Imposiso yoMatshini ibhekisa kwiqondo lokutenxa phakathi kwecandelo lelona candelo leeparamitha zejometri (ubungakanani bejometri, imilo yejometri, kunye nesikhundla sobabini) emva komatshini kunye nemilinganiselo yejometri efanelekileyo.

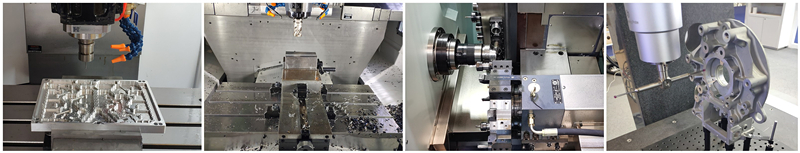

Iqondo lesivumelwano phakathi kweyona parameters yejometri neyiyo emva kokuba inxalenye yomatshini kukuchaneka komatshini. Incinci impazamo yomatshini, kokukhona inqanaba eliphezulu lokuhambelana nokuchaneka.7075 aluminium machining

Ukuchaneka komatshini kunye nempazamo yomatshini ziindlela ezimbini zengxaki. Ke ngoko, ubungakanani bempazamo yomatshini bubonisa inqanaba lokuchaneka komatshini. Izizathu eziphambili zeempazamo zomatshini zezi zilandelayo:

1. Impazamo yokwenziwa kwesixhobo somatshini

Impazamo yokwenziwa kwesixhobo somatshini ikakhulu ibandakanya impazamo yokujikeleza, impazamo yesikhokhelo sikaloliwe, kunye nempazamo yekhonkco lothumelo.

Impazamo yokujikeleza kwe-Spindle ibhekiselele kuguquko lweyona ndawo ijikelezayo i-axis ye-spindle ngokunxulumene ne-avareji yomjikelezo we-axis ngephanyazo ngalinye, eliya kuchaphazela ngokuthe ngqo ukuchaneka komsebenzi oza kuqhutyelwa phambili. Ezona zizathu ziphambili zempazamo yokujikeleza kokusonta yimpazamo ye-spindle's coaxiality, impazamo yokuthwala ngokwayo, impazamo ye-coaxiality phakathi kweebheringi, kunye nokujikeleza komsonto. Isikhokelo sikaloliwe luphawu lokumisela unxulumano lwendawo yecandelo ngalinye lesixhobo somatshini kwisixhobo somatshini, kwaye ikwaluphawu lwentshukumo yesixhobo somatshini.Aluminiyam CNC machining

Impazamo yokwenziwa kwesikhokelo sikaloliwe, ukuguga okungalinganiyo kwesiporo, kunye nomgangatho wofakelo zizinto ezibalulekileyo ezibangela impazamo. Impazamo yesixokelelwano sothumelo ibhekisa kwimpazamo yentshukumo ehambelanayo phakathi kwezinto zothumelo ekuqaleni nasekupheleni kwekhonkco lothumelo. Ibangelwa yimpazamo yokuvelisa kunye nendibano yecandelo ngalinye kwikhonkco lokuhambisa kunye nokunxiba ngexesha lokusetyenziswa.

2. Impazamo yejometri yesixhobo

Nasiphi na isixhobo siya kunxiba ngokuqinisekileyo ngexesha lokusika, okuya kubangela utshintsho kubukhulu kunye nokuma kwendawo yokusebenza. Impembelelo yempazamo yejiyometri yesixhobo kwimpazamo yomatshini iyahluka ngohlobo lwesixhobo: xa isixhobo sobungakanani obusisigxina sisetyenziselwa umatshini, impazamo yokwenziwa kwesixhobo iya kuchaphazela ngokuthe ngqo ukuchaneka komatshini womsebenzi; kwizixhobo eziqhelekileyo (ezifana nezixhobo zokuguqula, njl.), Iphutha layo lokuvelisa Ayinampembelelo ngqo kwiimpazamo zomatshini.

3. Impazamo yejiyometri yesixhobo

Umsebenzi we-fixture kukwenza i-workpiece ilingane nesixhobo, kwaye isixhobo somatshini sinendawo echanekileyo, ngoko ke impazamo yejometri ye-fixture ichaphazela kakhulu impazamo yomatshini (ingakumbi impazamo yendawo).

4. Impazamo yokubeka

Impazamo yokubeka ubukhulu becala ibandakanya impazamo yereferensi yokulungelelaniswa kakuhle kunye nempazamo engalunganga yokwenziwa kwesixhobo sokumisa isibini. Xa ucubungula i-workpiece kwisixhobo somatshini, izinto ezininzi zejometri kwi-workpiece kufuneka zikhethwe njengedatum yokubeka ngexesha lokucubungula. datum) ayingqamani, impazamo yolungelelwaniso lwedatum iya kwenzeka.

Indawo yokubeka iworkpiece kunye nefixture positioning element yenza iperi yokumisa. Olona tshintsho luphezulu lwendawo yokusebenza olubangelwa kukwenziwa ngendlela engachanekanga yeperi yokumisa kunye nomsantsa wokumatanisa phakathi kwezibini zokumisa ubizwa ngokuba yimpazamo yokwenziwa kwempazamo yokumisa iperi. Iphutha lokuvelisa elingalunganga lesibini sokumisa liya kwenzeka kuphela xa indlela yokulungelelanisa isetyenziselwa ukucubungula kwaye ayiyi kwenzeka kwindlela yokusika isilingo.

5. Impazamo ebangelwa kukuguqulwa kwamandla kwenkqubo yenkqubo

Ubunzima bomsebenzi womsebenzi: Ukuba ukuqina kwe-workpiece kwinkqubo yokucubungula kuncinci xa kuthelekiswa nezixhobo zoomatshini, izixhobo, kunye nezixhobo, phantsi kwesenzo samandla okusika, ukuguqulwa komsebenzi ngenxa yokungabikho ngokwaneleyo kuya kuba nefuthe elibi kakhulu kwiimpazamo zomatshini.

Ubulukhuni besixhobo: Ukuqina kwesixhobo sokujika esisilinda kumphezulu owenziwe ngomatshini kumyinge womphezulu womatshini (y) kwicala elikhulu, kwaye ukuguqulwa kwawo kunokungahoywa. Xa ubhobhoza umngxuma ongaphakathi kunye nobubanzi obuncinci, ukuqina kwebar yesixhobo kubi kakhulu, kwaye ukuguqulwa kwamandla kwibar yesixhobo kukuchaphazela kakhulu ukuchaneka komatshini womngxuma.

Ukuqina kwezixhobo zesixhobo somatshini: Izixhobo zesixhobo somatshini zenziwe ngamacandelo amaninzi. Akukho ndlela yokubala ilula ifanelekileyo yokuqina kwezixhobo zesixhobo somatshini. Iindlela zokuvavanya ikakhulu zimisela ukuqina kwezixhobo zesixhobo somatshini. Izinto ezichaphazela ukuqina kwezixhobo zesixhobo somatshini zibandakanya impembelelo yokunxibelelana kobuso bomda odibeneyo, impembelelo yokungqubana, ifuthe leenxalenye eziphantsi, kunye nefuthe lokucoca.Aluminiyam CNC iindawo machining

6. Iimpazamo ezibangelwa yi-thermal deformation yenkqubo yenkqubo

Inkqubo ye-thermal deformation ichaphazela kakhulu iimpazamo zomatshini, ngakumbi ngokuchaneka kunye nomatshini omkhulu. Iimpazamo ze-machuring ezibangelwa yi-thermal deformation ngamanye amaxesha zingabangela i-50% yephutha le-workpiece lilonke.

7. Impazamo yohlengahlengiso

Kwinkqubo nganye yomatshini, kuhlala kukho indlela enye okanye enye uhlengahlengiso kwinkqubo yenkqubo. Ekubeni uhlengahlengiso alukwazi kuchaneka, impazamo yohlengahlengiso iyenzeka. Kwinkqubo yokucubungula, ukuchaneka kwe-positional ye-mutual ye-workpiece kunye nesixhobo kwisixhobo somatshini siqinisekiswa ngokulungelelanisa isixhobo somatshini, isixhobo, ukulungiswa, okanye i-workpiece. Xa ukuchaneka kwasekuqaleni kwezixhobo zoomatshini, izixhobo, izilungiso, kunye neendawo ezingenanto zokusebenza zihlangabezana neemfuno zetekhnoloji ngaphandle kokuqwalasela izinto eziguqukayo, iimpazamo zohlengahlengiso zidlala indima eqinisekileyo kwiimpazamo zobuchwephesha.

8. Impazamo yomlinganiselo

Xa inxalenye ilinganiswa ngexesha okanye emva kokucubungula, ukuchaneka kokulinganisa kuchaphazeleka ngokuthe ngqo kwindlela yokulinganisa, ukuchaneka kwesixhobo sokulinganisa, i-workpiece, kunye nezinto ezizimeleyo kunye nenjongo.

9. Uxinzelelo lwangaphakathi

Uxinzelelo olukhoyo ngaphakathi kwenxalenye ngaphandle kwamandla angaphandle lubizwa ngokuba luxinzelelo lwangaphakathi. Emva kokuba uxinzelelo lwangaphakathi lwenziwe kwi-workpiece, isinyithi siya kungazinzi kwaye sibe nenqanaba eliphezulu lamandla. Iza kuguqula ngokuzenzekelayo ibe yimeko ezinzileyo yezinga eliphantsi lamandla, lihamba kunye ne-deformation, ngoko i-workpiece ilahlekelwa ukuchaneka kwayo kwasekuqaleni.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Jan-11-2022