Esi sisishwankathelo sabantu abakushishino xa sishwankathela uyilo lwezixhobo, kodwa akude kube lula. Kwinkqubo yokunxibelelana nezikimu ezahlukeneyo, sifumanise ukuba kuhlala kukho iingxaki ezithile zokubeka kunye nokucinezela kuyilo lokuqala. Ngale ndlela, nasiphi na iskimu sokwenziwa kwezinto ezintsha siya kuphulukana nentsingiselo yalo ebonakalayo. Kuphela ngokuqonda ulwazi olusisiseko lokubeka kunye nokubambelela apho sinokuthi siqinisekise ngokusisiseko imfezeko yoyilo loyilo kunye neskimu sokusebenza.

Ulwazi lwendawo

1, Umgaqo osisiseko wokumisa ukusuka kwicala lomsebenzi

Xa ubeka ukusuka kwicala lomsebenzi, umgaqo-siseko wezinto ezintathu ngowona mgaqo-siseko, njengenkxaso. Oku kufana nomgaqo-siseko wenkxaso, ebizwa ngokuba ngumgaqo-ntathu, ophuma kumgaqo othi "amanqaku amathathu angekho kumgca ofanayo anqume indiza". Amanqaku amathathu kwamane anokugqiba ubuso, ngoko ke ubuso obune bubonke bunokumiselwa. Nangona kunjalo, nokuba ifunyenwe njani, kunzima kakhulu ukwenza inqaku lesine kwinqwelomoya enye.

▲ Iingongoma ezintathu

Umzekelo, xa usebenzisa izikhundla ezi-4 ezizinzileyo zobude obumiselweyo, ngamanqaku ama-3 kuphela kwindawo enye anokunxibelelana nomsebenzi, kwaye amanqaku ama-4 aseleyo kusenokwenzeka ukuba angaqhagamshelana nomsebenzi.

Ngoko ke, xa uqwalasela i-positioner, ngokuqhelekileyo isekelwe kumanqaku amathathu, kwaye umgama phakathi kwala manqaku mathathu kufuneka unyuswe kangangoko kunokwenzeka.

Ukongezelela, xa uqwalasela i-positioner, kuyimfuneko ukuqinisekisa ulwalathiso lomthwalo wokucubungula osetyenzisiweyo kwangaphambili. Isalathiso somthwalo wokucubungula kwakhona isalathiso somqheba wesixhobo / uhambo lwesixhobo. Isikhundla siqwalaselwe ekupheleni kolwalathiso lwesondlo, esinokuchaphazela ngokuthe ngqo ukuchaneka okupheleleyo komsebenzi.

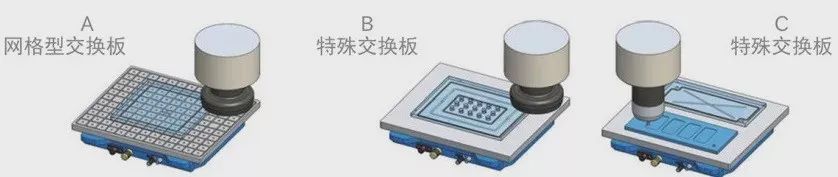

Ngokubanzi, uhlobo lwebholithi oluhlengahlengiswayo lusetyenziselwa ukubeka indawo engenanto yesixhobo sokusebenza, kunye nohlobo olusisigxina (I-CNC yokuguqula iinxalenyeumphezulu woqhagamshelwano ngumhlaba) isiphawuli sisetyenziselwa ukubeka umgangatho womatshini womsebenzi.

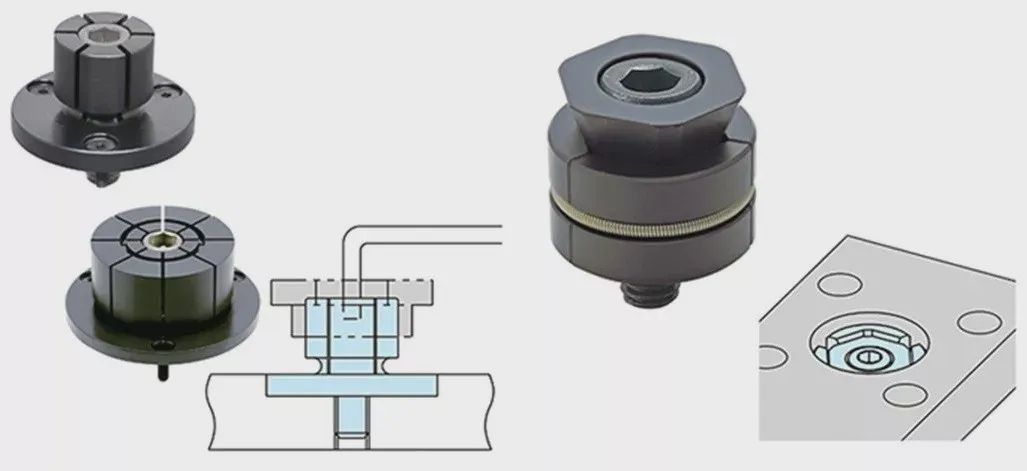

2, Umgaqo osisiseko wokuma kumngxuma wokusebenza

Xa usebenzisa umngxuma oqhutywe kwinkqubo yangaphambili ye-workpiece yokubeka, kuyimfuneko ukusebenzisa ipini yokunyamezela yokubeka. Ngokudibanisa ukuchaneka komngxuma wokusebenza kunye nokuchaneka kweprofayili yepini kunye nokudibanisa ngokuhambelana nokunyamezela, ukuchaneka kokumisa kunokuhlangabezana neemfuno zangempela.

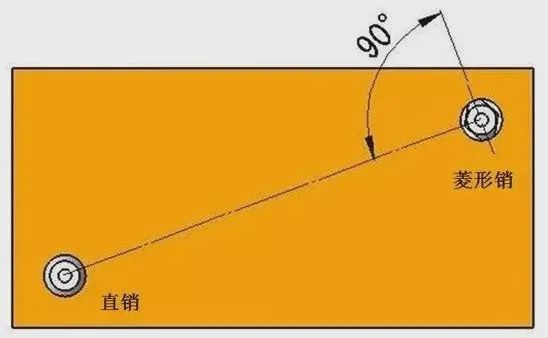

Ukongeza, xa usebenzisa isikhonkwane sokubeka, ngokuqhelekileyo omnye usebenzisa ipini ethe tye kwaye enye isebenzisa iphini yedayimani, ngoko kuya kuba lula ngakumbi ukudibanisa kunye nokuqhawula umsebenzi. Kunqabile ukuba i-workpiece ibambeke ngephini.

▲ Ukuma ngephini

Ewe kunjalo, kuyenzeka ukuba usebenzise ipini ethe tye kuzo zombini izikhonkwane ngokuhlengahlengisa ukunyamezelana okufanelekileyo. Ukubeka indawo echanekileyo, ngokuqhelekileyo kusebenza kakhulu ukusebenzisa ipini ethe tye kunye nepini yedayimane.

Xa isikhonkwane esithe tye kunye nepini yedayimani isetyenzisiwe, umgca wokudibanisa kwindlela yoqwalaselo (apho isikhonkwane sedayimani sinxibelelana ne-workpiece) ye-diamond pin idla ngokuba yi-90 ° perpendicular kumgca wokudibanisa phakathi kwephini elithe ngqo kunye nepini yedayimani. Olu lungelelwaniso lolokumiselwa kwe-angular (isalathiso sokujikeleza sesixhobo sokusebenza).

Ulwazi olufanelekileyo lwe-clamp

I-1, Ukuhlelwa kwee-grippers

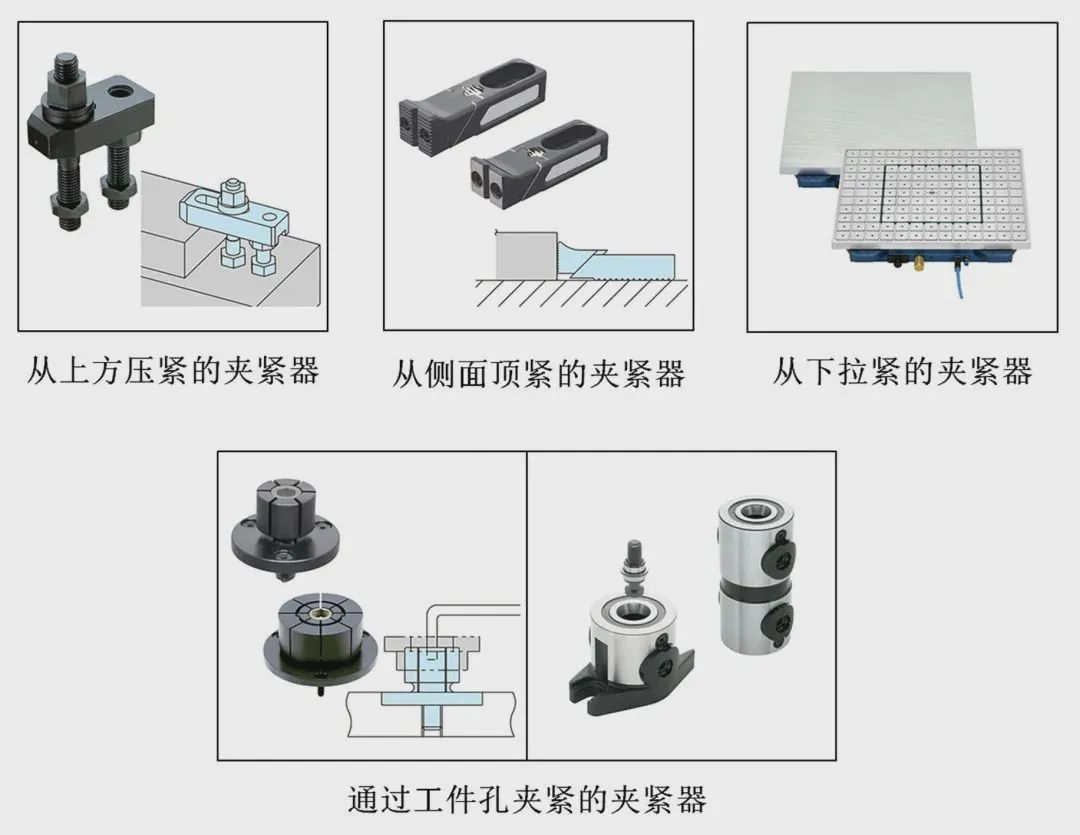

Ngokwalathiso lwe-clamping, yohlulwe ngokubanzi ngokwezi ndidi zilandelayo:

Okulandelayo, makhe sijonge kwiimpawu zeeclamps ezahlukeneyo.

1. Iiclamps zicinezelwe ukusuka phezulu

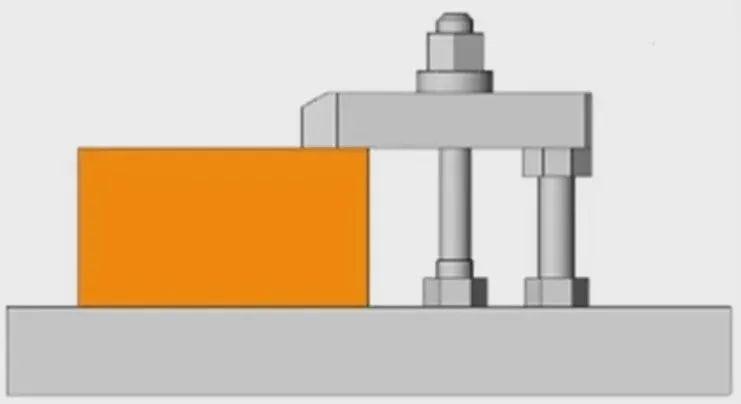

Isixhobo esicinezelayo esicinezelwe ukusuka phezulu kwesixhobo sokusebenza sineyona ndlela incinci yokuguqula ngexesha lokudibanisa, kwaye sesona sizinzile ngexesha lokucubungula i-workpiece. Ke ngoko, ngokubanzi, into yokuqala eqwalaselweyo kukubamba ngaphezulu kwesixhobo sokusebenza. Eyona nto ixhaphakileyo yokucinezela ukusuka phezulu kwesixhobo sokusebenza sisixhobo somatshini owenziwe ngesandla. Umzekelo, lo mzobo ulandelayo ubizwa ngokuba yi-clamp "yohlobo lweqabunga elikhululekile". I-clamp edityaniswe ngokucinezela ipleyiti, i-stud bolt, i-jack kunye ne-nut ibizwa ngokuba yi-"loose leaf" ibamba.

Ngaphezu koko, iipleyiti zokushicilela ezinemilo eyahlukeneyo zinokukhethwa ngokwemilo yendawo yokusebenza. NjengeCNC Machining Amacandelo, iiNdawo eziGuquguqukayo kunye nezahlulo zokugaya.

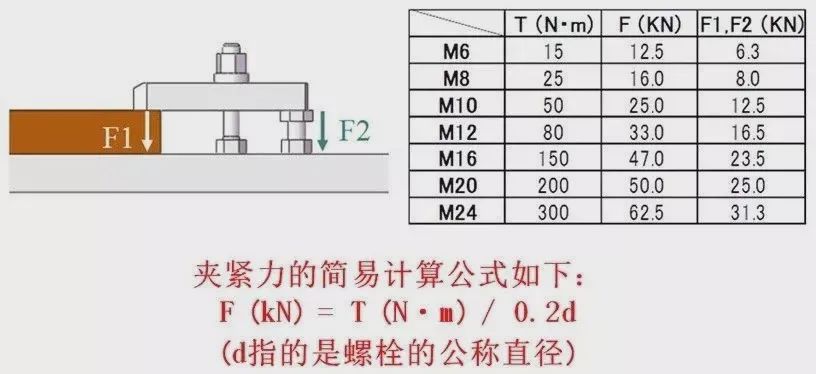

Ubudlelwane phakathi kwetorque kunye namandla okubamba ohlobo lwegqabi elixengaxengayo lunokubalwa ngokutyhala amandla ebholithi.

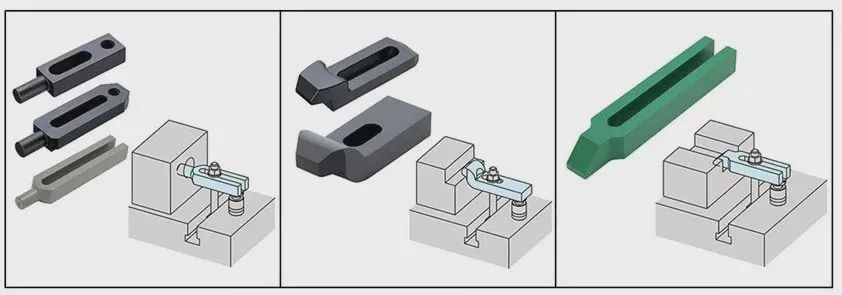

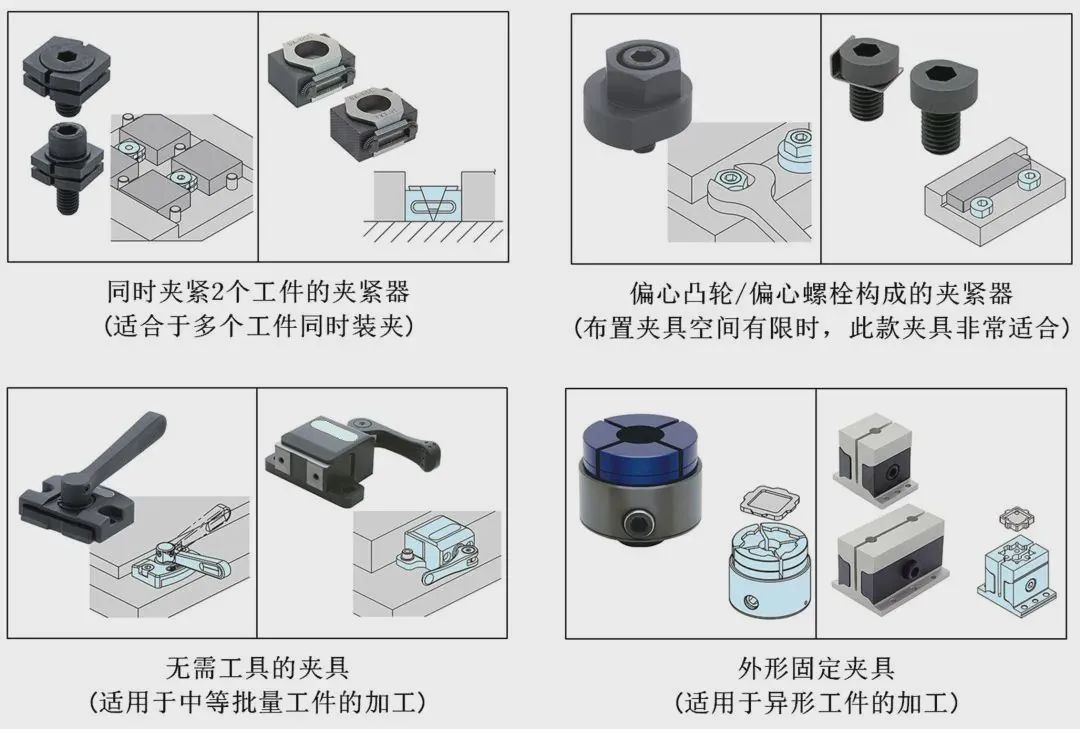

Ukongeza kwi-clamp yamagqabi evulekileyo, i-clamp elandelayo efanayo iyafumaneka ukuze ibambe ngaphezulu kwe-workpiece.

2. I-clamping clamp ukusuka ecaleni

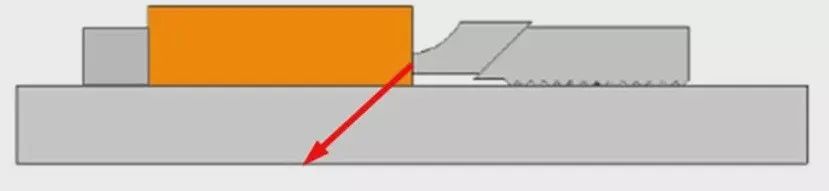

Ekuqaleni, indlela yokuqinisa i-clamping-workpiece evela phezulu iyona nto izinzile ngokuchaneka kunye nobuncinci ekuqhubeni umthwalo womsebenzi. Nangona kunjalo, xa kuyimfuneko ukucutshungulwa ngasentla kwe-workpiece, okanye ayifanelekanga ukuba ibambe ngaphezulu kwendawo yokusebenza, eyenza kube nzima ukuxinzelela phezulu kwendawo yokusebenza, unokukhetha ukudibanisa ukusuka kwicala lomsebenzi. Nangona kunjalo, xa sithetha, xa i-workpiece ibotshelelwe ecaleni, iya kuvelisa amandla adadayo. Indlela yokuphelisa la mandla kufuneka inikwe ingqwalasela xa uyila umzobo.

Njengoko kubonisiwe kulo mzobo ungentla, i-clamp esecaleni ikwanawo amandla asezantsi e-oblique ngelixa ivelisa i-thrust, enokuthintela ngempumelelo i-workpiece ukuba ingadada phezulu.

Iziqhoboshi ezithi zibambe ecaleni zikwanazo ezi clamp zilandelayo.

3. Isixhobo sokuqhoboshela ukuqinisa i-workpiece ukusuka ekutsaleni phantsi

Xa ulungisa umphezulu weplate ecekethekileyo yokusebenzela, akunakwenzeka nje ukuyibamba ukusuka phezulu, kodwa akukho ngqiqweni ukuyicinezela ukusuka kwicala. Eyona ndlela ifanelekileyo yokubambisa kukuqinisa i-workpiece ukusuka ezantsi. Xa i-workpiece igxininiswe ukusuka ezantsi, ukuba yenziwe ngentsimbi, i-clamp yohlobo lwemagnethi idla ngokusetyenziswa. Kwizixhobo zokusebenza zetsimbi ezingenayo intsimbi, iikomityi zokufunxa ngevacuum zingasetyenziselwa ukucinezela.

Kwezi meko zimbini zingasentla, amandla okubamba alingana nendawo yoqhagamshelwano phakathi kwesixhobo sokusebenza kunye nemagnethi okanye ivacuum chuck. Ukuba umthwalo wokucutshungulwa mkhulu kakhulu xa kusetyenzwa ama-workpieces amancinci, umphumo wokucubungula awuyi kuba yinto efanelekileyo.

Ukongeza, xa usebenzisa iimagnethi okanye ivacuum suckers, iindawo zoqhagamshelwano ezinomazibuthe kunye ne vacuum suckers kufuneka zenziwe kumlinganiselo othile wokuguda phambi kokuba zisetyenziswe ngokukhuselekileyo nangesiqhelo.

4. Isixhobo sokubamba ngemingxuma

Xa usebenzisa umatshini we-5-axis machining ukucubungula ubuso obuninzi ngexesha elinye okanye ukubunjwa kwe-mold, ukwenzela ukuthintela impembelelo yezixhobo kunye nezixhobo ekuqhubeni, ngokuqhelekileyo kufanelekile ukusebenzisa indlela yokudibanisa umngxuma. Xa kuthelekiswa nendlela yokudibanisa ukusuka phezulu kunye necala le-workpiece, indlela yokugubungela umngxuma inomthwalo omncinci kwi-workpiece kwaye inokuguqula ngokufanelekileyo i-workpiece.

▲ Ukuqhuba ngokuthe ngqo kunye nemingxuma

▲ Seta i-rivet yokubambelela

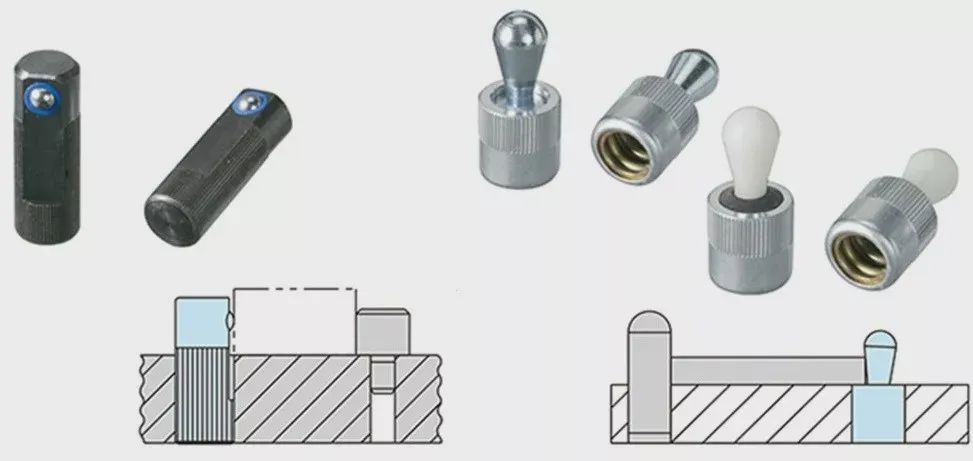

2, Ukubethelela kwangaphambili

Oku kungasentla kubhekiselele ikakhulu kwi-clamping fixture ye-workpiece. Indlela yokuphucula ukusebenza kunye nokusebenzisa i-pre clamping nayo ibalulekile. Xa i-workpiece ibekwe ngokuthe nkqo kwisiseko, i-workpiece iya kuwa ngenxa yomxhuzulane. Ngeli xesha, i-gripper kufuneka iqhutywe ngelixa ibambe i-workpiece ngesandla.

▲ Ukubamba kwangaphambili

Ukuba ii-workpieces zinzima okanye uninzi lwazo zixinzelelwe ngaxeshanye, ukusebenza kuya kuncitshiswa kakhulu kwaye ixesha lokuqinisa liya kuba lide kakhulu. Ngeli xesha, ukusetyenziswa kolu hlobo lwentwasahlobo imveliso ye-pre clamping inokwenza ukuba i-workpiece isebenze i-gripper kwindawo emileyo, iphucula kakhulu ukusebenza kunye nokunciphisa ixesha lokudibanisa le-workpiece.

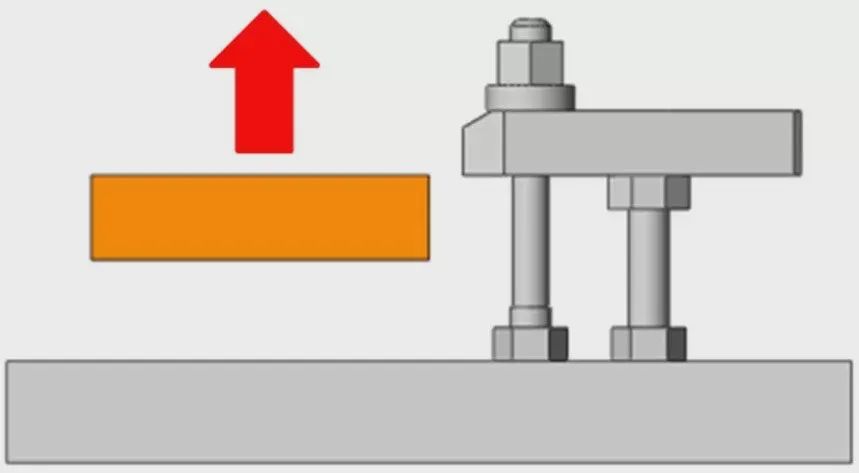

3, Ukhuseleko xa ukhetha into yokubamba

Xa iindidi ezininzi zeeclamps zisetyenziswa kwisixhobo esinye, izixhobo zokucinezela&zokukhulula kufuneka zidityaniswe. Umzekelo, njengoko kubonisiwe kumzobo osekhohlo, xa kusetyenziswa izikrweqe zesixhobo ezahlukahlukeneyo ukuze usebenze ngokucinezela, umthwalo opheleleyo womsebenzi uya kuba mkhulu, kwaye ixesha lokubamba elipheleleyo lesixhobo sokusebenza liya kuba lide. Umzekelo, kumzobo osekunene apha ngezantsi, izikrweqe zesixhobo kunye nobukhulu bebholiti zidityanisiwe ukuququzelela abaqhubi bentsimi.

▲ Ukusebenza okubambezelekayo kwesixhobo sokusebenza

Ukongeza, xa uqwalasela i-gripper, kuyimfuneko ukuqwalasela ukusebenza kwe-workpiece clamping kangangoko kunokwenzeka. Ukuba i-workpiece ifuna ukuthambeka ngexesha lokudibanisa, ukusebenza kunzima kakhulu. Le meko kufuneka iphetshwe xa uyila i-fixture.

Ixesha lokuposa: Oct-24-2022