1. Ngobuchule fumana amanani amancinci okutya kwaye usebenzise imisebenzi yetrigonometric ngobuchule

Fumana ukutya okuncinci ngobuchule kwaye usebenzise imisebenzi ye-trigonometric ngokufanelekileyo.Ngexesha lenkqubo yokuguqula, izixhobo zokusebenza ezinezangqa zangaphakathi nangaphandle ezifuna ukuchaneka okuphezulu zihlala zicutshungulwa. Imingeni efana nokusika ubushushu, ukukhuhlana okubangela ukunxiba kwesixhobo, kunye nokuchaneka okuphindaphindiweyo komphathi wesixhobo esisikweri kwenza kube nzima ukuqinisekisa umgangatho.

Ukujongana nobunzulu obuchanekileyo be-micro-intake, sihlengahlengisa umnini wesixhobo se-longitudinal kwi-engile esekelwe kubudlelwane phakathi kwamacala achaseneyo kunye ne-hypotenuse yonxantathu, ukuvumela ubunzulu obuchanekileyo obunqamlekileyo ngexesha lokujika. Le ndlela ijolise ukonga ixesha kunye nomsebenzi, ukugcina umgangatho wemveliso, kunye nokuphucula ukusebenza kakuhle.

Ixabiso eliqhelekileyo lesikali somphathi wesixhobo se-lathe se-C620 ngu-0.05mm ngecandelo ngalinye. Ukuphumeza ubunzulu obusecaleni obuyi-0.005mm, kubhekiselwa kwitheyibhile ye-sine trigonometric function:sinα=0.005/0.05=0.1 α=5º44′Ngoko ke, ukulungelelanisa isibambi sesixhobo sibe yi-5º44′ kwenza isixhobo sokujika sifikelele ubunzulu obuyi-0.005mm kwi-0.005mm isalathiso esiguquguqukayo kunye nentshukumo nganye yesakhelo sobude.

2. Amatyala amathathu obuchwepheshe bokuqhuba umva

Amava amaninzi emveliso abonise ukuba ukusebenzisa iteknoloji yokusika umva kwiinkqubo ezithile zokuguqula kunokuvelisa iziphumo ezilungileyo. Imizekelo yangoku ibandakanya:

(1) Amalungu entsimbi ye-martensitic asetyenziswa njengesixhobo sokubuyisela umva imisonto yokusika.

Xa usebenza kwii-workpieces ezifakwe kwi-threaded kunye ne-pitches ye-1.25 kunye ne-1.75mm, kuqhelekile ukuhlangabezana nemiba ehambelana nokurhoxiswa kwesixhobo kunye ne-buckling. Iileyile eziqhelekileyo zihlala zingenaso isixhobo sedisk esizinikeleyo, efuna izisombululo zesiko ezithatha ixesha. Ngenxa yoko, ukucutshungulwa kwemisonto kwezi pitshi ezithile kunokuthatha ixesha elininzi kwaye ukujika ngesantya esisezantsi inokuba yeyona ndlela isebenzayo.

Nangona kunjalo, ukusika ngesantya esiphantsi kunokukhokelela ekulumeni isixhobo kunye noburhabaxa bomhlaba obuhlwempuzekileyo, ngakumbi xa ujongana nezixhobo zentsimbi ye-martensitic enje nge-1Crl3 kunye ne-2 Crl3. Ukujongana nale mingeni, indlela yokusika "ezintathu ezibuyisela umva" yaphuhliswa kwindlela yokwenza oomatshini.

Le ndlela, ebandakanya ukulayishwa kwesixhobo esibuyela umva, ukusika umva, kunye nezalathiso zokusika ezichaseneyo, zingqineke zisebenza ngempumelelo ekuphumezeni ukusika intambo ngesantya esiphezulu ngesixhobo sokurhoxa. Le ndlela inenzuzo ngakumbi njengoko ivumela ukusika okusebenzayo kwaye inqanda imiba enokubakho yokuququda ehambelana nokujika kwesantya esisezantsi.

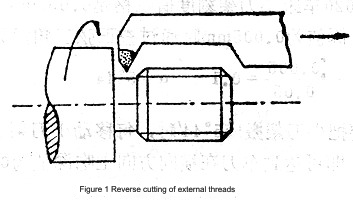

Xa ngaphandle kwemoto, gaya isiphatho esifana nentambo yemoto yangaphakathi (Umfanekiso 1);

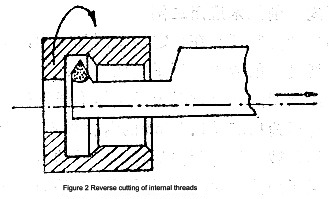

Xa intambo yangaphakathi yemoto igayiwe, i-reverse yangaphakathi imela edibeneyo (Umfanekiso 2).

Phambi kokuba uqalise inkqubo, hlengahlengisa i-spindle ye-counter-roating friction disc kancinane ukuqinisekisa isantya sokujikeleza xa uqalisa ukujikeleza. Emva koko, beka kwaye ukhusele umsiki wentambo, qalisa ukujikeleza phambili ngesantya esiphantsi, kwaye uye kwi-groove yesixhobo esingenanto. Emva koko, qhubela phambili ukufaka isixhobo sokuguqula intambo kubunzulu obufanelekileyo bokusika ngaphambi kokutshintsha ukujikeleza umva. Ngeli nqanaba, isixhobo sokuguqula kufuneka sijikeleze ukusuka kwesobunxele ukuya kwesokudla ngesantya esiphezulu. Emva kokusikeka okuliqela kulandela le ndlela, kunokwenzeka ukuba ufezekise intambo enoburhabaxa obusemagqabini kunye nokuchaneka okuphezulu.

(2) Iintyatyambo ezichasene nemoto

Xa usebenzisa i-lathe yendabuko, kuqhelekile ukuba iincinci zentsimbi kunye ne-debris zingene kwi-workpiece kunye nesixhobo sokusika. Ukusebenzisa ubuchule obutsha bokusebenza ngentambo yokusonta kunokunciphisa ngokufanelekileyo imiba ekuhlangatyenwe nayo ngexesha lomsebenzi wemveli kwaye ikhokelele kwiziphumo ezincomekayo zizonke.

(3) Ukubuyisela umva ukujika kwemisonto yangaphakathi nangaphandle yombhobho

Xa usebenza kwimicu yangaphakathi kunye ne-tapered tapered yangaphakathi kunye neemfuno ezichanekileyo ezisezantsi kunye neebhetshi ezincinci, ungasebenzisa ngokuthe ngqo indlela entsha yokuqhawula umva kunye nofakelo lokubuyisela isixhobo ngaphandle kwesidingo sesixhobo setemplate, ukugcina iinkqubo zokusika eziqhubekayo.

Ukusebenza kwemela yokuswayipha esecaleni kwemanuwali, etshayela ukusuka ekhohlo ukuya ekunene xa ijika intambo yombhobho wetape yangaphandle, ilele kumandla ayo okulawula ngokufanelekileyo ubunzulu bemela yokusika ukusuka kububanzi obukhulu ukuya kwidayamitha encinci ngenxa yoxinzelelo lwangaphambili ngexesha. inkqubo yokusika. Ukusetyenziswa kobu buchwephesha bokusebenza obutsha ekuguqukeni kuyaqhubeka ukukhula kwaye kunokuguquguquka kwiimeko ezahlukeneyo.

3. Ukusebenza okutsha kunye nokuveliswa kwesixhobo sokugrumba imingxuma emincinci

Ngethuba lemisebenzi yokuguqula, xa imingxuma yokubhoboza encinci kune-0.6mm, ububanzi obunqamlekileyo kunye nokuqina okungahambi kakuhle kwe-drill bit kuthintela ukwanda kwesantya sokusika. I-workpiece material, i-alloy-resistant-resistant alloy kunye nensimbi engenasici, ibonisa ukuchasana kokusika okuphezulu. Ngenxa yoko, ukusebenzisa indlela yokutya yokuhambisa ngoomatshini ngexesha lokomba kunokophula ngokulula i-drill bit. Isisombululo esilula nesisebenzayo kukusebenzisa indlela yokondla ngesandla kunye nesixhobo esikhethekileyo.

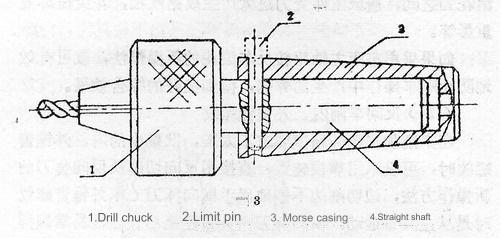

Inyathelo lokuqala libandakanya ukuguqula i-drill chuck ibe luhlobo oludadayo oluthe tye. Ngokucinezela intwana encinci yokomba kwichuck edadayo yokubhola, ukugrumba okugudileyo kuyafezekiswa. Ingxenye engasemva ye-drill bit idibanisa i-handle echanekileyo kunye ne-sliding fit, evumela ukunyakaza okukhululekile ngaphakathi kwe-puller. Ngeli xesha, xa kusemba umngxuma omncinci, i-micro-feeding ethambileyo ngesandla kunye ne-drill chuck ebambe ngesandla iququzelela ukugrumba okukhawulezayo, ukugcina umgangatho kunye nokwandisa ubomi benkonzo yamasuntswana okomba amancinci.

Ukongeza, i-chuck ye-drill eguquliweyo eneenjongo ezininzi inokusetyenziselwa ukucofa intambo yangaphakathi ye-diameter encinci, ukubuyisela kwakhona, kunye nemisebenzi efanayo. Kwimingxuma emikhulu, kucetyiswa ukuba ufake i-pin ye-limited pin phakathi komkhono wokutsala kunye nomqheba othe ngqo. Jonga kuMfanekiso 3 ngeenkcukacha ezibonakalayo.

4. I-Shockproof yokusetyenzwa komngxuma onzulu

Ngexesha lokucutshungulwa komngxuma onzulu, udibaniso lomngxuma omncinci we-diameter kunye ne-slender boring tool shank ingakhokelela kwi-vibration engenakuphepheka xa ujika iinxalenye ezinobubanzi bomngxuma ukusuka kwi-Φ30 ukuya kwi-Φ50mm kunye nobunzulu obumalunga ne-1000mm. Ukunciphisa ukungcangcazela kunye nokuqinisekisa umgangatho ophezulu wokusetyenzwa komngxuma onzulu, indlela ethe ngqo nesebenzayo ibandakanya ukuqhoboshela izixhaso ezimbini, ezakhiwe ngezinto ezifana nelaphu kunye ne-bakelite, kumzimba wentonga.

Ezi zixhasi kufuneka zihambelane nobukhulu bomngxuma wedayamitha ngokuchanekileyo. Ngokusebenzisa ibhloko ye-bakelite exutywe ngelaphu njengenkxaso yokumisa ngexesha lenkqubo yokusika, ibha yesixhobo iyazinziswa, inciphisa kakhulu amathuba okungcangcazela kwaye ivumela ukuveliswa kweendawo ezinzulu zomngxuma onzulu.

5. Ukuthintela ukuphulwa kwee-drills ezincinci zamaziko

Kwinkqubo yokuguqula, ukugrumba umngxuma ophakathi ongaphantsi kwe-Φ1.5mm kubangela umngcipheko omkhulu wokwaphula i-drill ephakathi. Indlela esebenzayo yokuthintela ukophuka kukuphepha ukutshixa i-tailstock ngelixa ubhobhoza umngxuma ophakathi. Oku kuvumela ubunzima obufileyo be-tailstock kunye namandla okukhuhla phakathi kwawo kunye nebhedi yesixhobo somatshini ukuba isetyenziselwe ukomba. Kwiimeko apho ukuxhathisa ukusika kugqithise, i-tailstock iya kuhoxisa ngokuzenzekelayo, ngaloo ndlela ikhusela i-drill center.

6. Ukusetyenziswa kwemathiriyeli yobunzima

Xa sinobunzima bokulungisa izinto ezifana ne-alloy yobushushu obuphezulu kunye nentsimbi yokucima, uburhabaxa bomphezulu we-workpiece bufuneka ukuba bube kwi-RA0.20 ukuya kwi-0.05 μm, kunye nokuchaneka kobungakanani kuphezulu. Ekugqibeleni, ukulungiswa kakuhle ngokuqhelekileyo kuqhutyelwa kwibhedi yokusila.

7. Ukulayisha ngokukhawuleza kunye nokukhulula i-spindle

Ngexesha leenkqubo zokujika, sihlala sidibana neentlobo ngeentlobo zeekhithi zokuthwala ezinezangqa ezijikwe kakuhle zangaphandle kunye nee-engile ze taper yesikhokelo. Ngenxa yobukhulu bebhetshi yabo enkulu, bafuna ukulayishwa kunye nokothula ngexesha lonke lokusetyenzwa. Ixesha elifunekayo lokutshintsha isixhobo lide kunexesha langempela lokusika, elikhokelela ekunciphiseni ukusebenza kwemveliso.

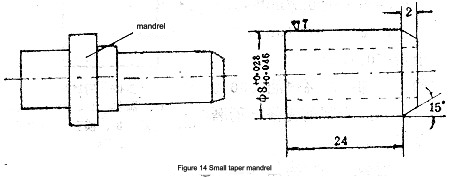

Ukulayisha ngokukhawuleza kunye nokukhupha i-mandrel, kunye ne-single-blade ye-multi-blade (i-tungsten carbide) yokuguqula isixhobo esichazwe ngezantsi, inokunciphisa ixesha elincedisayo kwaye iqinisekise umgangatho weemveliso xa kusetyenzwa kwiindawo ezahlukeneyo zokuthwala imikhono. Indlela yokuvelisa ngolu hlobo lulandelayo: Ukudala i-mandrel encinci ye-taper, i-taper encinci ye-0.02mm isetyenziswe ngasemva.

Nje ukuba ukuthwala kufakwe, iinxalenye zikhuselwe kwi-mandrel ngokusebenzisa ukukhuhlana, kwaye emva koko isixhobo sokujika esinamacangci amaninzi siqeshwe ukusebenza kumphezulu. Emva kokujikeleza, i-engile ye-cone iguqulwa ibe yi-15 °, apho i-wrench isetyenziselwa ukukhupha ngokukhawuleza nangokufanelekileyo iindawo, njengoko kubonisiwe kuMfanekiso we-14.

8. Ukuqhuba kwamacandelo entsimbi yokucima

(1) Omnye wemizekelo ephambili yokucimacnc iimveliso zoomatshini

①Isantya esiphezulu sentsimbi ye-W18CR4V yohlengahlengiso kunye nokuhlaziya (ukulungisa emva kwekhefu)

② IMigangatho ye-Slocculus engeyiyo eyenzelwe ekhaya (Ukuphela nzima)

③ Ukuqhuba kwehardware kunye neendawo zokutshiza

④ Iqhutywa bubuso obukhanyayo behardware

⑤ Impompo yokukhanya enentambo ecokisekileyo enemela yentsimbi enesantya esiphezulu

Xa ujongene ne-hardware eqinile kunye neendawo ezahlukeneyo zezinto ezicelomngeni kumatshini kwimveliso yethu, ukukhethwa ngokucokisekileyo kwezixhobo ezifanelekileyo zesixhobo kunye nobungakanani bokusika, kunye nesixhobo se-engile zejometri kunye neendlela zokusebenza, kunokuvelisa inzuzo ebalulekileyo yezoqoqosho. Ngokomzekelo, xa i-square-mouth broach iqhekeza kwaye ihlaziywa ukuze isetyenziswe ekuveliseni enye i-square-mouth broach, ayandisi nje umjikelo wokwenza izinto kodwa ikhokelela kwiindleko eziphezulu.

Indlela yethu ibandakanya ukusebenzisa i-carbide YM052 kunye nezinye iingcebiso ze-blade zokucoca ingcambu ephukileyo ye-broach yokuqala ibe yi-engile yangaphambili embi r. = -6 ° ~ -8 °, ukuvumela ukuba umgca wokusika ubuyiselwe emva kokugaya ngokucophelela nge-whetstone. Isantya sokusika sibekwe kwi-V = 10 ~ 15m / min. Emva kokuguqula isangqa sangaphandle, i-groove engenanto iyasikwa, kwaye emva koko intambo iguqulwe (iquka ukujika kunye nokuguqulwa kakuhle). Ukulandela ukuguquka okunzima, isixhobo kufuneka siphuculwe kwaye sihlanjwe ngaphambi kokugqiba intambo yangaphandle, kwaye emva koko, icandelo lentambo yangaphakathi lilungele ukudibanisa intonga yokubopha, ehlanjululwa emva kokudibanisa. Ngenxa yezi nkqubo zokuguqula, i-square broach ephukile kwaye ilahliwe yalungiswa kwaye yabuyiselwa kwimeko yayo yangaphambili.

(2) Ukukhethwa kwezixhobo zesixhobo somatshini wokwenza izinto ezilukhuni

①Amabanga amatsha okufakwa kwe-carbide njenge-YM052, YM053, kunye ne-YT05 ziqhele ukusetyenziswa kwizantya zokusika ezingaphantsi kwe-18m/min, ukuphumeza uburhabaxa bomphezulu we-Ra1.6~0.80μm.

②Isixhobo se-FD cubic boron nitride siyakwazi ukucubungula uluhlu lwentsimbi ecinyiweyo kunye neengxenye ezifakwe kwi-spray-coated-coated kwi-speed speed ukuya kwi-100m / min, okubangelwa ubuninzi be-Ra0.80 ~ 0.20μm. Isixhobo se-DCS-F esihlanganisiweyo se-cubic boron nitride esivela kwi-state-owned Capital Machinery Factory kunye ne-Guizhou No. Nangona umphumo wayo wokucubungula awukho ngaphezu kwe-carbide ene-cemented, ayinayo amandla afanayo kunye nobunzulu bokungena, kwaye iza neendleko eziphezulu kunye nomngcipheko wokulimala kwentloko ye-cutter xa isetyenziswe ngokungafanelekanga.

③Izixhobo zokusika i-Ceramic zisebenza ngesantya sokusika i-40-60m / min kodwa zinamandla angaphantsi.Isinye sezi zixhobo sibonisa iimpawu ezikhethekileyo zokucoca iindawo ezicinyiweyo kwaye kufuneka zikhethwe ngokusekelwe kwiimeko ezithile ezibandakanya izinto kunye nobunzima.

(3) IiMfuno zokuSebenza kweSixhobo kwiiMpahla eZiintlobo ngeentlobo zeeNdawo zetsimbi ezicinyiweyo Amalungu entsimbi acinyiweyo ezinto ezahlukeneyo afuna ukusebenza kwesixhobo esahlukileyo phantsi kobunzima obufanayo kwaye anokwahlulwa ngokwezi ndidi zintathu zilandelayo:

Intsimbi ephezulu yealloy:Oku kubhekiselele kwisixhobo sentsimbi kunye nentsimbi yokufa (ikakhulukazi iintsimbi ezahlukeneyo ezinesantya esiphezulu) kunye nesiqulatho esipheleleyo se-alloying element engaphezu kwe-10%.

Intsimbi yealloyi:Oku kubandakanya insimbi yensimbi kunye nentsimbi yokufa enomxholo we-alloy element ukusuka kwi-2 ukuya kwi-9%, umzekelo, i-9SiCr, i-CrWMn, kunye ne-high-high-power alloy structural steel.

Intsimbi yekhabhoni:Oku kubandakanya izixhobo ezahlukeneyo ze-carbon tool steels kunye ne-carburized steels ezifana ne-T8, T10, No. Oku kubangela ubuninzi bobunzima be-HV800 ~ 1000, ephezulu kune-WC kunye ne-TiC kwi-carbide ene-cemented kunye ne-A12D3 kwizixhobo ze-ceramic.

Ukongeza, ubulukhuni bayo obushushu bungaphantsi kunobo be-martensite ngaphandle kwezinto ze-alloy, ngokuqhelekileyo abukho ngaphezu kwe-200 ° C.

Ukwandisa ubukho bezinto ezixutywayo kwintsimbi kukhokelela ekunyuseni okuhambelanayo kwimixholo ye-carbide yentsimbi emva kokucima kunye nokufudumala, okubangelwa umxube onzima weentlobo ze-carbide. Isinyithi esinesantya esiphezulu sisebenza njengomzekeliso, apho umxholo we-carbide kwi-microstructure emva kokucima kunye nokufudumala kunokufikelela kwi-10-15% (umlinganiselo wevolumu). Oku kuquka iindidi ngeendidi zeekhabhidi ezifana ne-MC, M2C, M6, M3, 2C, kunye nezinye, ezineVC ezibonisa ubulukhuni obuphezulu (HV2800), obugqithise kakhulu ubulukhuni bezixhobo eziqhelekileyo zesixhobo.

Ngaphaya koko, ukuqina okushushu kwe-martensite equlethe izinto ezininzi zokuxuba kunokunyuswa ukuya kutsho malunga ne-600°C. Ngenxa yoko, ukunyanzeliswa kwentsimbi ecinyiweyo kunye nobunzima obukhulu obufanayo buhluka kakhulu. Ngaphambi kokwenza inxalenye yentsimbi ecinyiweyo, kubalulekile ukuba uqale uhlalutye udidi lwayo, uqonde iimpawu zayo, kwaye ukhethe izixhobo ezifanelekileyo zesixhobo, iiparamitha zokusika, kunye nejometri yesixhobo. Ngokuqwalaselwa ngokufanelekileyo, ukujika kweengxenye zetsimbi eziqinileyo kunokufezekiswa kwii-angles ezahlukeneyo.

I-Anebon inebhongo ngokufezekiswa okuphezulu kwabathengi kunye nokwamkelwa okubanzi ngenxa yokuzingisa kwe-Anebon yomgangatho ophezulu kwimveliso kunye nenkonzo yeSatifikethi se-CE esenziwe ngokweSiko loMgangatho oPhezulu weComputer.I-CNC Parts MillingIsinyithi, i-Anebon ibisoloko isukela i-WIN-WIN imeko kunye nabathengi bethu. I-Anebon yamkele ngokufudumeleyo abathengi abavela kwihlabathi liphela beza ngaphaya kotyelelo kunye nokuseka ubudlelwane bothando obuhlala ixesha elide.

Isatifikethi se-CE I-China cnc eyenziwe ngezixhobo ze-aluminium,I-CNC iguqule iinxalenyekunye neendawo ze-cnc lathe. Bonke abasebenzi kwifektri, ivenkile, kunye neofisi ye-Anebon bazabalazela injongo enye yokubonelela umgangatho ongcono kunye nenkonzo. Ishishini lokwenyani kukufumana win-win imeko. Singathanda ukunika inkxaso ngakumbi kubathengi. Wamkelekile bonke abathengi abalungileyo ukunxibelelana nathi ngeenkcukacha zeemveliso kunye nezisombululo!

Ukuba ufuna ukwazi ngakumbi okanye unemibuzo, nceda uqhagamshelaneinfo@anebon.com.

Ixesha lokuposa: Feb-18-2024