Sidla ngokuba neendlela ezintathu zokukhetha umjikelo wokomba:

1. G73 (Umjikelo wokuqhekeka kweChip)

Idla ngokusetyenziselwa ukwenza imingxunya ngaphezulu kwe-3 ububanzi bentwana, kodwa hayi ngaphezulu kobude obusebenzayo bomphetho webit

2. G81 (umngxuma ojikelezayo ongekho nzulu)

Ihlala isetyenziselwa ukugrumba imingxuma yeziko, i-chamfering kunye nemingxuma yokucoca ukuya kuthi ga kumaxesha ama-3 ubukhulu bendawo yokubhola.

Ngokufika kwezixhobo zokupholisa zangaphakathi, lo mjikelo ukwasetyenziselwa ukugrumba imingxuma ukuze kuphuculwe ukusebenza kakuhle.

3. G83 (Ujikelezo lomngxuma onzulu)

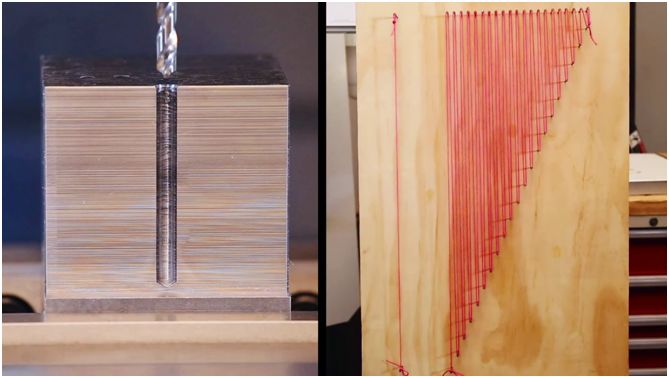

Ngokuqhelekileyo isetyenziselwa ukwenza imingxuma enzulucnc yenziwe ngoomatshini

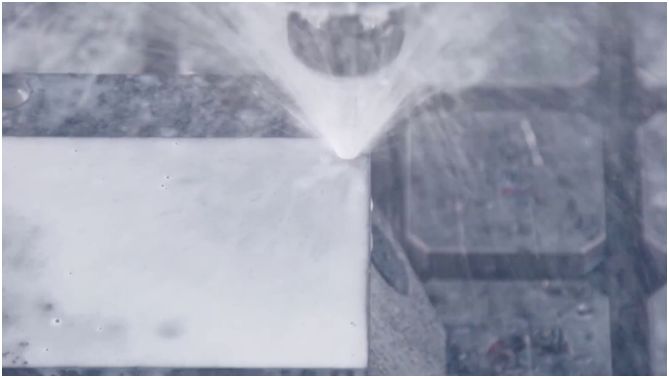

Ukupholisa (amanzi aphumayo) kumatshini oxhotyiswe ngeziko lokuphotha

Isisiki sikwaxhasa iimeko zokupholisa ezisembindini (zamanzi aphuma ngaphandle).

Ukukhetha i-G81 ukucubungula imingxunya lolona khetho lulungileyo

Uxinzelelo oluphezulu olupholileyo aluyi kuthabatha kuphela ubushushu obuveliswe ekubhobhozeni, luya kuba lubrication kwangexesha lokusika, uxinzelelo oluphezulu luya kuba nefuthe ngokuthe ngqo ukuphulwa kwe-chip kwintonga, ngoko ke i-chip encinci iya kuba nomngxuma wokukhupha amanzi ngoxinzelelo oluphezulu ngexesha, kuthintele isixhobo sokusika sesibini ukunxiba kunye nomgangatho wokuqhuba umngxuma, kuba akukho kupholisa, ukuthambisa, ingxaki yokususwa kwetshiphu, ke sesona sisombululo sikhuselekileyo nesona sisebenzayo sokugrumba okuthathu. imijikelo.i-aluminium extrusion

Izinto zokulungisa zinzima ukophula iitshiphusi kodwa ezinye iimeko zokusebenza zilungile

I-G73 lukhetho oluhle xa kungekho ukupholisa iziko lokuphotha (amanzi).

Oku kuya kumjikelo ngexesha elifutshane lokunqumama okanye umgama wencakuba ukuqonda i-chip breaker, kodwa ufuna isuntswana elilungileyo lokususwa kwetshiphu, itanki yokususa itshiphu egudileyo iya kwenza ama-scraps akhuphe ngokukhawuleza, ukunqanda umqolo olandelayo weimvuthuluka eziphothiweyo. , ukujongela phantsi umgangatho womngxuma, usebenzisa umoya ocinezelweyo njengokususwa kwe-chip encedisayo kwakhona ukhetho olufanelekileyo.

Ukuba iimeko azinzanga, i-G83 yeyona ndlela ikhuselekileyo.

nzulu umngxuma machining iya kuba ngenxa drill ukusika edge akakwazi ukupholisa kwangexesha, ukuthambisa kwaye banxibe ngokukhawuleza kakhulu, ubunzulu umngxuma chip kwakhona kuba ubudlelwane kunzima ukukhupha ngexesha, ukuba chip groove chip evalela ukupholisa. Ulwelo, alunako kuphela ukunciphisa kakhulu ubomi benkonzo yomsiki, kodwa ngenxa yokuba i-chip yesibini yokusika inokwenza udonga lomngxunya olurhabaxa ngakumbi, ngaloo ndlela ibangele umjikelo okhohlakeleyo.

Ukuba isixhobo siphakanyiselwe kumphakamo wereferensi -R wonke umgama omfutshane we -q, unokulungela umatshini kufutshane nomzantsi womngxuma, kodwa kuya kuthatha ixesha elininzi ukuqhubekekisa isiqingatha sokuqala somngxuma, okukhokelela ekubeni inkunkuma engeyomfuneko.

Ngaba kukho indlela engcono?cnc metal machining

Nazi iindlela ezimbini zokujikeleza komngxuma onzulu we-G83

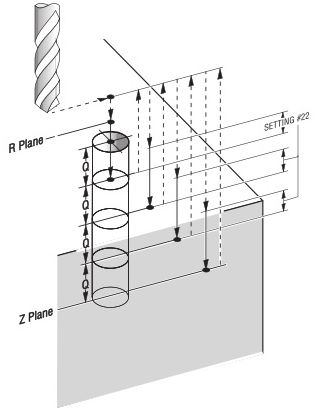

1: G83 X_ Y_ Z_ R_ Q_ F_

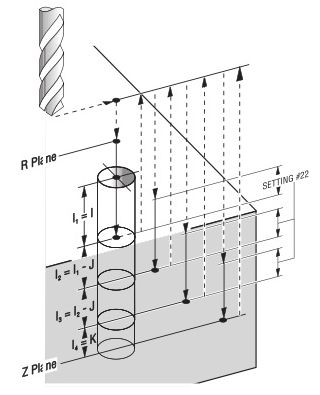

2: G83 X_ Y_ Z_ I_ J_ K_ R_ F_

Ngendlela yokuqala, ixabiso le-Q lixabiso eliqhubekayo, elithetha ukuba ubunzulu obufanayo busetyenziswa ukusuka phezulu ukuya phantsi komngxuma ixesha ngalinye. Ngenxa yesidingo sokhuseleko lokucutshungulwa, ixabiso elincinci lidla ngokukhethwa, oku kuthetha ukuba isantya esisezantsi sokususa isinyithi, esichitha ixesha elininzi lokucubungula phantse.

Kwindlela yesibini, ubunzulu bosiko ngalunye bubonakaliswe ngu-I,J, no-K:

Xa umphezulu womngxuma ukwimeko entle yokusebenza, sinokubeka ixabiso elikhulu le-I yokuphucula ukusebenza kakuhle; Xa imeko ephakathi yokusebenza komngxuma womatshini ngokubanzi, sithatha indlela yokunciphisa ixabiso le-J ngokuthe ngcembe ukuqinisekisa ukhuseleko kunye nokusebenza kakuhle; Xa imeko yokusebenza imbi phantsi komngxuma womatshini, sibeka ixabiso le-K ukuqinisekisa ukhuseleko lokucubungula.

Indlela yesibini, xa isetyenziswa xa kusenziwa, inokwenza ukuba u-50% usebenze kakuhle kwaye akubizi nto!

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Mar-17-2022