Ngaba uyawuqonda umda wesicelo sonyamezelo lwejometri kwi-CNC machining?

Ukucaciswa kokunyamezela kwejometri yinkalo ebalulekileyo ye-CNC machining, njengoko iqinisekisa ukuveliswa okuchanekileyo kwamacandelo. Ukunyamezela kwejometri kukwahluka okunokwenziwa kubungakanani, imilo, ukuqhelaniswa kunye nendawo yesici kwisiqwenga. Olu lwahluko lubalulekile ekusebenzeni okusebenzayo kwecandelo.

Ukunyamezela kwejometri kusetyenziswa kwi-CNC machining kwizicelo ezahlukeneyo.

Ulawulo lomda:

Ukunyamezela kwejometri kuvumela ulawulo oluchanekileyo lobungakanani kunye nobukhulu beempawu zomatshini. Iqinisekisa ukuba zonke iindawo zilungelelaniswe ngokugqibeleleyo kwaye zenza umsebenzi wazo ojoliswe kuwo.

Ulawulo lweFom:

Ukunyamezelwa kweJometri kuqinisekisa ukuba imilo efunwayo kunye ne-contour iphunyeziwe kwiimpawu zoomatshini. Kuyimfuneko kumalungu afuna ukudityaniswa, okanye aneemfuno ezithile zokukhwelana.

Ulawulo lokuqhelaniswa:

Ukunyamezela kwejometri kusetyenziselwa ukulawula ukulungelelaniswa kwe-angular yeempawu ezifana nemingxuma, iindawo zokubeka kunye neendawo. Kubaluleke ngakumbi kumalungu afuna ulungelelwaniso oluchanekileyo okanye ekufuneka angena ngokuchanekileyo kwamanye amalungu.

Unyamezelo lweJiyometri:

Ukunyamezela kwejometri kukutenxa okunokwenziwa kwindawo yeempawu kwinto. Iqinisekisa ukuba iimpawu ezibalulekileyo zenxalenye zibekwe ngokuchanekileyo ngokunxulumene enye kwenye, ivumela ukusebenza okufanelekileyo kunye nokudibanisa.

Ulawulo Lwenkangeleko Yesimo:

Ukunyamezela kweJometri kusetyenziselwa ukulawula imilo jikelele kunye neprofayili yeempawu ezinzima ezifana neegophe, iikhonto kunye neendawo. Oku kuqinisekisa ukuba iindawo ezinomatshini ziyahlangabezana neemfuno zeprofayili.

Ulawulo lwe-Concentricity & Symmetry:

Ukunyamezelana kwejiyometri kudlala indima ebalulekileyo ekufezekiseni ukugxila kunye ne-symmetry kwiimpawu zoomatshini. Kubaluleke ngakumbi xa ulungelelanisa amacandelo ajikelezayo afana neeshafts, iigiya kunye neebheringi.

Ulawulo lokuphuma:

Ukunyamezela kwejometri kuchaza ukuhluka okuvunyelweyo ngokuthe ngqo kunye nokujikeleza kokujikelezai-cnc yajika iinxalenye. Yenzelwe ukuqinisekisa ukusebenza kakuhle kunye nokunciphisa ukungcangcazela kunye neempazamo.

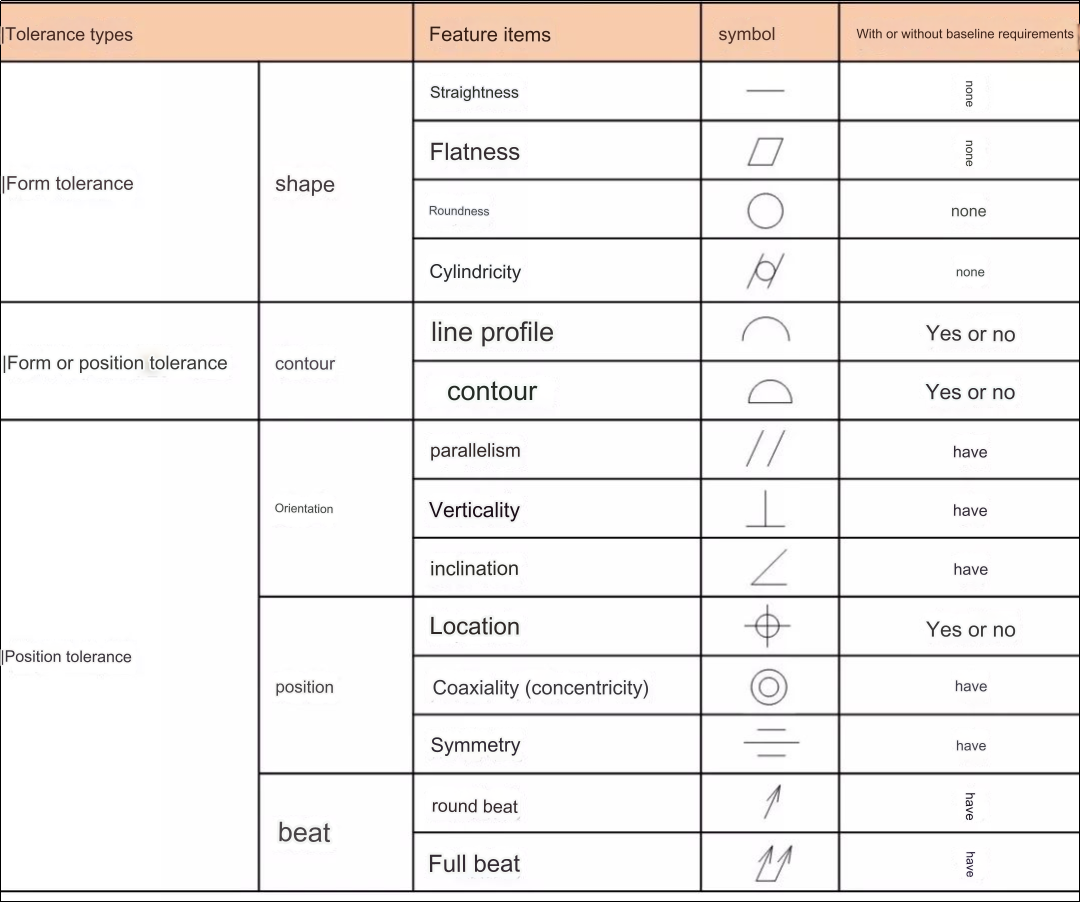

Ukuba asiyiqondi ukunyamezela kwejometri kwimizobo kwimveliso, ngoko uhlalutyo lokucubungula luya kucima kwaye iziphumo zokucubungula zinokuba zinzulu. Le theyibhile iqulethe isimboli yonyamezelo yejiyometri esemgangathweni yezinto ezili-14.

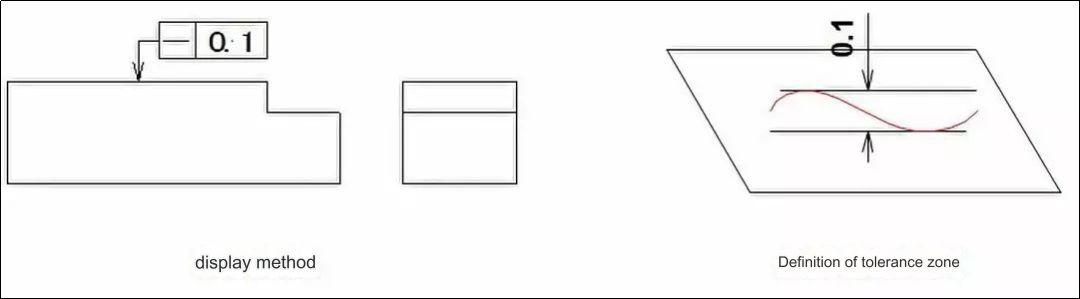

1. Ukuthe tye

Ukuthe tye kukukwazi kwenxalenye ukugcina umgca othe ngqo ofanelekileyo. Unyamezelo oluthe tye luchazwa njengolona tshintsho luphezulu lomgca othe ngqo osuka kumgca ofanelekileyo.

Umzekelo 1:Indawo yokunyamezelana kwinqwelomoya kufuneka ibe phakathi kweendlela ezithe ngqo ezidityanisiweyo ezinomgama oyi-0.1mm.

Umzekelo 2:Ukuba wongeza isimboli Ph kwixabiso lonyamezelo ngoko kufuneka ibekwindawo yomgangatho wecylindrical onobubanzi obuyi-0.08mm.

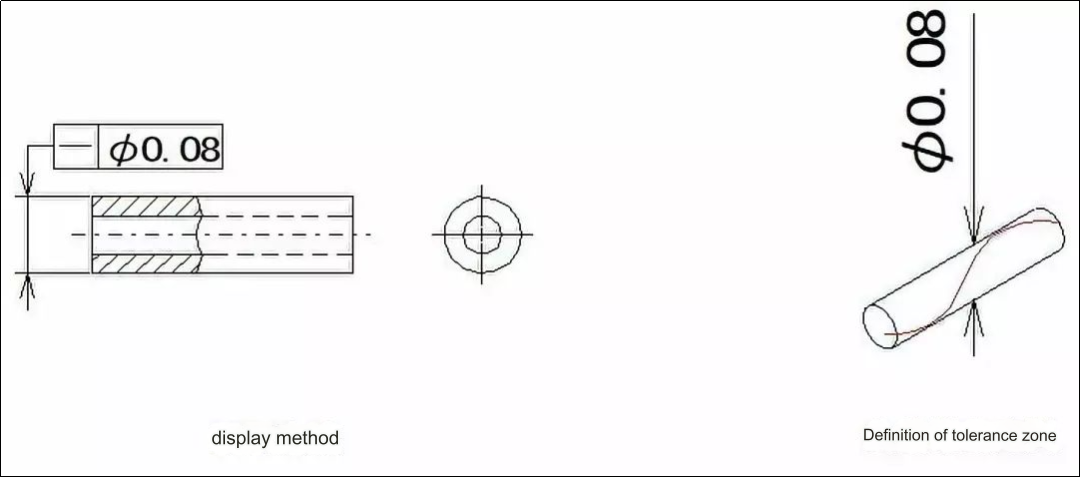

2. Ukucaba

Ukuthe tyaba (okukwabizwa ngokuba kucaba) yimeko apho inxalenye igcina inqwelomoya eyiyo. Ukunyamezelwa kwe-flatness ngumlinganiselo wophambuko oluphezulu olunokwenziwa phakathi kwendawo efanelekileyo kunye nomgangatho wangempela.

Ngokomzekelo, indawo yokunyamezela ichazwa njengesithuba phakathi kweenqwelo-moya ezihambelanayo eziqelelene nge-0.08mm.

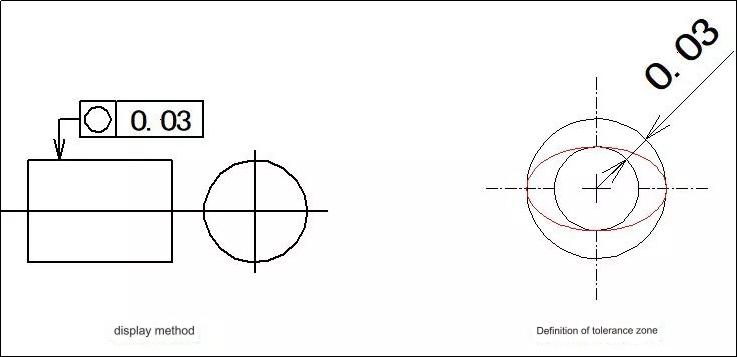

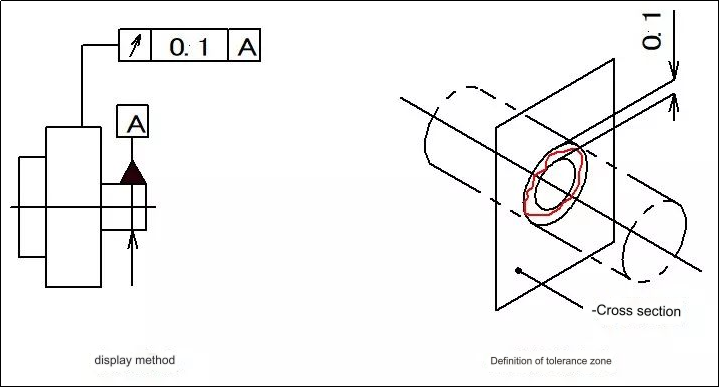

3. Ubungqukuva

Ubungqukuva becandelo ngumgama phakathi kombindi kunye neyona milo. Ukunyamezelana okungqukuva kuchazwa njengokutenxa okuphezulu kweyona milo yesetyhula ukusuka kwimilo yesetyhula efanelekileyo kwicandelo elifanayo lomnqamlezo.

Umzekelo:Indawo yokunyamezela kufuneka ibekwe kwicandelo eliqhelekileyo elifanayo. Umahluko weradiyasi uchazwa njengomgama phakathi kwamakhonkco amabini anonyamezelo lwe-0.03mm.

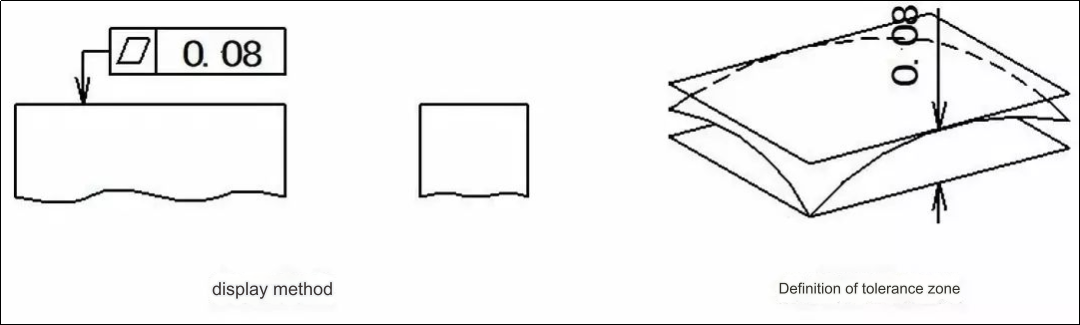

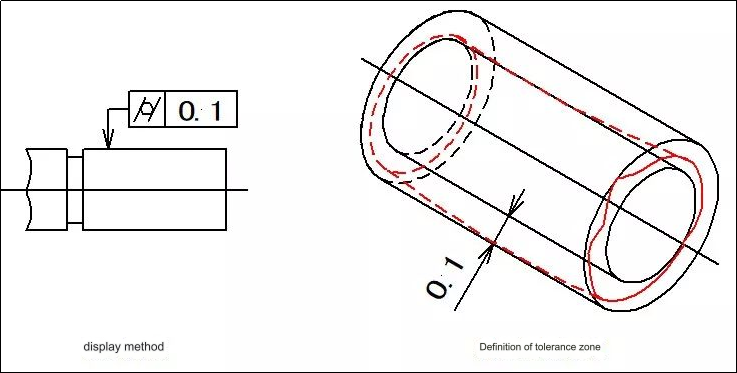

4. I-Cylindricity

Igama elithi 'Cylindricity' lithetha ukuba amanqaku omphezulu we-cylindrical wenxalenye akude ngokulinganayo kwi-axis yawo. Ukuhluka okuphezulu okuvunyelweyo phakathi kwendawo eyi-cylindrical yangempela kunye ne-cylindrical efanelekileyo ibizwa ngokuba yi-cylinderricity tolerance.

Umzekelo:Indawo yokunyamezela ichazwa njengendawo ephakathi kwe-coaxial cylindrical surfaces enomahluko kwi-radius ye-0.1mm.

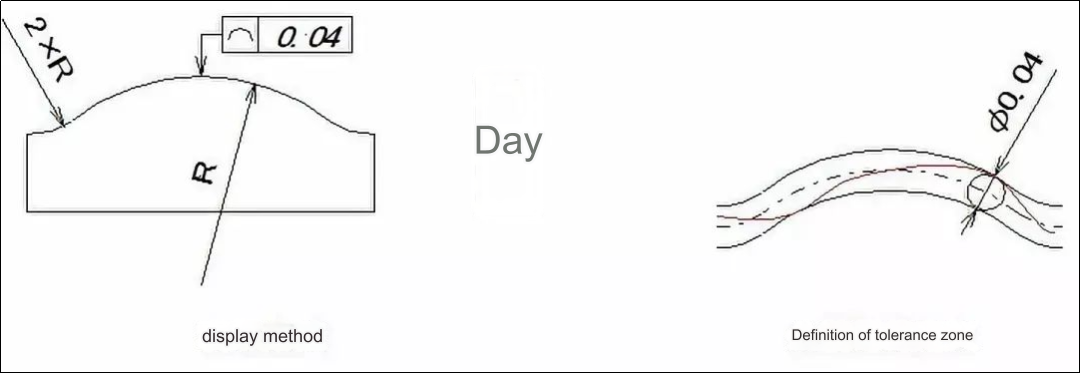

5. Icontour yomgca

Iprofayili yomgca yimeko apho nayiphi na ijika, kungakhathaliseki ukuba yiyiphi imilo, igcina imilo efanelekileyo kwindiza ethile yenxalenye. Ukunyamezela kwiprofayili yomgca yintlukwano enokuthi yenziwe kwi-contour ye-curves non-circular curves.

Umzekelo, indawo yokunyamezela ichazwa njengesithuba phakathi kweemvulophu ezimbini eziqulethe uchungechunge lwezangqa ze-diameter 0.04mm. Amaziko esangqa akwimigca eneemilo ezichanekileyo ngokwejometri.

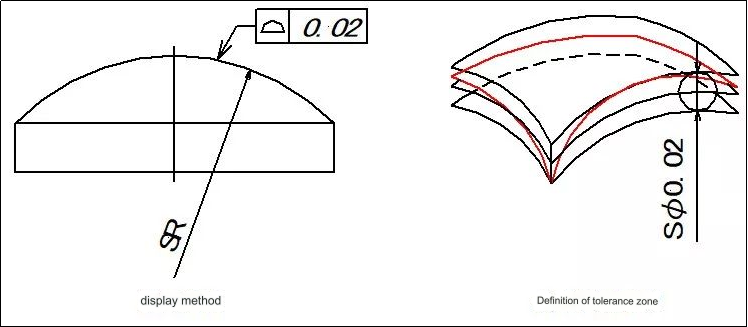

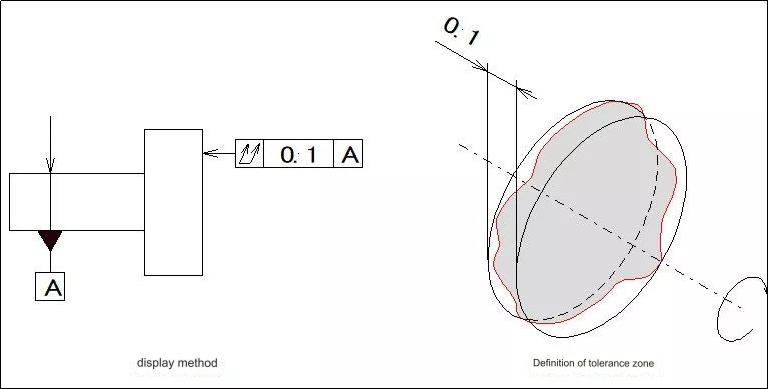

6. Umphezulu wecontour

Umphezulu wecontour yimeko apho umphezulu omise okwethutyana kwilungu ugcina imo yawo eyiyo. Ukunyamezela ikhontolo yomphezulu ngumahluko phakathi komgca wecontour kunye nomphezulu wecontour ofanelekileyo womphezulu ongekho setyhula.

Umzekelo:Ummandla wokunyamezela ulele phakathi kwemigca emibini yeemvulophu ezivale iibhola ezilandelelanayo ezinobubanzi obuyi-0.02mm. Umbindi webhola nganye kufuneka ube phezu komphezulu wemilo yejometri echanekileyo.

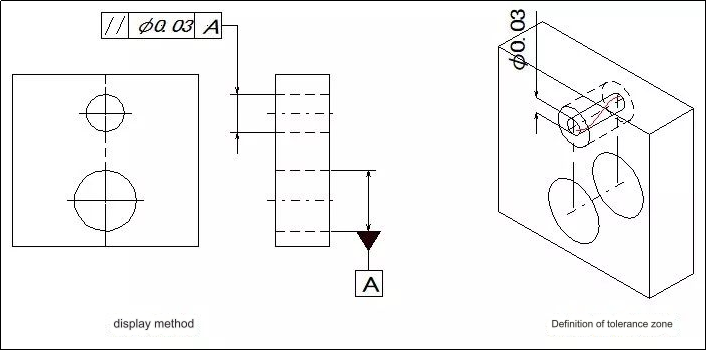

7. Ukufana

Iqondo lokunxulunyaniswa ligama elisetyenziselwa ukuchaza into yokuba amasuntswana akwindawo ethile alinganayo kude nedatum. Ukunyamezelana kwe-parallelism kuchazwa njengowona mahluko aphezulu anokwenziwa phakathi kwesalathiso apho into elinganiswayo ilele kunye necala elifanelekileyo, elihambelana nedatum.

Umzekelo:Ukuba wongeza uphawu lwe-Ph phambi kwexabiso lonyamezelo ngoko indawo yokunyamezela iya kuba ngaphakathi kwendawo yesilinda kunye nedayamitha yereferensi ye-Ph0.03mm.

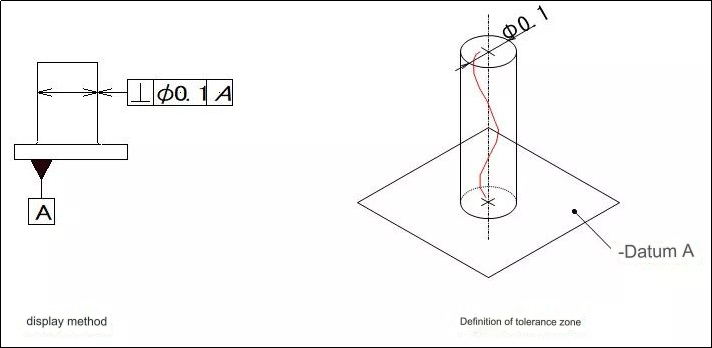

Iqondo le-orthogonality, elikwabizwa ngokuba yi-perpendicularity phakathi kwezinto ezimbini libonisa ukuba into elinganisiweyo kwinxalenye igcina i-90deg echanekileyo xa kuthelekiswa nedatha. Unyamezelo oluthe nkqo ngowona mahluko uphezulu phakathi kwesalathiso apho uphawu lulinganiswa khona kwaye ngokuthe ngqo kwidatum.

Umzekelo 1:Indawo yokunyamezela iya kuba yi-perpendicular surface kunye ne-cylindrical surface kunye nedatum ye-0.1mm ukuba amanqaku Ph avela phambi kwawo.

Umzekelo 2:Indawo yokunyamezela mayibe phakathi kweenqwelomoya ezimbini ezinxuseneyo, ziqelelene nge-0.08mm, kunye ne-perpendicular line datum line.

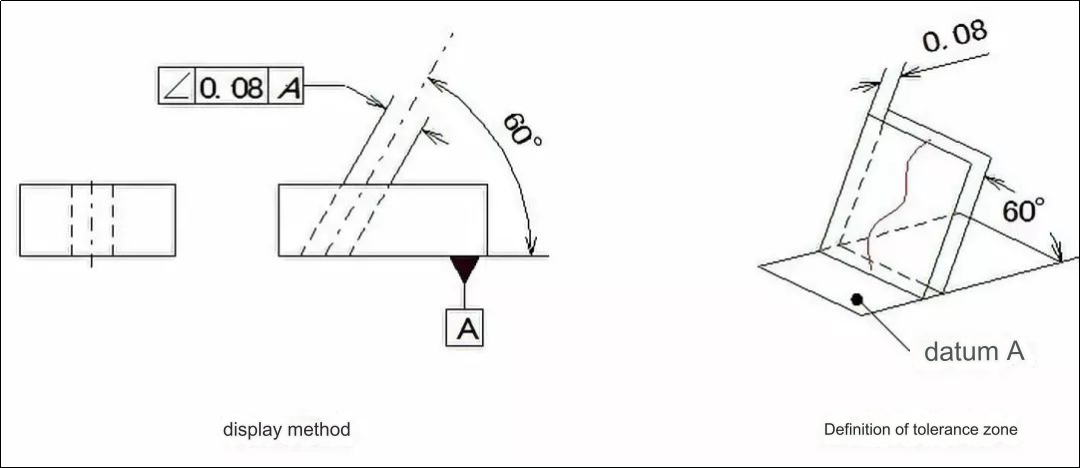

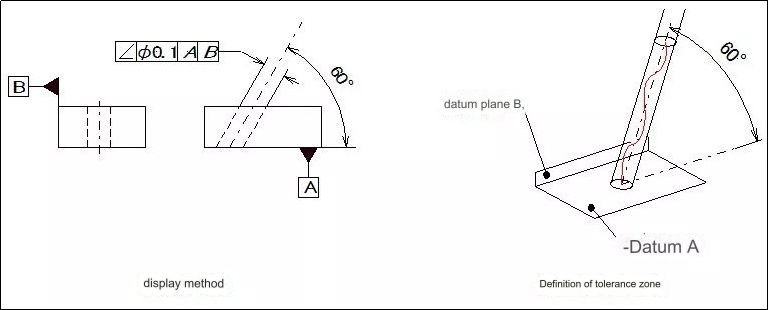

9. Utyekelo

Ukuthambekela yimeko yokuba izinto ezimbini mazigcine i-engile ethile kwiindlela zazo ezizalanayo. Unyamezelo lwethambeka sisixa sokwahluka okunokuvunyelwa phakathi kokuqhelaniswa nophawu oluza kulinganiswa kunye nolungelelwaniso olufanelekileyo, kuyo nayiphi na i-engile enxulumene nedatum.

Umzekelo 1:Indawo yokunyamezela yendiza elinganisiweyo yindawo ephakathi kweenqwelomoya ezimbini ezihambelanayo ezinokunyamezela kwe-0.08mm, kunye ne-angle ye-theory ye-60deg kwi-plane ye-datum.

Umzekelo 2:Ukuba wongeza isimboli Ph kwixabiso lonyamezelo ngoko indawo yokunyamezela kufuneka ibe ngaphakathi kwesilinda onobubanzi obuyi-0.1mm. Ummandla wokunyamezela kufuneka ungqamane neplani A ngokuthe tye ukuya kwidatum B kwaye kwi-engile ye-60deg ukusuka kwidatum A.

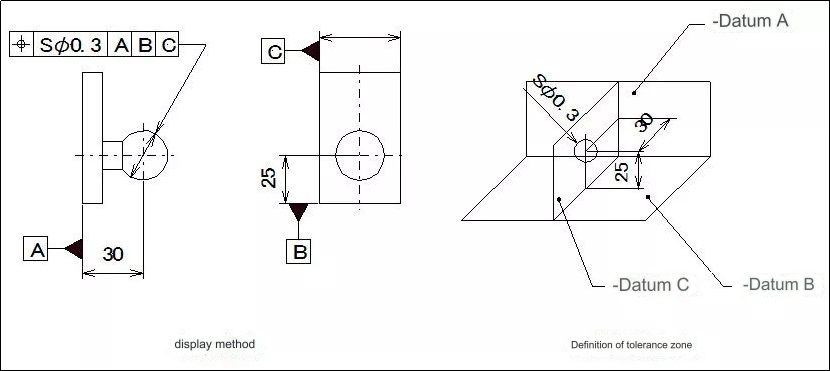

10. Indawo

Isikhundla kukuchaneka kwamanqaku, umphezulu, imigca kunye nezinye izinto ezihambelana nendawo yazo efanelekileyo. Ukunyamezela kwesikhundla kuchazwa njengokwahluka okukhulu okunokuvunyelwa kwindawo eyiyo ngokumalunga nendawo efanelekileyo.

Ngokomzekelo, xa uphawu lwe-SPh longezwa kwindawo yokunyamezela, ukunyamezela kungaphakathi kwebhola enobubanzi obuyi-0.3mm. Umbindi wendawo yokunyamezela yebhola ubukhulu obuchanekileyo kwithiyori, xa kuthelekiswa needatum zika-A, B kunye no-C.

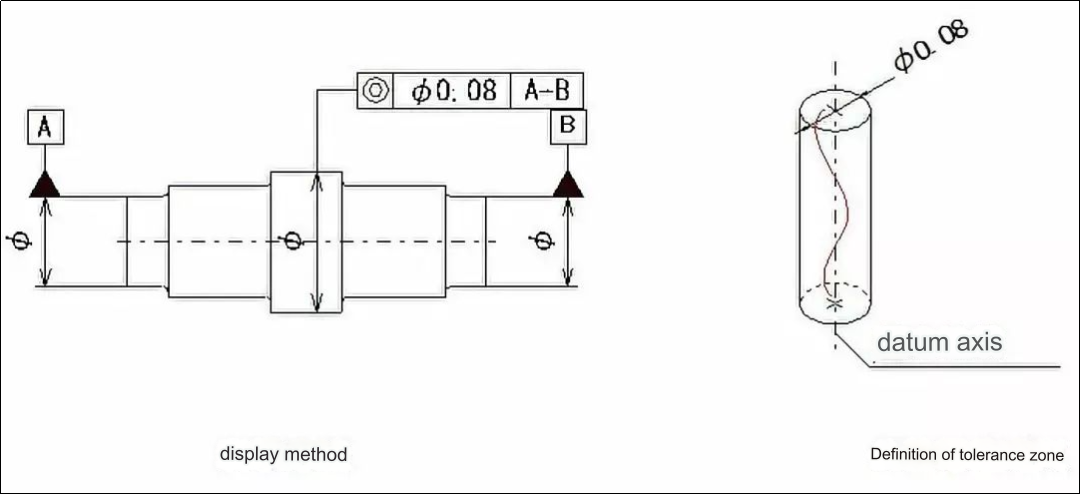

11. I-coaxiality (ukugxila).

I-Coaxiality ligama elisetyenziselwa ukuchaza into yokuba i-axis elinganisiweyo yenxalenye ihlala kumgca othe ngqo ohambelana ne-reference axis. Ukunyamezelana kwe-coaxiality kukwahluka okunokwenziwa phakathi kwe-axis yangempela kunye ne-reference axis.

Umzekelo:Indawo yokunyamezela, xa iphawulwe ngexabiso lokunyamezela, yindawo phakathi kweesilinda ezimbini zobubanzi be-0.08mm. I-axis yezowuni yokunyamezelana ingqamana nedatum.

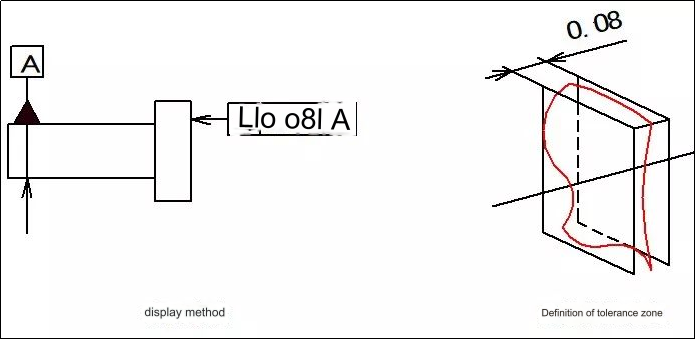

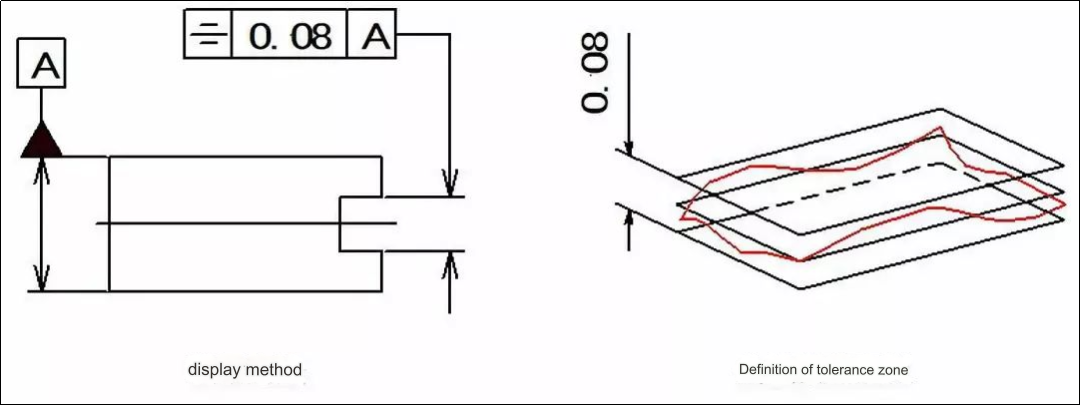

12. I-Symmetry

Ukunyamezela kwe-symmetry kukuphambuka okuphezulu kwendiza yeziko le-symmetry (okanye umgca ophakathi, i-axis) ukusuka kwindiza efanelekileyo ye-symmetric. I-symmetry tolerance ichazwa njengowona mgaqo uphezulu wokutenxa kweyona nto iphambili ye-symmetry center plane, okanye umgca osembindini (i-axis), ukusuka kweyona nqwelo-moya ifanelekileyo.

Umzekelo:Indawo yokunyamezelana yindawo ephakathi kwemigca emibini enxuseneyo okanye iindiza eziyi-0.08mm ukusuka komnye nomnye kwaye zilungelelaniswe ngokulinganayo kunye nendiza yedatum okanye i-centerline.

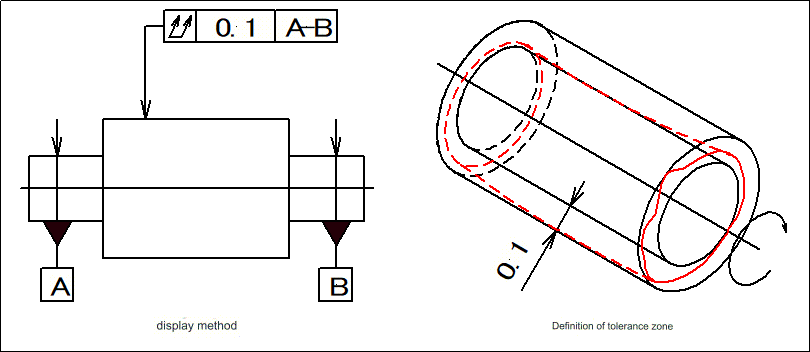

13. Ukubetha isangqa

Igama elithi circular runout libhekiselele kwinto yokuba umphezulu we-revolution kwilungu uhlala uzinzileyo ngokunxulumene ne-datum plane ngaphakathi kwenqwelomoya yomlinganiselo othintelweyo. Ukunyamezelana okukhulu kwesetyhula kuvunyelwe kuluhlu lomlinganiselo oluthintelweyo, xa i-elementi eza kulinganiswa igqibezela ukujikeleza okupheleleyo kwi-axis yereferensi ngaphandle kwentshukumo ye-axial.

Umzekelo 1:Indawo yokunyamezela ichazwa njengendawo ephakathi kwezangqa ezigxininisiweyo ezinomahluko kwiradiyasi ye-0.1mm kunye namaziko abo abekwe kwinqwelomoya yedatum enye.

14. Ukubetha ngokupheleleyo

Itotali yokubaleka yitotali yokuphuma kumphezulu wenxalenye elinganisiweyo xa ijikeleza ngokuqhubekayo kwi-axis yereferensi. Itotali yonyamezelo lokubaleka lolona luhlu luphezulu lokubaleka xa kumetwa i element ngelixa ijikeleza ngokuqhubekayo kwi-axis yedatum.

Umzekelo 1:Indawo yokunyamezela ichazwa njengendawo ephakathi kweendawo ezimbini ze-cylindrical ezinomahluko kwi-radius ye-0.1mm, kwaye i-coaxial kwi-datum.

Umzekelo 2:Indawo yokunyamezela ichazwa njengendawo phakathi kweenqwelomoya ezihambelanayo ezinomahluko kwiradiyasi ye-0.1mm, i-perpendicular kunye nedatum.

Unyamezelo lwedijithali lunaliphi ifuthe kumacandelo oomatshini be-CNC?

Ukuchaneka:

Unyamezelo lwedijithali luqinisekisa ukuba imilinganiselo yamacandelo omatshini angaphakathi kwemida echaziweyo. Ivumela ukuba kuveliswe amalungu adibana ngokuchanekileyo kwaye asebenze njengoko kucetywayo.

Ukungqinelana:

Ukunyamezela kwedijithali kuvumela ukuhambelana phakathi kwamalungu amaninzi ngokulawula ubungakanani kunye nokuhluka kwemilo. Oku kubaluleke ngakumbi kumalungu afuna ukutshintshwa, okanye asetyenziswe kwiinkqubo ezifana nokuhlanganisa apho kufuneka ukufana.

Fit kunye neNdibano

Ukunyamezela kwedijithali kusetyenziselwa ukuqinisekisa ukuba iindawo zinokudityaniswa ngokuchanekileyo kwaye zingenamthungo. Ithintela imiba efana nophazamiseko, ukucolwa ngokugqithisileyo, ukungahambi kakuhle kunye nokubophelela phakathi kwamalungu.

Ukusebenza:

Ukunyamezelana kwedijithali kuchanekile kwaye kuvumela iinxalenye ukuba ziveliswe ezihlangabezana nemigangatho yokusebenza. Unyamezelo lwedijithali lubalulekile kumashishini afana ne-aerospace kunye neemoto apho ukunyamezelana okuqinileyo kubalulekile. Iqinisekisa ukuba amalungu asebenza ngokufanelekileyo kwaye ahlangabezana nemigangatho engqongqo yobulunga.

UPhuculo lweendleko

Ukunyamezela kwedijithali kubalulekile ekufumaneni ibhalansi echanekileyo phakathi kokuchaneka, ixabiso kunye nokusebenza. Ngokuchaza ukunyamezela ngononophelo, abavelisi banokuphepha ukuchaneka okugqithisileyo, okunokunyusa iindleko ngelixa kugcinwa ukusebenza kunye nokusebenza.

Ulawulo lwemeko:

Unyamezelo lwedijithali luvumela ulawulo oluluqilima lomgangatho ngokubonelela ngeenkcukacha ezicacileyo xa kusenziwa umlinganiselo naxa kuhlolwa.amacandelo oomatshini. Ivumela ukubonwa kwangaphambili kokutenxa ekunyamezeleni. Oku kuqinisekisa umgangatho ongaguqukiyo kunye nezilungiso ngexesha.

Uyilo lokuguquguquka

Abaqulunqi banokuguquguquka ngakumbi xa kuziwa kuyiloiindawo ezenziwe ngoomatshiningonyamezelo lwedijithali. Abaqulunqi banokucacisa ukunyamezela ukumisela imida eyamkelekileyo kunye nokwahluka, ngelixa beqinisekisa ukusebenza kunye nokusebenza okufunekayo.

I-Anebon inokubonelela ngokulula ngezisombululo ezikumgangatho ophezulu, ixabiso elikhuphisanayo kunye neyona nkampani ingcono yabathengi. Indawo ekufikela kuyo i-Anebon “Uza apha ngobunzima kwaye sikunika uncumo oluzokuthatha” kubathengisi abaLungileyo abaLungileyo abaLungileyo kwiNdawo yeCNC Machining Hard Chrome Plating Gear, Ukubambelela kumgaqo weshishini elincinci leenzuzo ezifanayo, ngoku iAnebon iphumelele igama elihle phakathi kwethu. abathengi ngenxa yeenkampani zethu ezilungileyo, iimpahla ezisemgangathweni kunye nokhuphiswano lwamaxabiso. I-Anebon yamkele ngokufudumeleyo abathengi abasuka ekhayeni lakho naphesheya kweelwandle ukusebenzisana nathi ukufumana iziphumo ezifanayo.

Good Abathengisi China ngomatshini intsimbi stainless, ngokuchanekileyo 5 axis machining inxalenye kunyecnc millingiinkonzo. Ezona njongo ziphambili ze-Anebon kukubonelela abathengi bethu kwihlabathi liphela ngomgangatho olungileyo, ixabiso elikhuphisanayo, unikezelo olwaneleyo kunye neenkonzo ezigqwesileyo. Ukwaneliseka koMthengi yeyona njongo yethu iphambili. Siyakwamkela ukuba undwendwele igumbi lethu lomboniso kunye neofisi. I-Anebon ijonge phambili ekusekeni ubudlelwane beshishini nawe.

Ukuba ufuna ukwazi ngakumbi, nceda uqhagamshelaneinfo@anebon.com

Ixesha lokuposa: Nov-17-2023