Stainless Steel sisishunqulelo intsimbi stainless kunye acid resistant steel. Intsimbi echasene nemithombo ye-corrosion ebuthathaka njengomoya, umphunga kunye namanzi okanye inepropati engenanto ebizwa ngokuba yintsimbi engapheliyo; Intsimbi enganyangekiyo kwimichiza ye-corrosion medium (i-asidi, i-alkali, ityuwa kunye nezinye iikhemikhali ze-etching) ibizwa ngokuba yintsimbi enganyangekiyo kwi-asidi.

Intsimbi engatyiwayo ibhekisa kwintsimbi ekwaziyo ukumelana nemithombo yeendaba ebuthathaka enjengomoya, umphunga kunye namanzi kunye namajelo eendaba etshiza imichiza anjengeasidi, ialkali netyuwa, ekwaziwa ngokuba yintsimbi enganyangekiyo eneasidi. Kwizinto ezisetyenziswayo, intsimbi ekwaziyo ukumelana nentsimbi ebuthathaka idla ngokubizwa ngokuba yintsimbi engatyiwa, ngelixa intsimbi ekwaziyo ukumelana nemichiza ibizwa ngokuba yintsimbi enganyangekiyo kwiasidi. Ngenxa yomahluko kukwakheka kweekhemikhali phakathi kwezi zimbini, eyokuqala ayinyanzeli ukuba ixhathise kwi-corrosion yekhemikhali ephakathi, ngelixa le yokugqibela ingenabala. Ukuxhatshazwa kwe-corrosion yensimbi engenasici kuxhomekeke kwizinto ze-alloy eziqulethwe kwintsimbi.

Ngokuqhelekileyo, ngokwesakhiwo se-metallographic, iintsimbi eziqhelekileyo ezingenasici zihlulwe zibe ziindidi ezintathu: i-austenitic stainless steels, i-ferritic stainless steels kunye ne-martensitic stainless steels. Ngokwesiseko sezi zakhiwo zintathu ze-metallographic ezisisiseko, i-double phase iron, imvula eqinile iqinile insimbi engenasici kunye nentsimbi ephezulu ye-alloy kunye nomxholo wentsimbi engaphantsi kwe-50% ifunyenwe kwiimfuno kunye neenjongo ezithile.

Yahlulwe yaba:

Austenitic steel stainless

I-matrix ubukhulu becala i-austenitic structure (isigaba seCY) enobuso obugxile kwi-cubic crystal structure, engeyiyo imagnetic, kwaye iyomelezwa ngokukodwa (kwaye inokukhokelela kwimagnetism ethile) ngokusebenza okubandayo. I-American Iron and Steel Institute iboniswa ngamanani angama-200 kunye nama-300, njenge-304.

Ferritic steel stainless

I-matrix ubukhulu becala isakhiwo se-ferrite (isigaba a) kunye nesakhiwo se-cubic crystal yomzimba esigxile kwi-cubic crystal, enemagnethi, kwaye ngokubanzi ayinako ukuqina ngonyango lobushushu, kodwa inokuqiniswa kancinci ngokusebenza okubandayo. I-American Iron and Steel Institute iphawulwe ngo-430 kunye ne-446.

Intsimbi ye-Martensitic

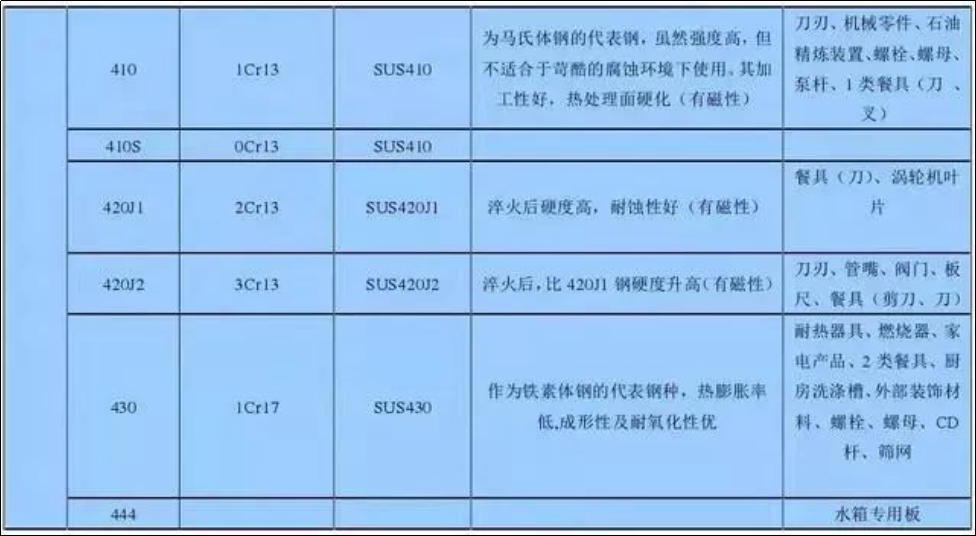

I-matrix yisakhiwo se-martensitic (i-cubic yomzimba ephakathi okanye i-cubic), i-magnetic, kunye neempawu zayo zomatshini zinokuhlengahlengiswa ngonyango lobushushu. I-American Iron and Steel Institute iboniswa ngamanani 410, 420, kunye ne-440. I-Martensite inesakhiwo se-austenitic kwiqondo lokushisa eliphezulu. Xa ipholile kwiqondo lokushisa kwiqondo elifanelekileyo, isakhiwo se-austenitic sinokuguqulwa sibe yi-martensite (oko kukuthi, lukhuni).

Austenitic ferritic (duplex) steel stainless

I-matrix inezo zombini i-austenite kunye ne-ferrite izakhiwo zesigaba sesibini, kunye nomxholo we-matrix yesigaba esingaphantsi ngokubanzi ngaphezu kwe-15%, enemagnethi kwaye inokomelezwa ngokusebenza okubandayo. I-329 yintsimbi eqhelekileyo ye-duplex. Xa kuthelekiswa nentsimbi ye-austenitic stainless, intsimbi yesigaba esimbini inamandla aphezulu, kwaye ukuchasana kwayo ne-intergranular corrosion, i-chloride stress corrosion kunye ne-pitting corrosion iphuculwe kakhulu.

Imvula yenza lukhuni intsimbi engatyiwayo

Intsimbi engatyiwayo enematrix yi-austenitic okanye i-martensitic kwaye inokuqiniswa yimvula eyenza lukhuni unyango. I-American Iron and Steel Institute iphawulwe ngamanani angama-600, afana ne-630, okt 17-4PH.

Ngokuqhelekileyo, ngaphandle kwe-alloy, i-austenitic stainless steel inokumelana nokugqwesa okugqwesileyo. I-Ferritic steel stainless ingasetyenziswa kwindawo ene-corrosion ephantsi. Kwimo engqongileyo enomoya opholileyo, intsimbi ye-martensitic stainless kunye nemvula eqinisa intsimbi engenasici ingasetyenziswa ukuba izinto ezifunekayo ukuba zibe namandla aphezulu okanye ukuqina.

Iimpawu kunye nenjongo

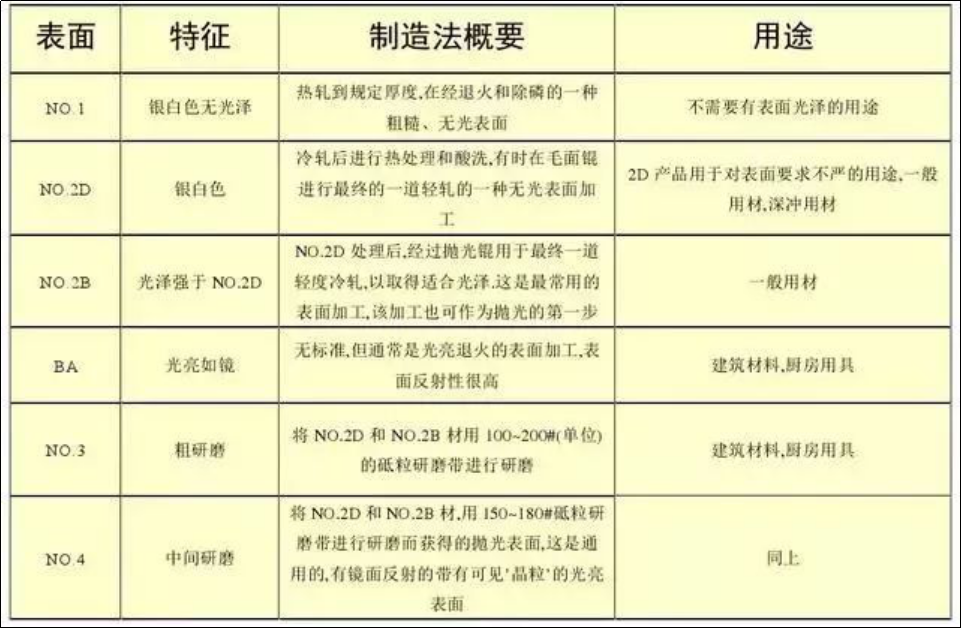

Unyango lomphezulu

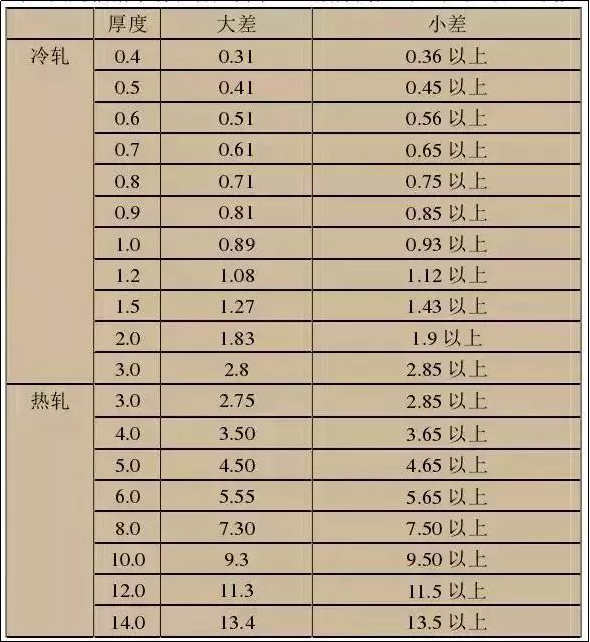

Ukwahlula ukutyeba

1. Ngenxa yokuba kwinkqubo yokuqengqeleka koomatshini beplanti yentsimbi, i-roll ikhubazeka kancinane ngenxa yokufudumeza, okukhokelela ekuphambukeni kobunzima beplate eqengqelekayo. Ngokuqhelekileyo, ubukhulu obuphakathi bubhityile kumacala omabini. Xa ulinganisa ubukhulu beplate, inxalenye ephakathi yentloko yepleyiti iya kulinganiswa ngokwemigaqo kazwelonke.

2. Unyamezelo luhlulwe ngokubanzi lube lunyamezelo olukhulu kunye nokunyamezelana okuncinci ngokwentengiso kunye nemfuno yabathengi: umzekelo.

Loluphi uhlobo lwentsimbi engatyiwayo lula ukurusa?

Kukho izinto ezintathu eziphambili ezichaphazela ukubola kwentsimbi engatyiwayo:

1. Umxholo wezinto zokudibanisa.

Ngokuqhelekileyo, intsimbi enomxholo we-chromium ye-10.5% ayilula ukurusa. Ukuphakama komxholo we-chromium kunye ne-nickel, ngcono ukuxhathisa ukubola. Ngokomzekelo, umxholo we-nickel wezinto ezingama-304 kufuneka ube ngu-8-10%, kwaye umxholo we-chromium kufuneka ube ngu-18-20%. Ngokuqhelekileyo, insimbi enjalo engenasici ayiyi kuhlwa.

2. Inkqubo yokunyibilikisa yomenzi nayo iya kuchaphazela ukuxhathisa kwe-corrosion yensimbi engenasici.

Izityalo ezinkulu zensimbi ezingenasici kunye nobuchwepheshe obuhle bokunyibilikisa, izixhobo eziphambili kunye nenkqubo ephuculweyo inokuqinisekisa ukulawulwa kwezinto ze-alloy, ukususwa kokungcola kunye nokulawula ubushushu bokupholisa i-billet, ngoko umgangatho wemveliso uzinzile kwaye uthembekile, umgangatho wangaphakathi ulungile, kwaye kunjalo. akukho lula ukugqwala. Ngokuchasene noko, ezinye izityalo ezincinci zetsimbi zisemva kwizixhobo kunye neteknoloji. Ngexesha lokunyibilikisa, ukungcola akukwazi ukususwa, kwaye iimveliso eziveliswayo ngokuqinisekileyo ziya kugqwala.

3. Imo engqongileyo yangaphandle, indawo eyomileyo nengena umoya akulula ukurusa.

Nangona kunjalo, iindawo ezinomswakama ophezulu womoya, imozulu yemvula eqhubekayo, okanye i-pH ephezulu emoyeni ithanda ukuhlwa. I-304 insimbi engenasici iya kuhlwa ukuba indawo engqongileyo imbi kakhulu.

Indlela yokujongana namabala omhlwa kwintsimbi engenasici?

1. Iindlela zemichiza

Sebenzisa intlama yokucoca iasidi okanye isitshizi ukuncedisa iindawo ezirulileyo ukuba zidlule kwakhona zenze ifilimu yechromium oxide ukubuyisela ukuxhathisa ukubola. Emva kokucoca i-asidi, ukwenzela ukususa zonke izinto ezingcolileyo kunye neentsalela ze-asidi, kubaluleke kakhulu ukuhlamba ngokufanelekileyo ngamanzi acocekileyo. Emva kwalo lonke unyango, phinda upholise ngezixhobo zokupholisa kwaye utywine nge-wax yokupolisha. Kwabo banamabala omhlwa amancinci ekuhlaleni, umxube we-oyile we-injini ye-petroli ongu-1:1 usenokusetyenziswa ukususa iindawo zerusi ngeragi ecocekileyo.

2. Indlela yomatshini

Ukucoca uqhushumbo, ukudutyulwa kweglasi okanye amasuntswana e-ceramic, ukuntywiliselwa, ukuxukuxa kunye nokupolisha. Kunokwenzeka ukususa ukungcola okubangelwa izinto ezisuswe ngaphambili, izinto zokupholisa okanye izinto zokutshabalalisa ngeendlela zoomatshini. Zonke iintlobo zongcoliseko, ingakumbi amasuntswana entsimbi angaphandle, asenokuba ngumthombo wokudusa, ngakumbi kwindawo efumileyo. Ngoko ke, indawo ecociweyo ngoomatshini kufuneka icocwe ngokusesikweni phantsi kweemeko ezomileyo. Indlela yomatshini ingasetyenziselwa kuphela ukucoca umphezulu, kwaye ayikwazi ukutshintsha ukuxhathisa kwe-corrosion yezinto ngokwayo. Ngoko ke, kucetyiswa ukuba uphinde upholise ngezixhobo zokupholisa emva kokucoca ngoomatshini kunye nokutywinwa nge-wax yokupholisa.

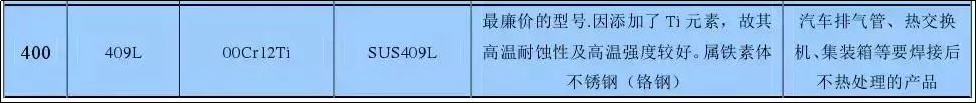

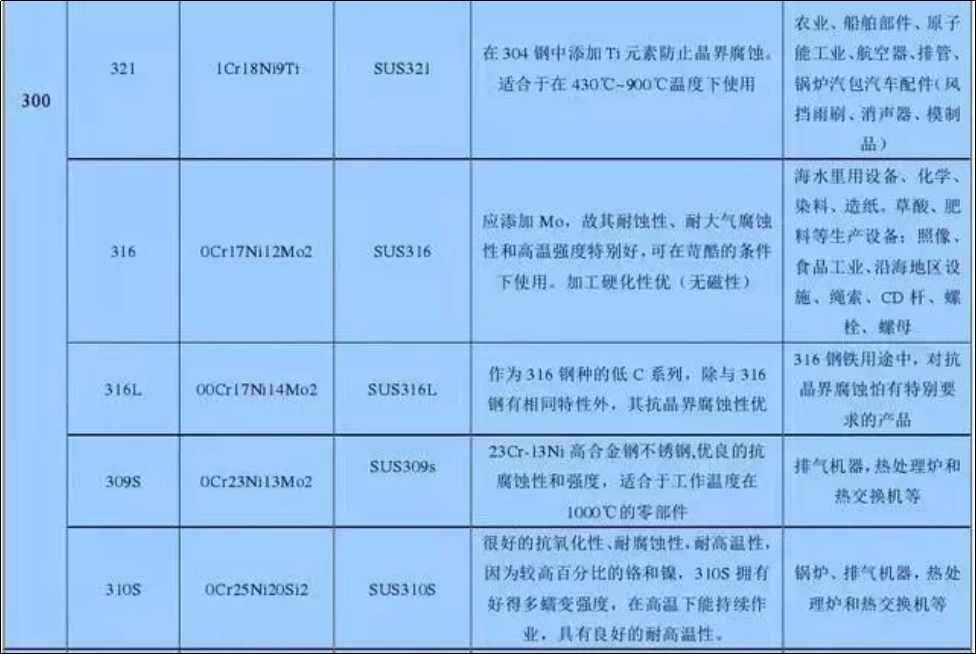

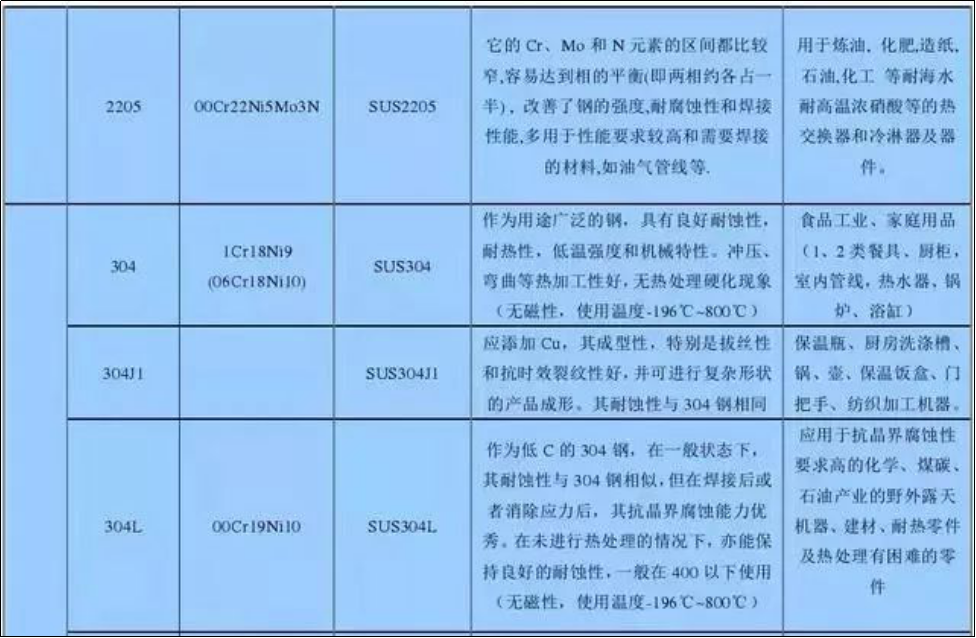

Ngokuqhelekileyo isetyenziswe amabakala ensimbi engenasici kunye neepropati

1. 304 intsimbi engenasici. Ngenye yezona zinto zisetyenziswa kakhulu i-austenitic stainless steels kunye nenani elikhulu lezicelo. Ilungele ukwenza umzobo onzulu wakhiwe iindawo, imibhobho yokuhambisa iasidi, iinqanawa,iindawo ze-cnc zokujika, imizimba yezixhobo ezahlukeneyo, njl., kunye nezixhobo ezingezizo zemagneti kunye nobushushu obuphantsi kunye namalungu.

2. 304L intsimbi engenasici. I-ultra-low carbon austenitic stainless steel iphuhliselwe ukusombulula i-intergranular corrosion tension ye-304 steel stainless ebangelwa yi-Cr23C6 imvula phantsi kweemeko ezithile, ukuxhathisa kwayo kwe-intergranular corrosion kungcono kakhulu kune-304 yentsimbi engenasici. Ngaphandle kwamandla aphantsi, ezinye iipropati zifana ne-321 yensimbi engenasici. Isetyenziswa ikakhulu kwizixhobo ezinganyangekiyo kwi-corrosion kunye namalungu afuna i-welding kodwa ayinakunyangwa isisombululo, kwaye ingasetyenziselwa ukwenza imizimba yezixhobo ezahlukeneyo.

3. 304H intsimbi engenasici. Kwisebe langaphakathi le-304 yensimbi engenasici, i-carbon mass fraction yi-0.04% - 0.10%, kwaye ukusebenza kweqondo lokushisa eliphezulu kuphezulu kwi-304 yensimbi engenasici.

4. 316 intsimbi engenasici. Ukongezwa kwe-molybdenum ngesiseko sentsimbi ye-10Cr18Ni12 yenza ukuba intsimbi ibe nokuchasana okulungileyo ekunciphiseni i-corrosion ephakathi kunye ne-pitting. Emanzini olwandle nakwamanye amajelo eendaba, ukuxhathisa kwe-corrosion kungaphezulu kwe-304 yensimbi engenasici, eyona nto isetyenziselwa ukugalela izinto ezinganyangekiyo kwi-corrosion.

5. 316L intsimbi engenasici. Intsimbi ephantsi yekhabhoni ephantsi kakhulu, enokumelana kakuhle ne-intergranular corrosion, ifanelekile ukuvelisa iinxalenye ezishinyeneyo zecandelo lokuwelda kunye nezixhobo, ezifana nezixhobo zokulwa nomhlwa kwizixhobo zepetrochemical.

6. 316H intsimbi engenasici. Kwisebe langaphakathi le-316 yensimbi engenasici, i-carbon mass fraction yi-0.04% - 0.10%, kwaye ukusebenza kweqondo lokushisa eliphezulu liphezulu kune-316 yensimbi engenasici.

7. 317 intsimbi engenasici. Ukuchasana nokuphosa i-corrosion kunye ne-creep iphezulu kune-316L yensimbi engenasici. Isetyenziselwa ukwenza izixhobo ze-petrochemical kunye ne-organic acid resistant.

8. 321 intsimbi engenasici. I-Titanium stabilized austenitic stainless steel inokutshintshwa yi-ultra-low carbon austenitic steel stainless steel ngenxa yokuphucula ukuxhathisa kwe-intergranular corrosion kunye neempawu ezilungileyo zokushisa eziphezulu. Ngaphandle kwezihlandlo ezikhethekileyo ezifana nobushushu obuphezulu okanye ukuxhathisa kwe-hydrogen corrosion, akukhuthazwa ukuba kusetyenziswe.

9. 347 intsimbi engenasici. Niobium uzinzile austenitic steel stainless. Ukongezwa kwe-niobium kuphucula ukuxhathisa kwe-corrosion intergranular. Ukumelana nokugqwala kwayo kwi-asidi, i-alkali, ityuwa kunye nezinye izinto ezidliwayo ziyafana ne-321 yensimbi engenasici. Ngokusebenza kakuhle kwe-welding, inokusetyenziswa njengezinto zombini ezinganyangekiyo kwi-corrosion kunye nentsimbi ekwazi ukumelana nobushushu. Isetyenziswa ikakhulu kumandla obushushu kunye nemimandla yepetrochemical, efana nokwenza iinqanawa, imibhobho, utshintshiselwano lobushushu, i-shafts, iityhubhu zesithando somlilo kwiziko lamashishini, kunye neethermometers zetyhubhu.

10. 904L intsimbi engenasici. Intsimbi egqibeleleyo ye-austenitic egqwesileyo yintsimbi egqwesileyo ye austenitic engatyiwa yintsimbi eyaqanjwa yiNkampani ye-OUTOKUMPU yaseFinland. I-nickel mass fraction yayo i-24% - 26%, kunye ne-carbon mass fraction ingaphantsi kwe-0.02%. Inokumelana nokugqwesa okugqwesileyo. Inokumelana ne-corrosion elungileyo kwiiasidi ezingezizo i-oxidizing ezifana ne-asidi ye-sulfuric, i-acetic acid, i-asidi ye-formic kunye ne-phosphoric acid, kunye nokuxhathisa okulungileyo kwi-corrosion kunye noxinzelelo lwe-corrosion. Isebenza kwiintlobo ezahlukeneyo ze-asidi ye-sulfuric engaphantsi kwe-70 ℃, kwaye inokumelana nokubola okulungileyo kwi-acetic acid yayo nayiphi na ingxinano kunye nobushushu phantsi koxinzelelo oluqhelekileyo kunye ne-asidi edibeneyo ye-asidi ye-formic kunye ne-acetic acid. Umgangatho wokuqala we-ASMESB-625 wawuchaza njenge-nickel base alloy, kwaye umgangatho omtsha wawuhlelwa njengensimbi engenasici. E-China, kukho kuphela uphawu olufanayo lwentsimbi ye-015Cr19Ni26Mo5Cu2. Abavelisi bezixhobo ezimbalwa zaseYurophu basebenzisa i-904L yensimbi engenasici njengento ebalulekileyo. Ngokomzekelo, ityhubhu yokulinganisa ye-E + H mass flowmeter isebenzisa i-904L yensimbi engenasici, kwaye imeko yeewotshi ze-Rolex isebenzisa i-904L yensimbi engenasici.

11. 440C steel stainless. Ubunzima be-martensitic steel stainless, intsimbi eqinile kunye nensimbi engenasici iyona nto iphezulu, kwaye ubunzima yi-HRC57. Isetyenziswa ikakhulu ukwenza imilomo, iibheringi, iintsimbi zevalvu, izihlalo zevalvu, imikhono, iziqu zevalvu,cnc iindawo zomatshininjl.

12. 17-4PH intsimbi engenasici. Imvula ye-Martensitic eyenza lukhuni intsimbi engatyiwayo, enobulukhuni be-HRC44, inamandla amakhulu, ukuqina kunye nokumelana nomhlwa, kwaye ayinakusetyenziswa kumaqondo obushushu angaphezu kwama-300 ℃. Inokumelana ne-corrosion efanelekileyo kwi-atmosfera kunye ne-asidi edibeneyo okanye ityuwa. Ukuxhatshazwa kwayo kwe-corrosion kufana ne-304 yensimbi engenasici kunye ne-430 yensimbi engenasici. Isetyenziselwa ukwenza amaqonga angaphesheya kolwandle, iiblade zeinjini yomoya, iintsimbi zevalvu, izitulo zevalvu, imikhono, iziqu zevalvu, njl.

13. 300 Series - Chromium Nickel Austenitic Stainless Steel

I-301 - i-ductility enhle, esetyenziselwa iimveliso zokubumba. Isenokwenziwa lukhuni ngokukhawuleza ngokulungiswa ngoomatshini, kunye ne-weldability elungileyo. Ukumelana nokunxiba kunye namandla okukhathala kuphezulu kune-304 yensimbi engenasici. I-301 insimbi engenasici ibonisa umsebenzi ocacileyo wokuqina ngexesha lokuguqulwa, kwaye isetyenziswa kwiimeko ezahlukeneyo ezifuna amandla aphezulu.

302 - Ngokusisiseko, luhlobo lwentsimbi engama-304 ecocekileyo enomxholo ophezulu wekhabhoni, enokufumana amandla aphezulu ngokuqengqeleka okubandayo.

I-302B - yintsimbi engenasici enomxholo ophezulu we-silicon, enokumelana okuphezulu nokushisa okuphezulu kwe-oxidation.

I-303 kunye ne-303Se zikhululekile ukusika iintsimbi ezingenasici eziqukethe isulfure kunye ne-selenium ngokulandelanayo, ezisetyenziswa kwiimeko apho ukusika simahla kunye neglosi ephezulu ifunwa kakhulu. I-303Se insimbi engenasici isetyenziselwa ukwenza iinxalenye zoomatshini ezifuna ukuphazamiseka okushushu, kuba phantsi kweemeko ezinjalo, le nsimbi engenasici inokusebenza kakuhle okushushu.

I-304N - yintsimbi engenasici equkethe i-nitrogen. I-nitrogen yongezwa ukuphucula amandla entsimbi.

I-305 kunye ne-384 - Insimbi engenasici iqulethe i-nickel ephezulu, kwaye izinga lokuqina komsebenzi walo liphantsi, elifanelekileyo kwiimeko ezahlukeneyo kunye neemfuno eziphezulu zokubumba okubandayo.

308 - Ukwenza intonga ye-welding.

Iziqulatho ze-nickel kunye ne-chromium ze-309, 310, 314 kunye ne-330 zentsimbi ezingenasici ziphezulu kakhulu ukuphucula ukuxhathisa i-oxidation kunye namandla okunyuka kweentsimbi kumaqondo obushushu aphezulu. Ngelixa i-30S5 kunye ne-310S zizinto ezahlukeneyo ze-309 kunye ne-310 zensimbi ezingenasici, umahluko kukuba umxholo wekhabhoni uphantsi, ukuze kuncitshiswe i-carbide yemvula kufuphi ne-weld. I-330 yensimbi engenasici inokumelana ne-carburizing ephezulu kakhulu kunye nokumelana nokothuka kwe-thermal.

Ixesha lokuposa: Dec-05-2022