Uphuhliso lwezixhobo zokusebenza luhlala lusenzeka ngokuhambelana neemfuno ezithile zenkqubo enikiweyo, nje ukuba inkqubo yomatshini yamacandelo isekiwe. Kubalulekile ukuqwalasela ngokupheleleyo ukuba nokwenzeka kokuphunyezwa kwezixhobo ngelixa uqulunqa inkqubo. Xa udala izixhobo zokusebenza, ukulungiswa kwenkqubo kufuneka kucetyiswe xa kuyimfuneko.

Umgangatho woyilo lwezixhobo zokusebenza kufuneka uvavanywe ngokusekwe kubuchule bawo bokuqinisekisa ngokungaguqukiyo umgangatho wokusetyenzwa kwesixhobo sokusebenza, ukufikelela kwimveliso ephezulu, ukunciphisa iindleko, ukwenza kube lula ukususwa kwetshiphu, ukuqinisekisa ukusebenza okukhuselekileyo, ukonga abasebenzi, kunye nokuququzelela ukwenziwa lula kunye ukugcinwa. Iiparamitha zovavanyo zibandakanya ezi zinto.

1. Izikhokelo ezisisiseko zokuyila izixhobo zokusebenza

1) Qinisekisa uzinzo kunye nokuthembeka kwendawo yokusebenza ngexesha lokusetyenziswa;

2) Nikeza ngokwaneleyo ukuthwala umthwalo okanye amandla okubamba ukuqinisekisa ukusetyenzwa kwesixhobo sokusebenza kwisixhobo;

3)Yenza ukusebenza okulula kunye nokukhawuleza ngexesha lenkqubo yokubamba;

4) Dibanisa iindawo ezinxitywayo kunye nesakhiwo esinokutshintshwa, ngokufanelekileyo ukuphepha ukusetyenziswa kwezinye izixhobo xa iimeko zivuma;

5) Ukuseka ukuthembeka kwindawo ephindaphindiweyo yokumiswa ngexesha lohlengahlengiso okanye ukutshintshwa;

6) Nciphisa ukuntsonkotha kunye neendleko ngokunqanda izakhiwo ezintsonkothileyo xa kusenzeka;

7)Sebenzisa amalungu asemgangathweni njengenxalenye yecandelo kangangoko kunokwenzeka;

8) Ukuseka inkqubo yemveliso yangaphakathi kunye nomgangatho phakathi kwenkampani.

2. Ulwazi olusisiseko lwezixhobo kunye noyilo lwezixhobo

Isixhobo esigqwesileyo somatshini kufuneka sifezekise ezi mfuno zilandelayo:

1) Ukuqinisekisa ukuchaneka komatshini womsebenzi kufuna ukuba kukhethwe idata yokubeka efanelekileyo, ubuchule, kunye namalungu, kunye nokuqhuba uhlalutyo lwempazamo yokubeka ukuba kuyafuneka. Kufuneka kuqwalaselwe kwakhona ifuthe leempembelelo zezakhiwo ekuqhubeni ukuqinisekisa ukuba olu luhlu luyahlangabezana neenkcukacha zokuchaneka kwesixhobo sokusebenza.

2) Ukuphucula ukusebenza kakuhle kwemveliso, lungelelanisa ukuntsonkotha kwezinto ezikhethekileyo ezihambelana nomthamo wemveliso. Sebenzisa iindlela zokubambelela ezikhawulezayo nezisebenzayo nanini na xa kunokwenzeka ukwenza lula ukusebenza, ukunciphisa ixesha elincedisayo, kunye nokunyusa ukusebenza kakuhle kwemveliso.

3)Khetha ulwakhiwo olulula nolunengqiqo lwezilungiso ezikhethekileyo ezinomsebenzi ogqwesileyo wokusebenza ukuze ulungelelanise ukwenziwa, ukudibanisa, uhlengahlengiso, ukuhlolwa, kunye neenkqubo zokugcina.

4)Ukulungiswa komsebenzi okukumgangatho ophezulu kufuneka kube namandla okwaneleyo kunye nobungqongqo, kudityaniswa nokusebenza okulula, okusebenzayo, okukhuselekileyo, kunye nokusebenza okuthembekileyo. Nanini na xa kunokwenzeka kwaye kungabizi kakhulu, sebenzisa i-pneumatic, hydraulic, kunye nezinye izixhobo zokubamba ezisebenza ngoomatshini ukunciphisa umfutho wabasebenzi. Ukongeza, isixhobo sokusebenza kufuneka siququzelele ukususwa kwetshiphu kunye nokuphumeza izakhiwo, ukuba kukho imfuneko, ukuthintela iitshiphusi ekubeni zibeke esichengeni indawo yokusebenzela, ukonakaliswa kwesixhobo, okanye kubangele ukuqokelelwa kobushushu kunye nenkqubo yokuguqulwa kwenkqubo.

5) Izilungiso ezikhethekileyo ngokoqoqosho kufuneka zisebenzise amacandelo kunye nezakhiwo kangangoko kunokwenzeka. Zama ukuyila ngokulula kunye nokwenza lula ukunciphisa iindleko zemveliso. Ngoko ke, yenza uhlalutyo oluyimfuneko lobugcisa noqoqosho lwesisombululo sexesha loyilo olusekwe kucwangco kunye namandla emveliso ukuze kuphuculwe inzuzo yoqoqosho ngexesha lemveliso.

3. Isishwankathelo sokumiselwa komgangatho wezixhobo kunye noyilo lwezixhobo

1. Iindlela ezisisiseko kunye namanyathelo ezixhobo kunye noyilo lwe-fixture

Ukulungiswa phambi koyilo Idatha yentsusa yezixhobo kunye noyilo loyilo ibandakanya oku kulandelayo:

a)Ukubonelela ngezaziso zoyilo, imizobo yenxalenye egqityiweyo, imizobo yokuqala, kunye neendlela zenkqubo, kunye nezinye iinkcukacha zobugcisa. Ukufumana ukuqonda kweemfuno zobugcisa kwinkqubo nganye, kubandakanywa iindlela zokubeka kunye nokubambelela, iinkcukacha zokucubungula ukusuka kwinqanaba elandulelayo, iimeko zomphezulu, izixhobo zomatshini eziqeshwe, izixhobo zokusebenza, izixhobo zokuhlola, ukunyamezelwa komatshini, kunye nokusika ubuninzi.

b)Qonda ubungakanani bebhetshi yemveliso kunye neemfuno zokulungisa.

c)Ziqhelanise neeparitha eziphambili zobugcisa, ukusebenza, ukucaciswa, ukuchaneka, kunye nemilinganiselo ehambelana nesakhiwo sokudibanisa inxalenye yesixhobo somatshini esisetyenzisiweyo.

d)Gcina uluhlu olusemgangathweni lwezinto zokulungisa.

2. Imiba ekufuneka iqwalaselwe kuyilo lwezixhobo zokusebenza

Uyilo lwe-clamp ngokubanzi lunesakhiwo esisodwa, esinika ingcamango yokuba isakhiwo asinzima kakhulu. Ngokukodwa ngoku ukuthandwa kweeclamp zehydraulic kuye kwalula kakhulu ukwakheka komatshini wokuqala. Nangona kunjalo, ukuba iingqwalasela ezicacileyo azithathwanga ngexesha lenkqubo yoyilo, iingxaki ezingeyomfuneko ziya kwenzeka:

a)Xa uyila, qinisekisa ukuba umda ongenanto we-workpiece uthathwa ngokuchanekileyo ukukhusela ukuphazamiseka ngenxa yokugqithisa. Lungiselela umzobo ongenanto ngaphambi kokuba uqhubeke nenkqubo yoyilo ukuvumela indawo eyaneleyo.

b)Ukuqinisekisa ukusebenza ngokufanelekileyo kunye nokususwa kwetshiphu egudileyo yolu luhlu, kubalulekile ukulungisa imiba enokubakho efana nokuqokelelana kweefayili zentsimbi kunye nokuphuma kakubi kolwelo lokusika kwangethuba kwinqanaba loyilo. Ukulindela kunye nokusombulula iingxaki zokusetyenzwa kwasekuqaleni kubalulekile ukunyusa injongo yezixhobo ekuphuculeni ukusebenza kakuhle kunye nokulula ukusebenza.

c)Gxininisa ukuvuleka ngokubanzi kwesixhobo ukwenza lula inkqubo yokufakela abaqhubi, ukuphepha ixesha elide kunye nemisebenzi enzima. Ukungahoyi ukuvuleka kwezixhobo akulunganga kuyilo.

d)Hlala unamathela kwimigaqo yethiyori esisiseko kuyilo lokulungisa ukugcina ukuchaneka kunye nobomi obude. Uyilo akufuneki ludibanise le migaqo, nokuba lubonakala luhlangabezana neemfuno zokuqala zabasebenzisi, njengoko uyilo olulungileyo kufuneka lumelane novavanyo lwexesha.

e)Qwalasela ukutshintshwa okukhawulezileyo nokulula kwezinto zokumisa ukulungisa ukunxitywa okuqatha kwaye uphephe ukuyila iinxalenye ezinkulu, ezintsokothileyo. Ukulula ukutshintshwa kufuneka kube yinto ephambili kuyilo lwamacandelo.

Ukuqokelelwa kwamava oyilo lwezixhobo kubaluleke kakhulu. Ngamanye amaxesha uyilo luyinto enye kwaye ukusetyenziswa okusebenzayo kungenye, ngoko uyilo olulungileyo yinkqubo yokuqokelela okuqhubekayo kunye nesishwankathelo.

Izixhobo zokusebenza ezisetyenziswa ngokuqhelekileyo zohlulwe ngokwezi ndidi zilandelayo ngokokusebenza kwazo:

01 ibumba lokubumba

02 Ukwemba kunye nezixhobo zokusila

03 CNC, isixhobo chuck

04 Uvavanyo lwegesi kunye nezixhobo zokuvavanya amanzi

05 Ukucheba kunye nokubetha izixhobo

06 Ukufakwa kwezixhobo zokuwelda

07 Ijig yokupholisha

08 Izixhobo zeNdibano

09 Ukuprintwa kwePad, isixhobo sokukrola ngelaser

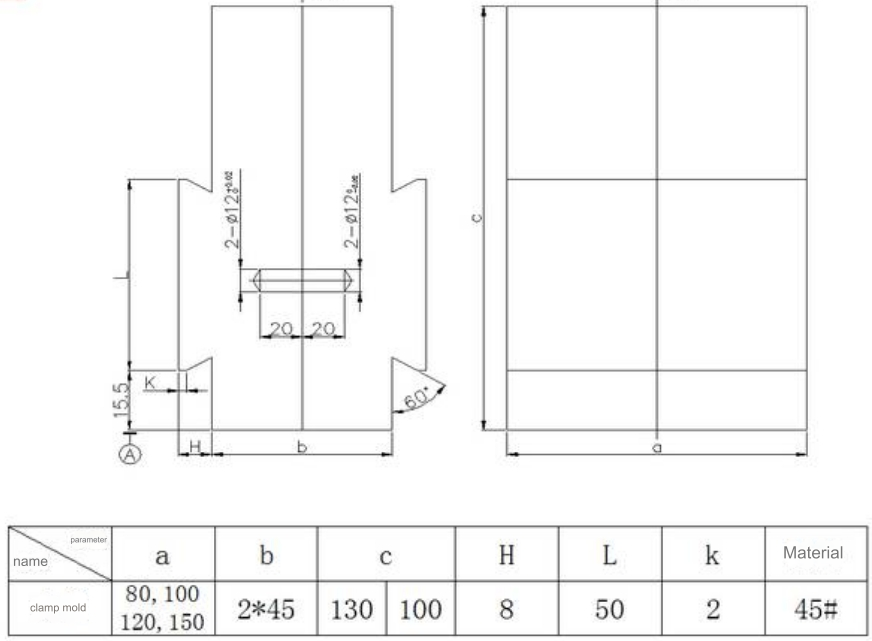

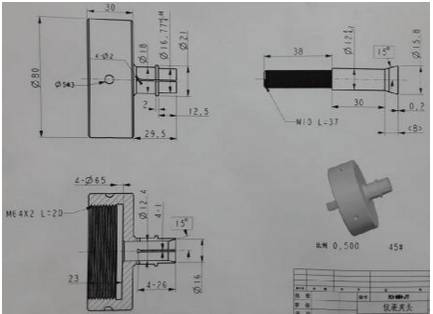

01 ibumba lokubumba

Ingcaciso: Isixhobo sokubeka kunye nokubambelela ngokusekelwe kwimilo yemveliso

Amanqaku oyilo:

1) Olu hlobo lwesibambiso lufumana usetyenziso lwalo oluphambili kwi-vise, kwaye lubonelela ngokuguquguquka ukucuthwa ngokweemfuno.

2) Izixhobo ezongezelelweyo zokubeka zingadityaniswa kwi-clamping mold, ngokuqhelekileyo ikhuselwe nge-welding.

3)Umzobo ongentla ngumboniso owenziwe lula, kwaye imilinganiselo yesakhiwo somgodi wokungunda ixhomekeke kwiimeko ezithile.

4) Beka ngokufanelekileyo i-12mm yedayamitha yokubeka iphini kwindawo yokubumba eshukumayo, ngelixa umngxuma ohambelana nokungundo omiselweyo uyilelwe ukulungiselela ngokutyibilikayo isikhonkwane.

I-5) Ngexesha lesigaba sokuyila, i-cavity yendibano kufuneka ilungiswe kwaye ikhuliswe ngu-0.1mm, ithathela ingqalelo umzobo wenkcazo yomzobo ongenanto ongenanto.

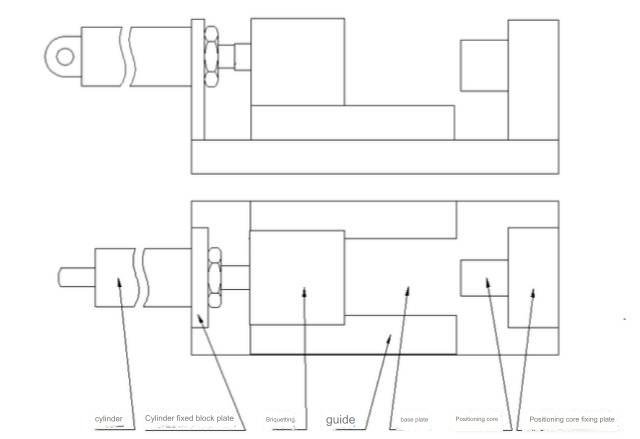

02 Ukwemba kunye nezixhobo zokusila

Amanqaku oyilo:

1) Ukuba kuyimfuneko, iindlela ezongezelelweyo zokubeka zingabandakanywa kwi-core esisigxina kunye nepleyiti ehambelana nayo.

2) Umfanekiso obonisiweyo lulwandlalo lolwakhiwo olusisiseko. Eyona meko ifuna uyilo olulungelelanisiweyo oluhambelana nolwakhiwo lwemveliso.

3)Ukhetho lwesilinda luphenjelelwa yimilinganiselo yemveliso kunye noxinzelelo olufumanayo ngexesha lokucubungula. I-SDA50X50 lolona khetho lukhoyo kwiimeko ezinjalo.

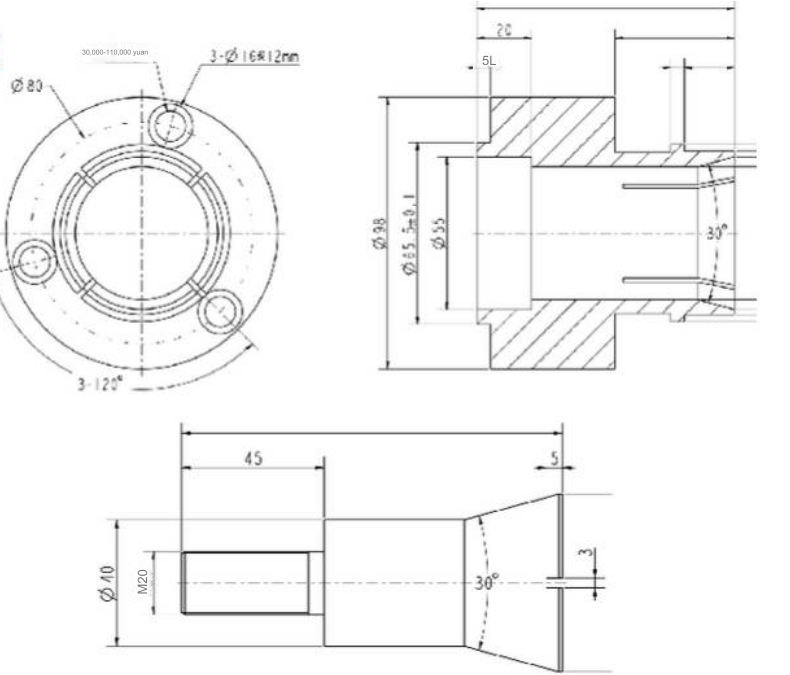

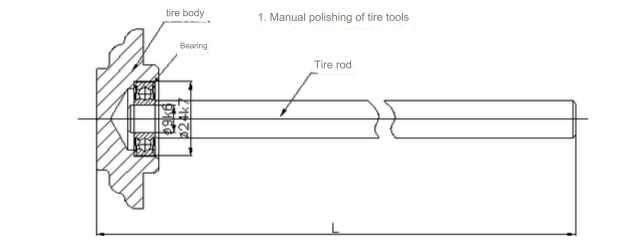

03 CNC, isixhobo chuck

I-CNC chuck

Toe-in chuck

Amanqaku oyilo:

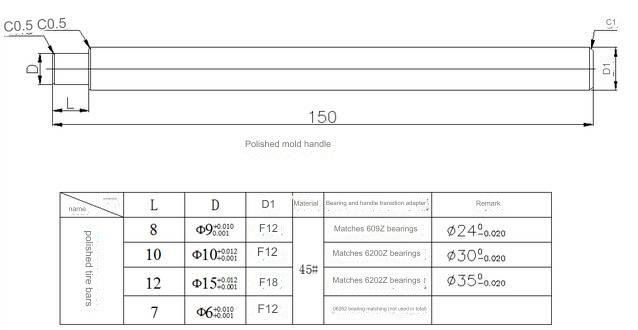

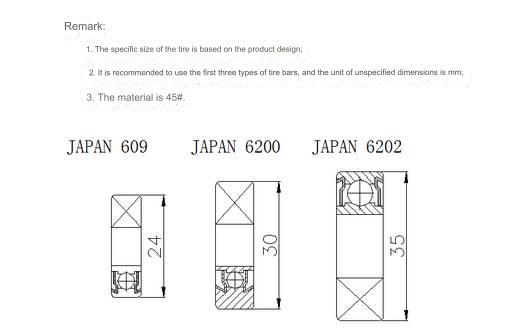

1. Imilinganiselo engaphawulwanga kumfanekiso ongentla isekelwe kwisakhiwo sobungakanani bomngxuma wangaphakathi wemveliso yangempela;

2. Isangqa sangaphandle esikwindawo yokunxibelelana nomngxuma wangaphakathi wemveliso kufuneka sishiye umda we-0.5mm kwicala elinye ngexesha lokuvelisa, kwaye ekugqibeleni sifakwe kwisixhobo somatshini we-CNC kwaye emva koko siguqulwe ngokucokisekileyo sibe sisayizi ukuthintela ukuguqulwa kunye ukunyaniseka okubangelwa yinkqubo yokucima;

3. Kucetyiswa ukuba kusetyenziswe intsimbi yasentwasahlobo njengento yokudibanisa inxalenye kunye ne-45 # ye-tie rod part;

4. Intambo ye-M20 kwinqanaba le-tie liyinto esetyenziswa ngokuqhelekileyo, enokuthi ihlengahlengiswe ngokwemeko yangempela.

Isixhobo se-toe-in chuck

Amanqaku oyilo:

1. Lo mfanekiso ungentla ngumzobo wereferensi, kwaye imilinganiselo yendibano kunye nesakhiwo sisekelwe kwimilinganiselo yemveliso kunye nesakhiwo;

2. Izinto eziphathekayo ziyi-45 # kwaye zicinywe.

Isixhobo sokubamba sangaphandle

Amanqaku oyilo:

1. Lo mfanekiso ungentla ngumzobo wereferensi, kwaye ubungakanani bokwenene buxhomekeke kwisakhiwo sobungakanani bomngxuma wangaphakathi wemveliso;

2. Isangqa sangaphandle esikwindawo yokunxibelelana nomngxuma ongaphakathi wemveliso kufuneka sishiye umda we-0.5mm kwelinye icala ngexesha lemveliso, kwaye ekugqibeleni sifakwe kwisixhobo sokucoca, emva koko siguqulwe ngokucokisekileyo sibe sisayizi ukuthintela ukonakala kunye ne-eccentricity. okubangelwa yinkqubo yokucima;

3. Izinto eziphathekayo ziyi-45 # kwaye zicinywe.

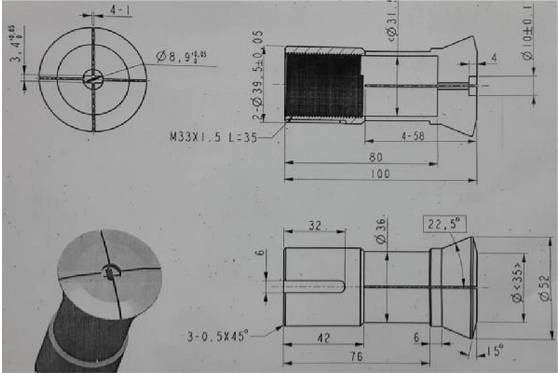

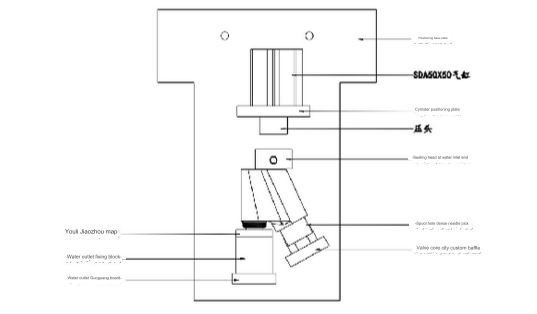

04 Isixhobo sokuvavanya igesi

Amanqaku oyilo:

1) Umfanekiso onikeziweyo usebenza njengesikhokelo sokuvavanya igesi. Uyilo lwesakhiwo esithile kufuneka sihambelane nemveliso yangempela. Injongo kukudala indlela yokutywina echanekileyo yokuvavanya igesi kunye nokuqinisekisa ukunyaniseka kwemveliso.

2) Ubungakanani be-cylinder bunokulungelelaniswa nobukhulu bemveliso, ukuqinisekisa ukuba i-cylinder stroke yenza kube lula ukuphathacnc imveliso yomatshini.

I-3) Ukutywinwa kweendawo ezidibana nemveliso, izinto ezikwazi ukunyanzeliswa ngamandla njenge-Uni glue kunye ne-NBR i-rubber rings zisetyenziswa ngokuqhelekileyo. Ukongeza, xa usebenzisa iibhloko zokubeka ezichukumisa umphezulu wangaphandle wemveliso, kucetyiswa ukusebenzisa iibhloko zeplastiki zeglue ezimhlophe ngexesha lokusebenza. Ngaphaya koko, ukugquma iziko ngelaphu lomqhaphu kunceda ukukhusela inkangeleko yemveliso.

4) Xa uyila, kubalulekile ukuqwalasela ukuma kwemveliso ukuthintela ukuvuza kwegesi ngaphakathi kwendawo yemveliso, enokukhokelela ekubhaqweni kobuxoki.

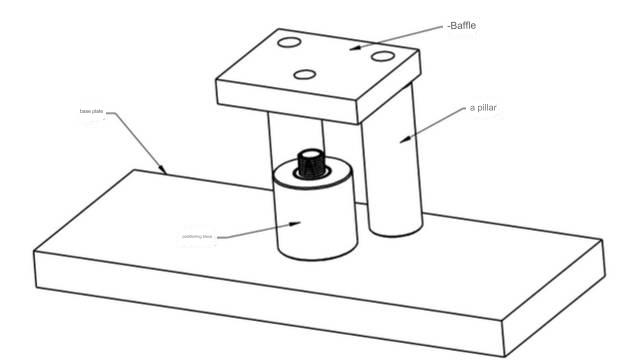

05 Ukubetha izixhobo

Amanqaku oyilo:

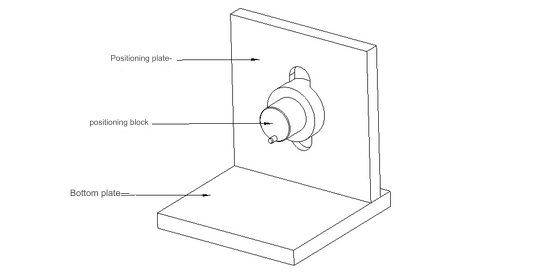

Lo mfanekiso ungasentla ubonisa uyilo oluqhelekileyo lwezixhobo zokubethelela. I-base plate incamathele ngokukhuselekileyo kwi-workbench yomatshini we-punch, ngelixa ibhloko yokumisa isetyenziselwa ukuzinzisa imveliso. Ubumbeko oluchanekileyo lulungelelaniswe kwiimfuno ezithile zemveliso. Inqaku eliphakathi livumela ukuphathwa ngokukhuselekileyo kunye nokungasebenzi kunye nokubekwa kwemveliso, ngelixa i-baffle inceda ekwahluleni imveliso kwi-punching knife.

Iintsika zisebenzela ukukhusela i-baffle kwindawo, kwaye izikhundla zendibano kunye nobukhulu bala macandelo anokwenziwa ngokwezifiso ukulungiselela iimpawu ezizodwa zemveliso.

06 Ukufakwa kwezixhobo zokuwelda

Umsebenzi ophambili we-welding tooling kukukhusela indawo echanekileyo yecandelo ngalinye ngaphakathi kwendibano ye-welding kunye nokuqinisekisa ukulinganisa okuhambelanayo kwenxalenye nganye. Ulwakhiwo olungundoqo lubandakanya ibhloko yokumisa, eyenzelwe ukuhambelana nesakhiwo esithile secnc amacandelo aluminiyam ngoomatshini. Okubalulekileyo, xa ubeka imveliso kwi-welding tooling, kubalulekile ukuphepha ukudala indawo evaliweyo ukukhusela nayiphi na impembelelo embi kubukhulu benxalenye ngenxa yoxinzelelo olugqithisileyo ngexesha le-welding kunye nenkqubo yokufudumeza.

07 ukulungiswa kokupholisha

08 Izixhobo zeNdibano

Umsebenzi ophambili wezixhobo zendibano kukubonelela ngenkxaso yokumisa ngexesha lokuhlanganisa amacandelo. Ingcamango yoyilo kukuphucula ukukhululeka kokuthatha kunye nokubeka iimveliso ngokuhambelana nesakhiwo sendibano yamacandelo. Kubalulekile ukuqinisekisa ukuba inkangeleko yemveliso ihlala ingonakaliswa ngexesha lokudibanisa kwaye inokugqunywa ngexesha lokusetyenziswa. Khusela imveliso ngokusebenzisa ilaphu lomqhaphu, kwaye ucinge ngokusebenzisa izinto ezingezizo ezentsimbi ezifana neglu emhlophe xa ukhetha izinto.

09 Ukuprintwa kwePad, isixhobo sokukrola ngelaser

Amanqaku oyilo:

Yila ubume bokumisa isixhobo ngokweemfuno zokukrola eyona mveliso. Nikelani ingqalelo kubuchule bokukha kunye nokubeka imveliso, kunye nokukhuselwa kwembonakalo yemveliso. Ibhloko yokumisa kunye nesixhobo esincedisayo sokudibanisa nemveliso kufuneka senziwe ngeglue emhlophe kunye nezinye izinto ezingezona zetsimbi kangangoko kunokwenzeka.

I-Anebon inezona zixhobo ziphambili zemveliso, iinjineli ezinamava naqeqeshiweyo kunye nabasebenzi, iinkqubo ezaziwayo zolawulo lomgangatho kunye neqela lokuthengisa elinobubele phambi / emva kokuthengisa inkxaso yeOEM yePlastiki ye-ABS/PA/POM yaseTshayina.CNC Metal LatheCNC Milling 4 Axis / 5 Axis CNC iindawo machining,CNC ukuguqula iindawo. Okwangoku, i-Anebon ijonge phambili kwintsebenziswano enkulu ngakumbi nabathengi baphesheya ngokweenzuzo ezifanayo. Nceda ufumane amava simahla ukuze uqhagamshelane nathi ukuze ufumane iinkcukacha ezithe vetshe.

2022 Umgangatho ophakamileyo waseTshayina we-CNC kunye noMatshini, Kunye neqela labasebenzi abanamava nabanolwazi, imarike ye-Anebon igubungela uMzantsi Merika, i-USA, iMid East, kunye noMntla Afrika. Abathengi abaninzi baye baba ngabahlobo be-Anebon emva kwentsebenziswano elungileyo kunye ne-Anebon. Ukuba unayo imfuneko kuyo nayiphi na imveliso yethu, khumbula ukudibana nathi ngoku. I-Anebon ijonge phambili ukuva kuwe kungekudala.

Ixesha lokuposa: Feb-26-2024