Wazi kangakanani malunga noyilo lomatshini?

Uyilo lweMechanical lisebe lobunjineli elisebenzisa imigaqo eyahlukeneyo kunye nobuchule ukuyila, ukuhlalutya kunye nokwandisa iinkqubo zoomatshini kunye namalungu. Uyilo lomatshini luquka ukuqonda injongo ekujoliswe kuyo yecandelo okanye inkqubo, ukukhetha izinto ezifanelekileyo, kuthathelwa ingqalelo izinto ezahlukeneyo, ezifana noxinzelelo kunye noxinzelelo kunye nemikhosi, kunye nokuqinisekisa ukusebenza okuthembekileyo nokusebenzayo.

Uyilo lomatshini lubandakanya uyilo lomatshini, uyilo lolwakhiwo, uyilo lomatshini kunye noyilo lwemveliso. Uyilo lwemveliso lujongene noyilo lweemveliso ezibonakalayo ezifana nempahla yabathengi, izixhobo zoshishino kunye nezinye izinto ezibonakalayo. Uyilo lomatshini, kwelinye icala, lugxile ekudaleni oomatshini abafana neenjini, iiinjini zomoya kunye nezixhobo zokuvelisa. Uyilo lweMechanism lujongene noyilo lweendlela eziguqula amagalelo abe kwiziphumo ezinqwenelekayo. Uyilo lolwakhiwo linyathelo lokugqibela. Ibandakanya uhlalutyo kunye noyilo lwezakhiwo ezifana neebhulorho, izakhiwo, kunye nezakhelo zokomelela kwazo, uzinzo, ukhuseleko kunye nokuqina.

Injani inkqubo yoyilo oluthile?

Inkqubo yoyilo ngokuqhelekileyo ibandakanya amanyathelo ahlukeneyo, afana nokuchongwa kophando lwengxaki kunye nohlalutyo, ukuveliswa kweengcamango kunye noyilo oluneenkcukacha kunye neprototyping, kunye novavanyo kunye nokucacisa. Kwezi zigaba iinjineli zisebenzisa ubuchule kunye nezixhobo ezahlukeneyo ezifana nesoftware yoyilo oluncediswa yikhompyuter (CAD), uhlalutyo lwento ephelelisiweyo (FEA) kunye nokulinganisa ukuqinisekisa kunye nokuphucula uyilo.

Ziziphi izinto ekufuneka ziqwalaselwe ngabayili?

Uyilo loomatshini ludla ngokubandakanya izinto ezifana nokwenza, i-ergonomics, ukusebenza kakuhle kweendleko kunye nokuzinza. Iinjineli zizama ukuphuhlisa iimodeli ezingasebenziyo kwaye zisebenza ngokufanelekileyo nangona kunjalo, kufuneka ziqwalasele iimfuno zabasebenzisi, impembelelo yokusingqongileyo kunye nemida yezoqoqosho.

Kubalulekile ukukhumbula ukuba intsimi yoyilo lomatshini intsimi ebanzi kwaye eqhubekayo eguqukayo enezixhobo ezintsha, iteknoloji kunye neendlela eziqhubekayo ziphuhliswa. Ke ngoko, abaqulunqi boomatshini kufuneka baqhubeke behlaziya izakhono zabo kunye nolwazi ukuze bahlale bephambili kwinkqubela phambili yetekhnoloji.

Oku kulandelayo ngamanqaku olwazi malunga noyilo lomatshini oluqokelelwe kwaye luququzelelwe liqela lobunjineli be-Anebon ukuze babelane noogxa.

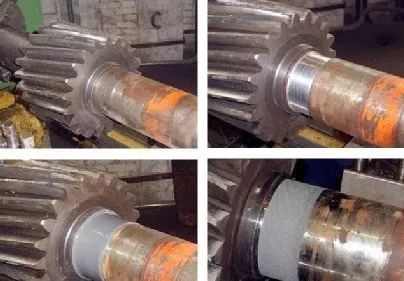

1. Izizathu zokungaphumeleli kumacandelo oomatshini kukuba: ukwaphuka ngokubanzi okanye ukonakala okugqithisileyo komphezulu oshiyekileyoizinto eziguquliweyo ezichanekileyo(i-corrosion wear, ukudinwa kunye nokuguga) Ukusilela ngenxa yeempembelelo zeemeko eziqhelekileyo zokusebenza.

2. Amacandelo oyilo kufuneka akwazi ukuhlangabezana: iimfuno zokuthintela ukungaphumeleli kwixesha elichaziweyo (amandla okanye ukuqina, ixesha) kunye neemfuno zeenkqubo zesakhiwo, iimfuno zezoqoqosho, iimfuno zomgangatho ophantsi, kunye neemfuno zokuthembeka.

3. Iikhrayitheriya zoyilo lwenxalenye zibandakanya iinqobo zokuqina, iinqobo zokuqina zobomi, iikhrayitheriya zokuzinza kwe-vibration kunye nemigangatho yokuthembeka.

4. Iindlela zoyilo lwenxalenye: uyilo lwethiyori, uyilo lobuchule, uyilo lovavanyo lwemodeli.

5. Ngokuqhelekileyo zisetyenziselwa amacandelo omatshini Izinto eziphathekayo zamacandelo omatshini ziquka izinto ze-ceramic, izinto ze-polymer kunye nezinto ezidibeneyo.

6. Ukomelela kweiindawo ezenziwe ngoomatshiniluhlelwa lwangamandla oxinzelelo oluzinzileyo kunye namandla oxinzelelo oluguquguqukayo.

7. Umlinganiselo woxinzelelo r = -1 yi-asymmetrical cyclic stress. umlinganiselo r = 0 ubonisa uxinzelelo lwebhayisikile olude.

8. Kukholelwa ukuba inqanaba le-BC laziwa ngokuba yi-strain fatigue (ukudinwa komjikelo ophantsi); I-CD linqanaba lokugqibela lokudinwa kobomi. icandelo lomgca elilandela inqaku elingu-D limele inqanaba lokungaphumeleli kobomi bomzekelo. D ngumda osisigxina wokudinwa.

9. Amaqhinga okuphucula amandla eenxalenye xa udiniwe Nciphisa impembelelo yoxinzelelo loxinzeleloiindawo ezigayiweyo zecncukuya kowona mgangatho unokwenzeka (ukunciphisa umthwalo umjelo ovulekileyo) Khetha imathiriyeli enamandla okudinwa okuqinileyo kwaye uchaze iindlela zonyango lobushushu kunye neendlela zokuqinisa ezonyusa amandla ezinto ezidinwayo.

10. Ukukhuhlana kwezilayidi: Imida yokhuhlane eyomileyo, ukukhuhlana kwamanzi, kunye nokuxubana okuxubeneyo.

11. Inkqubo yokugqoka yamacandelo ibandakanya i-run-in stage kunye nenqanaba lokunxiba elizinzile kunye nenqanaba elibi kakhulu. Iinzame kufuneka zenziwe ukunciphisa ixesha lokugijima, ukwandisa ixesha lokunxiba elizinzile kunye nokulibaziseka ukubonakala kokugqoka okubuhlungu kakhulu.

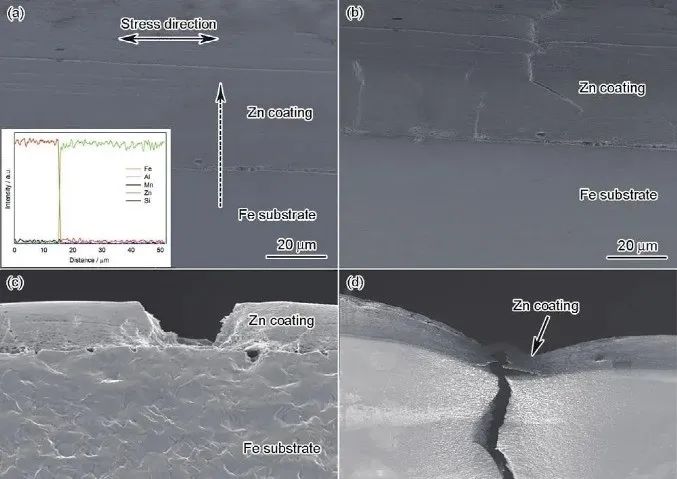

12. Ukuhlelwa kokunxitywa kukunxitywa kwe-Abrasive, ukuncamatheliswa kokuncamathelisa kunye nokudinwa kukulahleka, ukunxitywa kokhukuliseko kunye nokunxitywa okukhathazayo.

13. I-Lubricants ingahlelwa kwiintlobo ezine ezilulwelo, i-gas semi-solid, i-rolid kunye ne-liquid greases zihlelwa njengeendidi ezintathu: i-calcium-based greases nano-based greases lithium-based grease, igrisi esekelwe kwi-aluminium, kunye ne-aluminium-based.

14. Uyilo lwezinyo oluqhelekileyo lokudibanisa intambo ngunxantathu olinganayo oneempawu ezibalaseleyo zokuzivalela kunye nokusebenza kokuhanjiswa komsonto wokuhambisa uxande ungaphezulu kweminye imisonto. imisonto yetrapezoidal yeyona isetyenziswa kakhulu intambo yothumelo.

15. Uninzi lwemisonto yokuqhagamshela inamandla okuzivalela, ngoko ke imisonto enye iqhele ukusetyenziswa. Imisonto yothumelo ifuna ukusebenza okuphezulu kokuhanjiswa kwaye ke ngoko imisonto emithathu, okanye imisonto ephindwe kabini isetyenziswa kakhulu.

16. Uqhagamshelo lwebholiti yohlobo oluqhelekileyo (ngomngxuma okanye imingxuma exhonyiweyo evulekileyo kwiindawo ezidityanisiweyo) udibaniso, uxhulumaniso lwe-stud uxhumano lwe-screw, ukuseta uxhulumaniso lwe-screw.

17. Isizathu sokuqhagamshelwa kwentambo kwangaphambili kukuphucula amandla kunye nokuqina koqhagamshelwano. Kwakhona kunceda ukumisa izithuba kunye nokutyibilika phakathi kwamacandelo emva kokulayisha. Umba ophambili wokukhulula uxhulumaniso olunentambo kukuthintela ukunyakaza okujikelezayo kwi-screws ngelixa ulayishiwe. (Ukukhuhlana ukuthintela ukukhulula, ukuxhathisa koomatshini ukuyeka ukukhulula, ukunyibilikisa ubudlelwane bentshukumo yesikruru)

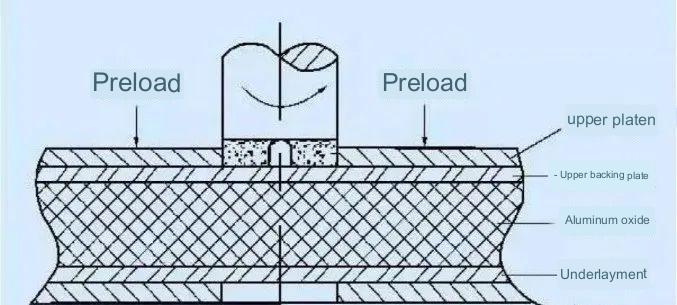

18. Iindlela zokwandisa amandla okudibanisa okudibeneyo Ukunciphisa i-amplitude yoxinzelelo oluchaphazela amandla okukhathala kwi-bolt (ukunciphisa ukuqina kwebholithi kunye nokunyusa ukuqina kwamacandelo adibeneyo) kunye nokuphucula ukusabalalisa kokungalingani komthwalo phezu kwe-bolt. amazinyo emisonto, yehlisa isiphumo sokugxininiswa koxinzelelo kwaye isebenzise inkqubo esebenzayo yokuvelisa.

19. Uhlobo loqhagamshelo olungundoqo Uhlobo loqhagamshelo olungundoqo: mcaba (amacala omabini anemigangatho esebenzayo) uqhagamshelo lwesitshixo sesemicircular isitshixo sewedge uqhagamshelwano lweqhosha elibambekayo.

20. Ukuhanjiswa kwebhanti kunokwahlulwa kube ziindidi ezimbini: uhlobo lwe-meshing kunye nohlobo lwe-friction.

21. Uxinzelelo oluphezulu lokuqala kwibhanti kwindawo apho isiphelo esiqinileyo sebhanti siqala ukuhamba malunga ne-pulley encinci. Uxinzelelo lutshintsha amaxesha angama-4 ngexesha lekhosi kwibhanti.

22. Uxinzelelo lwe-V-belt transmission: isixhobo soxinzelelo rhoqo, isixhobo esizenzekelayo, isixhobo soxinzelelo sisebenzisa i-pulley yoxinzelelo.

23. Ikhonkco lekhonkco lekhonkco kwitsheyini yokuqengqeleka ngokuqhelekileyo lilingana (isixa samazinyo kwi-sprocket linani elingaqhelekanga) kwaye ikhonkco lekhonkco eligqithisiweyo lisetyenziswa xa inani lekhonkco lekhonkco linani elingaqhelekanga.

24. Isizathu soxinzelelo lwe-chain drive kukuqinisekisa ukuba i-meshing ayiphosakalanga kwaye uthintele ukungcangcazela kwekhonkco ukuba i-sag kwisiphelo esikhululekileyo inkulu kakhulu kunye nokunyusa umgama we-meshing phakathi kwekhonkco kunye ne-sprocket.

25. Isizathu sokungaphumeleli kwesixhobo kukuphuka kwezinyo, ukunxiba kumphezulu wezinyo (isixhobo esivulekileyo) i-pitting yamazinyo (isixhobo esivaliweyo) I-gluing yezinyo kunye nokuguqulwa kweplastiki (i-ridges ibonakala kwimigca yevili lokuqhuba ibonakala. ivili lokuqhuba).

26. Iigiya ezinobunzima obungaphezulu kwe-350HBS kunye ne-38HRS zaziwa njengeegiya ezinobuso obulukhuni okanye, ukuba azinjalo, iigiya ezinobuso obuthambileyo.

27. Ukuphucula ukuchaneka kokuvelisa kunye nokunciphisa ubungakanani begiya ukuthoba isantya esihamba ngaso kunokunciphisa umthwalo oguqukayo. Ukuze unciphise lo mthwalo ngamandla, isixhobo sinokulungiswa phezulu. amazinyo egiya abunjwa abe ligubu lokuphucula umgangatho wamazinyo egiya. ukulayisha ukuhanjiswa.

28. Inkulu i-angle yokukhokela ye-coefficient ye-diameter, inkulu ukusebenza kakuhle, kunye nokukhuseleka okuncinci ukukwazi ukuzitshixa.

29. Hambisa igiya leentshulube. Emva kokufuduswa uya kuqaphela ukuba izangqa zepitch kunye nepitch circle ziyadibana, nangona kunjalo kuyacaca ukuba ipitch line worm yeworm itshintshile, kwaye ayisahambelani nepitch circle yayo.

30. Unobangela wokungaphumeleli kwi-worm drive kuku- pitting corrosion kunye nokwaphuka kweengcambu zezinyo, ukuncamathisela komphezulu wezinyo kunye nokuguga okugqithisileyo. Ukungaphumeleli ngokuqhelekileyo kubangelwa yi-worm drive.

31. Ukuphulukana nombane kwi-closed worm drive i-meshing wear ilahleko Ukuphulukana neebheringi kunye nokulahleka kokuchaphaza kwe-oyile njengoko iinxalenye zingena kwitanki yeoli zishukumisa i-oyile.

32. I-worm drive kufuneka ibale ibhalansi yobushushu ngokwemfuno yokuqinisekisa ukuba ixabiso le-calorific ngeyunithi yexesha lilingana nomlinganiselo wokushisa ochithwayo ngexesha elifanayo.

Izisombululo: Yongeza iisinki zobushushu ukwandisa indawo yokuchitha ubushushu. faka iifeni kufutshane ne-shaft ukuze unyuse ukuhamba komoya, kwaye emva koko ufake iisinki zobushushu ngaphakathi kwebhokisi yothumelo. Zinokudityaniswa kumbhobho wokupholisa ojikelezayo.

33. Izinto ezifunekayo ukuze kwenziwe i-hydrodynamic lubrication kukuba imiphezulu emibini etyibilikayo kufuneka yenze umsantsa omise okwe wedge. Imiphezulu emibini eyahlulwe yifilimu yeoli kufuneka ibe nesantya esaneleyo sokutyibilika, kwaye ukuhamba kwayo kufuneka yenze ukuba ioli yokuthambisa ihambe ngomlomo omkhulu emlonyeni omncinci. iyadingeka ukuze ioli ibe ne-viscosity ethile kwaye unikezelo lweoli lufunekayo ukuba lwanele.

34. Isakhiwo esisisiseko se-rolling bearings yindandatho yangaphandle, i-Hydrodynamic body yangaphakathi, i-cage.

35. Iibheringi ezintathu ezinetapered roller iibheringi ezintlanu ezinebhola etyhutyha enzulu. D=10mm, 12mm 15mm, 17,mm ibhekisa ku-20mm d=20mm kwaye i-12 ilingana no-60mm.

36. Ubomi bomgangatho osisiseko: Ipesenti ezili-10 zeebheringi ngaphakathi kweebheringi ezahlukeneyo ziphethwe ngumonakalo wemingxuma, kanti i-90% yeebheringi azichatshazelwa ngumonakalo wemingxuma. Isixa seeyure ezisetyenziweyo bubude bobomi obukhoyo.

37. Umlinganiselo osisiseko oguquguqukayo: ubungakanani bokuba ukuthwala kukwazi ukuxhasa xa ukulinganiswa kwesiseko somatshini ngokuchanekileyo kwi-revolutions eyi-106.

38. Indlela yokumisela ukucwangciswa kokuthwala: iiFulcrum ezimbini zigxininiswe kwicala elinye ngalinye. Inqaku elinye lizinze macala omabini, ngelixa elinye ifulcrum liphela liqubha kumacala omabini, ngelixa elinye liphela liqubha ukunika inkxaso.

39. Iibheringi zihlelwa ngokwenani le-shaft yomthwalo (umzuzu wokugoba kunye ne-torque) i-mandrel (umzuzu wokugoba) kunye ne-Transmission shaft (torque).

I-Anebon ibambelela kwingcamango esisiseko "Umgangatho ngundoqo weshishini kwaye isimo sinokuba sisiseko salo" Ngesaphulelo esikhulu kwi-Custom precision 5 Axis Latheiindawo zoomatshini ze-cnc, I-Anebon iqinisekile ukuba siya kubonelela ngeemveliso ezikumgangatho ophezulu kunye neenkonzo ngexabiso elifikelelekayo kunye nenkonzo ebalaseleyo emva kokuthengisa kubathengi. Ukongeza, i-Anebon iya kuba nakho ukwakha ubudlelwane bexesha elide kunye nawe.

ICandelo laseTshayina leCNC leNgcali yaseTshayina kunye nezahlulo zeMetal Machining, iAnebon ixhomekeke kwiimveliso ezikumgangatho ophezulu, uyilo olugqibeleleyo, inkonzo yabathengi ekhethekileyo kunye neendleko ezifikelelekayo zokufumana intembeko yenani elikhulu labathengi abavela phesheya kunye nase-US. Uninzi lweemveliso zithunyelwa kwiimarike zaphesheya kweelwandle.

Ixesha lokuposa: Aug-02-2023