Unolwazi olungakanani malunga nokubeka kunye nokubambelela kumatshini?

Ukufumana iziphumo ezichanekileyo nezichanekileyo, ukubeka kunye nokubambelela yimiba ebalulekileyo yomatshini.

Funda ngokubaluleka kokubeka kunye nokubambelela xa umatshini:

Ukubekwa: Oku kukubekwa ngokuchanekileyo kwendawo yokusebenza ngokumalunga nesixhobo sokusika. Ukulungelelanisa i-workpiece kunye ne-axes ezintathu eziphambili (X, Y, Z) kuyafuneka ukufumana imilinganiselo efunekayo kunye nendlela yokusika.

Ulungelelwaniso lubalulekile kumatshini ochanekileyo:Ukulungelelanisa i-workpieces ngokuchanekileyo kunokwenzeka ngeendlela ezifana ne-edge finders, izikhombisi kunye nokulungelelanisa umatshini wokulinganisa (CMM).

Kubalulekile ukuseka umphezulu wedatum okanye indawo yokuma okuhambelanayo:Oku kuvumela bonke oomatshini abalandelayo ukuba basekelwe kwindawo eqhelekileyo okanye kwindawo yokubhekisela.

Ukuqinisa yinkqubo yokukhusela i-workpiece kumatshini:Inika uzinzo kwaye inqande ukungcangcazela okanye ukunyakaza okunokukhokelela kumatshini ongachanekanga.

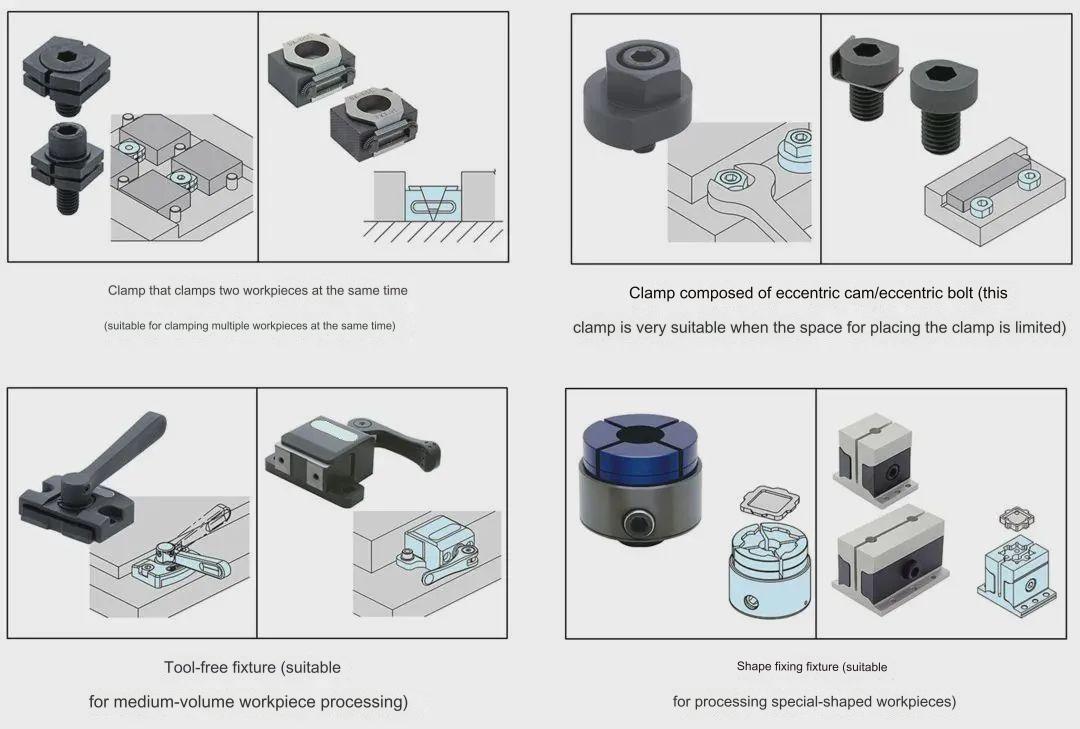

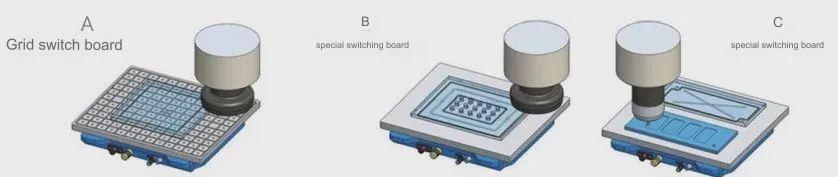

Iindidi zeeKlampu:Kukho iintlobo ezininzi zee-clamps ezinokuthi zisetyenziswe ukwenza umatshini. Ezi ziquka i-magnetic clamps kunye ne-pneumatic, hydraulic, okanye i-hydraulic-pneumatic clamps. Ukukhethwa kweendlela zokubambelela kusekelwe kwizinto ezifana nobukhulu kunye nokumila, amandla omatshini, kunye neemfuno ezithile.

Iindlela zokuQwalasela:I-clamping efanelekileyo ibandakanya ukusabalalisa ngokulinganayo amandla okubamba, ukugcina uxinzelelo oluqhubekayo kwi-workpiece kunye nokuphepha ukuphazamiseka. Ukuthintela umonakalo kwi-workpiece ngelixa ugcina uzinzo, kubalulekile ukusebenzisa i-clamping pressure efanelekileyo.

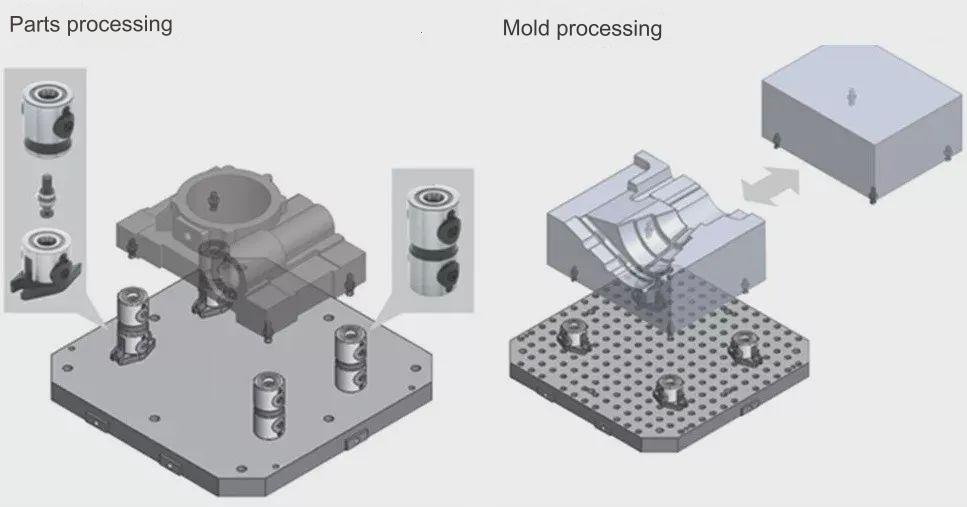

Ukulungiswa zizixhobo ezikhethekileyo ezithi zibambe kwaye zibeke iindawo zokusebenza:Banikezela ngenkxaso, ulungelelwaniso kunye nokuzinza kwimisebenzi yomatshini. Oku kunciphisa umngcipheko wempazamo kunye nokuphucula imveliso.

Ukulungiswa kuza kwiindidi ezininzi ezahlukeneyo, njengee-V-blocks kunye nee-angle plates. Zisenokwenziwa ngokwezifiso. Ukukhethwa kokulungiswa okufanelekileyo kunqunywe ngobunzima beqhekeza kunye neemfuno zomatshini.

I-Fixture Design ibandakanya ukuqwalaselwa ngokucophelela kwezintonjengemilinganiselo yesixhobo somsebenzi, ubunzima, imathiriyeli kunye neemfuno zofikelelo. Uyilo olululo luya kuqinisekisa ukubamba ngokufanelekileyo kunye nokumiswa komatshini osebenzayo.

Ukunyamezela kunye nokuchaneka:Ukuma okuchanekileyo kunye nokubambelela kubalulekile ekufezekiseni ukunyamezela okuqinileyo kunye nokuchaneka xa kusetyenzwa. Impazamo encinci ekubambeni okanye ekumiseni ingakhokelela kutshintsho lwedimension kunye nomgangatho wokuthomalalisa.

Uhlolo kunye noQinisekiso:Ukuhlolwa rhoqo kunye nokuqinisekiswa kwe-clamping kunye nokuchaneka kwendawo kubalulekile ukuqinisekisa ukuhambelana kumgangatho. Ukuqinisekisa ukuchaneka kwamacandelo omatshini, izixhobo zokulinganisa ezifana ne-calipers kunye ne-micrometers kunye nee-CMM zinokusetyenziswa.

Ayilula ngolu hlobo. Siye safumanisa ukuba uyilo lokuqala luhlala luneengxaki ezithile ngokucinezela kunye nokubeka indawo. Izisombululo ezitsha ziphulukana nokubaluleka kwazo. Sinokuqinisekisa kuphela imfezeko kunye nomgangatho woyilo lwesixhobo ngokuqonda indawo esisiseko kunye nolwazi olubambekayo.

Ulwazi lwendawo

1. Ukubeka i-workpiece ukusuka kwicala ngumgaqo osisiseko.

Umgaqo we-3-point, njengenkxaso, ngumgaqo osisiseko wokumisa i-workpiece ukusuka kwicala. Umgaqo-siseko we-3 ufana naleyo yenkxaso. Lo mgaqo uthatyathwe sisibakala sokuba “imigca emithathu ethe tye engadibaniyo imisela inqwelo-moya.” Amanqaku amathathu kwamane angasetyenziselwa ukumisela inqwelomoya. Oku kuthetha ukuba imiphezulu emi-4 iyonke inokumiselwa. Kunzima ukufumana inqaku lesine kwinqwelomoya enye, kungakhathaliseki ukuba amanqaku abekwe njani.

▲ umgaqo-nkqubo we-3

Ngokomzekelo, kwimeko yokusebenzisa iindawo ezine zobude obusisigxina, zintathu kuphela iingongoma ezithile ezikwaziyo ukunxibelelana nesixhobo sokusebenza, nto leyo eshiya amathuba okuba indawo yesine eseleyo ingaqalisi unxibelelwano.

Ke ngoko, ngelixa ulungiselela indawo yokufumana indawo, isenzo esiqhelekileyo kukuseka kumanqaku amathathu ngelixa ukhulisa umgama phakathi kwala manqaku.

Ngaphezu koko, ngexesha lokucwangciswa kwe-positioner, kunyanzelekile ukuba uqinisekise kwangaphambili ulwalathiso lomthwalo wokucubungula osetyenzisiweyo. Isalathiso somthwalo womatshini sihambelana nokuhamba komphathi/isixhobo. Ukubeka i-positioner ekupheleni kolwalathiso lwesondlo luchaphazela ngokuthe ngqo ukuchaneka okupheleleyo kwendawo yokusebenza.

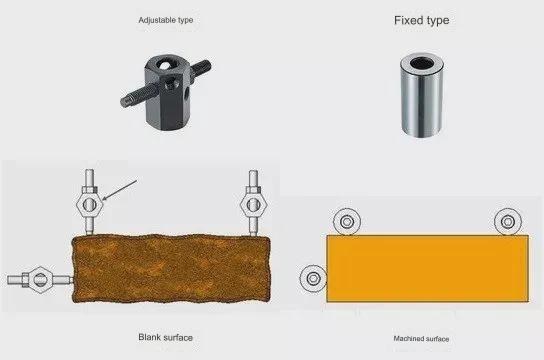

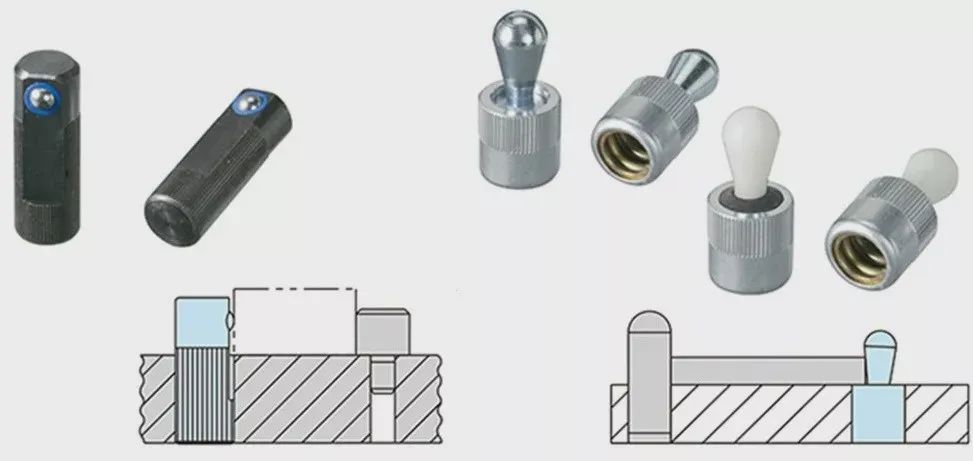

Ngokuqhelekileyo, ukubeka umphezulu orhabaxa womsebenzi, uhlobo lwebholiti olulungelelanisiweyo luyasetyenziswa, ngelixa isimiseli sohlobo olusisigxina (esinomphezulu wokudibanisa umphezulu womhlaba) sisetyenziselwa ukubeka umphezulu omatshini womatshini.iindawo zomatshini.

2. Imigaqo esisiseko yokubeka ngokusebenzisa imingxuma yokusebenza

Xa ubeka indawo usebenzisa imingxunya eyenziwe ngexesha lenkqubo yomatshini yangaphambili, izikhonkwane ezinokunyamezela kufuneka zisetyenziswe. Ngokulungelelanisa ukuchaneka komngxuma wokusebenza kunye nokuchaneka kobume bepini, kunye nokudibanisa ngokusekelwe kukunyamezela okufanelekileyo, ukuchaneka kokumisa kunokuhlangabezana neemfuno zangempela.

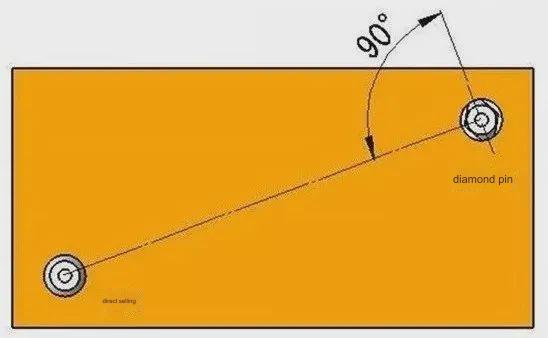

Ukongeza, xa usebenzisa izikhonkwane zokubeka indawo, kuqhelekile ukusebenzisa iphini elithe tye ecaleni kwephini ledayimani. Oku akuncedi kuphela ukudityaniswa kunye nokuchithwa kweworkpiece kodwa kunciphisa ithuba lomsebenzi kunye nephini lokuxinana kunye.

▲Sebenzisa indawo yephini

Ngokuqinisekileyo, kuyenzeka ukufezekisa ukunyamezelana ngokufanelekileyo ngokusebenzisa izikhonkwane ezithe tye kuzo zombini izikhundla. Nangona kunjalo, ukuchaneka ngakumbi ekumiseni, ukudityaniswa kwephini elithe tye kunye nentsimbi yedayimani kubonakala kusebenza ngakumbi.

Xa usebenzisa iphini elithe tye kunye nephini lerhombus, kuyacetyiswa ngokubanzi ukuba ubeke isikhonkwane serhombus ngendlela apho umgca odibanisa isalathiso sawo kwisixhobo sokusebenza ukwi-perpendicular (kwi-angle engama-90 °) ukuya kumgca odibanisa iphini elithe tye kunye. iphini yerhombus. Olu lungiselelo lukhethekileyo lubalulekile ekumiseleni i-engile yokuma kunye necala lokujikeleza kwe-workpiece.

Ulwazi olunxulumene ne-Clamp

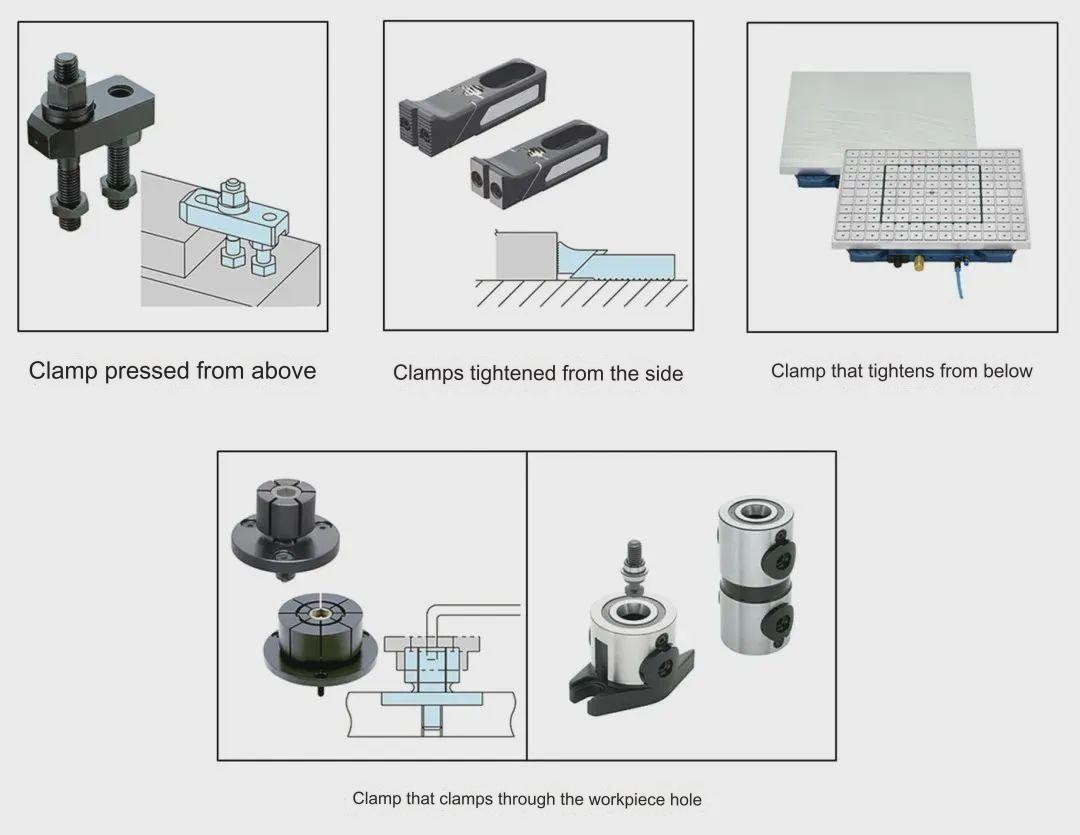

1. Ukuhlelwa kweeclamps

Ngokwalathiso lwe-clamping, yohlulwe ngokubanzi ngokwezi ndidi zilandelayo:

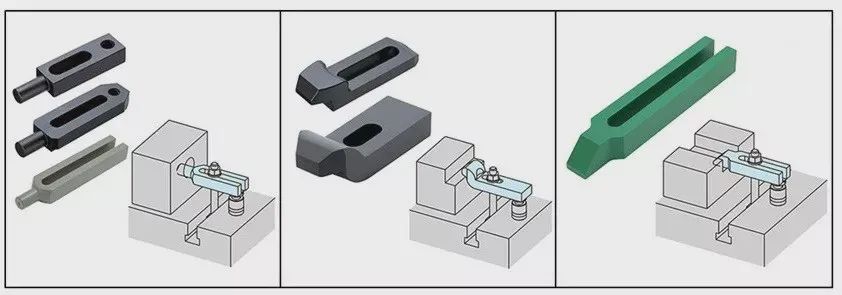

1. I-Overhead Compression Clamp

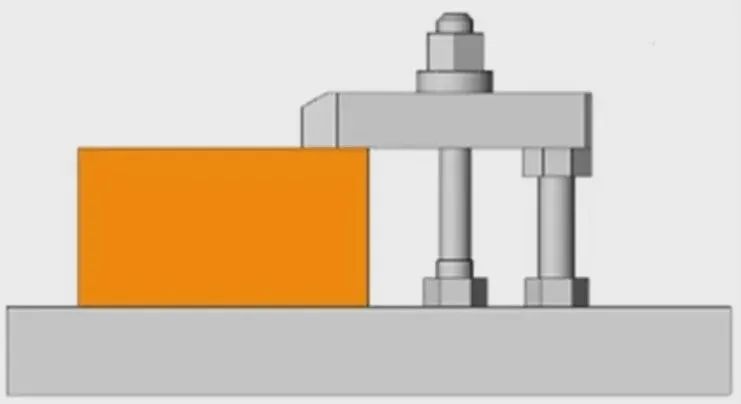

Isibambi socinezelo esingaphezulu senza uxinzelelo oluvela ngaphezulu kwesixhobo sokusebenza, esikhokelela kuguquko oluncinci ngexesha lokucinezela kunye nokuzinza okongeziweyo ngexesha lokusetyenzwa kwesixhobo sokusebenza. Ngenxa yoko, ukucinezela i-workpiece ukusuka phezulu kudla ngokuba yinto ephambili. Olona hlobo luxhaphakileyo lwe-clamp esetyenziswa ngolu hlobo sisibambiso esisebenza ngoomatshini. Umzekelo, isibambiso esiboniswe ngezantsi sibhekiswa kuso 'njengodidi lwegqabi lomthi'. Olunye uhlobo, olwaziwa ngokuba 'sisibambeli samagqabi', siquka ipleyiti yoxinzelelo, iibholiti, iijekhi, kunye namandongomane.”

Ngaphezu koko, kuxhomekeke kwimilo ye-workpiece, unokhetho lokukhetha kwiindidi zeepleyiti zoxinzelelo ezenzelwe ngokukodwa ukufanisa iimilo zepiece workpiece ezahlukeneyo.

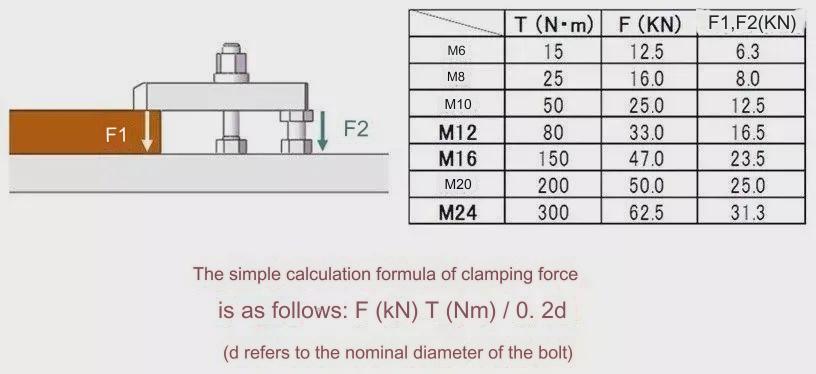

Kuyenzeka ukumisela ulungelelwaniso phakathi kwetorque kunye namandla okubamba ekubambeni kwamagqabi akhululekileyo ngokuhlalutya amandla okutyhala okwenziwa yibholiti.

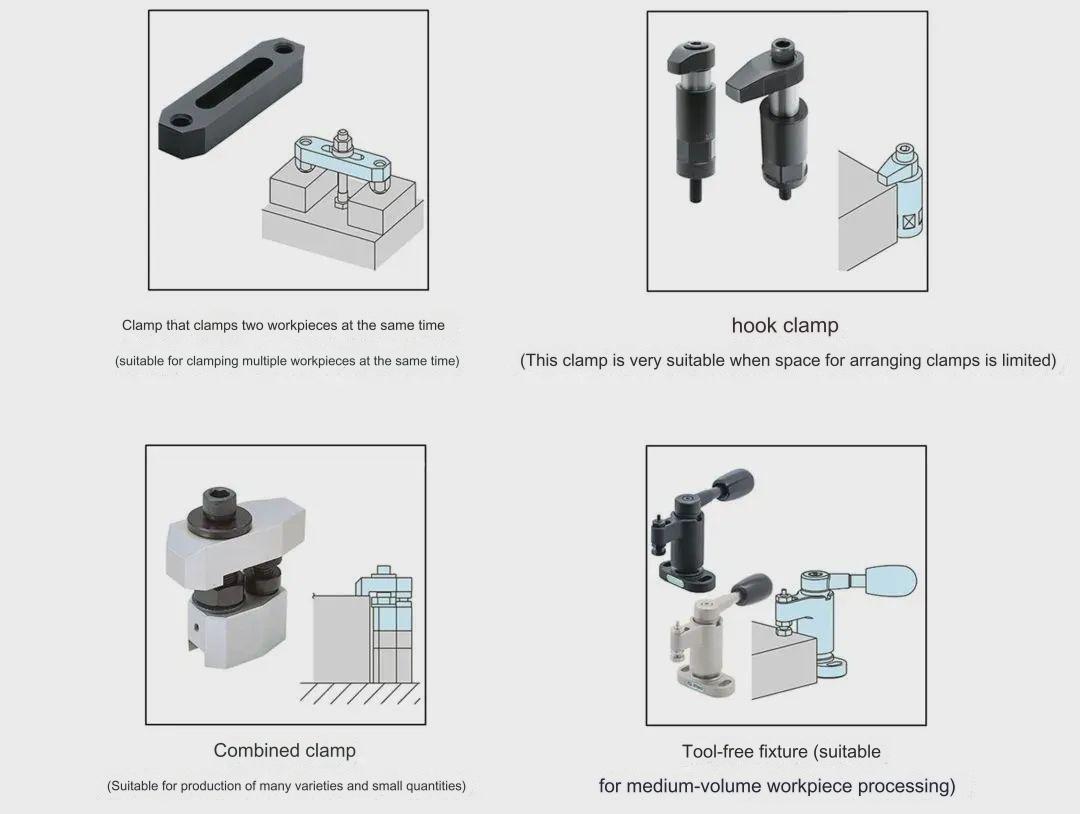

Ngaphandle kwesibambiso sohlobo lwamagqabi, kukho nezinye iiclamps ezikhoyo ezikhusela i-workpiece ukusuka phezulu.

2. I-Clamp esecaleni ye-workpiece clamping

Indlela yokudibanisa eqhelekileyo ibandakanya ukukhusela i-workpiece ukusuka phezulu, ukunika uzinzo oluphezulu kunye nomthwalo omncinci wokucubungula. Nangona kunjalo, iimeko zinokuvela apho ukubamba okuphezulu kungafanelekanga, njengaxa umphezulu womhlaba ufuna ukwenziwa ngomatshini okanye xa i-top clamping ingenzeki. Kwiimeko ezinjalo, ukukhetha i-clamping yecala kuba yimfuneko.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukucinezela i-workpiece ukusuka kwicala kuvelisa amandla adadayo. Ingqalelo kufuneka inikwe ekupheliseni la mandla ngexesha loyilo lwesixhobo ukuqinisekisa ukusebenza ngokupheleleyo.

Uqwalaselo lungabandakanya ukudibanisa iindlela ezichasene nesiphumo samandla adadayo, njengokusebenzisa inkxaso eyongezelelweyo okanye uxinzelelo lokuzinzisa umsebenzi. Ngokujongana ngempumelelo namandla adadayo, isisombululo esithembekileyo nesikhuselekileyo secala sinokufezekiswa, sandise ukuguquguquka kokusetyenzwa kwe-workpiece.

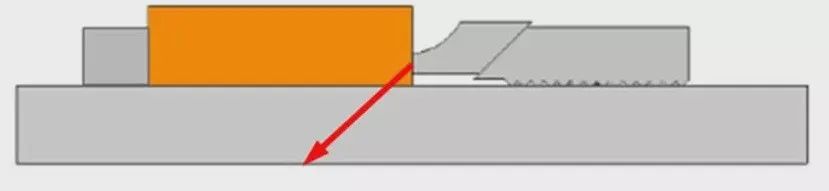

Kukwakho nezithinteli ezisecaleni ezifumanekayo, njengoko kubonisiwe kulo mfanekiso ungasentla. Ezi clamps zisebenzisa i-thrust force esuka kwicala, idala amandla aphantsi oblique. Olu hlobo oluthile lwe-clamp lusebenza kakhulu ekuthinteleni i-workpiece ukuba ingadada ukuya phezulu.

Ngokufanayo nala mabamba asecaleni, kukho ezinye iiclamps ezisebenza ukusuka ecaleni.

I-Workpiece Clamping ukusuka eZantsi

Xa ubamba icwecwe elicwecwe elicwecwe kwaye lifuna ukusetyenzwa ngaphezulu komphezulu, iindlela zokucinezela eziqhelekileyo ukusuka phezulu okanye ukusuka ecaleni zingqineka zingenakwenzeka. Kwiimeko ezinjalo, isisombululo esisebenzayo kukucinezela i-workpiece ukusuka ngaphantsi. Kwizixhobo zokusebenza ezenziwe ngentsimbi, i-clamp yohlobo lwemagnethi ihlala ifanelekile, ngelixa i-non-ferrousukugaya intsimbi yesikoizixhobo zokusebenza zinokukhuselwa kusetyenziswa iikomityi zokufunxa ivacuum.

Kuzo zombini iimeko ezikhankanywe ngasentla, amandla okubamba axhomekeke kwindawo yoqhagamshelwano phakathi kwendawo yokusebenza kunye nemagnethi okanye i-vacuum chuck. Kuyafaneleka ukuba uqaphele ukuba ukuba umthwalo wokucubungula kwizinto ezincinci zokusebenza uba ngokugqithiseleyo kakhulu, umphumo ofunekayo wokucubungula awunakufezekiswa.

Ukongeza, kubalulekile ukuqinisekisa ukuba iindawo zoqhagamshelwano zeemagnethi kunye neekomityi zokufunxa ivacuum zigudile ngokwaneleyo ukuze zisetyenziswe ngokukhuselekileyo nangokufanelekileyo.

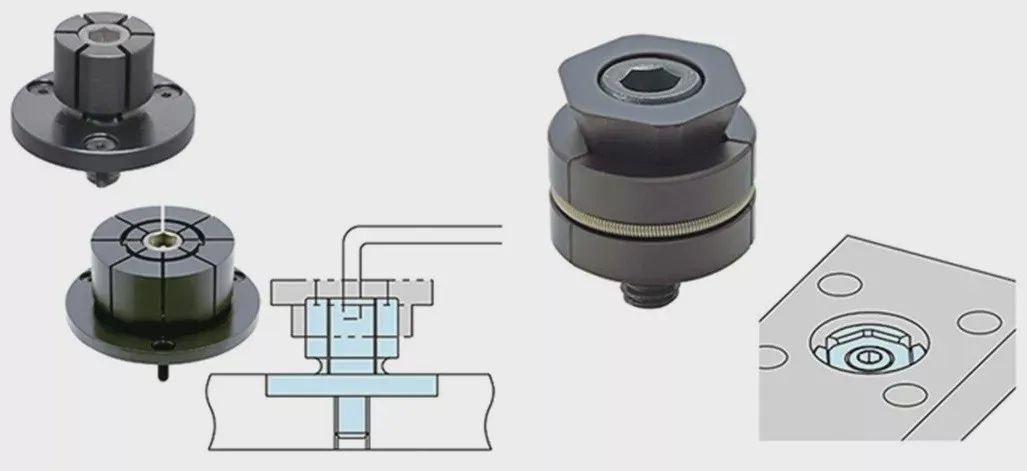

Ukuphumeza ukuBamba umngxuma

Xa usebenzisa umatshini we-5-axis womatshini wokwenza imisebenzi efana nokucwangciswa kobuso obuninzi ngaxeshanye okanye ukusetyenzwa komngundo, kuyacetyiswa ukuba ukhethe ukugoba umngxuma njengoko kunceda ukunciphisa impembelelo yezixhobo kunye nezixhobo kwinkqubo yokucubungula. Xa kuthelekiswa nokubamba ukusuka phezulu okanye kwicala lesixhobo sokusebenza, ukubanjwa komngxuma kusebenzisa uxinzelelo oluncinci kwaye kunciphisa ngokufanelekileyo i-deformation ye-workpiece.

▲ Sebenzisa imingxuma ukusetyenzwa ngokuthe ngqo

▲UFakelo lweRivet lokuQinisa

Ukubethelela kwangaphambili

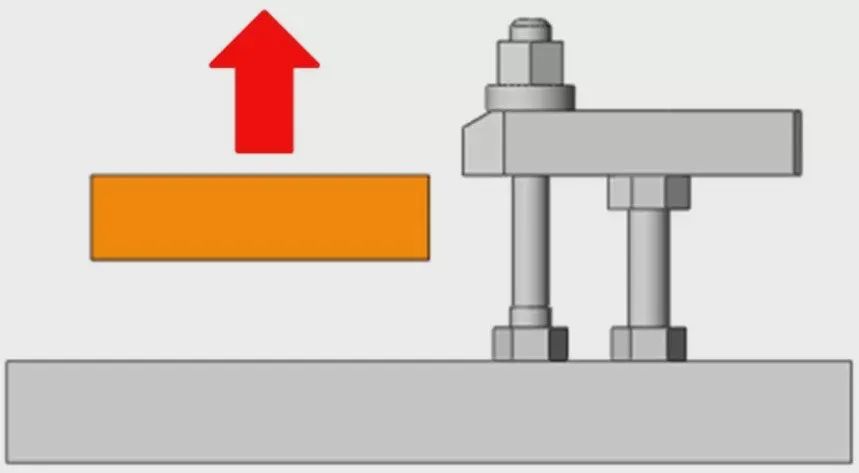

Ulwazi olwandulelayo lugxile ikakhulu kwizixhobo zokusebenza ezibambayo. Kubalulekile ukuqwalasela indlela yokuphucula ukusebenziseka kunye nokuphucula impumelelo ngokusebenzisa i-pre-clamping. Xa ubeka umsebenzi ngokuthe nkqo kwisiseko, umxhuzulane unokubangela ukuba iworkpiece iwe phantsi. Kwiimeko ezinjalo, kuye kube yimfuneko ukubamba i-workpiece ngesandla ngelixa usebenzisa i-clamp ukunqanda nakuphi na ukufuduswa ngengozi.

▲Ukubamba kwangaphambili

Ukuba i-workpiece inzima okanye iziqwenga ezininzi zibotshiwe ngaxeshanye, zinokuphazamisana kakhulu nokusebenza kunye nokwandisa ixesha lokubamba. Ukujongana noku, ukusebenzisa imveliso yohlobo lwasentwasahlobo yangaphambili ivumela i-workpiece ukuba ibambeke ngelixa ihleli imile, iphucula kakhulu ukusebenza kunye nokunciphisa ixesha lokubamba.

Ukuqwalaselwa xa ukhetha i-clamp

Xa usebenzisa iindidi ezininzi zee-clamp kwisixhobo esifanayo, kubalulekile ukusebenzisa izixhobo ezifanayo zombini ukudibanisa kunye nokukhulula. Umzekelo, kumfanekiso osekhohlo ongezantsi, ukusebenzisa izixhobo ezininzi zokutywina ukusebenza konyusa umthwalo kumsebenzisi kwaye kwandise ixesha lokubamba. Kwelinye icala, kumfanekiso osekunene ongezantsi, ukudibanisa izikrweqe zesixhobo kunye nobukhulu bebholithi zenza lula inkqubo yabaqhubi bendawo.

▲Ukwenziwa kokuSebenza kokuBamba iMisebenzi

Ngaphaya koko, xa ulungiselela isixhobo sokubambelela, kubalulekile ukuba uthathele ingqalelo ukusebenza kokusebenza kwe-workpiece clamping. Ukuba i-workpiece ifuna ukunyanzeliswa kwi-angle ethathiweyo, inokuphazamisa kakhulu imisebenzi. Ke ngoko, kubalulekile ukuphepha iimeko ezinjalo xa uyila izixhobo zokulungisa.

Ukusukela i-Anebon kunye nenjongo yenkampani ihlala "ihlala isanelisa iimfuno zethu zabathengi". I-Anebon qhubeka nokufumana kunye nesimbo kunye nokuyila iimveliso ezikumgangatho ophezulu ezikumgangatho ophezulu kuye ngamnye abathengi bethu abaphelelwe lixesha kunye nabatsha kwaye ufikelele kwithemba lokuphumelela kubathengi be-Anebon kunye nathi kwiProfayili yoMzimveliso we-Original extrusions aluminium,cnc yajika inxalenye, cnc yokugaya inayiloni. Samkela ngokunyanisekileyo abahlobo ukuba bathengise ishishini kwaye baqalise intsebenziswano nathi. I-Anebon inethemba lokubamba izandla nabahlobo abasenyongweni kumashishini ahlukeneyo ukuvelisa ixesha elide eliqaqambileyo.

China Manufacturer for China High Precision and Metal Stainless Steel Foundry, Anebon ifuna amathuba ukudibana bonke abahlobo abavela zombini ekhaya nakwamanye amazwe ukuze win-win intsebenziswano. I-Anebon inethemba elinyanisekileyo lokuba nentsebenziswano yexesha elide kunye nani nonke kwiziseko zenzuzo efanayo kunye nophuhliso olufanayo.

Ixesha lokuposa: Sep-25-2023