Ukujika isixhobo

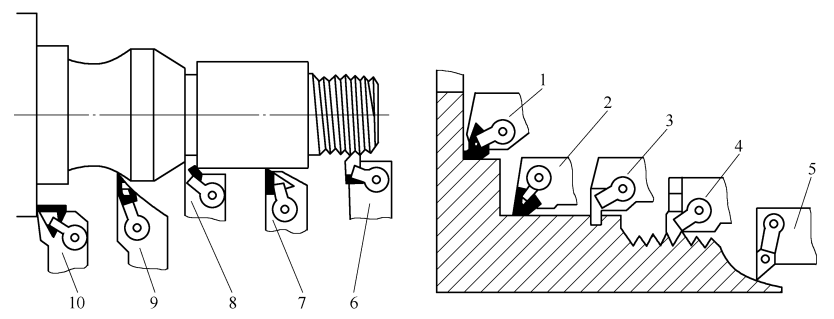

Isixhobo esiqhelekileyo ekusikeni isinyithi sisixhobo sokuguqula. Izixhobo zokujika zisetyenziselwa ukusika izangqa ezingaphandle, imingxuma embindini, imisonto, imijelo, amazinyo, kunye nezinye iimilo kwiileyile. Iintlobo zayo eziphambili ziboniswa kuMfanekiso 3-18.

Umzobo 3-18 Iintlobo eziphambili zezixhobo zokuguqula

3

Izixhobo zokuguqula zihlelwe ngokusekelwe kwisakhiwo sazo zibe yinguqu eqinile, i-welding turning, i-clamp clamp turning, kunye nezixhobo ezichazwe. Izixhobo zokuguqula izalathiso ziya zithandwa kakhulu ngenxa yokwanda kokusetyenziswa kwazo. Eli candelo lijolise ekwaziseni imigaqo yoyilo kunye nobuchule be-indexable kunye nezixhobo zokuguqula i-welding.

1. Isixhobo sokuwelda

Isixhobo sokuguqula i-welding senziwe nge-blade yesimo esithile kunye nomphathi oxhunywe nge-welding. Amacwecwe ahlala enziwe ngamabakala ahlukeneyo ezinto ze-carbide. Iingqimba zesixhobo ngokuqhelekileyo ziyintsimbi ye-45 kwaye zilolwe ukuze zihambelane neemfuno ezithile ngexesha lokusetyenziswa. Umgangatho wezixhobo zokuguqula i-welding kunye nokusetyenziswa kwazo zixhomekeke kwibakala le-blade, imodeli ye-blade, i-parameters yesixhobo sejometri kunye nokuma kunye nobukhulu be-slot. Umgangatho wokugaya, njl Umgangatho wokugaya, njl.

(1) Kukho iingenelo kunye nokungonakali kwizixhobo zokuguqula i-welding

Isetyenziswa ngokubanzi ngenxa yesakhiwo sayo esilula, esincinci; ukuqina okuphezulu kwesixhobo; kunye nokumelana nokungcangcazela kakuhle. Ikwanazo nezinto ezininzi ezingalunganga, kuquka:

(1) Ukusebenza kokusika kwe-blade kubi. Ukusebenza kokusika kwe-blade kuya kuncitshiswa emva kokuba i-welded kwiqondo lokushisa eliphezulu. Ubushushu obuphezulu obusetyenziselwa i-welding kunye nokulola kubangela ukuba i-blade ibe phantsi koxinzelelo lwangaphakathi. Ekubeni i-coefficient yokwandiswa komgca we-carbide isiqingatha somzimba wesixhobo, oku kunokubangela ukuqhekeka ukuba kubonakale kwi-carbide.

(2) Umphathi wesixhobo akaphinda asetyenziswe. Imathiriyeli ekrwada iyamosha ngenxa yokuba isibambi sesixhobo asinakuphinda sisetyenziswe.

(3) Ixesha elincedisayo lide kakhulu. Ukutshintsha isixhobo kunye nokuseta kuthatha ixesha elininzi. Oku akuhambelani neemfuno zoomatshini be-CNC, iisistim zomatshini ezizenzekelayo, okanye izixhobo zomatshini ezizenzekelayo.

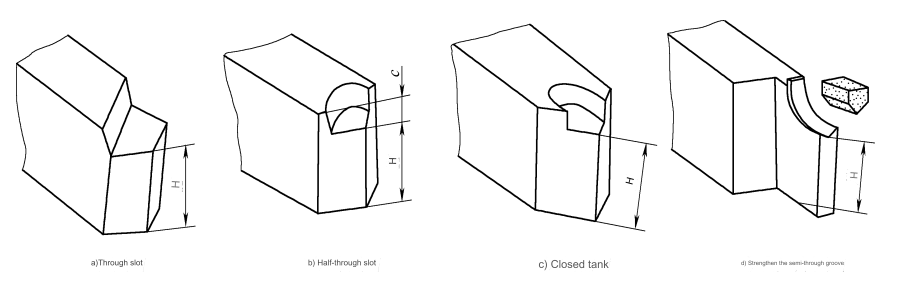

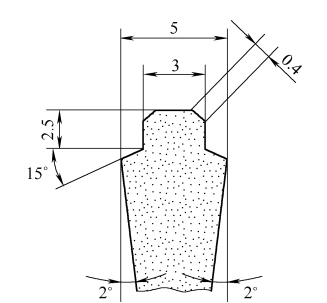

(2) Uhlobo lwegroove yesibambi

Kwizixhobo zokuguqula i-welded, izixhobo ze-shank grooves kufuneka zenziwe ngokwemilo kunye nobukhulu be-blade. Isixhobo se-shank grooves sibandakanya ngokusebenzisa i-grooves, i-semi-through grooves, i-grooves evaliweyo, kunye ne-semi-through grooves eqinisiweyo. Njengoko kubonisiwe kuMfanekiso 3-19.

Umzobo 3-19 Ijeyometri yesibambi sesixhobo

I-groove yomnini wesixhobo kufuneka ihlangabezane nezi mfuno zilandelayo ukuqinisekisa ukuwelda okusemgangathweni:

(1) Lawula ubukhulu. (1) Lawula ubukhulu bomzimba womsiki.

(2) Lawula umsantsa phakathi kweblade kunye negroove yesibambi sesixhobo. Umsantsa ophakathi kweblade kunye negroove yesibambi akufunekanga ube mkhulu kakhulu okanye ube mncinci, ngokuqhelekileyo ube yi-0.050.15mm. I-arc edibeneyo kufuneka ifane ngokusemandleni kwaye isithuba esiphezulu sendawo akufanele sibe ngaphezu kwe-0.3mm. Ngaphandle koko, amandla e-weld aya kuchaphazeleka.

(3) Lawula ixabiso lomphezulu woburhabaxa begroove yesibambi. Igroove yesibambi sinoburhabaxa bomphezulu beRa=6.3mm. Umphezulu we-blade kufuneka ube mcaba kwaye ugudileyo. Ngaphambi kwe-welding, i-groove yomphathi wesixhobo kufuneka ihlambuluke ukuba kukho nayiphi na ioli. Ukugcina indawo ye-welding icocekile, ungasebenzisa i-sandblasting okanye utywala okanye i-petroli ukuyixubha.

Lawula ubude be-blade. Kwiimeko eziqhelekileyo, iblade ebekwe kwigroove yesimeli kufuneka iphumele ngaphandle nge-0.20.3mm ukuvumela ukulolwa. I-groove yesibambi sesixhobo ingenziwa ibe nde nge-0.20.3mm kune-blade. Emva kwe-welding, umzimba wesixhobo uye welding. Ukuze ibonakale icocekile, susa nakuphi na ukugqithisela.

(3) Inkqubo yokubrawuza incakuba

I-solder eqinile isetyenziselwa ukuwelda iiblade ze-carbide eziqinileyo (i-solder eqinile i-refractory okanye i-brazing material enobushushu obunyibilikayo obungaphezulu kwe-450degC). I-solder ifudunyezwa ukuya kwimeko etyhidiweyo, edla ngokuba yi-3050degC ngaphezu kwendawo yokunyibilika. I-flux ikhusela i-solder ekungeneni kunye nokusabalalisa phezu komhlabaamacandelo oomatshini. Kwakhona kuvumela ukusebenzisana kwe-solder kunye necandelo elidibeneyo. Isenzo sokunyibilika senza ukuba i-carbide blade ifakwe ngokuqinileyo kwi-slot.

Uninzi lweendlela zokufudumeza zokutshisa ziyafumaneka, ezifana ne-gas flame welding kunye ne-high frequency welding. Ukudibanisa i-welding yombane yeyona ndlela yokufudumeza. Ukuchasana kwindawo yoqhagamshelwano phakathi kwebhloko yobhedu, kunye nentloko ye-cutter iyona nto iphezulu, kwaye yilapho ukushisa okuphezulu kuya kuveliswa. Umzimba womsiki uqala ubebomvu kwaye ubushushu budluliselwe kwincakuba. Oku kubangela ukuba i-blade ifudumale kancinane kwaye ngokuthe ngcembe inyuke iqondo lobushushu. Ukuthintela iintanda kubalulekile.

I-blade "ayitshisi kakhulu" kuba amandla avaliwe ngokukhawuleza xa izinto zinyibilika. I-welding yoqhagamshelwano yombane ibonakaliswe ukunciphisa ukuqhekeka kwe-blade kunye ne-desoldering. I-Brazing ilula kwaye izinzile, kunye nomgangatho omhle. Inkqubo yokubrawuza ayisebenzi kangako kunewelds ezixhaphakileyo, kwaye kunzima ukubrawuza izixhobo ezinemiphetho emininzi.

Umgangatho wokuqhafaza uchaphazeleka kwizinto ezininzi. Izinto zokuqhafaza, i-flux kunye nendlela yokufudumala kufuneka ikhethwe ngokuchanekileyo. Kwisixhobo se-carbide brazing, izinto eziphathekayo kufuneka zibe nendawo yokuncibilika phezulu kunokushisa kokusika. Yinto efanelekileyo yokusika ngenxa yokuba inokugcina amandla okubopha i-blade ngelixa igcina ukumanzi kwayo, ukumanzi kunye nokuhanjiswa kwe-thermal. Ezi mathiriyeli zokubrawuza zilandelayo zidla ngokusetyenziswa xa kubrandwa iincakuba zesamente-carbide:

1 Amaqondo obushushu okusebenza avumelekileyo yi-700900degC. Oku kunokusetyenziswa kunye nezixhobo ezinomsebenzi onzima.

(2) Ubhedu-zinc okanye 105 # isinyithi filler kunye lobushushu ukunyibilika phakathi 900920degC & 500600degC. Ifanelekile kwisixhobo somthwalo ophakathi.

Indawo yokuncibilika kwe-alloy yesilivere-yobhedu yi-670820. Ubushushu bayo obukhulu bokusebenza ngama-400 degrees. Nangona kunjalo, ifanelekile kwi-welding echanekileyo yokujika izixhobo kunye ne-cobalt ephantsi okanye i-titanium carbide ephezulu.

Umgangatho wokubhobhoza uchaphazeleka kakhulu kukhetho kunye nokusetyenziswa kwe-flux. I-flux isetyenziselwa ukususa i-oxides phezu kwendawo yokusebenza eya kuba yibrazed, ukwandisa ukumanzi kunye nokukhusela i-weld kwi-oxidation. Ii-fluxes ezimbini zisetyenziselwa ukubhobhoza izixhobo ze-carbide: i-borax i-Na2B4O2 i-dehydrated okanye i-borax e-dehydrated 25% (i-massfraction) + i-boric Acid 75% (i-massfraction). Amaqondo obushushu eBrazing aqala kwi-800 ukuya kwi-1000degC. I-Borax inokuchithwa ngokunyibilikisa i-borax, ize iyityumze emva kokupholisa. Hluza. Xa ubhuqa izixhobo ze-YG, i-borax ene-dehydrated idla ngokuba ngcono. Unokufikelela kwiziphumo ezanelisayo xa ubrawuza izixhobo ze-YT usebenzisa i-formula dehydrated borax (massfraction) 50% + boric (massfraction) 35% + dehydrated potassium (massfraction) fluoride (15%).

Ukongezwa kwe-potassium fluoride kuya kuphucula ukumanzi kunye nokukwazi ukunyibilika kwe-titanium carbide. Ukuze unciphise uxinzelelo lwe-welding xa ubhobhoza i-alloys ye-titanium ephezulu (YT30 kunye ne-YN05), iqondo lokushisa eliphantsi phakathi kwe-0.1 kunye ne-0.5mm lisetyenziswa ngokuqhelekileyo. Njenge-gasket yembuyekezo phakathi kwee-blades kunye nabaphathi besixhobo, i-carbon steel okanye i-iron-nickel isetyenziswa rhoqo. Ukunciphisa uxinzelelo lwe-thermal, i-blade kufuneka ifakwe i-insulated. Ngokuqhelekileyo isixhobo sokuguqula siya kufakwa kwisithando somlilo kunye nokushisa kwe-280 ° C. Zigqume iiyure ezintathu kwi-320degC, kwaye emva koko uzipholise kancinci mhlawumbi kwiziko, okanye kwi-asbestos okanye i-straw ash powder.

(4) Ukudityaniswa kwe-inorganic

I-inorganic bonding isebenzisa isisombululo se-phosphoric kunye nomgubo wobhedu we-inorganic, odibanisa i-chemistry, i-mechanics, kunye ne-physics kwi-bond blades. I-inorganic bonding ilula ukuyisebenzisa kunokuba i-brazing kwaye ayibangeli uxinzelelo lwangaphakathi okanye ukuqhekeka kwi-blade. Le ndlela iluncedo kakhulu kwizixhobo zeblade ekunzima ukuzidibanisa, ezifana neeseramics.

Imisebenzi yeempawu kunye namatyala asebenzayo omatshini

4. Ukukhetha i-angle ye-edge inclination kunye ne-bevel cut

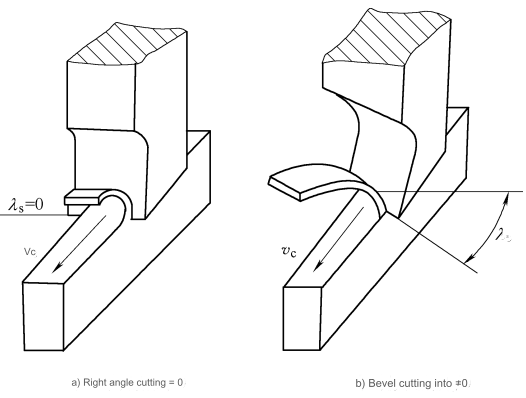

(1) Ukusika iBevel ngumbono okudala ukhona.

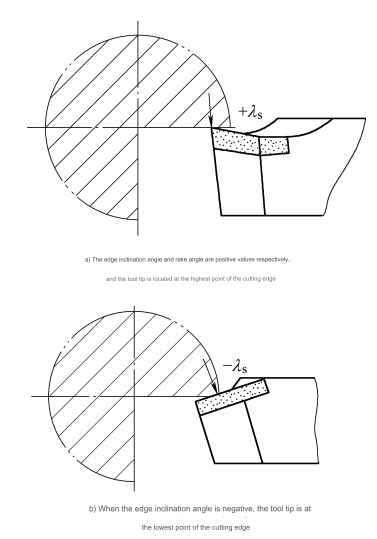

Ukusika i-angle ekunene kukusika apho i-blade yokusika yesixhobo ihambelana nesalathiso sokusika siya kuthatha. Ukusika kwe-bevel kuxa umgca wokusika wesixhobo awukho perpendicular kunye nolwalathiso lwentshukumo yokusika. Njengoncedo, umphumo wesondlo unokungahoywa. Ukusika oku-perpendicular kunye nesantya esiphezulu sentshukumo okanye i-edge inclination angles lss=0 ithathwa njengokusika i-angle echanekileyo. Oku kuboniswe kuMfanekiso 3-9. Ukusika okungekho perpendicular kunye nesantya sentshukumo ephambili okanye i-edge inclination angles lss0, ibizwa ngokuba yi-oblique angle-cutting. Umzekelo, Njengoko kubonisiwe kuMfanekiso 3-9.b, xa kuphela i-cut cut cut, oku kwaziwa ngokuba yi-free cut. Ukusika i-bevel kuxhaphake kakhulu kwi-metal cutting.

Umzobo 3-9 Ukusika i-angle yokunene kunye nokusika i-bevel

(2) Impembelelo yokusika i-bevel kwinkqubo yokusika

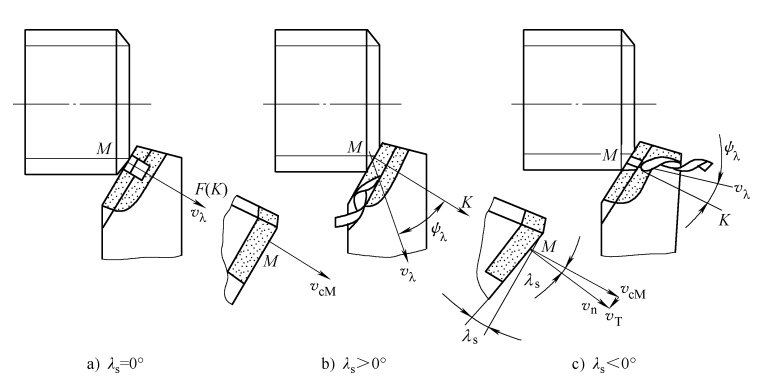

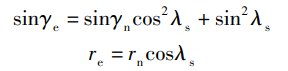

1. Phembelela isalathiso sokuphuma kwetshiphu

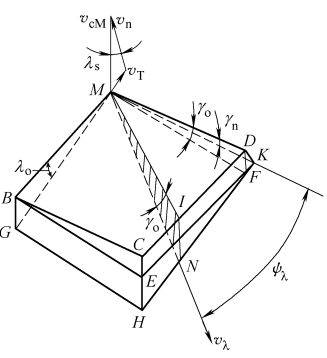

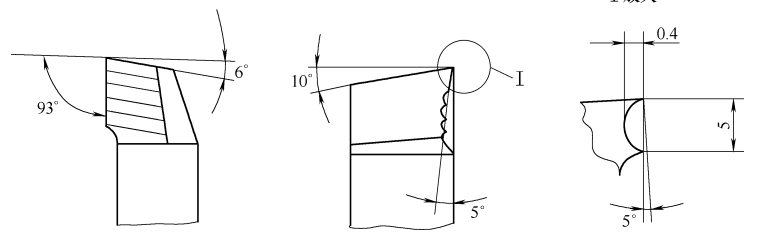

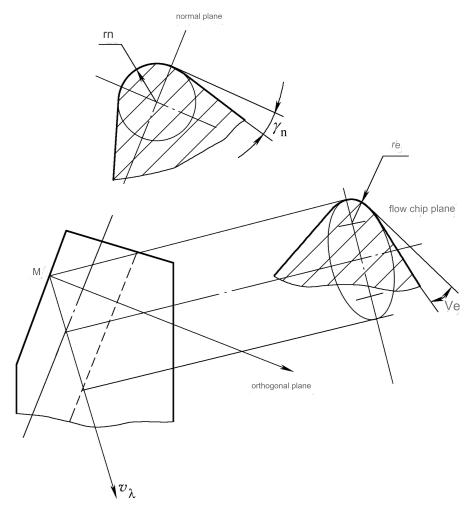

Umzobo 3-10 ubonisa ukuba isixhobo sokuguqula sangaphandle sisetyenziselwa ukuguqula umbhobho. Xa kuphela umgca wokusika oyintloko uthatha inxaxheba ekusikeni, i-particle M kwi-cutting layer (icinga ukuba ubude obufanayo nombindi wenxalenye) iba yi-chip phantsi kwe-extrusion phambi kwesixhobo kwaye iphuma ngaphandle ngaphambili. Ubudlelwane phakathi kolwalathiso lokuhamba kwetshiphu kunye ne-engile yokuthambekela komphetho kukuthintela iyunithi yomzimba we-MBCDFHGM kunye nenqwelomoya ye-orthogonal kunye nenqwelomoya yokusika kunye neendiza ezimbini ezihambelana nazo ngenqaku uM.

Umfanekiso 3-10 Isiphumo se-λs kwindlela ye-flow chip

I-MBCD yindiza yesiseko kwi-Figure 3-11. Xa i-ls = 0, i-MBEF ingaphambili kwi-Figure 3-11, kunye ne-MDF yenqwelomoya yinqwelomoya ye-orthogonal kunye nesiqhelo. I-Point M ngoku i-perpendicular edge yokusika. Xa iitshiphusi zikhutshiwe, uM licandelo lesantya ecaleni kwendlela yokusika. I-MF i-perpendicularly parallel kwi-cut edge. Njengoko kubonisiwe kuMfanekiso 3-10a, ngeli xesha, iiChips zigobile zibe yimo efana nentwasahlobo okanye zihamba ngendlela echanekileyo. Ukuba i-ls inexabiso elihle ke inqwelomoya ye-MGEF ingaphambili kwaye intshukumo ephambili yokusika isantya i-vcM ayihambelani ne-MG yokusika. Isuntswana lesantya esinguMcnc ukuguqula amacandeloI-vT enxulumene nesixhobo kwicala leendawo zokusika eziya kwi-MG. Xa inqaku M liguqulwa libe yitshiphu ephuma ngaphambili kwaye ichatshazelwa yi-vT isantya se-chip ye-vl siya kuphambuka kwinqwelomoya yesiqhelo ye-MDK kwi-angle ye-chip ye-psl. Xa i-ls inexabiso elikhulu, iitshiphusi ziya kumpompoza kwicala lokulungisa umphezulu.

Inqwelomoya MIN, njengoko kuboniswe kwiMifanekiso 3-10b kunye ne-3-11, yaziwa ngokuba yi-chip flow. Xa i-ls inexabiso elibi icandelo le-velocity vT kwicala le-cut edge libuyiselwa umva, likhomba kwi-GM. Oku kubangela ukuba iitshiphusi zihlukane ukusuka kwinqwelomoya eqhelekileyo. Ukuhamba kukwicala elichaseneyo ukuya kumphezulu womatshini. Njengoko kubonisiwe kuMfanekiso 3-10.c. Le ngxoxo kuphela malunga nomphumo we-ls ngexesha lokusika mahhala. Ukuhamba kweplastiki yentsimbi kwincam yesixhobo, i-edge encinci yokusika, kunye ne-chip groove zonke ziya kuba nefuthe kwicala lokuphuma kwee-chips ngexesha lenkqubo yokwenyani yokuguqula izangqa zangaphandle. Umzobo 3-12 ubonisa ukucofa kwemingxuma ephumela kunye nemingxuma evaliweyo. Impembelelo ye-cutting edge yokuthambekela ekuhambeni kwe-chip. Xa ucofa umsonto ongenamngxuma, ixabiso ls lilungile, kodwa xa ucofa enye ngomngxuma, lixabiso elingalunganga.

Umzobo 3-11 I-Oblique yokusika i-chip flow direction

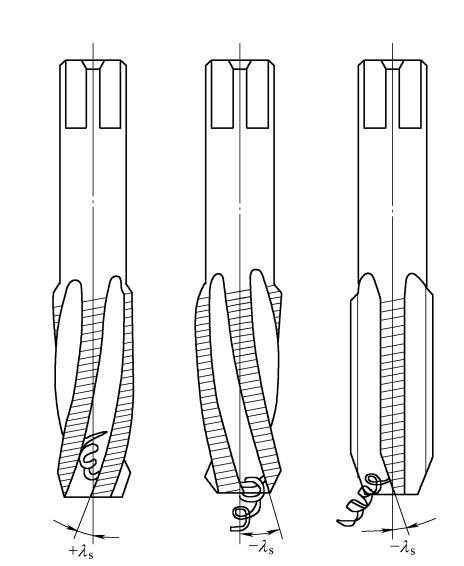

2. Iraki yokwenyani kunye ne-obtuse radii ziyachaphazeleka

Xa i-ls = 0, ekusikeni simahla, ii-engile zehariki kwinqwelomoya ye-orthogonal kunye nenqwelomoya ye-chip zilingana ngokulinganayo. Ukuba i-ls ayingo-zero, inokuchaphazela ngokwenene ubukhali bokusika kunye nokumelana nokukhuhlana xa iitshiphusi zikhutshelwa ngaphandle. Kwinqwelomoya yetshiphu, i-engile yeharika esebenzayo kunye ne-cutting edge obtuse radii re kufuneka ilinganiswe. Umzobo 3-13 uthelekisa ijometri yendiza eqhelekileyo edlula kwi-M-point yomgca oyintloko kunye ne-obtuse radii re ye-chip flow plane. Kwimeko yomgca obukhali, indiza eqhelekileyo ibonisa i-arc eyenziwe yi-obtuse radius rn. Nangona kunjalo, kwiprofayili ye-chip flow, ukusika kuyingxenye ye-ellipse. Iradiyasi yegophe ecaleni kwe-axis ende yeyona nto iphambili yokusika obtuse radius re. Ifomula elandelayo eqikelelweyo ingabalwa kumanani obudlelwane bejometri kwiMifanekiso 3-11 kunye ne-3-13.

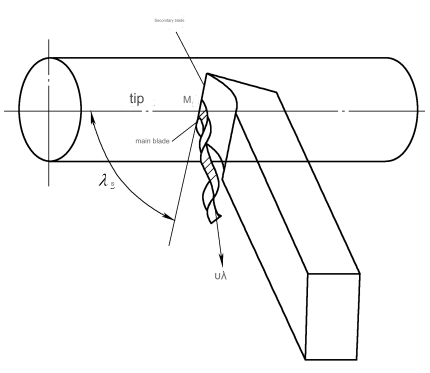

Ifomyula engentla ibonisa ukuba ukunyuka kwakhona njengoko ixabiso elipheleleyo linyuka, ngelixa i-ge iyancipha. Ukuba i-ls=75deg, kunye ne-gn=10deg nge-rn=0.020.15mm ngoko ke i-ge ingabankulu njenge-70deg. kwakhona ingaba yincinci njenge 0.0039mm. Oku kwenza i-cut cut ibukhali kakhulu, kwaye inokufezekisa i-micro-cutting (ap0.01mm) ngokusebenzisa ixabiso elincinci lokusika umva. Umzobo 3-14 ubonisa indawo yokusika isixhobo sangaphandle xa i-ls ibekwe kwi-75deg. Imiphetho ephambili kunye neyesibini yesixhobo iye yalungelelaniswa kumgca ochanekileyo. Umphetho wokusika wesixhobo ubukhali kakhulu. Umgca wokusika awulungiswanga ngexesha lenkqubo yokusika. Kwakhona i-tangent kunye nomphezulu we-cylindrical wangaphandle. Ukufakela kunye nohlengahlengiso kulula. Isixhobo sisetyenziswe ngempumelelo kwi-high-speed turning finishing of carbon steel. Isenokusetyenziswa ukugqiba ukusetyenzwa kwemathiriyeli enzima kumatshini efana nentsimbi ephezulu.

Umfanekiso 3-12 Impembelelo ye-edge edge inclination angle kwi-chip flow direction ngexesha lokucofa intambo

Umfanekiso 3-13 Uthelekiso lwe-rn kunye neejometri re

3. Ukuchasana kwempembelelo kunye namandla esicatshulwa sesixhobo kuyachaphazeleka

Xa i-ls ingalunganga, njengoko kubonisiwe kwi-Figure 3-15b, i-tip yesixhobo iya kuba yindawo ephantsi kakhulu ecaleni kwendlela yokusika. Xa imiphetho yokusika inqunyulwe kwiiinxalenye zeprototypeinqaku lokuqala lempembelelo kunye ne-workpiece yi-tooltip (xa ihamba inexabiso elihle) okanye i-front (xa i-negative) Oku akukhuseli kuphela kwaye kuqinise i-tip, kodwa kunceda ukunciphisa umngcipheko womonakalo. Izixhobo ezininzi ezinerakhi enkulu zisebenzisa i-edge edge inclination. Bobabini banokunyusa amandla kunye nokunciphisa impembelelo kwisixhobo sesixhobo. I-back force Fp iyanda ngeli xesha.

Umzobo 3-14 Isixhobo esikhulu sokuguqula i-engile ye-blade ngaphandle kwengcebiso esisigxina

4. Ichaphazela ukuzinza kokusika ngaphakathi nangaphandle.

Xa i-ls = 0, i-cut cut cut in and out of workpiece phantse ngaxeshanye, amandla okusika atshintsha ngokukhawuleza, kwaye impembelelo inkulu; xa i-ls ingekho i-zero, i-edge yokusika iyancipha ngokuthe ngcembe kwaye iphume kwi-workpiece, impembelelo incinci, kwaye ukusika kulula. Umzekelo, i-helix angle enkulu ye-cylindrical milling cutters kunye ne-end mill inekona ezibukhali zokusika kunye nokusika okugudileyo kune-standard standard cutters. Ukusebenza kwemveliso kwanda ngamaxesha angama-2 ukuya kwe-4, kunye nexabiso le-roughness ye-Ra inokufikelela ngaphantsi kwe-3.2 mm.

5. Ukusika imilo yecala

Ubume obunqamlekileyo besixhobo sinye semixholo esisiseko yeeparamitha zejometri ezifanelekileyo zesixhobo. Utshintsho kwi-blade shape yesixhobo sitshintsha iphethini yokusika. Okubizwa ngokuba yiphethini yokusika ibhekisela kumyalelo kunye nokuma apho umgca wensimbi oza kucutshungulwa khona ususwe ngumgca wokusika. Ichaphazela ubungakanani bomthwalo osikiweyo, iimeko zoxinzelelo, ubomi besixhobo kunye nomgangatho owenziwe ngomatshini. yima. Izixhobo ezininzi eziphambili zihambelana ngokusondeleyo nokukhethwa okufanelekileyo kweemilo ze-blade. Phakathi kwezixhobo ezisebenzayo eziphambili, iimilo ze-blade zinokushwankathelwa kwezi ntlobo zilandelayo:

(1) Ukuphucula imilo ye-blade yomgca wokusika. Le milo ye-blade ikakhulu ukuqinisa amandla omgca wokusika, ukwandisa i-angle edge edge, ukunciphisa umthwalo kwiyunithi yobude bomda, kunye nokuphucula iimeko zokutshatyalaliswa kobushushu. Ukongeza kwiimilo ezininzi zeengcebiso zesixhobo eziboniswe kuMfanekiso 3-8, kukwakho neemilo zomphetho we-arc (izixhobo zokuguqula umphetho we-arc, i-arc edge hobbing face milling cutters, i-arc edge drill bits, njl. , njalo njalo) )linda;

(2) Ubume bomphetho obunciphisa indawo eshiyekileyo. Lo mzobo womphetho usetyenziswa ikakhulu ukugqiba izixhobo, ezifana nezixhobo zokuguqula umxhesho omkhulu kunye nezisiki zobuso zokusila ngee-wipers, izixhobo ezidikayo ezidadayo kunye nezixhobo eziqhelekileyo ezikruqulayo ezine-cylindrical wipers. IiReamers, njl.

Umzobo 3-15 Isiphumo se-edge edge inclination angle kwindawo yempembelelo xa isixhobo sokusika

(3) Imilo yeblade ehambisa ngokufanelekileyo umda wokusika kwaye ikhuphe iitshiphusi ngokutyibilikayo. Uphawu lolu hlobo lwe-blade shape kukuba lwahlula-hlula umaleko obanzi kunye nobhityileyo wokusika ube ziitshiphusi ezininzi ezimxinwa, ezingavumeli kuphela iitshiphusi ukuba zikhutshwe ngokutyibilikayo, kodwa zikwanyusa izinga langaphambili. Nika isixa kwaye unciphise amandla okusika iyunithi. Ngokomzekelo, xa kuthelekiswa neemela zokusika eziqhelekileyo ezinqamlekileyo, iintambo zokusika eziphindwe kabini zahlula umgca wokusika ube ngamacandelo amathathu, njengoko kuboniswe kuMfanekiso 3-16. Iichips nazo zohlulwe zibe yimicu emithathu ngokufanelekileyo. Ukungqubuzana phakathi kwee-chips kunye neendonga ezimbini kuncitshisiwe, okuthintela ii-chips ukuba zivaliwe kwaye zinciphisa kakhulu amandla okusika. Njengoko ubunzulu bokusika bukhuphuka, izinga lokuhla liyenyuka, kwaye umphumo ungcono. Ngexesha elifanayo, ubushushu bokusika buyancipha kwaye ubomi besixhobo buphuculwe. Zininzi izixhobo ezizezolu hlobo lweblade shape, ezinje nge step milling cutters, staggered edge milling cutters, staggered edge saw blades, chip drill bits, staggered tooth corn cutters, and wave edge end Mills. Kunye nevili-cut broaches, njl.;

Umfanekiso 3-16 Imela yokusika ephindwe kabini

(4) Ezinye iimilo ezikhethekileyo. Iimilo ezikhethekileyo ze-blade ziyimilo ye-blade eyenzelwe ukuhlangabezana neemeko zokucubungula inxalenye kunye neempawu zayo zokusika. Umfanekiso 3-17 ubonisa imilo yebhodi yokuhlamba yangaphambili esetyenziselwa ukusetyenzwa kobhedu olulothe. Eyona nto iphambili yokusika le blade ibunjwe kwii-arches ezininzi ezine-dimensional. Inqaku ngalinye kwi-cutting edge line-angle yokuthambekela eyonyuka ukusuka kwi-negative, ukuya kwi-zero kwaye emva koko ukuya kwi-positive. Oku kubangela ukuba ubutyobo bucudiswe kwiitshiphusi ezimile okweribhoni.

I-Anebon alyways iphakamisa ifilosofi "Yiba nguNombolo we-1 kumgangatho ophezulu, ugxininise kwityala kunye nokuthembeka ekukhuleni". I-Anebon iya kuhlala isebenzela amathemba angaphambili kunye namatsha avela ekhaya naphesheya kolwandle ngokushushu ngesaphulelo esiQhelekileyo 5 Axis Precision Custom Rapid PrototypeI-5 axis cnc millingI-Turning Machining, e-Anebon enomgangatho ophezulu ukuqala njenge-motto yethu, senza iimveliso ezenziwe ngokupheleleyo eJapan, ukusuka ekuthengeni izixhobo ukuya ekuqhubeni. Oku kwenza ukuba abathengi abasuka kulo lonke ilizwe basetyenziswe ngokuzithemba ngoxolo lwengqondo.

Iinkqubo zokwenziwa kweTshayina, iinkonzo zokugaya intsimbi kunye nenkonzo yokucofa ngokukhawuleza. I-Anebon ijonga “amaxabiso afanelekileyo, ixesha lokuvelisa elisebenzayo kunye nenkonzo entle emva kokuthengisa” njengesiseko sethu. I-Anebon inethemba lokusebenzisana nabathengi abaninzi kuphuhliso olufanayo kunye neenzuzo. Siyabamkela abathengi abanokuthi baqhagamshelane nathi.

Ixesha lokuposa: Dec-14-2023