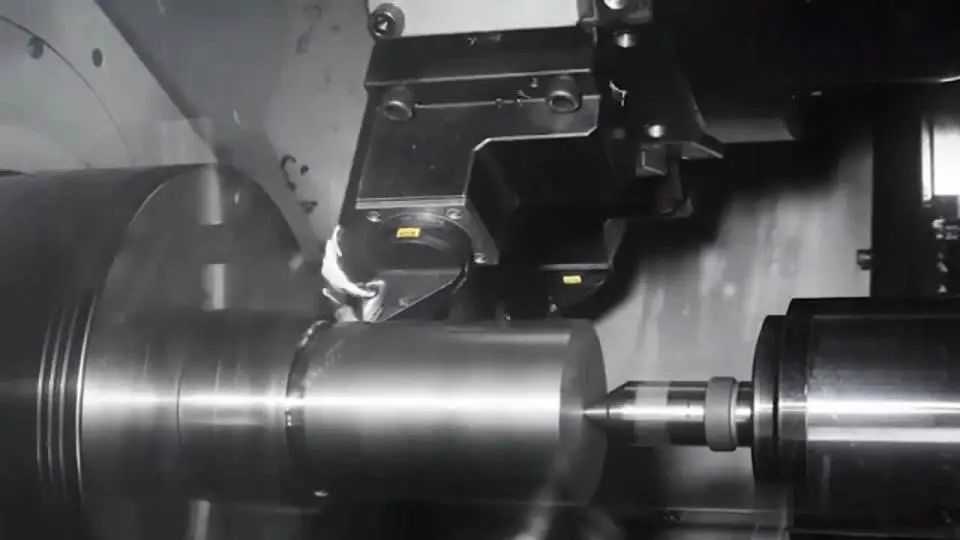

Umzi-mveliso usebenzisa izixhobo zomatshini ze-CNC ezichanekileyo (iziko lomatshini, i-EDM, ukuhamba ngocingo olucothayo, kunye nezinye izixhobo zomatshini) ukwenzela ukuchaneka okuphezulu. Ngaba unawo amava anjalo:ukuqala-upp ukusetyenzwa rhoqo kusasa, ukuchaneka machining yesiqwenga sokuqala kaninzi akulunganga ngokwaneleyo; Ukuchaneka kwamacandelo okuqala ahlala engazinzanga kakhulu, kwaye amathuba okusilela kuphezulu kakhulu xa kusenziwa umatshini ngokuchaneka okuphezulu, ngakumbi ukuchaneka kwesikhundla.inxalenye yomatshini

Iifektri ezingenawo amava omatshini achanekileyo zihlala zigxeka umgangatho wesixhobo sokuchaneka okungazinzanga. Iifektri ezinobuchwephesha bokuchaneka komatshini ziya kuncamathela ukubaluleka okukhulu kwibhalansi ye-thermal phakathi kobushushu be-ambient kunye nesixhobo somatshini. Ziyacaca ukuba izixhobo zomatshini ezichanekileyo zinokufumana kuphela ukuchaneka komatshini ozinzileyo phantsi kwendawo yokushisa ezinzileyo kunye nokulingana kwe-thermal. Ukufudumeza isixhobo somatshini yeyona ngqiqo isisiseko yokuchaneka komatshini xa utyala imali kumatshini ochanekileyo emva kokuba umatshini uvuliwe.

1. Kutheni isixhobo somatshini kufuneka sifudunyezwe?aluminium CNC machining inxalenye

Iimpawu ze-thermal zezixhobo zomshini we-CNC zinempembelelo ebalulekileyo ekuchanekeni komatshini, kubalwa ngaphezu kwesiqingatha sokuchaneka komatshini.

I-spindle yesixhobo somatshini, iileyili zesikhokelo, izikrufu ezikhokelayo, kunye nezinye izinto ezisetyenziswa kwi-shaft ye-XYZ eshukumayo ziya kutshisa kwaye zigqwese ngenxa yomthwalo kunye nokungqubuzana ngexesha lokuhamba. Okwangoku, ikhonkco lempazamo ye-thermal deformation ethe ekugqibeleni ichaphazela ukuchaneka komatshini yi-spindle kunye ne-XYZ shaft eshukumayo, ekukufuduswa kwetafile.

Ukuchaneka komatshini wesixhobo somatshini kwimeko yokusebenza kwexesha elide lokumisa kunye nemeko yokulinganisa i-thermal ihluke kakhulu. Isizathu kukuba ubushushu be-spindle kunye ne-axis yentshukumo nganye yesixhobo somatshini we-CNC igcinwa ngokuthe ngqo kwinqanaba elithile emva kokubaleka ixesha elithile. Ngotshintsho kwixesha lokucubungula, ukuchaneka kwe-thermal yezixhobo zoomatshini be-CNC kudla ukuzinza, kubonisa ukuba ukufudumeza i-spindle kunye neendawo ezihambayo ngaphambi kokuba kuqhutywe kubalulekile.

Nangona kunjalo, "umsebenzi wokufudumala" wesixhobo somatshini awuhoywa okanye ayaziwa ngamafektri amaninzi.

2. Indlela yokutshisa ngaphambili isixhobo somatshini?

Ukuba isixhobo somatshini sibekwe ukubamba ixesha elingaphezu kweentsuku ezimbalwa, kucetyiswa ukuba ufudumeze ngaphezu kwemizuzu engama-30 ngaphambi komatshini ochanekileyo; ukuba umatshini ubanjwe kwiiyure ezimbalwa kuphela, kuyacetyiswa ukuba ufudumeze ngemizuzu emi-5 ukuya kwe-10 ngaphambi komatshini ochanekileyo.

Inkqubo yokufudumeza kwangaphambili ivumela isixhobo somatshini ukuba sithathe inxaxheba kwintshukumo ephindaphindiweyo ye-axis machining. Kungcono ukwenza unxibelelwano lwe-multi-axis. Umzekelo, vumela i-axis ye-XYZ ihambe ukusuka kwikona esezantsi ekhohlo yenkqubo yokulungelelanisa ukuya kwikona ephezulu ngasekunene kwaye uphinde umgca wediagonal.cCNCmachining inxalenye

Xa uphumeza, ungabhala inkqubo enkulu kwisixhobo somatshini ukuvumela isixhobo somatshini senze ngokuphindaphindiweyo isenzo sokufudumeza. Ngokomzekelo, xa isixhobo somatshini we-CNC siyeka ukusebenza ixesha elide okanye ngaphambi kokuba sisebenze iindawo ezichanekileyo, ngokwemathematika ye-3D ellipse parameter curve kunye noluhlu lwesithuba somatshini oshushu ngaphambili, t isetyenziswa njengoguquko oluzimeleyo, kunye nezilungelelanisi. iiaxes ezintathu ezishukumayo ze XYZ zisetyenziswa njenge parameters. Ngomgama wenyathelo elithile elongezelekayo, uluhlu oluchaziweyo lwe-XYZ ye-axis yentshukumo ephezulu isetyenziswa njengemeko yomda weparameter curve. Isantya sokusonta kunye nesantya se-XYZ esishukumayo se-axis feed zinxulunyaniswa noguquguquko oluzimeleyo t ukuze lutshintshe ngokuqhubekayo ngaphakathi koluhlu oluchaziweyo, luvelisa Inkqubo yolawulo lwamanani enokuqatshelwa ngesixhobo somatshini wolawulo lwamanani isetyenziselwa ukuqhuba iiasi ezihambayo ze isixhobo somatshini ukwenza i-synchronous no-load motion, kwaye ihamba kunye nokuguqulwa kokulawulwa kwesantya se-spindle kunye nesantya sokutya ngexesha lokunyakaza.

Emva kokuba umatshini ufudunyezwe ngokupheleleyo, umatshini oguqukayo unokufakwa kwimveliso yomatshini ochanekileyo, kwaye uya kuzinza kwaye ungaguquguquki ukuchaneka komatshini.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Apr-21-2022