Ukugrumba, ukutsala, ukuphinda uhlaziye, ukukruqula... Bathetha ukuthini? Oku kulandelayo kuya kukufundisa ukuba uqonde ngokulula umahluko phakathi kwala magama.

Xa kuthelekiswa nokucwangciswa kwendawo yangaphandle, iimeko zokucutshungulwa komngxuma zibi kakhulu, kwaye kunzima kakhulu ukucubungula imingxuma kunokucubungula izangqa zangaphandle. Oku kungenxa yokuba:

I-1) Ubungakanani besixhobo esisetyenziselwa ukucoca umngxuma bukhawulelwe ngubungakanani bomngxuma oza kwenziwa ngawo, kwaye ukuqina kubi, okulungele ukugoba i-deformation kunye ne-vibration;

2) Xa mashini umngxuma ngeisixhobo sobungakanani obusisigxina, ubungakanani bomngxuma buhlala buchongwa ngokuthe ngqo ngobungakanani obuhambelanayo besixhobo, kwaye impazamo yokuvelisa kunye nokugqoka isixhobo kuya kuchaphazela ngokuthe ngqo ukuchaneka kwe-machining yomngxuma;

3) Xa imingxuma yomatshini, indawo yokusika ingaphakathi kwendawo yokusebenza, ukukhutshwa kwe-chip kunye neemeko zokutshatyalaliswa kobushushu zihlwempuzekileyo, kwaye ukuchaneka kwe-machining kunye nomgangatho ophezulu akulula ukulawula.

1. Ukugrumba kunye nokuhlaziya kwakhona

1. Ukugrumba

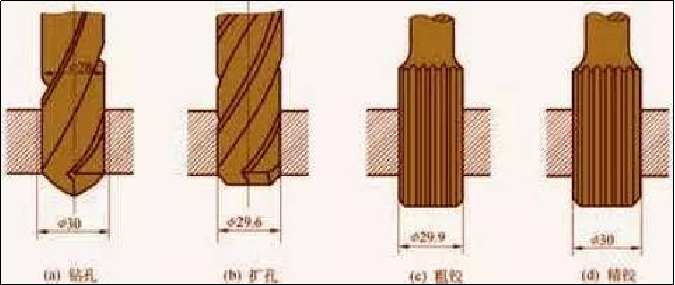

Ukugrumba yinkqubo yokuqala yokwenza imingxuma kwizinto eziqinileyo, kwaye ububanzi bemingxuma ngokubanzi bungaphantsi kwe-80mm. Kukho iindlela ezimbini zokomba: enye kukujikeleza kwe-drill; enye kukujikeleza kweworkpiece. Iimpazamo eziveliswe zezi ndlela zimbini zokomba zingasentla zahlukile. Kwindlela yokugaya kunye ne-drill bit ejikelezayo, xa i-drill drill ichithwa ngenxa ye-asymmetry ye-cut cut and insufficient rigidity of drill bit, umgca ophakathi komngxuma owenziweyo uya kuxutywa okanye uphazamiseke. Akunjalo, kodwa i-diameter yomngxuma ayitshintshanga; ngokuchaseneyo, kwindlela yokugaya apho i-workpiece ijikeleziswa khona, ukuphambuka kwe-drill bit kuya kubangela ukuba ububanzi bomngxuma butshintshe, ngelixa i-centerline yomngxuma isathe tye.

Izixhobo zokugaya ezisetyenziswa ngokuqhelekileyo ziquka: i-twist drill, i-drill center, i-deep hole drill, njl.

Ngenxa yokulinganiselwa kolwakhiwo, ukugoba ukugoba kunye nobungqongqo bokugoba bentwana yokubhora zombini ziphantsi, zidibene nokungaqondi kakuhle, ukuchaneka kokomba kuphantsi, kufikelela kuphela kwi-IT13 ~ IT11; uburhabaxa bomphezulu bukwakhulu, kwaye iRa ngokuqhelekileyo yi-50 ~ 12.5μm; kodwa isantya sokususa isinyithi sokugaya sikhulu, kwaye ukusebenza kakuhle kokusika kuphezulu. Ukugrumba kusetyenziswa ikakhulu ukucubungula imingxuma enemfuno ezikumgangatho ophantsi, njengemingxuma yebholiti, imingxuma esezantsi ephothiweyo, imingxuma yeoli, njl.njl. Kwimingxuma enomatshini obuchanekileyo obuphezulu kunye neemfuno zomgangatho womphezulu, kufuneka zifezekiswe ngokuhlaziya, ukuhlaziya, ukudika okanye ukugaya ngaphakathi. oomatshini abalandelayo. 2. Ukuhlaziya

I-Reaming kukuqhubela phambili nokusetyenzwa kwemingxunya eye yagrunjwa, yaphoswa okanye yadityaniswa nge-reaming drill ukwandisa imbobo nokuphucula umgangatho wokusetyenzwa kwemingxuma.Umatshini wokugqibelayemingxuma engabalulekanga kangako. I-drill yokubuyisela kwakhona ifana ne-twist drill, kodwa enamazinyo amaninzi kunye ne-chisel edge.

Xa kuthelekiswa nokugrumba, ukubuyisela kwakhona kunezi mpawu zilandelayo: (1) inani lamazinyo okugaya likhulu (3 ~ 8 amazinyo), isikhokelo silungile, kwaye ukusika kuzinzile; (2) i-drill yokubuyisela i-chisel ayinasiphelo, kwaye iimeko zokusika zilungile; (3) Isibonelelo somatshini sincinci, ipokotho ye-chip inokwenziwa ingabi nzulu, i-drill core inokwenziwa ibe ngqindilili, kwaye amandla kunye nobungqongqo bomzimba womsiki bungcono. Ukuchaneka komngxuma reaming ngokubanzi IT11~IT10, kunye noburhabaxa umphezulu Ra yi 12.5 ~ 6.3μm. Ukubuyisela kwakhona kudla ngokusetyenziselwa imingxuma yomatshini enobubanzi obuncinci kuno. Xa ubhobhoza umngxuma kunye nobubanzi obukhulu (D ≥ 30mm), i-drill bitana (i-diameter yi-0.5 ~ 0.7 amaxesha ububanzi bomngxuma) isoloko isetyenziselwa ukubhobhoza kwangaphambili, kwaye ngoko ubungakanani obuhambelanayo bokucoca kwakhona. isetyenziselwa ukukhupha umngxuma, nto leyo enokuphucula umgangatho womngxuma. Ukulungiswa komgangatho kunye nokusebenza kakuhle kwemveliso.

Ukongeza ekusetyenzweni kwemingxunya yesilinda, ukuphinda kuphinde kusetyenziswe imilo eyohlukeneyo enemilo ekhethekileyo yokuphinda-phinda (ekwaziwa ngokuba zii-countersinks) ukusetyenzwa kwemingxunya yezihlalo ezitshonelweyo ezahlukeneyo kunye nokutshona. Isiphelo sangaphambili se-countersink sihlala sinekholamu yesikhokelo, ekhokelwa ngumngxuma owenziwe ngomatshini.

2. Ukuhlaziya

Ukuhlaziya enye yeendlela zokugqiba imingxuma, esetyenziswa ngokubanzi kwimveliso. Kwimingxunya emincinci, ukuphinda kuphinde kusetyenziswe indlela eyongayo nesebenzayo kunokusila kwangaphakathi kunye nokudika.

1. IiReamers

IiReamers zohlulwe ngokubanzi zibe ziindidi ezimbini: iireamers zezandla kunye neereamers zoomatshini. Umqheba we-rereamer wesandla sisiphatho esithe tye, inxalenye esebenzayo inde, kwaye umsebenzi okhokelayo ungcono. Umxhasi wezandla unezakhiwo ezibini zodidi oludityanisiweyo kunye nedayamitha yangaphandle ehlengahlengiswayo. Kukho iindidi ezimbini zomatshini wokubuyisela kwakhona, uhlobo lwe-shank kunye nohlobo lwemikhono. I-Reamers ayinakucubungula imingxuma esetyhula kuphela, kodwa kunye nemingxuma ye-taper inokucutshungulwa kunye ne-taper reamers. 2. Inkqubo yokubuyisela kwakhona kunye nokusetyenziswa kwayo

Isibonelelo sokubuyisela kwakhona sinempembelelo enkulu kumgangatho wokubuyisela kwakhona. Ukuba isibonelelo sikhulu kakhulu, umthwalo we-reamer uya kuba mkhulu, umgca wokusika uya kuphazamiseka ngokukhawuleza, akulula ukufumana umgangatho owenziwe ngomatshini, kwaye ukunyamezela kwe-dimensional akulula ukuqinisekiswa; ukuba isibonelelo sincinci kakhulu, Ukuba iimpawu zesixhobo ezishiywe yinkqubo yangaphambili azikwazi ukususwa, ngokwemvelo ayiyi kuphucula umgangatho wokucubungula umngxuma. Ngokubanzi, isibonelelo sehinge erhabaxa yi-0.35 ~ 0.15mm, kwaye ihenjisi ecolekileyo yi-01.5 ~ 0.05mm.

Ukuze ugweme ukubunjwa kwe-edge eyakhiweyo, ukuhlaziya ngokuqhelekileyo kwenziwa ngesantya esisezantsi sokusika (v <8m / min kwi-high-speed steel reamers yensimbi kunye nentsimbi). Ixabiso lokutya linxulumene nendawo yokuvula ukuze iqhutywe. Okukhona kuvuleka indawo enkulu, kokukhona ixabiso lesondlo. Xa i-high-speed steel reamer isebenza ngentsimbi kunye nentsimbi, isondlo sivame ukuba yi-0.3 ~ 1mm / r.

Xa imingxuma iphinda ilungiswa, kufuneka ipholiswe, ithanjiswe kwaye icocwe ngolwelo olufanelekileyo lokusika ukuthintela ukwakhiwa kunye nokususa iitshiphusi ngexesha. Xa kuthelekiswa nokusila kunye nokudika, ukubuyisela kwakhona kunemveliso ephezulu kwaye kulula ukuqinisekisa ukuchaneka komngxuma; nangona kunjalo, ukubuyisela kwakhona akunakulungisa impazamo yendawo ye-axis yomngxuma, kwaye ukuchaneka kwendawo yomngxuma kufuneka kuqinisekiswe yinkqubo yangaphambili. Ukubuyisela kwakhona akufuneki kuqhube imingxunya enyathelweyo kunye nemingxuma engaboniyo.

Ukuchaneka kwe-dimensional of the reming hong ngokubanzi yi-IT9~IT7, kunye noburhabaxa bomphezulu i-Ra ngokubanzi yi-3.2~0.8 μm. Kwimingxuma ephakathi kunye neemfuneko ezichanekileyo ezichanekileyo (ezifana ne-IT7-level echanekileyo yemingxuma), inkqubo yokugaya-yokwandisa-i-reaming yinkqubo eqhelekileyo yokucubungula esetyenziswa ngokuqhelekileyo kwimveliso.

3. Kuyadika

Ukudika yindlela yokucubungula esebenzisa izixhobo zokusika ukukhulisa imingxuma eyenziwe ngaphambili. Umsebenzi odinisayo unokuqhutywa kumatshini odikayo okanye i-lathe.

1. Indlela ekruqulayo

Kukho iindlela ezintathu ezahlukeneyo zomatshini wokukruqula.

(1) Umsebenzi uyajikeleza kwaye isixhobo siyatya. Uninzi lwento ekruqulayo kwi-lathe yeyale ndlela ikruqulayo. Iimpawu zenkqubo zezi: umgca we-axis womngxuma emva komatshini uhambelana ne-axis ejikelezayo ye-workpiece, ukujikeleza komngxuma ubukhulu becala kuxhomekeke ekujikelezweni kokuchaneka kwesixhobo sokuphotha somatshini, kunye nempazamo yejometri ye-axial yomngxuma ubukhulu becala ixhomekeke. kwisalathiso sokutya kwesixhobo esinxulumene ne-axis ejikelezayo ye-workpiece. ukuchaneka kwesikhundla. Le ndlela ekruqulayo ilungele ukusetyenzwa kwemingxuma eneemfuno ze-coaxiality kunye nomphezulu wangaphandle.

(2) Isixhobo sijikeleza kwaye i-workpiece yenza intshukumo yokutya. I-spindle yomatshini odikayo iqhuba isixhobo esikruqulayo ukujikeleza, kwaye i-worktable iqhuba i-workpiece ukwenza intshukumo yokutya.

(3) Xa isixhobo sijikeleza kwaye senza intshukumo yokutya, indlela ekruqulayo isetyenziselwa ukudika. Ubude be-overhang ye-bar ekruqulayo buyatshintshwa, kwaye ukuguqulwa kwamandla kwi-bar ekruqulayo kuyatshintshwa. I-diameter yomngxuma incinci, yenza umngxuma odibeneyo. Ukongeza, ubude be-overhang ye-bar boring buyanda, kwaye i-deformation yokugoba ye-shaft ephambili ngenxa yobunzima bayo nayo iyanda, kwaye i-axis yomngxuma owenziwe ngomatshini iya kugoba ngokufanelekileyo. Le ndlela ekruqulayo ifanelekile kuphela kwimingxuma emfutshane.

2. Idayimani iyadika

Xa kuthelekiswa nokukruqula okuqhelekileyo, idayimani idikile ibonakaliswe sisixa esincinci sokusika umva, ukutya okuncinci, kunye nesantya esiphezulu sokusika. Ingakwazi ukufumana ukuchaneka okuphezulu kwe-machining (IT7~IT6) kunye nomphezulu ogudileyo kakhulu (i-Ra yi-0.4 ~ 0.05 μm). Idayimani ekruqulayo yayisenziwa ekuqaleni ngezixhobo zedayimani ezikruqulayo, kwaye ngoku ilungiswa ngokubanzi ngekhabhide enesamente, i-CBN kunye nezixhobo zedayimani zokwenziwa. Ikakhulu isetyenziselwa ukusetyenzwa kwentsimbi engasebenziyo, kodwa isetyenziselwa ukulungisa intsimbi kunye nentsimbi.

Ubuninzi bokusika obusetyenziswa ngokuqhelekileyo kwi-diamond boring yile: ukubuyisela umva we-pre-boring ngu-0.2 ~ 0.6mm, kwaye i-boring yokugqibela yi-0.1mm; izinga lokutya ngu-0.01 ~ 0.14mm / r; isantya sokusika yi-100 ~ 250m / min xa usenza i-iron cast cast, kunye ne-machining 150 ~ 300m / min yentsimbi, i-300 ~ 2000m / min yokulungiswa kweentsimbi ezingenayo i-ferrous.

Ukuze kuqinisekiswe ukuba i-diamond boring inokufezekisa ukuchaneka okuphezulu kwe-machining kunye nomgangatho ophezulu, isixhobo somatshini (i-Diamond boring machine) esetyenzisiweyo kufuneka sibe nokuchaneka okuphezulu kwejometri kunye nokuqina. I-shaft ephambili yesixhobo somatshini idla ngokuxhaswa ngokuchaneka kwebhola ye-angular okanye i-hydrostatic sliding bearings, kunye neendawo ezijikelezayo ezijikelezayo. Imele ilungelelaniswe ngokuchanekileyo; ukongeza, ukuhamba kwendlela yokutya kufuneka kuzinze kakhulu ukuqinisekisa ukuba i-worktable inokwenza intshukumo ezinzileyo kunye nesantya esisezantsi.

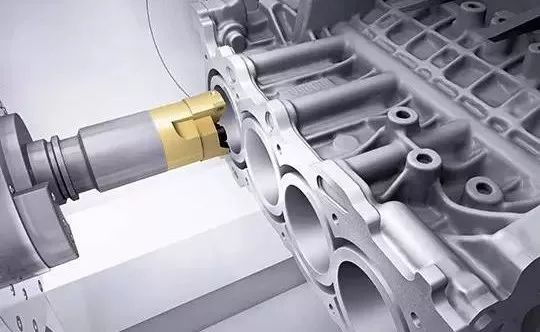

Idayimani ekruqulayo inomgangatho wokusetyenzwa kakuhle kunye nokusebenza kakuhle kwemveliso, kwaye isetyenziswa ngokubanzi ekusetyenzweni kokugqibela kwemingxunya echanekileyo kwimveliso yobuninzi, njengemingxuma ye-injini yesilinda, imingxuma yepiston yepiston, kunye nemingxuma yokusonta kwiibhokisi zokusonta zesixhobo somatshini. Nangona kunjalo, kufuneka kuqatshelwe ukuba xa usebenzisa idayimani ekruqulayo ukucubungula iimveliso zesinyithi, izixhobo ezikruqulayo kuphela ezenziwe ngesamente ye-carbide kunye ne-CBN zingasetyenziswa, kwaye izixhobo ezidikayo ezenziwe ngedayimani azinakusetyenziswa, kuba iiathom zekhabhoni kwidayimani zinobudlelwane obukhulu. ngezinto zeqela lentsimbi. , ubomi besixhobo buphantsi.

3. Isixhobo esikruqulayo

Izixhobo ezikruqulayo zinokwahlulwa zibe zizixhobo ezikruqulayo zomphetho omnye kunye nezixhobo ezidikayo eziphindwe kabini.

4. Iimpawu zobuchwepheshe kunye noluhlu lwesicelo sokukruqula

Xa kuthelekiswa nenkqubo ye-drilling-expanding-reaming, ububanzi bomngxuma abukhawulelwanga ngobukhulu besixhobo, kwaye i-boring inamandla amakhulu okulungisa impazamo. Imiphezulu ekruqulayo kunye nokubeka indawo igcina ukuchaneka okuphezulu kwendawo.

Xa kuthelekiswa nesangqa sangaphandle umngxuma ekruqulayo, ngenxa yobungqongqo amahlwempu kunye deformation enkulu isixhobo umnini isixhobo, ukuchithwa ubushushu kunye neemeko ukususwa chip ayilunganga, kunye deformation thermal of workpiece kunye nesixhobo kakhulu ngokwentelekiso. Umgangatho womatshini kunye nokusebenza kakuhle kwemveliso yomngxuma odikayo awukho phezulu njengesangqa sangaphandle semoto. .

Ngokusekwe kolu hlalutyo lungasentla, kunokubonwa ukuba ukukruqula kunoluhlu olubanzi lokusetyenzwa, kwaye kunokuqhuba imingxunya yobukhulu obahlukeneyo kunye namanqanaba ahlukeneyo okuchaneka. Kwimingxuma kunye neenkqubo zomngxunya ezinobubanzi obukhulu kunye neemfuno zokuchaneka komgangatho ophezulu kunye neendawo, ukudika phantse kukuphela kokulungiswa. indlela. Ukuchaneka komatshini wokukruqula yi-IT9~IT7. Ukudinwa kunokwenziwa kwizixhobo zoomatshini ezinje ngoomatshini abadikayo, iileyile, kunye noomatshini bokusila. Ineenzuzo zokuguquguquka kwaye isetyenziswa ngokubanzi kwimveliso. Kwimveliso yobuninzi, ukuze kuphuculwe ukusebenza kakuhle okukruqulayo, ukufa okukruqulayo kuhlala kusetyenziswa.

4. imingxuma yokulola

1. Umgaqo wokuhlonipha kunye nentloko yokuhlonitshwa

I-Honing yindlela yokugqiba umngxuma ngentloko ye-honing ngentonga yokusila (whitstone). Ngexesha lokugcoba, i-workpiece igxininiswe, kwaye intloko ye-honing iqhutywe yi-spindle yomatshini ukujikeleza kunye nokwenza ukunyakaza okuhambelanayo. Kwinkqubo ye-honing, i-bar yokugaya yenza phezu kwendawo yokusebenza kunye noxinzelelo oluthile, kwaye inqumle umgca omncinci kakhulu wezinto eziphathekayo ukusuka kumphezulu womsebenzi, kwaye i-trajectory yokusika i-mesh enqamlekileyo. Ukuze wenze umkhondo wentshukumo yeenkozo ezirhabaxa zentlabathi ungaphindi, ukuguqulwa ngomzuzu kwentshukumo ejikelezayo yentloko yentloko kunye nenani lemivumbo ephindaphindayo ngomzuzu wentloko yentloko kufuneka ibe ngamanani aphambili omnye komnye.

I-angle ye-intersection ye-honing track inxulumene nesantya sokubuyisela kunye nesantya se-peripheral yentloko ye-honing. Ubungakanani be-angle buchaphazela umgangatho wokucubungula kunye nokusebenza kakuhle kwe-honing. Ngokuqhelekileyo, ithathwa njenge-° yokuhombisa rhabaxa kunye nokuhombisa kakuhle. Ukuze kuququzelelwe ukukhutshwa kwee-particle abrasive abrasive and chips, ukunciphisa ubushushu bokusika kunye nokuphucula umgangatho wokucubungula, ulwelo olwaneleyo lokusika kufuneka lusetyenziswe ngexesha le-honing.

Ukuze wenze udonga lomngxuma lucutshungulwe ngokufanayo, ukubetha kwe-sand bar kufuneka kudlule inani eligqithisiweyo kwiiphelo zombini zomngxuma. Ukuze kuqinisekiswe isibonelelo sokuhomba esifanayo kunye nokunciphisa impembelelo yempazamo yokujikeleza kwesixhobo somatshini ekuchanekeni komatshini, uninzi lweentloko zokuhombisa kunye nezixhobo zokuphotha zomatshini zidityaniswe ngokudada.

Ukwandiswa kwe-radial kunye nokulungiswa kwe-contraction ye-honing head grinding bar ineendlela ezahlukeneyo zesakhiwo ezifana ne-manual, i-pneumatic kunye ne-hydraulic.

2. Iimpawu zenkqubo kunye noluhlu lwesicelo se-honing

I-1) I-Honing inokufumana ukuchaneka okuphezulu kunye nokuchaneka kwemilo. Ukuchaneka komatshini yi-IT7 ~ IT6, kwaye ukujikeleza kunye neempazamo ze-cylindricity zemingxuma zingalawulwa ngaphakathi koluhlu lwe-, kodwa ukuhlonitshwa akukwazi ukuphucula ukuchaneka kwendawo yemingxuma eyenziwe ngoomatshini.

I-2) I-Honing inokufumana umgangatho ophezulu, uburhabaxa be-Ra yi-0.2 ~ 0.25μm, kwaye ubunzulu bomgangatho we-metamorphic defect of the surface metal buncinci kakhulu 2.5 ~ 25μm.

3) Xa kuthelekiswa nesantya sokugaya, nangona isantya se-peripheral sentloko ye-honing asiphezulu (vc = 16 ~ 60m / min), kodwa ngenxa yendawo enkulu yoqhagamshelwano phakathi kwebar yesanti kunye ne-workpiece, isantya esibuyiselayo siphezulu kakhulu. (va=8~20m/min). min), ke ukuhoya kusenemveliso ephezulu.

I-Honing isetyenziswa ngokubanzi kumatshini wemingxuma yesilinda ye-injini kunye nemingxuma echanekileyo kwizixhobo ezahlukeneyo ze-hydraulic kwimveliso yobuninzi. Nangona kunjalo, i-honing ayifanelekanga ukusetyenzwa kwemingxuma kwizinto zokusebenza zetsimbi ezingenayo i-ferrous kunye neplastiki enkulu, kwaye ingakwazi ukucubungula imingxuma ene-grooves engundoqo, imingxuma ye-spline, njl.

5. Tsala umngxuma

1. Ukubhula kunye nokukhangela

I-Hole broaching yindlela yokugqiba evelisa kakhulu eyenziwa kumatshini wokucoca nge-broach ekhethekileyo. Kukho iintlobo ezimbini zebhedi yokufunxa: ibhedi ehonjisiweyo exwebileyo kunye nebhedi yokuqhafaza ethe nkqo, enebhedi yokuqhafaza ethe tyaba iyeyona ixhaphakileyo.

Xa i-broach, i-broach yenza kuphela i-low-speed linear motion (intshukumo engundoqo). Inani lamazinyo e-broach esebenza ngexesha elifanayo kufuneka ngokuqhelekileyo lingabi ngaphantsi kwe-3, ngaphandle koko i-broach ayiyi kusebenza kakuhle, kwaye kulula ukuvelisa i-annular ripples phezu kwendawo yokusebenza. Ukuze kuthintelwe i-broach ukuba ingaphumi ngenxa yokunyanzeliswa kwamandla okugqithisa, xa i-broach isebenza, inani lamazinyo asebenzayo akufanele lidlule kwi-6 ukuya kwi-8.

Kukho iindlela ezintathu ezahlukeneyo ze-broaching, ezichazwe ngolu hlobo lulandelayo:

1) I-Layered broaching Uphawu lwale ndlela yokuqhafaza kukuba i-broach inqumla i-workpiece machining allowance layer ngumaleko ngokulandelelana. Ukuze kube lula ukuqhawuka kwetshiphu, amazinyo okusika acolwa ngemijelo yokwahlula itshiphu egxadazayo. I-broach eyenzelwe ngokwendlela yokuqhafaza elayitiweyo ibizwa ngokuba yi-broach eqhelekileyo.

I-2) I-Block broaching Uphawu lwale ndlela ye-broaching kukuba uluhlu ngalunye lwetsimbi kumphezulu womatshini luquka iqela lamazinyo anomlinganiselo ofanayo kodwa amazinyo adibeneyo (ngokuqhelekileyo iqela ngalinye linamazinyo angama-2-3) akhutshiwe. Izinyo ngalinye linqumla kuphela inxalenye yomaleko wesinyithi. I-broach eyenzelwe ngokwendlela yebhloko yokubhula ibizwa ngokuba yi-wheel-cut broach.

3) Ukubhula okubanzi Le ndlela igxininisa iingenelo zokuqhafaza okucwangcisiweyo kunye nezahlulo. Inxalenye yezinyo elirhabaxa ithatha i-broaching ecandekileyo, kwaye inxalenye yezinyo elicolekileyo ithatha i-broaching. Ngale ndlela, ubude be-broach bunokufinyezwa, imveliso inokuphuculwa, kwaye umgangatho ongcono wendawo unokufumaneka. I-broach eyenzelwe ngokwendlela ebanzi yokuqhafaza ibizwa ngokuba yi-comprehensive broach.

2. Iimpawu zenkqubo kunye noluhlu lwesicelo sokutsala umngxuma

I-1) I-broach sisixhobo esine-multi-blade, esinokugqibezela ngokulandelelana ukugoba, ukugqiba kunye nokugqiba umngxuma kwi-stroke enye ye-broaching, kunye nokusebenza okuphezulu kwemveliso.

2) Ukuchaneka kwe-broaching ikakhulu kuxhomekeke ekuchanekeni kwe-broach. Ngaphantsi kweemeko eziqhelekileyo, ukuchaneka kwe-broaching kunokufikelela kwi-IT9 ~ IT7, kunye nobukhulu bomhlaba uRa unokufikelela kwi-6.3 ~ 1.6 μm.

3) Xa utsala umngxuma, i-workpiece ibekwe ngumngxuma owenziwe ngomatshini ngokwawo (indawo ehamba phambili ye-broach yindawo yokubeka i-workpiece), kwaye akulula ukuqinisekisa ukuchaneka kwesigxina somngxuma kunye nezinye iindawo; Ekulungiseni amalungu omzimba, imingxuma idla ngokutsalwa kuqala, emva koko eminye imiphezulu yenziwe ngoomatshini kusetyenziswa imingxuma njengesalathiso sokubeka. I-4) I-broach ayikwazi kuphela ukucubungula imingxuma ejikelezileyo, kodwa yenza imingxuma kunye nemigodi ye-spline.

I-5) I-broach sisixhobo esisisigxina esinemilo enzima kunye nexabiso eliphezulu, elingafanelanga ukutshiza imingxuma emikhulu.

Imingxuma yokutsala isetyenziswa ngokuqhelekileyo kwimveliso yobuninzi ukuze kuqhutywe imingxuma kwiindawo ezincinci kunye neziphakathi kunye nobubanzi be-Ф10 ~ 80mm kunye nobunzulu bomgodi obungadluli amaxesha angama-5 ububanzi bomngxuma.

Ixesha lokuposa: Aug-29-2022