Iziko lomatshini lidibanisa ioyile, irhasi, umbane, kunye nolawulo lwamanani, kwaye inokuqonda ukubanjwa kwexesha elinye leenxalenye ezahlukeneyo ezinje ngeediski, iipleyiti, amaqokobhe, iikhamera, ukubumba, njl., kwaye inokugqiba ukomba, ukugaya, ukudika, ukwandisa. , reming, Ukucofa okungqongqo kunye nezinye iinkqubo zicutshungulwa, ngoko sisixhobo esifanelekileyoukuchaneka okuphezulu komatshini. Eli nqaku liza kwabelana ngokusetyenziswa kwamaziko omatshini ukusuka kule miba ilandelayo:

Iziko lomatshini lisibeka njani isixhobo?

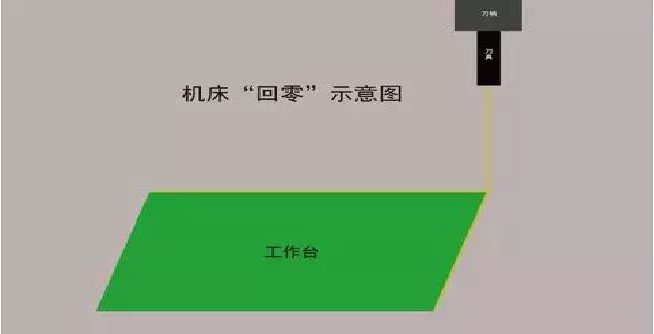

1. Buyela ku-zero (buyela kwimvelaphi yomatshini)

Ngaphambi kokusetwa kwesixhobo, qiniseka ukwenza umsebenzi wokubuyela kwi-zero (ubuyela kwimvelaphi yesixhobo somatshini) ukuze ucime idatha yolungelelwaniso lomsebenzi wokugqibela. Qaphela ukuba i-X, Y, kunye no-Z ii-axes zonke kufuneka zibuyele ku-zero.

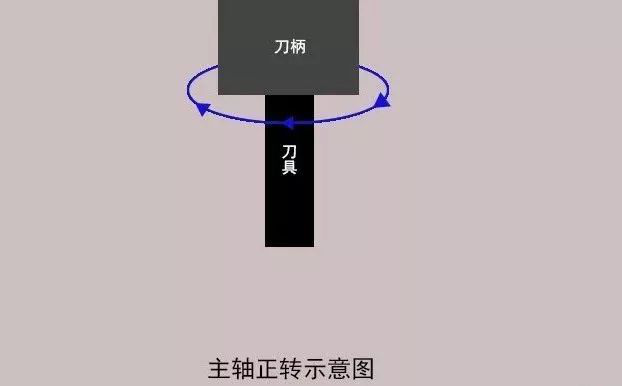

2. I-Spindle ijikeleza phambili

Kwimo ye "MDI", i-spindle ijikeleziswa phambili ngokufaka ikhowudi yomyalelo, kwaye igcina isantya esiphakathi. Emva koko utshintshe kwimodi ye "handwheel", kwaye uhambise isixhobo somatshini ngokutshintsha izinga lohlengahlengiso.

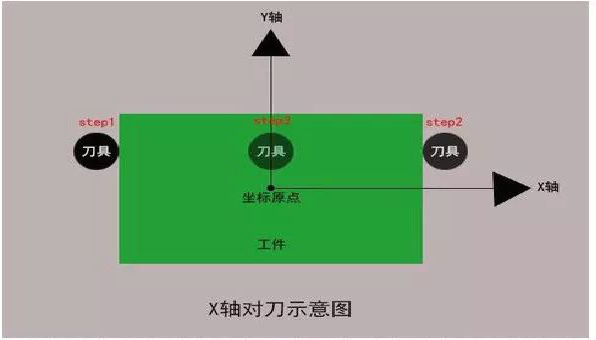

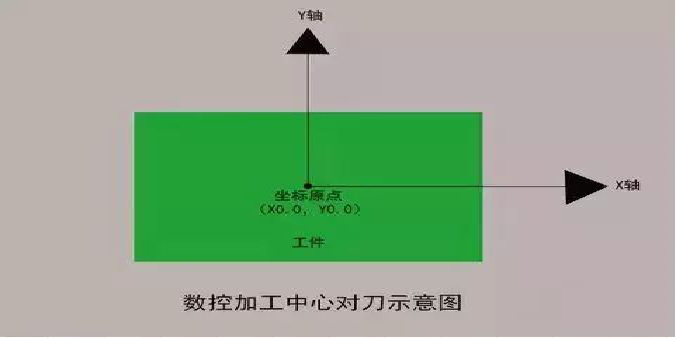

3. X-direction isixhobo setting

Chukumisa ngobunono isixhobo kwicala lasekunene lomsebenzi ukucima ulungelelwaniso olunxulumene nesixhobo somatshini; phakamisa isixhobo ecaleni kwendlela ye-Z, emva koko uhambise isixhobo kwicala lasekhohlo lomsebenzi, wehla ukuya kubude obufanayo nangaphambili, hambisa isixhobo kunye nesixhobo sokusebenza Bamba kancinci, phakamisa isixhobo, bhala phantsi ixabiso le-X lolungelelwaniso oluhlobene. yesixhobo somatshini, hambisa isixhobo kwisiqingatha solungelelwaniso lwe-X, bhala phantsi ixabiso le-X lolungelelwaniso olupheleleyo lwesixhobo somatshini, kwaye ucinezele (INPUT) ukungena kwinkqubo yolungelelwaniso.

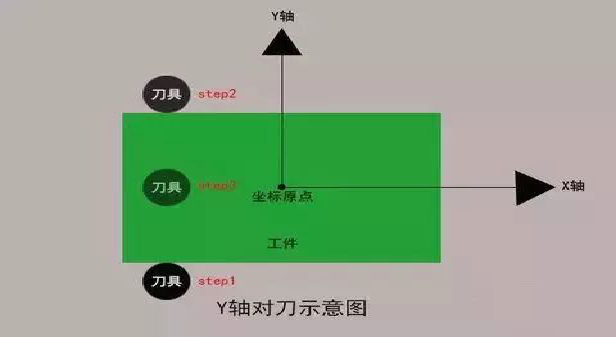

4.Y-isixhobo sokumisela isixhobo

Thinta ngobumnene isixhobo phambi kwendawo yokusebenza ukuze ucime ulungelelwaniso olunxulumene nesixhobo somatshini; phakamisa isixhobo ecaleni kwendlela ye-Z, emva koko uhambise isixhobo ngasemva kwendawo yokusebenza, ezantsi ukuya kubude obufanayo nangaphambili, hambisa isixhobo kunye nesixhobo sokusebenza Chukumisa kancinane, phakamisa isixhobo, bhala phantsi ixabiso le-Y lonxulumano oluzalanayo. isixhobo somatshini, susa isixhobo ukuya kwisiqingatha solungelelwaniso oluhlobene noY, bhala phantsi ixabiso le-Y lolungelelwaniso olupheleleyo lwesixhobo somatshini, kwaye ucinezele (INPUT) ukungena kwinkqubo yolungelelwaniso.

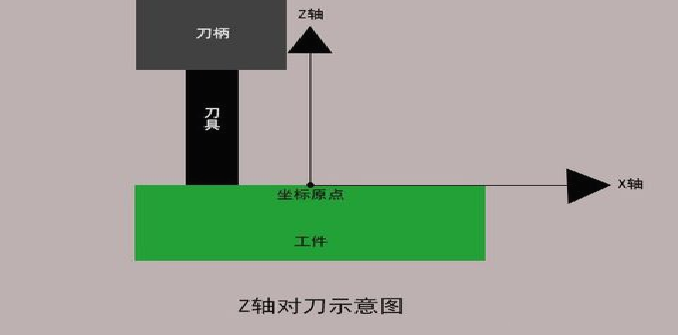

5. Z-direction isixhobo setting

Hambisa isixhobo kumphezulu womsebenzi odinga ukujongana nenqaku elingu-zero kwicala le-Z, kancinane hambisa isixhobo ukuze uqhagamshelane kancinci nomphezulu womsebenzi, urekhode ixabiso le-Z kwinkqubo yolungelelwaniso yesixhobo somatshini ngeli xesha. , kwaye cinezela (INPUT) ukufaka igalelo kwindlela yolungelelaniso.

6. Ukumisa i-spindle

Qala umise intambo yokusonta, uhambise intambo yokusonta kwindawo efanelekileyo, biza inkqubo yokulungisa, kwaye ulungiselele ukusetyenzwa okusesikweni.

Ingaba iziko lomatshini livelisa kwaye licokiseke njani iindawo ezinokukhubazeka ngokulula?

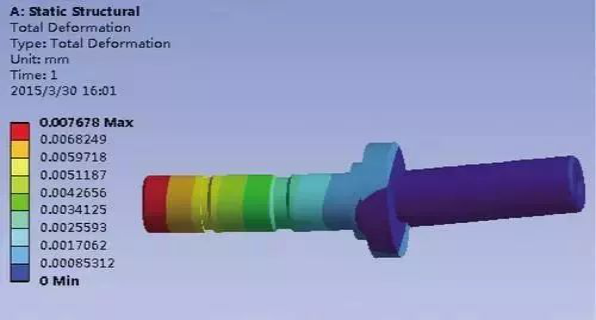

Kwiindawo ezinobunzima obulula, ukuqina okungahambi kakuhle kunye namandla abuthathaka, zikhubazeka ngokulula ngamandla kunye nobushushu ngexesha lokucubungula, kwaye isantya esiphezulu se-scrap sokucubungula sikhokelela ekunyukeni okukhulu kweendleko. Kwiindawo ezinjalo, kufuneka siqale siqonde oonobangela botshintsho:

Nyanzela ukuguqulwa:

Amacandelo anjalo aneendonga ezinqabileyo, kwaye phantsi kwesenzo samandla okudibanisa, kulula ukuba nobukhulu obuhlukeneyo kwi-machining kunye nenkqubo yokusika, kwaye i-elasticity ihlwempuzekileyo, kwaye ukumila kwamacandelo kunzima ukuzibuyisela ngokwawo.

Utshintsho lweThermal:

I-workpiece ilula kwaye incinci, kwaye i-radial force ngexesha lenkqubo yokusika iya kubangela ukuba i-workpiece ibe yintlupheko ngokushisa, ngaloo ndlela yenza ubungakanani bomsebenzi obungachanekanga.

Utshintsho lweVibration:

Ngaphantsi kwesenzo samandla okusika i-radial, iinxalenye zixhomekeke kwi-vibration kunye ne-deformation, echaphazela ukuchaneka kwe-dimensional, imilo, ukuchaneka kwendawo kunye nobunzima bomhlaba bomsebenzi.

Indlela yokucubungula yamalungu akhubazeka lula:

Iindawo eziguquguqukayo ngokulula ezimelwe ngamalungu anodonga olucekethekileyo zinokuthatha imo yesantya esiphezulu somatshini kunye nesantya esincinci sokutya kunye nesantya esikhulu sokusika ukunciphisa amandla okusika kwindawo yokusebenza ngexesha lokusetyenzwa, kwaye kwangaxeshanye wenze uninzi lokusika ubushushu bubhabha. kude neetshiphusi zesixhobo sokusebenza ngesantya esiphezulu. Thatha, ngaloo ndlela unciphisa ubushushu bomsebenzi kunye nokunciphisa i-thermal deformation ye-workpiece.

Kutheni kufuneka kugqitywe izixhobo zeziko lomatshini?

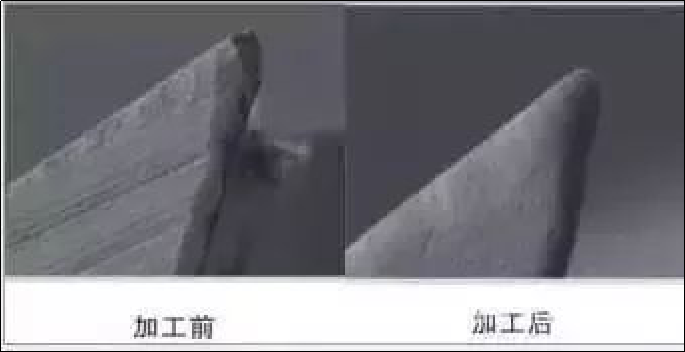

Izixhobo ze-CNC azikhawulezanga, ngoko kutheni zigqithise? Enyanisweni, ukusetyenziswa kwesixhobo akusiyo into eqondwa ngumntu wonke, kodwa yindlela yokuphucula ubomi benkonzo yesixhobo. Ukuphucula umgangatho wesixhobo ngeenkqubo ezinjengokulinganisa, ukupolishwa, kunye nokususa izixhobo. Le yinkqubo eqhelekileyo emva kokuba isixhobo sicolwe kakuhle naphambi kokugquma.

▲Uthelekiso lokugqitha isixhobo

Isixhobo siya kuphuculwa ngevili lokusila phambi komkhiqizo ogqityiweyo, kodwa inkqubo yokulola iya kubangela idigri ezahlukeneyo zezithuba ezincinci. Xa isikhungo somatshini senza i-high-speed cutting, i-micro-notch iya kwandiswa ngokulula, eya kukhawulezisa ukugqoka kunye nokulimala kwesixhobo. Itekhnoloji yanamhlanje yokusika ineemfuno ezingqongqo kuzinzo kunye nokuchaneka kwesixhobo, ngoko ke isixhobo se-CNC kufuneka sigqitywe ngaphambi kokugquma ukuze kuqinisekiswe ukuqina kunye nobomi benkonzo yokugquma. Iingenelo zokugqitha isixhobo zezi:

1. Kuxhathise ukunxitywa kwezixhobo zomzimba

Ngethuba lenkqubo yokusika, umphezulu wesixhobo uya kugqithwa ngokuthe ngcembe yi-workpiece, kwaye umgca wokusika uphinde ulungele ukuguqulwa kweplastiki phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu ngexesha lokusika. Ukugqithiswa kwesixhobo kunokunceda ukuphucula ukuqina kwesixhobo kunye nokuthintela isixhobo ekulahlekelweni kokusika ukusebenza kwangaphambi kwexesha.

2. Gcina isiphelo se-workpiece

I-Burrs kwi-cut cut yesixhobo iya kubangela ukuba isixhobo sinxibe kwaye umphezulu womsebenzi owenziwe ngomatshini uya kuba rhabaxa. Emva kokunyangwa kwe-passivation, umda wokusika wesixhobo uya kuba lula kakhulu, i-chipping phenomenon iya kuncitshiswa ngokufanelekileyo, kwaye ukugqitywa komphezulu we-workpiece kuya kuphuculwa.

3. Ukususwa kwetshiphu yegroove

Ukugudisa igroove yesixhobo kunokuphucula umgangatho womphezulu kunye nokusebenza kokukhutshwa kwetshiphu. Okukhona ugudileyo umphezulu wegroove, kokukhona ukukhutshwa kwetshiphu kungcono, kwaye kokukhona ukusika okungaguqukiyo kunokufezekiswa. Emva kokuba isixhobo se-CNC seziko lomatshini sigqithiswe kwaye siphuculwe, imingxuma emininzi encinci iya kushiywa phezu komhlaba. Le mingxunya mincinci inokufunxa ngakumbi ulwelo lokusika ngexesha lokucutshungulwa, okunciphisa kakhulu ubushushu obuveliswa ngexesha lokusika kwaye iphucule kakhulu ukusebenza kakuhle kokusika. isantya.

Iziko lomatshini linciphisa njani uburhabaxa bomphezulu wesixhobo sokusebenza?

Umphezulu orhabaxa wamalungu yenye yeengxaki eziqhelekileyo zeCNC machiningamaziko, ebonisa ngokuthe ngqo umgangatho wokucubungula. Indlela yokulawula uburhabaxa bomphezulu wokulungiswa kwamalungu, kufuneka siqale sihlalutye oonobangela boburhabaxa bomphezulu, ikakhulu kubandakanywa: iimpawu zesixhobo ezibangelwa kukusila; i-thermal deformation okanye i-plastic deformation ebangelwa ukuhlukana kokusika; isixhobo kunye nomatshini wokubetha umphezulu phakathi.

Xa ukhetha ubuninzi bomphezulu we-workpiece, akufanele kufezekise iimfuno zokusebenza kwendawo yecandelo, kodwa kuqwalaselwe ingqiqo yezoqoqosho. Kwisiseko sokwanelisa ukusebenza kokusika, ixabiso elikhulu lesalathiso soburhabaxa bomphezulu kufuneka likhethwe kangangoko ukunciphisa ixabiso lemveliso. Njengomabi weziko lokusika, isixhobo kufuneka sinikele ingqalelo ekugcinweni kwemihla ngemihla kunye nokusila kwangexesha ukuthintela uburhabaxa obungafanelanga bomhlaba obubangelwa sisixhobo esiluthuntu.

Kufuneka ndenze ntoni emva kokuba iziko lomatshini ligqityiwe?

Ngokubanzi, imithetho yenkqubo yomatshini yezixhobo zoomatshini bemveli kumaziko omatshini aphantse afane. Umahluko ophambili kukuba amaziko omatshini enza umatshini ozenzekelayo oqhubekayo ukugqiba zonke iinkqubo zokusika ngokusebenzisa i-clamping enye. Ke ngoko, amaziko omatshini kufuneka enze "umsebenzi osemva".

1. Yenza unyango lokucoca. Emva kokuba iziko lomatshini ligqibe umsebenzi wokusika, kuyimfuneko ukususa iitshiphusi kwaye usule umatshini ngexesha, kwaye usebenzise isixhobo somatshini kunye nokusingqongileyo ukuze uhlale ucocekile.

2. Ukuhlolwa kunye nokutshintshwa kwezinto ezincedisayo, okokuqala, qaphela ukuba ukhangele i-oyile yokucima i-oyile kwi-rail yesikhokelo, kwaye uyitshintshe ngexesha ukuba igugile. Jonga imeko yeoyile yokuthambisa kunye nesipholisi. Ukuba i-turbidity iyenzeka, kufuneka itshintshwe ngexesha, kwaye umgangatho wamanzi ongaphantsi kwesikali kufuneka wongezwe.

3. Ukulungelelanisa inkqubo yokuvala, ukunikezelwa kombane kunye nombane oyintloko kwipaneli yokusebenza yesixhobo somatshini kufuneka icinywe ngokulandelelana. Ukungabikho kweemeko ezikhethekileyo kunye neemfuno ezikhethekileyo, umgaqo wokubuyela kwi-zero kuqala, i-manual, i-jog, kunye ne-othomathikhi kufuneka ilandelwe. Iziko lomatshini kufuneka libaleke ngesantya esiphantsi, isantya esiphakathi, emva koko sibaleke ngesantya esiphezulu. Isantya esisezantsi kunye nexesha eliphakathi kwexesha lokubaleka aliyi kuba ngaphantsi kwemizuzu engama-2-3 ngaphambi kokuba kungabikho imeko engaqhelekanga ngaphambi kokuqala ukusebenza.

4. Ukusebenza okusemgangathweni, akukwazi ukubetha, ukulungisa okanye ukulungisa i-workpiece kwi-chuck okanye phezulu, kwaye umsebenzi olandelayo kufuneka uqinisekiswe emva kokuba i-workpiece kunye nesixhobo sigxininiswe. Izixhobo zokukhusela kunye nokukhusela izixhobo kumatshini akufanele zichithwe kwaye zihanjiswe ngaphandle kwesizathu. Eyona ndlela isebenzayo kukuqhubekeka ngokukhuselekileyo. Njengesixhobo sokusebenza esisebenzayo, ukusebenza kweziko lomatshini xa livaliwe kufuneka lilinganiswe ngokufanelekileyo, kungekhona nje ukugcinwa kwenkqubo egqityiweyo yangoku, kodwa nokulungiswa kwesiqalo esilandelayo.

Ixesha lokuposa: Sep-19-2022