Kwi-machining, ukwenzela ukwandisa umgangatho wokucubungula kunye nokuphindaphinda ukuchaneka, kuyimfuneko ukukhetha ngokuchanekileyo kwaye unqume isixhobo esifanelekileyo. Kolunye ucelomngeni kunye nomatshini onzima, ukhetho lwesixhobo lubaluleke kakhulu.

1. Indlela yesixhobo esinesantya esiphezulu

1. Indlela yesixhobo esinesantya esiphezulu

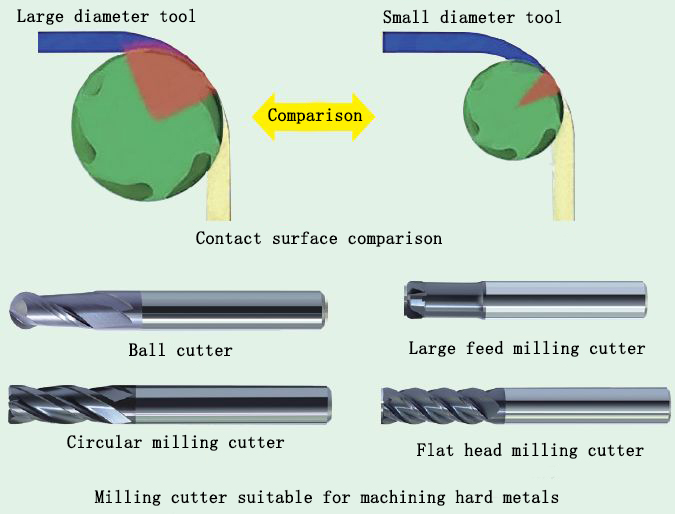

Inkqubo ye-CAD / CAM ifezekisa ukuchaneka okuphezulu ngokugqithisileyo ngokulawula ngokuchanekileyo ubude be-arc yesixhobo sokusika kwi-high-speed cycloid tool path. Xa i-cutter yokugaya inqumla kwikona okanye kwezinye iimilo zejometri eziyinkimbinkimbi, isixa sokutya kweemela asiyi kunyuka. Ukuthatha ithuba elipheleleyo lenkqubela phambili yetekhnoloji, abavelisi bezixhobo baye bayila kwaye baphuhlisa abasiki abancinci bedayamitha yokusila. Abasiki be-milling-diameter encinci banokusika izinto ezininzi zokusebenza ngexesha leyunithi ngokusebenzisa iindlela zesixhobo esinesantya esiphezulu, kwaye bafumane izinga eliphezulu lokususa isinyithi.

Ngexesha lomatshini, ukudibanisa kakhulu phakathi kwesixhobo kunye nomphezulu we-workpiece kunokubangela ukuba isixhobo singaphumeleli ngokukhawuleza. Umgaqo osebenzayo wesithupha kukusebenzisa i-milling cutter enobubanzi obumalunga ne-1/2 yeyona ndawo imxinwa yomsebenzi. Xa i-radius ye-milling cutter incinci kunobukhulu beyona ndawo incinci ye-workpiece, kukho indawo yesixhobo sokuhamba ngasekhohlo nasekunene, kwaye i-angle encinci yokutya inokufumaneka. Abasiki bokugaya bangasebenzisa imiphetho yokusika ngakumbi kunye namazinga aphezulu okutya. Ukongezelela, xa i-cutter yokugaya kunye nobubanzi be-1/2 yeyona nxalenye encinci ye-workpiece isetyenzisiweyo, i-angle yokusika ingagcinwa encinci ngaphandle kokunyusa ukujika kwe-cutter.

Ukuqina komatshini kukwanceda ukumisela ubungakanani bezixhobo ezinokusetyenziswa. Ngokomzekelo, xa usika kumatshini we-40-taper, ububanzi be-milling cutter kufuneka bube ngokuqhelekileyo <12.7mm. Ukusetyenziswa komsiki onobubanzi obukhulu kuya kuvelisa amandla amakhulu okusika anokuthi agqithise amandla omatshini wokuthwala, okukhokelela kwincoko, ukuguqulwa, ukugqiba umphezulu ombi, kunye nobomi besixhobo obufutshane.

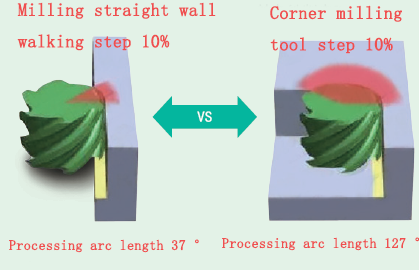

Xa usebenzisa indlela entsha yesixhobo esinesantya esiphezulu, isandi somgayi wokusila ekoneni siyafana nesokusika umgca othe ngqo. Isandi esiveliswa ngumsiki wokugaya ngexesha lenkqubo yokusika iyafana, ebonisa ukuba ayizange ifakwe kwi-thermal and mechanical shocks. I-milling cutter yenza isandi esikhalayo rhoqo xa ijika okanye inqumla kwikona, ebonisa ukuba ububanzi be-milling cutter bunokufuneka buncitshiswe ukunciphisa i-angle yokutya. Isandi sokusika sihlala singatshintshi, esibonisa ukuba uxinzelelo lokusika kwi-cutter yokugaya lufana kwaye aluguquguquki phezulu naphantsi kunye nokutshintsha kwejometri ye-workpiece. Oku kungenxa yokuba i-engile yemela ihlala ihleli.

2. Ukugaya iinxalenye ezincinci

Umsikeli omkhulu wokusila ufanelekile ukugaya iindawo ezincinci, ezinokuvelisa isiphumo sokunciphisa i-chip, okwenza kube lula ukuguba ngesantya esiphezulu sokutya.

Xa kusetyenzwa imingxuma lokusila spiral kunye iimbambo lokusila, isixhobo ngokuqinisekileyo uya kwenza uqhagamshelwano ngakumbi kunye umphezulu machining, kunye nokusetyenziswa umsiki enkulu ifidi feed kunokunciphisa uqhagamshelwano umphezulu kunye workpiece, ngaloo ndlela ukunciphisa ubushushu ukusika kunye deformation isixhobo .

Kwezi ntlobo zimbini zokucutshungulwa, isisiki esikhulu sokusila sihlala sikwimeko evaliweyo ngexesha lokusika. Ngoko ke, inqanaba eliphezulu lokusika i-radial kufuneka libe yi-25% yobubanzi be-cutter yokugaya, kunye nobukhulu be-Z bokusika ubunzulu be-cutter nganye kufuneka bube yi-2% ye-diameter ye-milling cutter.cnc machining inxalenye

Kumngxuma wokusila ojikelezayo, xa umsiki wokusila esika kwisixhobo sokusika esinomzila kaloliwe ojikelezayo, i-engile yokusika i-spiral yi-2 ° ~ 3 ° ide ifike kubunzulu be-Z-cut ye-2% yedayamitha ye-milling cutter.

Ukuba i-cutter-feed milling cutter ikwimeko evulekileyo ngexesha lokusika, inyathelo layo lokuhamba nge-radial lixhomekeke kubunzima bezinto zokusebenza. Xa izixhobo zokusila zinobulukhuni be-HRC30-50, inyathelo eliphezulu lokusika i-radial kufuneka libe yi-5% yedamitha yokusila; xa ubunzima bezinto eziphathekayo buphezulu kune-HRC50, inqanaba eliphezulu lokusika i-radial kunye ne-Z ephezulu ngokudlula Ubunzulu bokusika buyi-2% yobubanzi be-cutter yokugaya.inxalenye yealuminiyam

3. Ukugaya iindonga ezithe tye

Xa ukugaya ngeembambo ezisicaba okanye iindonga ezithe tye, kungcono ukusebenzisa i-arc cutter. Abasiki be-Arc abanemiphetho emi-4 ukuya kwe-6 bafaneleke ngokukodwa ukugaya iprofayili yeendawo ezithe ngqo okanye ezivuleleke kakhulu. Ngokuya lisanda inani lencakuba zesisiki sokusila, kokukhona sikhulu isantya sokutya esinokusetyenziswa. Nangona kunjalo, umdwelisi wenkqubo womatshini usafuna ukunciphisa unxibelelwano phakathi kwesixhobo kunye nomphezulu wendawo yokusebenza kwaye usebenzise ububanzi obuncinci bokusika i-radial. Xa umatshini kwisixhobo somatshini esinobunzima obunzima, kunenzuzo ukusebenzisa i-cutter yokugaya kunye nobubanzi obuncinci, obunokunciphisa ukudibanisa nomphezulu we-workpiece.cnc yokugaya inxalenye

Isinyathelo sokusika kunye nokusika ubunzulu be-multi-edge arc milling cutter ziyafana nezo ze-high-feed milling cutter. Indlela yesixhobo se-cycloid ingasetyenziselwa ukukrola izinto eziqinileyo. Qinisekisa ukuba i-diameter ye-milling cutter i malunga ne-50% yobubanzi be-groove, ukwenzela ukuba i-milling cutter inesithuba esaneleyo sokuhamba, kwaye uqinisekise ukuba i-angle ye-cutter ayiyi kunyuka kwaye ivelise ubushushu obugqithisileyo.

Isixhobo esihle kakhulu somatshini othile asixhomekanga kuphela kwizinto ezisikwayo, kodwa nakwindlela yokusika kunye nokugaya esetyenziswayo. Ngokulungiselela izixhobo, isantya sokusika, amaxabiso okutya kunye nezakhono zokucwangcisa izixhobo, iinxalenye zinokuveliswa ngokukhawuleza nangcono kwiindleko eziphantsi zomatshini.

I-Anebon Metal Products Limited inokubonelela ngomatshini we-CNC, ukuphosa ukufa, iinkonzo zomatshini wesinyithi, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Ixesha lokuposa: Epreli-28-2020