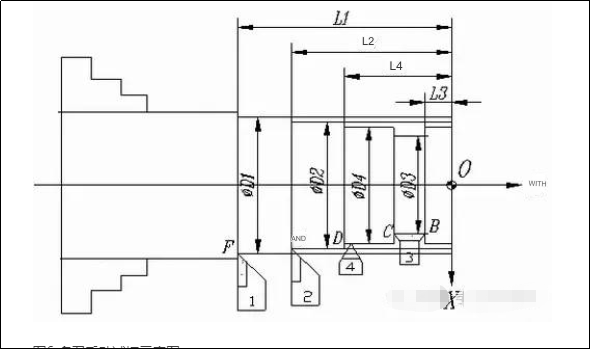

Ulungelelwaniso "lwesixhobo somatshini" lusetyenziselwa ukusetwa kwesixhobo. Njengoko kubonisiwe kumzobo woku-1, isixhobo sokukhangela “uvavanyo ngesandla sisika isangqa sangaphandle kunye nesiphelo sobuso bomsebenzi kwaye sirekhoda isixhobo somatshini weXZ ulungelelanisa kwisiboniso. Isixhobo somatshini silungelelanisa imvelaphi yenkqubo ye-O ithathwe kubudlelwane phakathi kolungelelwaniso lwesixhobo somatshini kwindawo A kunye ne-O: XO=XA - Phd, ZO=ZA. Ukusebenzisa ulungelelwaniso lwe-workpiece ye-H ngokumalunga ne-point O (100,50), ekugqibeleni sinokufumana ulungelelwaniso lwesixhobo somatshini kwindawo H: XH = 100 – Phd, ZH=ZA+50. Le nkqubo yolungelelwaniso lweworkpiece isekwe phezu kwendawo yengcebiso yesixhobo kwisixhobo sokubhekisela.

Umzobo 1 Umzobo weSchematic wokusika isilingo sokwenziwa ngesandla kunye noseto lwesixhobo

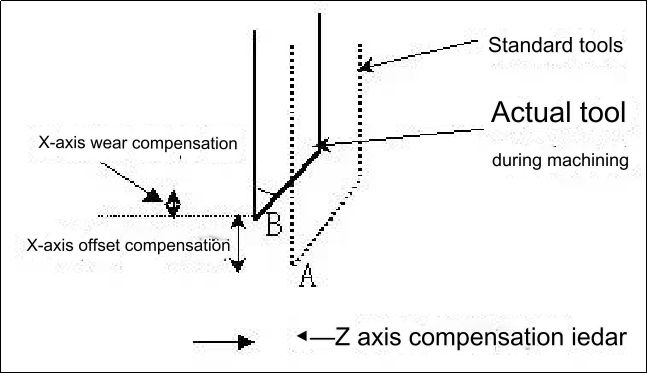

Kwi-Figure 2, i-offset phakathi kwenqaku A kunye nesixhobo se-tip B senzeke ngenxa yokungafani kwezandiso kunye nezikhundla kwi-X- kunye ne-Z-direction yezixhobo ezifakwe kumphathi wesixhobo. Isixokelelwano sokuqala solungelelwaniso lomsebenzi asisasebenzi. Isixhobo ngasinye siya kunxiba ngesantya esahlukileyo ngexesha lokusetyenziswa. Ngoko ke, isixhobo sokunciphisa kunye nexabiso lokunxiba kwisixhobo ngasinye kufuneka sibuyekezwe.

Ukumisela i-offset yesixhobo, isixhobo ngasinye kufuneka sihambelane kwindawo ethile yokubhekisela (inqaku A okanye B kwi-Figure 1) kwi-workpiece. I-CRT ibonisa ulungelelwaniso lwesixhobo somatshini olwahlukileyo kwizixhobo ezisetyenzisiweyo zezixhobo ezingabhekiseliyo. Ngoko ke, zibekwe kwindawo enye. Ngokusebenzisa izibalo zezandla okanye izibalo zesoftware, ulungelelwaniso lwesixhobo somatshini luthatyathwe kwezo zesixhobo sokubhekisela. Isixhobo sokususa isixhobo sibalwa kwisixhobo ngasinye esingesiso esiqhelekileyo.

Umzobo 2 Imbuyekezo yesixhobo sokumisa kunye nokuguga

Ukuchaneka kwesethingi yesixhobo sokusika isilingo sesandla silinganiselwe. Oku kwaziwa njengokusebenzisa izixhobo ezirhabaxa. Njengoko kubonisiwe kuMfanekiso 3, ukufumana iziphumo ezichaneke ngakumbi ngaphakathi kwezibonelelo zoomatshini zecnc auto inxalenye, inkqubo yokusika isilingo esilula ngokuzenzekelayo ingenziwa. Imela yereferensi ilungiswa ngokuqhubekayo kusetyenziswa ingcamango "yembuyekezo ye-automatic cutting-measurement-error". Isixhobo sokunciphisa isixhobo kunye nendawo yokuqalisa inkqubo yesixhobo esingabhekiseliyo sisetyenziselwa ukuqinisekisa ukuba umahluko phakathi kwexabiso lomyalelo wokusetyenzwa kunye nelona xabiso lilinganisiweyo liyahlangabezana neemfuno zokuchaneka. Ulungiselelo lwesixhobo oluchanekileyo luseto lwesixhobo esenzeka kweli nqanaba.

Kuqhelekile ukulungisa izinto ezingekho mgangathweni emva kokulungiswa kokuqala. Oku kungenxa yokuba ukuqinisekisa indawo ekuqalelwa kuyo isixhobo sereferensi ichanekile yinto efunekayo ukuze kusetyenziswe izixhobo ezichanekileyo.

Le nkqubo yokumisela isixhobo esisiseko iphunyezwa ngokudibanisa ezi zigaba zimbini: uvavanyo ngesandla ukusika imela ngereferensi yokufumana ulungelelwaniso lwesixhobo somatshini kwireferensi yokuseta isixhobo. -Bala okanye uzibale ngokuzenzekelayo izixhobo ezisetyenzisiweyo kwisixhobo ngasinye esingabhekiseliyo. – Imela yereferensi ifumaneka ekuqaleni kwenkqubo. – Ireferensi imela ibiza ngokuphindaphindiweyo inkqubo yokusika uvavanyo. Umphathi wesixhobo uya kuhanjiswa kwi-MDI okanye kwimodi yesinyathelo ukuze ahlawule iimpazamo kwaye alungise indawo yokuqala. Emva kokulinganisa ubungakanani imela engeyosiseko iya kubiza ngokuphindaphindiweyo inkqubo yokusika uvavanyo. Isixhobo sokulinganisa silungiswa ngokusekwe kolu hlaselo. Oku kuthetha ukuba isixhobo sokukhangela siya kuhlala simi kwasekuqaleni kweprogram.

Umzobo 3 Umzobo weSchematic weSixhobo sokuSeta i-Multi-Knife Trial Cutting

Isishwankathelo sobuchule bokucwangcisa imela

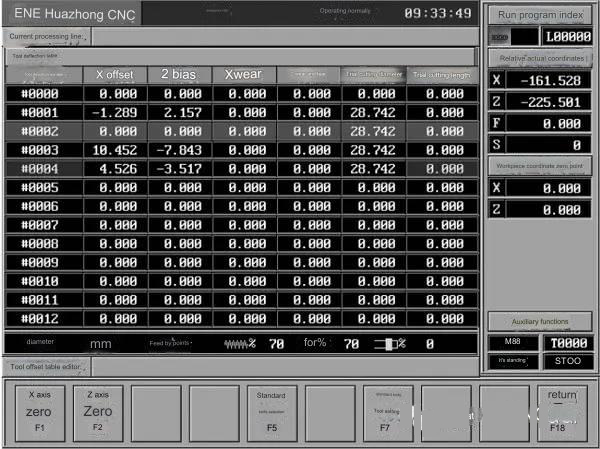

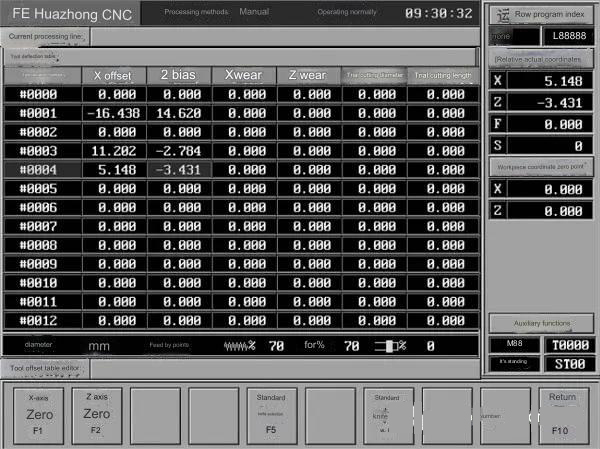

Ukulungiselela ukusetwa kwesixhobo, ungasebenzisa naziphi na iindlela ezilandelayo: cofa iqhosha le-F2 kwimenyu ephantsi ye-MDI yokufikelela kwitafile yesixhobo. Sebenzisa izitshixo ukuhambisa ibha yokuqaqambisa kwindawo yenombolo yesixhobo ehambelana nesixhobo ngasinye kwaye ucinezele iqhosha leF5. Guqula u-X kunye no-Z amaxabiso okuphelisa amanani esixhobo #0000 kunye ne #0001, emva koko ucinezele iqhosha F5.

1) Seta ngokuzenzekelayo indlela yokucima isixhobo ngokukhetha isixhobo sokubhekisela.

Amanyathelo okuseta isixhobo aboniswe kwiMifanekiso 1 kunye ne-4.

Ibha eluhlaza okwesibhakabhaka egxininiswe kunye nezitshixo inokushukunyiswa ukulungelelanisa i-tool offset #0002 ye-No. Isixhobo sokubhekisela 2. Ukuseta i-No.2, cofa iqhosha le-F5. Isixhobo esi-2 siya kusekwa njengesixhobo esihlala sihleli.

2) Sika isangqa sangaphandle kunye nesixhobo sokubhekisela kwaye uqaphele i-X yokulungelelanisa isixhobo somatshini. Emva kokubuyisela isixhobo, yeka umatshini kwaye ulinganise ububanzi bangaphandle becandelo le-shaft.

I-3) I-reference blade ibuyela kwindawo A ebhalwe nge "jog + step" indlela. Igalelo le-PhD kunye ne-zero kwiikholomu zokusika ububanzi bovavanyo kunye nobude bokusika uvavanyo ngokulandelanayo.

4) Hlehlisa isixhobo esisemgangathweni kwaye ukhethe inani lesixhobo esingenamgangatho. Emva koko, sitshintshe ngesandla isixhobo. Ingcebiso yesixhobo kwisixhobo ngasinye esingeyomgangatho kufuneka ihambelane ngokubonakalayo nenqaku A kusetyenziswa indlela “yokujog + inyathelo”. Lungisa i-offset ehambelanayo emva kokuba isixhobo silungelelaniswe ngokubonakalayo. Ukuba ufaka i-zero kunye ne-PhD kwiikholamu zobude bokulingwa kunye nobubanzi, i-knife offsets yazo zonke iimela ezingabhekiseliyo ziya kuboniswa ngokuzenzekelayo kwikholamu ye-X offset kunye ne-Z.

5) Emva kokuba isixhobo sokubhekisela sibuyele kwindawo A, i-MDI iya kuqhuba "G91 G00 / okanye" G01 X[100 PhD] Z50 ukuya kwindawo yokuqala yeprogram.

Umzobo 4 Umzobo weSchematic wesixhobo sokubhekisela ngokuzenzekelayo ukusetha i-offset yesixhobo kwisixhobo esiqhelekileyo

2. Cwangcisa ulungelelwaniso lwesixhobo sereferensi ku-zero kwindawo yokubeka isixhobo kwaye ubonise ngokuzenzekelayo indlela yokuphelisa isixhobo.

Njengoko kubonisiwe kuMfanekiso 1 kunye noMzobo 5, amanyathelo okuseta isixhobo alandelayo:

1) Ngokufanayo nenyathelo (2) ngasentla.

I-2) I-reference knife ibuyela kwindawo yokusika isilingo A ngokusebenzisa "i-jog + step" indlela ngokwexabiso elirekhodiweyo.

3) Kwi-interface eboniswe kwi-Figure 4, cinezela iqhosha le-F1 "ukusetha i-X-axis ukuya kwi-zero" kwaye ucinezele iqhosha le-F2 "ukusetha i-Z-axis ukuya kwi-zero". Emva koko "ulungelelwaniso lwangempela" oluboniswe yi-CRT lu (0, 0).

4) Guqula ngesandla isixhobo esingabhekiseliyo ukwenzela ukuba isixhobo saso sixhobo sihambelane ngokubonakalayo kunye nenqaku A. Ngeli xesha, ixabiso "lokulungelelaniswa kwangempela" eliboniswe kwi-CRT sisixhobo sokunciphisa isixhobo esinxulumene nesixhobo sokubhekisela. Sebenzisa i-▲ kunye nezitshixo ukuhambisa ibhlowu Gqamisa inombolo yokucima isixhobo yesixhobo esingabhekiseliyo, usirekhode kwaye usifake kwindawo ehambelanayo.

5) Ngokufanayo nesinyathelo sangaphambili (5).

Umzobo 5 Umzobo weSchematic weSixhobo se-Offset uboniswa ngokuzenzekelayo xa iSixhobo seReferensi sisetelwe kwi-zero kwisixhobo sokucwangcisa iindawo zereferensi zokulungelelanisa.

3. Indlela ye-knife offset ibalwa ngokubala ngesandla ukusika isilingo ngeemela ezininzi zecandelo le-shaft shaft yangaphandle.

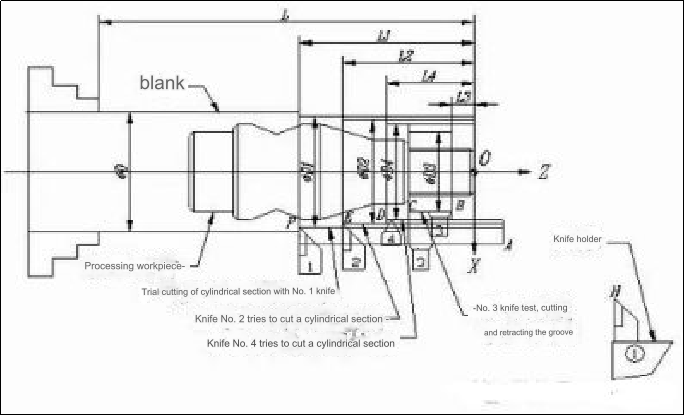

Njengoko kuboniswe kumfanekiso wesi-6, inkqubo yokulungelelanisa ngesandla iimela 1, 2 kunye ne-4 kwaye inqumle i-axis. Emva koko irekhoda ulungelelwaniso lomatshini kwiincam zokusika zemela nganye. (Amanqaku F, D, kunye no-E kumfanekiso 6). Yenza umlinganiselo wedayamitha kunye nobude becandelo ngalinye. Faka esikhundleni imela yokusika ye-1. Njengoko kubonisiwe kumfanekiso, sika ikhefu lesixhobo. Ukulungelelanisa i-blade yokusika kunye nencam echanekileyo, bhala ulungelelwaniso lwenqaku B kwaye ulinganise i-L3 kunye ne-PhD3 ngokomfanekiso. Ubudlelwane bokulungelelaniswa okunyukayo phakathi kwamanqaku e-F, E kunye no-D kwisixhobo ngasinye, kunye nemvelaphi ye-O inokumiselwa ngokuthelekisa idatha engentla.

Emva koko kunokubonwa ukuba ulungelelwaniso lwesixhobo somatshini lu (X2-PhD2 + 100 kunye ne-Z2-L2 + 50) kunye nolungelelwaniso lwesixhobo somatshini ukulungiselela indawo yokuqala ehambelana nesixhobo sokubhekisela. Indlela yokubala iboniswe kwitheyibhile 1. Kwiindawo ezingenanto, faka ixabiso elibalwe kwaye lirekhodwe. Qaphela: Umgama wokusikwa kwesilingo ngumgama phakathi kwendawo yolungelelaniso enguziro yesixhobo sokusebenza kunye nesiphelo sovavanyo olusikwe kwi-Z-direction. Izalathiso ezilungileyo nezingalunganga zichongwa yi-coordinate axis.

Umzobo 6 Umzobo weSchematic wokusika isilingo sokwenza iimela ezininzi

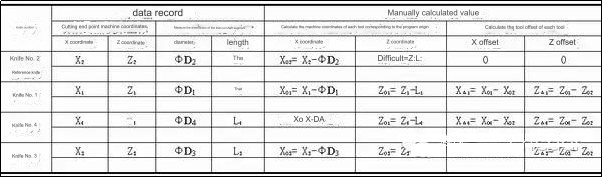

Itheyibhile 1 Ukubalwa kwezixhobo zokususa izixhobo ezingezizo ezisemgangathweni

Le ndlela ivumela inkqubo yokusika uvavanyo olulula, njengoko isusa isidingo sokujonga ngokubonakalayo amanqaku okusika uvavanyo. Nangona kunjalo, i-knife offset kufuneka ibalwe ngesandla. Unako ukubala isixhobo offset ngokukhawuleza ukuba uprinte iphepha ngefomula uze ugcwalise izikhewu.

Umzobo 7 Umzobo weSchematic wokusetwa kwesixhobo esizenzekelayo kwinkqubo ye-Century Star CNC

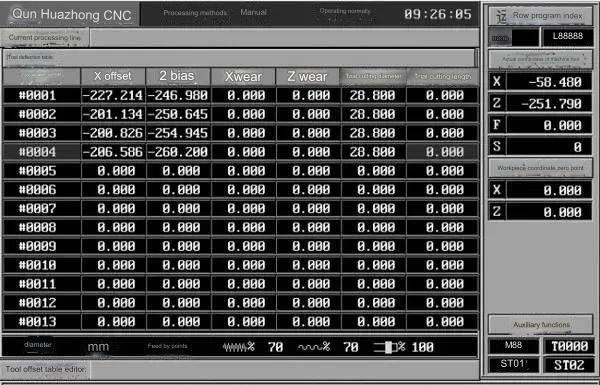

Isixhobo esizenzekelayo sesixhobo sokuseta indlela ye-4th Century Star CNC

Zonke ezi ndlela zikhankanywe ngasentla zesixhobo sokuthotywa kwesixhobo ziindlela ezihambelanayo. Emva kokuba abasebenzi abaqeqeshiweyo benze i-parameter setting kunye novavanyo lwenkqubo, i-HNC-21T ivumela abasebenzisi ukuba bakhethe "indlela yokucima ngokupheleleyo" xa bebeka izixhobo. Kwinkqubo yokucwangcisa, i-absolute tool offset yahluke kancinane kunendlela yokucima isixhobo. Akuyimfuneko ukusebenzisa i-G92 okanye i-G54 kwiinkqubo zokulungelelanisa i-workpiece, kwaye akukho mfuneko yokukhansela imbuyekezo yesixhobo. Jonga inkqubo O1005 umzekelo. Njengoko kubonisiwe kuMfanekiso 6, emva kokuba inkqubo ibuyele ku-zero, vumela imela nganye izame ngesandla ukusika icandelo le-cylinder.

Gcwalisa amanani okunciphisa isixhobo kwimela nganye emva kokulinganisa ubude kunye nobubanzi. Ubude bokusika kwesilingo zidweliswe kwikholamu yovavanyo lokusika idayamitha. Isoftware yenkqubo, isebenzisa indlela echazwe kwi "Multiknife Cutting of External Shaft Segment - Manual Calculation for Knife Offset", ingabala ngokuzenzekelayo izixhobo zomatshini zokulungelelanisa imela nganye ngokwemvelaphi yeprogram. Le ndlela yokumisela isixhobo yeyona ikhawulezayo, kwaye ifaneleke ngokukodwa kwimveliso yemizi-mveliso.

Isishwankathelo seendlela ezihlanu ezichanekileyo zokucwangcisa izixhobo

Umgaqo wokusetwa kwesixhobo esichanekileyo “kumlinganiselo ozenzekelayo, ukusika isilingo esizenzekelayo kunye nembuyekezo yempazamo”. Imbuyekezo yemposiso inokwahlulwa ibe ziindidi ezimbini: Kuba isixhobo sokubhekisela kwi-MDI yokusebenza, okanye inyathelo lezithuba zesixhobo sokubuyisela inkqubo yayo yokuqalisa; kunye nesixhobo esingengomgangatho sihlawulela isixhobo saso sokulinganisa okanye ukunxiba amaxabiso. Ukuphepha ukudideka, iThebhile 2 yenzelwe ukubala nokurekhoda amaxabiso.

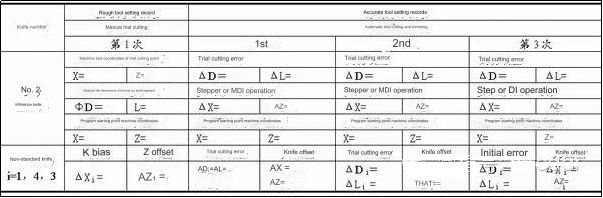

Itheyibhile ye-2 yeSixhobo sokuSeta iRekhodi yeTheyibhile yeNdlela yokuLinga yokuSika (Iyunithi: mm

1. Guqula indlela ye-offset yesixhobo ngasinye esingenamgangatho emva kokuba isixhobo sokubhekisela silungise indawo yokuqala.

Amanyathelo okuseta isixhobo aboniswe kuMfanekiso 3.

Emva kokulungelelaniswa kwesixhobo esirhabaxa, isixhobo sokubhekisela kufuneka sibe ekuqaleni kwenkqubo. Faka i-offset yesixhobo ngasinye esingengomgangatho kwindawo efanelekileyo yetafile.

Sebenzisa inkqubo ye-O1000 ukucubungula i-PhD2xL2 ukuze wenze ulingo lokusika.

Emva koko, linganisa ububanzi kunye nobude be-shaft yokusika edibeneyo, thelekisa ngexabiso kwiprogram yomyalelo, kwaye unqume iphutha.

Guqula indawo yokuqalisa yenkqubo ukuba ixabiso lemposiso ye-MDI okanye intshukumo yenyathelo inkulu kunexabiso lemposiso ye-MDI.

5) Guqula ixabiso lomyalelo we-O1000 ngokuguquguqukayo ngokusekelwe kwimilinganiselo elinganisiweyo kwaye ugcine inkqubo. Phinda amanyathelo (2) de indawo yokuqala yesixhobo sokubhekisela ingaphakathi kwinqanaba lokuchaneka. Qaphela ulungelelwaniso lwesixhobo somatshini kwindawo yokuqala yenkqubo elungisiweyo. Seta ulungelelwaniso kwiqanda.

6) Cofa i-O1001 (i-knife no. 1, No. O1002 (imela no. 3) kwisilingo ngasinye sokusika, kwaye ulinganise ubude be-Li (i = 1, 2, 3) kunye nobukhulu be-PhDi yecandelo ngalinye.

7) Buyekeza iimpazamo usebenzisa indlela yetafile yesi-3.

Phinda amanyathelo 6 ukuya ku-7 de iimpazamo zomatshini zingaphakathi koluhlu lokuchaneka kwaye isixhobo sokubhekisela simisiwe kwindawo yokuqala yeprogram kwaye ayishukumi.

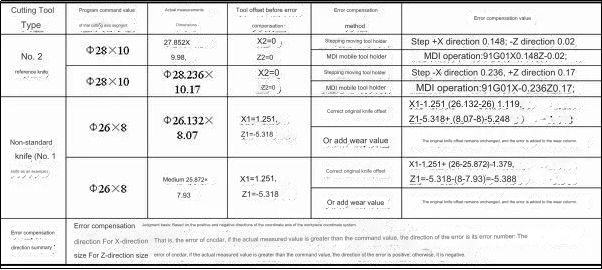

Itheyibhile 3 Umzekelo wembuyekezo yempazamo yokusikwa kovavanyo oluzenzekelayo lwezahlulo ze-cylindrical shaft (iyunithi: mm).

2. Ukuguqula indawo yokuqala yesixhobo ngasinye

Umgaqo-siseko wesixhobo sendlela kukuba isixhobo ngasinye sihlengahlengisa indawo yaso yokuqalisa inkqubo, ngaloo ndlela silungelelaniswa ngokungangqalanga nendawo yemvelaphi efanayo.

Amanyathelo okuseta isixhobo aboniswe kuMfanekiso 3.

Emva kokulungelelaniswa kwesixhobo esirhabaxa, iNombolo. Emva kokulungelelaniswa kwesixhobo esirhabaxa kunye nokurekhoda i-offsets, isixhobo sokubhekisela seNombolo ye-2 kufuneka sibe ekuqaleni kweprogram.

Amanyathelo 2) ukuya ku-(5) endlela yokuqala echanekileyo yokuseta isixhobo ayafana.

Sebenzisa inkqubo ye-O1000 ukwenza ulingo lovavanyo. Ukulinganisa ubude uLi kunye nedayamitha yePhDi yecandelo ngalinye.

Isixhobo sokunyakaza kwenyathelo okanye umnini wesixhobo se-MDI uhlawulela iimpazamo kwaye ulungelelanise indawo yokuqala yenkqubo yesixhobo.

Phinda kwakhona amanyathelo (6) de indawo yokuqala kwisixhobo seprogram esingenamgangatho siphakathi koluhlu lokuchaneka oluvunyelweyo.

Itheyibhile yesixhobo sokuphelisa inokufikelela ngokungenisa ulungelelwaniso olunxulumeneyo oluboniswe kwi-CRT kwi-X ye-offset kunye nekholamu ye-Z ehambelana nenani lesixhobo sokususa. Le ndlela ifanelekile kwaye ilula. Le ndlela ilula kwaye ifanelekile.

3. Guqula zonke iindlela zokunciphisa izixhobo ezingezizo ezisemgangathweni ngexesha elifanayo emva kokuguqula indawo yokuqala yeprogram yereferensi yesixhobo.

Indlela iyafana naleyo yokuqala echanekileyo yokuseta isixhobo. Ukwahlukana kuphela phakathi kwezi zibini kukuba kwinqanaba le-7, inkqubo ye-O1003 ibizwa, ebiza iimela ezintathu ngaxeshanye (i-O1004 isusa iNo. Inkqubo ye-O1003 ithatha indawo ye-2 yecandelo lokucubungula isixhobo. Amanyathelo aseleyo afana.

6. Iimela ezine zinokulungiswa ngexesha elinye kusetyenziswa le ndlela

Ukufumana impazamo yomatshini, linganisa ububanzi becandelo ngalinye, i-PhDi, kunye nobude becandelo ngalinye, i-Li (i = 2, 1, 4), usebenzisa indlela ye-tool-offset ehambelanayo. Sebenzisa i-MDI okanye intshukumo ye-stepwise kumphathi wesixhobo kwisixhobo sokubhekisela. Guqula indawo yokuqalisa inkqubo. Kwizixhobo ezingezizo ezisemgangathweni, qala ulungise i-offset usebenzisa i-offset yokuqala. Emva koko, faka i-offset entsha. Impazamo yomatshini wesixhobo sokubhekisela kufuneka ifakwe kwakhona kwikholam yokugqoka. Tsalela i-O1005 inkqubo yokusika isilingo ukuba isixhobo esipheleleyo sisetyenziselwa ukulinganisa isixhobo. Emva koko, ubuyekeze iimpazamo ze-machining zezixhobo kwiikholamu zokunxiba zamanani abo okunciphisa izixhobo.

Yeyiphi impembelelo ekukhetheni indlela yokuseta isixhobo esichanekileyo se-CNC lathes kumgangatho weCNC Machining iindawo?

Ukuchaneka nokuchaneka:

Izixhobo zokusika ziya kulungelelaniswa ngokufanelekileyo ukuba isixhobo sibekwe ngokuchanekileyo. Oku kuchaphazela ngokuthe ngqo ukuchaneka nokuchaneka kwimisebenzi yomatshini. Ukusetwa kwesixhobo esingalunganga kunokukhokelela kwiimpazamo zobukhulu, umphezulu ombi wokugqiba, kunye nokulahlwa.

Ukungqinelana:

Izicwangciso zezixhobo ezihambelanayo ziqinisekisa ukufana kwemisebenzi yomatshini kunye nomgangatho ohambelanayo kwiindawo ezininzi. Inciphisa ukuhluka kokugqitywa komphezulu kunye nemilinganiselo, kwaye inceda ukugcina ukunyamezela okuqinileyo.

Ubomi besixhobo kunye nezixhobo zokusebenza:

Ngokuqinisekisa ukuba isixhobo sidityaniswe ngokufanelekileyo nesixhobo sokusebenza, ukusetwa kwesixhobo esichanekileyo kunokwandisa ubomi besixhobo. Izicwangciso zezixhobo ezingafanelekanga zingabangela ukugqoka ngokugqithiseleyo kunye nokuphulwa kwezixhobo, okuya kunciphisa ubomi besixhobo.

Imveliso kunye nemfezeko

Izixhobo ezisebenzayo zokumisela izixhobo zinokunciphisa ixesha lokumisela umatshini kunye nokwandisa ixesha. Yandisa imveliso ngokunciphisa amaxesha angasebenziyo kunye nokwandisa ixesha lokusika. Oku kuvumela utshintsho olukhawulezayo lwesixhobo kunye nokunciphisa amaxesha omatshini ngokubanzi.

Ukhuseleko lomSebenzi

Ukhuseleko lomsebenzisi lunokuchaphazeleka ngokukhetha indlela efanelekileyo yokumisela isixhobo. Ezinye iindlela ezifana nokuqaphela umfanekiso okanye umlinganiselo wesixhobo se-laser zisusa isidingo sokuphatha izixhobo ngesandla, ukunciphisa ithuba lokulimala.

Injongo ye-Anebon kukuqonda ukonakaliswa okugqwesileyo kwimveliso kunye nokubonelela ngenkxaso ephezulu kubathengi basekhaya nabaphesheya ngentliziyo epheleleyo ngo-2022 Umgangatho oPhezulu weNtsimbi yeAluminiyam eFanelekileyo eyenziwe ngokweSiko.Ukujika kwe-CNC, Milling,iindawo ezisecaleni ze-cnckwi-Aerospace, Ukuze kwandiswe imarike yethu yamazwe ngamazwe, i-Anebon ibonelela ikakhulu kubathengi bethu baphesheya kolwandle Umgangatho ophezulu wokusebenza kwamalungu oomatshini, iindawo ezigudileyo kunye nenkonzo yokuguqula i-cnc.

I-China i-wholesale yase-China iCandelo loomatshini kunye ne-CNC Machining Service, i-Anebon iphakamisa umoya "wokutsha, ukuhambelana, umsebenzi weqela kunye nokwabelana, iindlela, inkqubela phambili yepragmatic". Sinike ithuba kwaye siza kubonakalisa amandla ethu. Ngoncedo lwakho olunobubele, i-Anebon ikholelwa ukuba singadala ikamva eliqaqambileyo kunye nawe kunye.

Ixesha lokuposa: Oct-19-2023