Wazi kangakanani malunga nayo yonke inkqubo yokudibanisa ngoomatshini?

Indibano yomatshini yinkqubo yokudibanisa iindawo ezahlukeneyo ukwenza inkqubo esebenzayo yomatshini okanye imveliso. Oku kubandakanya ukufunda kunye nokuqonda imizobo yobunjineli, ukukhetha nokusebenzisa izixhobo ezifanelekileyo kunye nezixhobo zokulungelelanisa kunye nokulungelelanisa iinxalenye, ukuqhotyoshela amacandelo ngeendlela ezahlukeneyo (ezifana ne-bolting, i-adhesives, okanye i-welding), kunye nokwenza iimvavanyo ezisemgangathweni ukuqinisekisa ukusebenza okufanelekileyo. Iinkqubo zeNdibano zinokulungelelaniswa neemfuno kunye nobunzima bemveliso nganye.

Ukulungiselela umsebenzi wasekhaya

(1)Idatha yokusebenza: ibandakanya imizobo yendibano jikelele (GA), imizobo yendibano yecandelo (CA), imizobo yamacandelo (PD), izintlu zezinto zeBOM njl.njl. Ukugqibelela, ukucoceka, kunye nokuthembeka kwazo zonke iirekhodi zolwazi lwenkqubo kunye nemizobo kufuneka zigcinwe kude kube sekupheleni kolwakhiwo. iprojekthi.

(2)Indawo yokusebenza: Indawo apho iinxalenye zibekwe khona kunye namacandelo adityanisiweyo kufuneka achazwe. Kubalulekile ukucwangcisa indawo oya kuhlanganisana kuyo kwaye ubeke umatshini wakho. Zonke iindawo zokusebenza kufuneka zicoceke, zifane kwaye zicwangciswe de iprojekthi igqitywe.

(3)Izinto zeNdibano. Izinto zokuhlanganisa kufuneka zibe zilungile phambi kokuhlinzwa. Ulandelelwano lwemisebenzi lunokutshintshwa ukuba izinto ezithile ezingabonakaliyo azifumaneki. Makuzaliswe ifom yokukhawulezisa izinto eziphathekayo ize ithunyelwe kwisebe lokuthenga.

(4)Ngaphambi kwendibano, kubalulekile ukuqonda isakhiwo, inkqubo yokuhlanganisa kunye neemfuno zobuchwepheshe bezixhobo.

Iinkcukacha ezisisiseko

(1) Indibano yomatshini kufuneka yenziwe ngokuthotyelwa ngokungqongqo kwimidwebo yendibano, iimfuno zenkqubo kunye nemiyalelo enikwe liqela loyilo. Akuvumelekanga ukutshintsha umxholo womsebenzi ngaphandle kwemvume, okanye ukuguqula iinxalenye ngendlela engaqhelekanga.

(2) Amacandelo adibeneyo kufuneka abe ngamacandelo aphumelele ukuhlolwa kunye nokuvunywa lisebe lokuqinisekisa umgangatho. Xela naziphi na iinxalenye ezingezizo ezifunyenwe ngexesha lendibano.

(3) Indawo yokudibanisa kufuneka ingabi nothuli kunye nezinye izinto ezingcolileyo. Amalungu kufuneka agcinwe kwindawo engenathuli, eyomileyo kwaye ikhuselwe ngeepads.

(4) Amalungu kufuneka ahlanganiswe ngaphandle kokubethelwa, ukusika okanye ukonakala kumphezulu. Nangona kunjalo, zisenokuba zigobile, zijijekile okanye zikhubazeke ngendlela ebalulekileyo. Imiphezulu yokukhwelana nayo mayingonakali.

(5) Xa udibanisa iindawo ezihamba ngokukhawuleza, kuyacetyiswa ukuba ungeze igrisi yokuthambisa (ioli) phakathi kweendawo zoqhagamshelwano.

(6) Imilinganiselo yamalungu ahambelanayo kufuneka ichaneke.

(7) Iinxalenye kunye nezixhobo kufuneka zibekwe ngendlela ekhethekileyo ngexesha lendibano. Amacandelo kunye nezixhobo akufanele zibekwe ngokuthe ngqo okanye phezulu kumatshini. Kwimeko apho kufuneka i-mats yokukhusela okanye iikhaphethi, kufuneka zibekwe kwindawo yokubeka.

Ngokomgaqo, akuvumelekanga ukunyathela kumatshini ngexesha lokudibanisa. Kwimeko apho kuyimfuneko ukuhamba kumatshini, iikhaphethi okanye iimathi kufuneka zibekwe phezulu. Ukunyathela kwiindawo ezibalulekileyo okanye amacandelo angeyontsimbi enamandla aphantsi akuvumelekanga ngokungqongqo.

Dibanisa indlela

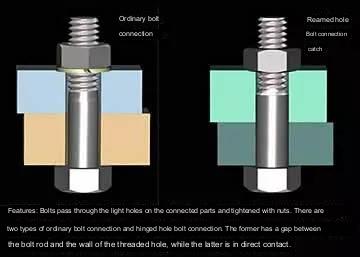

(1) Uqhagamshelo lwebholithi

A. Sebenzisa iwasha enye kuphela xa uqinisa iibholithi. Iintloko zezikhonkwane kufuneka zifakwe kwiindawo zomatshini emva kokuba i-screw countersunk iqinisiwe.

B. Ngokubanzi imidibaniso enemisonto ifuna iiwasha ezichasene nokuxengaxenga. Indlela yokuqinisa iibholithi ezininzi ze-symmetrical kukuziqinisa ngokuthe ngcembe kwaye ngendlela elinganayo. izihlanganisi Strip kwakhona ziqiniswe kancinci kwaye symmetrically ukusuka embindini ngaphandle.

C. Xa i-screws ingadingeki ukuba idibaniswe ngexesha lokukhawuleza okanye ukugcinwa kwesixhobo esishukumayo, kufuneka ifakwe kwi-glue yentambo ngaphambi kokuhlanganisana.

D. I-torque wrench isetyenziselwa ukuqinisa izibophelelo eziye zachaza iimfuno zetorque. Iibholithi ngaphandle kwetorque echaziweyo kufuneka ziqiniswe ngokwemigaqo "yeSihlomelo".

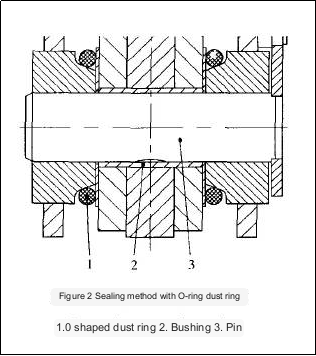

(2) Uqhagamshelo lwephini

A. Ngokubanzi, isiphelo ubuso isikhonkwane kufuneka ibe phezulu kancinci kunomphezuluamacandelo okugaya. Isiphelo esikhulu se-screw-tail tapered pin kufuneka itshone emngxunyeni emva kokuba ifakwe kwindawo.

B. Imisila ye-cotter pin kufuneka ibe yi-60deg ukuya kwi-90deg ngaphandle emva kokuba ilayishwe kwiindawo ezifanelekileyo.

(3) Uqhagamshelwano oluphambili

A. Makungabikho msantsa phakathi kweendawo zokukhwelana zeflethi nezitshixo ezisisigxina.

B. Xa iindawo ezihambayo zesitshixo okanye i-spline zihanjiswe kwi-axial direction emva kokuhlanganisana, akufanele kubekho ukungalingani.

C. Isitshixo se-hook kunye nezitshixo ze-wedge kufuneka zidityaniswe ukuze indawo yabo yoqhagamshelwano ingabi ngaphantsi kwe-70% yendawo yonke yokusebenza. Amalungu angadibanisiyo akufuneki adityaniswe kunye, kwaye indawo evelileyo kufuneka ibe ngaphezulu kwe-10% -15% yobude.

(4) Ukucaphuka

A. Izinto eziphathekayo kunye neenkcukacha ze-riveting kufuneka zihambelane neemfuno zoyilo. Ukulungiswa kwemingxuma yee-rivets kufuneka kwakhona kuhlangabezane nemigangatho efanelekileyo.

B. Umphezulu we-rivetedamacandelo aluminiyamakufunekanga yonakaliswe okanye ikhubazeke xa i-riveting.

C. Akufuneki kubekho ukuxengaxenga kwindawo ekhutshiweyo, ngaphandle kokuba kukho iimfuno ezithile. Intloko yee-rivets kufuneka idibane nenxalenye edibeneyo kunye ne-smooth and round.

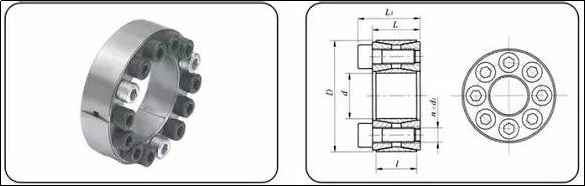

(5) Ukwandiswa kwemikhono yokudibanisa

Indibano yomkhono wokwandisa: Faka igrisi yokuthambisa kumkhono wokwandisa, faka umkhono wokwandisa kumngxuma wehabhu odityanisiweyo, faka i-shaft yokufakela, uhlengahlengise indawo yendibano, emva koko uqinise iibholithi. Umyalelo wokuqiniswa ubophelelwe yi-slit, kwaye ngakwesobunxele nangakwesokudla bawela kwaye baqiniswe ngokulinganayo ngokulandelelana ukuqinisekisa ukuba ixabiso elilinganisiweyo le-torque lifikelelwe.

(6) Uqhagamshelwano oluqinileyo

Cwangcisa izikrufu ezineephelo ze-conical kufuneka zibe ne-90-degree tapered end. Umngxuma kufuneka ube ngama-90 degrees.

Ukufakwa kwezikhokelo zomgca

(1) Umphezulu wofakelo wesiporo sesikhokelo kufuneka ube mcaba kwaye ungabi nabumdaka.

(2) Ukuba umzila wesikhokelo unomgca wokubhekisela, umzila kufuneka ufakwe kufuphi nomda. Ukuba akukho ngqamaniso yereferensi, ngoko ulwalathiso lwesilayidi kufuneka luhambelane neemfuno zoyilo. Jonga indlela yesilayidi emva kokuqinisa izikrufu kumzila wesikhokelo. Ukuba akunjalo, kuya kufuneka ukuba ilungiswe.

(3) Ukuba isilayidi siqhutywa ngamabhanti okuhambisa, ke iibhanti kufuneka zilungiswe kwaye zinyanzeliswe ngaphambi kokuba ibhanti itsalwe kwicala le-oblique. Ngaphandle koko, i-pulley kufuneka ilungelelaniswe ukuqinisekisa ukuba indlela yokuqhuba ibhanti ihambelana nomzila wesikhokelo.

Indibano yamatyathanga esprocket

(1) I-sprocket kufuneka yenzelwe ukusebenzisana ne-shaft.

(2) Amazinyo egiya azo zombini iiprokethi zokuqhuba neziqhutywayo afanele abe nenqwelo-moya esembindini yejiyometri efanayo, kwaye ukulinganisa kwazo akufuneki kudlule kwiimfuno zoyilo. Kufuneka ibe ngaphantsi okanye ilingane ne-2%0, ukuba ayichazwanga luyilo.

(3) Icala elisebenzayo lekhonkco kufuneka liqiniswe xa lidibanisa nge-sprocket.

(4) Ikhonkco lekhonkco kwicala elingasetyenziswanga kufuneka libe phakathi kwemida yoyilo. Kufuneka ilungiswe ukuba ayichazwanga kuyilo.

Ukudibanisa izixhobo

(1) Xa udini lwegiya luyi-20mm okanye ngaphantsi, ulungelelwaniso lweaxial alufanelekanga ukuba ludlule kwi-1mm. Ukuba ububanzi begiya bungaphezulu kwe-20mm ukungahambi kakuhle akunakudlula kwi-5%.

(1) I-JB180-60 "I-Bevel Gear transmission Tolerance", i-JB162 kunye ne-JB162 kufuneka icacise iimfuno zokufakela ukuchaneka kwezixhobo ze-cylindrical kunye ne-bevel gear.

Ngokweemfuno zobugcisa, imigangatho yemeshing yeegiya kufuneka ithanjiswe ngokwesiqhelo. Ibhokisi yegiya kufuneka izaliswe kumgca wenqanaba kunye neoli yokuthambisa.

(4) Inqanaba lengxolo yothumelo kumthwalo opheleleyo kufuneka lingagqithi kuma-80dB.

Uhlengahlengiso lweRakhi kunye noqhagamshelo

(1) Iiracks ezikumacandelo ahlukeneyo eerekhi kufuneka zonke zibekwe kwindawo yobude obufanayo, kusetyenziswa indawo yokukhangela enye.

(2) Zonke iiphaneli zodonga lweerack kufuneka zilungelelaniswe kwinqwelomoya enye eme nkqo.

(3) Iipleyiti zokudibanisa ezisisigxina kufuneka zifakwe phakathi kwamacandelo emva kokuba ii-racks zilungelelaniswe nobude obufunekayo kunye nemilinganiselo.

Indibano yamacandelo e-pneumatic

(1) Ukucwangciswa kwesethi nganye yezixhobo zokuqhuba i-pneumatic kufuneka zixhunywe ngokungqongqo ngokuhambelana nomzobo wesekethe ye-pneumatic enikezelwa lisebe loyilo. Umzimba wevalve, iijoyinti zemibhobho, iisilinda, njl. njl. mazidityaniswe ngokuchanekileyo.

(2) Indawo yokungena nokuphuma ivelufa yokunciphisa uxinzelelo lomoya iyonke idityaniswe kwicala lotolo, kwaye ikomityi yamanzi nekomityi ye-oyile yesihluzo somoya kunye nesithambisi kufuneka zifakwe ngokuthe nkqo ezantsi.

(3) Phambi kombhobho, umgubo wokusika nothuli kumbhobho kufuneka uvuthelwe ngokupheleleyo.

(4) Umbhobho odibeneyo ufakwe intambo. Ukuba intambo yombhobho ayinayo iglue yentambo, i-tape yezinto eziluhlaza kufuneka isongwe. Icala elijikajikayo lijika ngasekunene xa lijongwe ngaphambili. Iteyiphu yempahla ekrwada mayingaxutywa kwivalve. I-tape yezinto eziluhlaza akufanele ixutywe kwivalve. Xa ujija, umsonto omnye kufuneka ugcinwe.

5 I-90deg elbows kufuneka isetyenziswe kwiikona. Xa ulungisa i-trachea, musa ukubeka uxinzelelo olongezelelweyo kumalungu, ngaphandle koko kuya kubangela ukuvuza komoya.

(6) Xa udibanisa i-valve ye-solenoid, nikela ingqalelo kumsebenzi wenombolo ye-air port nganye kwi-valve: P: i-air inlet iyonke; A: indawo yomoya 1; B: indawo yomoya 2; R (EA): i-exhaust ehambelana no-A; S (EB) : Umbhobho ohambelana no-B.

(7) Xa i-cylinder ihlanganiswe, i-axis yentonga yepiston kunye nesalathiso sokuhamba komthwalo kufuneka sihambelane.

(8) Xa usebenzisa isikhokelo somgca womgca, emva kokuba isiphelo sangaphambili se-cylinder piston rod sidibaniswe nomthwalo, akufuneki kubekho amandla angaqhelekanga ngexesha lokubetha, ngaphandle koko i-cylinder iya konakala.

(9) Xa usebenzisa i-valve ye-throttle, kufuneka ubeke ingqalelo kuhlobo lwe-valve ye-throttle. Ngokuqhelekileyo, yahlulwa lutolo olukhulu oluphawulwe kumzimba wevalvu. Utolo olukhulu olukhomba ekupheleni komsonto lusetyenziselwa isilinda; utolo olukhulu olukhomba ekupheleni kombhobho lusetyenziselwa ivalve yesolenoid. .

Umsebenzi wokuhlola iNdibano

(1) Ngalo lonke ixesha indibano yecandelo igqityiwe, kufuneka ihlolwe ngokwezi zinto zilandelayo. Ukuba kufunyenwe ingxaki yendibano, ifanele ihlalutywe ize isingathwe kwangethuba.

A. Ukuthembeka komsebenzi wendibano, jonga imizobo yendibano, kwaye ujonge ukuba akukho nxalenye ilahlekileyo.

B. Ukuchaneka kwendawo yokufakela inxalenye nganye, khangela umzobo wendibano okanye iimfuno ezichazwe kule ngcaciso ingentla.

C. Ukuthembeka kwecandelo ngalinye lokudibanisa, nokuba i-screw nganye yokudibanisa ifikelela kwi-torque efunekayo kwindibano, kunye nokuba i-fasteners ekhethekileyo ihlangabezana neemfuno zokuthintela ukukhulula.

D. Ukuguquguquka kokuhamba kwezinto ezihambayo, njengokuba kukho nayiphi na i-jamming okanye i-stagnation, i-eccentricity okanye ukugoba xa ujikeleza ngesandla okanye uhambisa i-roller conveyor, i-pulleys, i-rails yesikhokelo, njl.

(2) Emva kwendibano yokugqibela, uhlolo oluphambili kukujonga unxibelelwano phakathi kwamacandelo endibano. Umxholo wokuhlola usekelwe "kwiipropati ezine" ezichazwe kwi-(1) njengomgangatho womlinganiselo.

(3) Emva kwendibano yokugqibela, iifayili zetsimbi, i-debris, uthuli, njl. kuzo zonke iindawo zomatshini kufuneka zicocwe ukuze kuqinisekiswe ukuba akukho miqobo kwiindawo zokuhambisa.

(4) Xa uvavanya umatshini, jonga ngokucophelela inkqubo yokuqalisa. Emva kokuba umatshini uqalisiwe, jonga ngokukhawuleza iiparamitha eziphambili zokusebenza kunye nokuba ngaba iindawo ezihambayo zihamba ngokuqhelekileyo.

(5) Iiparamitha eziphambili zokusebenza ziquka isantya sokuhamba, ukuhamba kakuhle, ukujikeleza kwe-shaft nganye yokuhambisa, ukushisa, ukungcangcazela kunye nengxolo, njl.

I-Anebon iya kwenza umsebenzi ngamnye onzima ukuba ube ngobalaseleyo kwaye ugqwese, kwaye ikhawulezise imilinganiselo yethu yokuma ukusuka kwinqanaba le-intercontinental top-grade kunye namashishini aphezulu e-China Gold Supplier ye-OEM, inkonzo ye-cnc yesiko lomatshini, inkonzo yokwenziwa kweShiti leNsimbi, ukugaya. iinkonzo. I-Anebon iya kwenza ukuthenga kwakho ukuze uhlangabezane nokwanelisayo kwakho! Ishishini le-Anebon limisela amasebe amaninzi, kubandakanywa isebe lemveliso, isebe lengeniso, isebe lolawulo olugqwesileyo kunye neziko lenkonzo, njl.

Factory Supply Chinaiindawo eziguqukayo ezichanekileyokunye neAluminiyam Inxalenye, Unokwenza i-Anebon yazi ingcamango yakho yokuphuhlisa uyilo olulodwa lwemodeli yakho ukukhusela iindawo ezifanayo kakhulu kwimarike! Siza kunika inkonzo yethu engcono ukwanelisa zonke iimfuno zakho! Khumbula ukuqhagamshelana neAnebon ngoko nangoko!

Ixesha lokuposa: Sep-04-2023