Ngaba uyazi ukuba zeziphi iindawo ezifuna ukuchaneka okuphezulu kumacandelo oomatshini?

I-Aerospace:

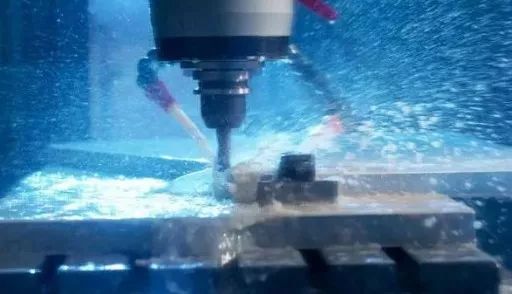

Amalungu oshishino lwe-aerospace afana neencakuba zeinjini yomoya okanye iinxalenye zeenqwelo-moya kufuneka zenziwe ngoomatshini ngokuchanekileyo, kwaye ngaphakathi kokunyamezelana okuqinileyo. Oku kwenziwa ukuqinisekisa ukusebenza kunye nokhuseleko. I-injini ye-jet blade, umzekelo, inokufuna ukuchaneka ngaphakathi kwee-microns ukuze kugcinwe ukusebenza kakuhle kwamandla kunye nokuhamba komoya.

Izixhobo zonyango:

Ukuqinisekisa ukhuseleko kunye nokuhambelana, zonke iindawo ezenziwe ngoomatshini bezixhobo zonyango ezifana nezixhobo zotyando okanye izinto ezifakelwayo kufuneka zichaneke. Ukufakelwa kwe-orthopedic yesiko, umzekelo, kunokufuna imilinganiselo echanekileyo kunye nokugqitywa phezulu ukuze kuqinisekiswe ukufaneleka okufanelekileyo kunye nokudibanisa emzimbeni.

Iimoto:

Kushishino lweemoto, ukuchaneka kuyafuneka kumacandelo afana nothumelo kunye neenxalenye zenjini. Isixhobo sothumelo esenziwe ngokuchanekileyo okanye isitofu sepetroli sinokufuna ukunyamezelana okuqinileyo ukuze kuqinisekiswe ukusebenza okufanelekileyo kunye nokuqina.

I-Electronics:

Amalungu omatshini kumashishini ombane afuneka ukuba achaneke kakhulu kwiimfuno ezithile zoyilo. Izindlu ze-microprocessor ezenziwe ngokuchanekileyo zinokufuna ukunyamezela okuqinileyo ukulungelelaniswa okufanelekileyo kunye nokusabalalisa ubushushu.

Umoya ovuselelekayo:

Ukwandisa imveliso yamandla, kunye nokuqinisekisa ukuthembeka, iinxalenye zomatshini kwiiteknoloji ezivuselelekayo ezifana nokunyuswa kweepaneli zelanga okanye amacandelo e-injini yomoya afuna ukuchaneka. Inkqubo yegiya ye-injini yomoya eyenziwe ngokuchanekileyo inokufuna iiprofayili zamazinyo ezichanekileyo kunye nokulungelelaniswa ukuze kwandiswe impumelelo yokuvelisa amandla.

Kuthekani ngeendawo apho ukuchaneka koomatshini kungafunwa kakhulu?

Ulwakhiwo:

Ezinye iindawo, ezifana neziqhoboshi kunye namalungu olwakhiwo, asetyenziswa kwiiprojekthi zolwakhiwo, asenokungafuni ukuchaneka okufanayo njengeenxalenye ezibalulekileyo zoomatshini okanye iinxalenye ze-aerospace. Izibiyeli zentsimbi kwiiprojekthi zokwakha zisenokungafuni ukunyamezela okufanayo njengamacandelo achanekileyo kumatshini ochanekileyo.

Ukwenziwa kwefanitshala:

Amanye amacandelo okwenziwa kwefenitshala, njenge-trim yokuhombisa, izibiyeli okanye ii-hardware, akufuneki ukuba zibe zichanekileyo. Ezinye iindawo, ezinje ngezixhobo ezichanekileyo zoomatshini kwiindlela zefenitshala eziguquguqukayo ezifuna ukuchaneka, zinokunyamezela okungaphezulu kokuxolela.

Izixhobo zokusetyenziswa kwezolimo:

Amalungu athile oomatshini bezolimo abanje ngezibiyeli, izixhaso okanye izigqubuthelo zokhuselo zinokungafuneki ukuba zibanjwe kunyamezelo olungqongqo kakhulu. Isibiyeli esisetyenziselwa ukunyusela icandelo lesixhobo esingachanekanga sinokungafuneki ukuchaneka okufanayo njengeenxalenye zoomatshini bezolimo obuchanekileyo.

Ukuchaneka kwenkqubo yinqanaba lokuhambelana nobukhulu bomphezulu, imilo kunye nendawo kwiiparamitha zejometri ezichazwe kumzobo.

Ubungakanani obuqhelekileyo yiparameter yejometri efanelekileyo yobukhulu.

Ijometri yomphezulu sisangqa, isilinda okanye indiza. ;

Kunokwenzeka ukuba ube nemiphezulu ehambelanayo, i-perpendicular okanye i-coaxial. Impazamo yoMatshini ngumahluko phakathi kweeparamitha zejometri zenxalenye kunye neeparamitha zazo ezifanelekileyo zejometri.

1. Intshayelelo

Injongo ephambili yokuchaneka komatshini kukuvelisa iimveliso. Zombini ukuchaneka komatshini kunye neempazamo zomatshini yimigaqo esetyenziselwa ukuvavanya iiparamitha zejometri zomgangatho owenziwe ngomatshini. Ibanga lokunyamezela lisetyenziselwa ukulinganisa ukuchaneka komatshini. Ukuphakama kokuchaneka, ibakala elincinci. Impazamo yomatshini inokubonakaliswa njengexabiso lamanani. Ukuba likhulu ixabiso lamanani kokukhona impazamo enkulu. Ngokuchaseneyo, ukuchaneka okuphezulu kokucubungula kuhambelana neempazamo ezincinci zokucwangcisa. Kukho amanqanaba angama-20 okunyamezela, ukusuka kwi-IT01 ukuya kwi-IT18. I-IT01 yinqanaba lokuchaneka komatshini elona liphezulu, i-IT18 esezantsi, kunye ne-IT7 kunye ne-IT8 ngokubanzi ngamanqanaba achanekileyo aphakathi. inqanaba.

Akunakwenzeka ukufumana iiparamitha ezichanekileyo ngokusebenzisa nayiphi na indlela. Ngethuba nje impazamo yokucubungula iwela kuluhlu lokunyamezela oluchazwe ngumzobo wenxalenye kwaye alikho mkhulu kunomsebenzi wecandelo, ukuchaneka kokucubungula kunokuqwalaselwa okuqinisekisiweyo.

2. Umxholo onxulumeneyo

Ukuchaneka komda

Ummandla wokunyamezela yindawo apho ubukhulu benxalenye yangempela kunye neziko lommandla wokunyamezela zilingana.

Ukuchaneka kobume:

Iqondo apho imilo yejometri yomphezulu wecandelo lomatshini ihambelana nefom yejometri efanelekileyo.

Ukuchaneka kwendawo:

Umahluko kwisikhundla sokuchaneka phakathi kwemiphezulu yamalungu acutshungulwayo.

Ubudlelwane:

Xa uyila iinxalenye zomatshini kunye nokucacisa ukuchaneka kwabo kwemishini, kubalulekile ukulawula impazamo yokuma kunye nokunyamezela isikhundla. Impazamo yendawo kufuneka ibe ncinane kunonyamezelo lwedimension. Kwiindawo ezichanekileyo kunye neendawo ezibalulekileyo, iimfuno zokuchaneka kwemilo kufuneka zibe phezulu.

3. Indlela yoLungiso

1. Uhlengahlengiso lwenkqubo yenkqubo

Ukulungiswa kwendlela yokusika isilingo: Ukulinganisa ubungakanani, lungisa inani lokusika isixhobo uze usike. Phinda ude ufikelele kubungakanani obufunekayo. Le ndlela isetyenziselwa ikakhulu kwi-batch encinci kunye nemveliso enye.

Indlela yokulungelelanisa: Ukufumana ubungakanani obufunekayo, lungisa iindawo ezihambelanayo zesixhobo somatshini, ukulungiswa kunye nomsebenzi. Le ndlela inemveliso ephezulu kwaye isetyenziswa ikakhulu kwimveliso yobuninzi.

2. Nciphisa iimpazamo zesixhobo somatshini

1) Ukuphucula ukuchaneka kwecandelo le-spindle

Ukuchaneka komjikelezo wokuthwala kufuneka kuphuculwe.

1 Khetha iibheringi eziqengqelekayo ezichanekileyo;

2 Sebenzisa iibheringi zoxinzelelo oluguquguqukayo ngokuchaneka okuphezulu kwe-oyile ezininzi.

3 Ukusebenzisa iibheringi ze-hydrostatic ezichanekileyo

Kubalulekile ukuphucula ukuchaneka kwezixhobo zokuthwala.

1 Ukuphucula ukuchaneka kwejenali ye-spindle kunye nemigodi yokuxhasa ibhokisi;

2 Ukuphucula ukuchaneka kokuhambelana komphezulu kunye nokuthwala.

3 Linganisa kwaye ulungelelanise uluhlu lweradial lwamalungu ukulinganisa okanye ukuhlawula iimpazamo.

2) Layisha kwangaphambili iibheringi ngokufanelekileyo

1 Inokuphelisa izithuba;

2 Yandisa ubunzima bokuthwala

3 Impazamo yento enye yokuqengqeleka.

3) Gwema ukubonakaliswa kokuchaneka kwe-spindle kwi-workpiece.

3. Iimpazamo zesixokelelwano sothumelo: Zinciphise

I-1) Ukuchaneka kokuhanjiswa kunye nenani leengxenye ziphezulu.

2) Umlinganiselo wothumelo uncinci xa isibini sothumelo sisondele ekupheleni.

I-3) Ukuchaneka kwesiqwenga sokuphela kufuneka sibe sikhulu kunezinye iindawo zokuhambisa.

4. Nciphisa iSixhobo sokunxiba

Izixhobo zokuhlaziya kwakhona ziyimfuneko ngaphambi kokuba zifike kwinqanaba lokunxiba kakhulu.

5. Ukunciphisa ukuguqulwa koxinzelelo kwinkqubo yenkqubo

Isuka ikakhulu:

1) Ukwandisa ukuqina kunye namandla enkqubo. Oku kubandakanya awona makhonkco abuthathaka enkqubo yenkqubo.

2) Nciphisa umthwalo kunye neenguqu zayo

Ukwandisa ukuqina kwenkqubo

1 Uyilo lwesakhiwo olufanelekileyo

I-1) Ngokusemandleni, ukunciphisa inani leendawo ezidibanisayo.

2) Ukuthintela amakhonkco asekuhlaleni okuqina okuphantsi;

3) Amacandelo asisiseko kunye nezinto ezixhasayo kufuneka zibe nesakhiwo esifanelekileyo kunye necandelo elinqamlezayo.

2 Phucula ukuqina koqhagamshelwano kumphezulu woqhagamshelwano

I-1) Ukuphucula umgangatho kunye nokuhambelana kweendawo ezidibanisa iinxalenye kunye nezixhobo zoomatshini.

2) Ukulayisha kwangaphambili izixhobo zesixhobo somatshini

I-3) Ukwandisa ukuchaneka kokubeka i-workpiece kunye nokunciphisa uburhabaxa bomhlaba.

3 Ukwamkela iindlela zokubethelela ezifanelekileyo kunye neendlela zokubeka

Ukunciphisa umthwalo kunye nemiphumo yawo

1 Khetha izixhobo zejometri iiparamitha kunye nobungakanani bokusika ukunciphisa amandla okusika.

2 Izikhewu ezirhabaxa kufuneka zidityaniswe kunye kwaye isibonelelo sokusebenza kufuneka sifane nohlengahlengiso.

6. I-thermal deformation yenkqubo yenkqubo ingancitshiswa

1 Yahlula imithombo yobushushu kwaye unciphise imveliso yobushushu

1) Sebenzisa inani elincinci lokusika;

2) Yahlula roughing kunye nokugqiba xaamacandelo okugayazifuna ukuchaneka okuphezulu.

I-3) Ngokusemandleni, yahlula umthombo wokushisa kunye nomatshini wokunciphisa ukuguqulwa kwe-thermal.

4) Ukuba imithombo yobushushu ayinako ukwahlulwa (njengeebheringi zokuphotha okanye izibini ze-screw nut), phucula iimpawu zokukhuhlana ukusuka kwisakhiwo, ukuthambisa kunye neminye imiba, ukunciphisa ukuveliswa kobushushu, okanye ukusebenzisa izinto zokukhusela ukushisa.

5) Sebenzisa ukupholisa umoya ngenkani okanye ukupholisa amanzi kunye nezinye iindlela zokuphelisa ubushushu.

2 Iqondo lobushushu elilinganayo

3 Yamkela imigangatho efanelekileyo yokudibanisa isixhobo somatshini kunye nesakhiwo

I-1) Ukwamkela i-thermal-symmetrical structure kwi-gearbox - i-shafts yokucwangcisa i-symmetrically, ii-bearings kunye ne-transmission gears inokunciphisa ukuguqulwa kwebhokisi ngokuqinisekisa ukuba ubushushu bodonga lwebhokisi bufana.

2) Khetha umgangatho wokuhlanganisa izixhobo zomatshini ngokunyamekela.

4 Ukukhawulezisa ibhalansi yokudlulisa ubushushu

5 Lawula ubushushu bendawo

7. Nciphisa uxinzelelo olushiyekileyo

1. Yongeza inkqubo yokushisa ukuphelisa uxinzelelo ngaphakathi komzimba;

2. Lungiselela inkqubo yakho ngendlela efanelekileyo.

4. Izizathu zempembelelo

1 Impazamo yomgaqo womatshini

Igama elithi "impazamo yomgaqo womatshini" libhekisa kwimpazamo eyenzekayo xa ukwenziwa komatshini kusenziwa kusetyenziswa iprofayili eqikelelweyo, okanye ubudlelwane bothumelo. Ukucutshungulwa kwemigangatho entsonkothileyo, imisonto kunye neegiya kunokubangela impazamo yomatshini.

Ukuze kube lula ukuyisebenzisa, endaweni yokusebenzisa i-worm esisiseko kwi-involute, isiseko se-Archimedean worm okanye isiseko seprofayili eqhelekileyo sisetyenziswa. Oku kubangela iimpazamo kwimilo yezinyo.

Xa ukhetha i-gear, ixabiso le-p lingaqikelelwa kuphela (p = 3.1415) kuba kukho inani elincinci lamazinyo kwi-lathe. Isixhobo esisetyenziselwa ukwenza i-workpiece (i-spiral motion), ayiyi kuchaneka. Oku kukhokelela kwimpazamo yesandi.

Ukucutshungulwa kudla ngokuqhutywa ngokucokisekileyo phantsi kwengcinga yokuba iimpazamo zethiyori zinokuncitshiswa ukuhlangabezana neemfuno zokuchaneka kokusebenza (i-10% -15% yokunyamezela kwimilinganiselo) ukwenzela ukwandisa imveliso kunye nokunciphisa iindleko.

2 impazamo yohlengahlengiso

Xa sisithi isixhobo somatshini sinokulungiswa okungalunganga, sithetha impazamo.

3 Impazamo yomatshini

Igama elithi impazamo yesixhobo somatshini lisetyenziselwa ukuchaza impazamo yokwenziwa, impazamo yofakelo, kunye nokunxitywa kwesixhobo. Oku kubandakanya ubukhulu becala iimpazamo zesikhokelo kunye nokujikeleziswa kukaloliwe wesixhobo somatshini kunye nempazamo yothumelo kwikhonkco lothumelo lwesixhobo somatshini.

Impazamo yesikhokelo somatshini

1. Kukuchaneka kwesikhokelo sikaloliwe wesikhokelo - umahluko phakathi kwesalathiso sokuhamba samalungu ashukumayo kunye nesikhokelo esifanelekileyo. Ibandakanya:

Isikhokelo silinganiswa ngokuthe tye kwe-Dy (indiza ethe tye) kunye ne-Dz (inqwelomoya ethe nkqo).

2 Ukuhambelana kweereyili zangaphambili nasemva (ukuphazamiseka);

(3) Iimpazamo ezithe nkqo okanye ezinxuseneyo phakathi kwe-spindle rotation kunye nesikhokelo sikaloliwe kuzo zombini iiplani ezithe tye nezithe nkqo.

2. Ukuchaneka kwesikhokelo sikaloliwe kunempembelelo enkulu ekugawulweni komatshini.

Oku kungenxa yokuba ithathela ingqalelo ukufuduswa okuzalanayo phakathi kwesixhobo kunye nomsebenzi obangelwa yimpazamo yesikhokelo sikaloliwe. Ukujika ngumsebenzi wokujika apho umkhomba-ndlela othe tye unempazamo. Iimpazamo zendlela ethe nkqo zinokungahoywa. Isalathiso sokujikeleza sitshintsha indlela isixhobo esinovakalelo lwempazamo. Isalathiso esithe nkqo lelona cala linobuntununtunu kwiimpazamo xa ucwangcisa. Ukuchaneka kwezikhokelo zokulala kwinqwelo-moya ethe nkqo imisela ukuchaneka kwe-flatness kunye nokuthe tye kweendawo ezinomatshini.

Impazamo yokujikeleza isixhobo somatshini womatshini

Impazamo yokujikeleziswa kwe-spindle ngumahluko phakathi kwe-axis eyiyo kunye nefanelekileyo yokujikeleza. Oku kuquka i-spindle face circular, spindle circular radial kunye ne-spindle angle tilt.

I-1, Impembelelo ye-spindle runout setyhula ekuqhubeni ukuchaneka.

① Akukho mpembelelo kunyango lomphezulu wecylindrical

② Iya kubangela i-perpendicularity okanye impazamo ye-flatness phakathi kwe-cylindrical axis kunye ne-endface xa ijika kwaye ibhonqa.

③ Impazamo yomjikelezo wepitch yenziwa xa imisonto isenziwa ngoomatshini.

2. Iimpembelelo zeradial spindle zisebenza ngokuchaneka:

① Impazamo engqukuva yesangqa seradial ilinganiswa nge-ruout amplitude yomngxuma.

② I-radius yesangqa ingabalwa ukusuka kwincam yesixhobo ukuya kwi-shaft avareji, kungakhathaliseki ukuba i-shaft iyaguqulwa okanye idikwe.

3. Impembelelo ye-engile yokuthambeka kwe-axis yejiyometri yeshaft engundoqo ekuchanekeni komatshini.

① I-axis yejiyometri icwangciswe ngendlela yeconical kunye ne-cone angle, ehambelana nentshukumo ye-eccentric ejikeleze i-axis ye-geometrical axis xa ijongwa kwicandelo ngalinye. Eli xabiso le-eccentric liyahluka kumbono we-axial.

② I-axis yijiyometri ejikelezayo kwinqwelomoya. Oku kuyafana ne-axis yokwenyani, kodwa ihamba kwinqwelomoya kumgca othe ngqo we-harmonic.

③ Ngokwenyani, i-engile ye-axis yejiyometri yeshaft engundoqo imele indibaniselwano yezi ntlobo zimbini zokujingi.

Imposiso yothumelo lwekhonkco lothumelo lwezixhobo zoomatshini

Impazamo yothumelo ngumahluko kwintshukumo ehambelanayo phakathi kwento yokuqala yothumelo kunye neyokugqibela yothumelo lwekhonkco lothumelo.

④ Impazamo yokwenziwa kwemveliso kunye nokuguga kwi-fixture

Impazamo ephambili kwi-fixture yile: 1) impazamo yokwenziwa kwento yokubeka indawo kunye nezixhobo zokukhokela izixhobo, kunye ne-indexing mechanism kunye ne-clamping concrete. 2) Emva kokudityaniswa koluhlu, impazamo yobungakanani bobungakanani phakathi kwala macandelo ahlukeneyo. 3) Nxiba phezu kwendawo yokusebenza ebangelwa yi-fixture. Umxholo we-Metal Processing Wechat ugqwesileyo, kwaye ufanelekile ukuqwalaselwa kwakho.

⑤ iimpazamo zokwenziwa kunye nokunxitywa kwezixhobo

Iindidi ezahlukeneyo zezixhobo zineempembelelo ezahlukeneyo ekuchanekeni komatshini.

I-1) Ukuchaneka kwezixhobo ezinemilinganiselo emiselweyo (ezifana ne-drills, i-reamers, i-keyway milling cuts, i-broaches ejikelezayo, njl.). Ukuchaneka kwe-dimensional kuchatshazelwa ngokuthe ngqo yi-workpiece.

2) Ukuchaneka kwesixhobo sokubumba (ezifana nezixhobo zokuguqula, izixhobo zokugaya, amavili okugaya, njl.), Kuya kuchaphazela ngokuthe ngqo ukuchaneka kwemilo. Ukuchaneka kobume be-workpiece kuchaphazeleka ngokuthe ngqo kukuchaneka kwemilo.

3) Impazamo yemilo kwincakuba yesisiki ephuhlisiwe (ezifana nehobs yegiya, i-spline hobos, ii-gear shaper cutters, njl. njl.). Ukuchaneka kobume bomphezulu kuya kuchaphazeleka ngempazamo ye-blade.

4) Ukuchaneka kokuveliswa kwesixhobo akuchaphazeli ngokuthe ngqo ukuchaneka kwayo. Nangona kunjalo, kulula ukuyisebenzisa.

⑥ Inkqubo yokuguqulwa koxinzelelo lwenkqubo

Phantsi kweempembelelo zamandla okubamba kunye nomxhuzulane, inkqubo iya konakala. Oku kuya kukhokelela kwiimpazamo zokucubungula kwaye kuya kuchaphazela uzinzo. Iingcamango eziphambili kukuguqulwa kwezixhobo zoomatshini, ukuguqulwa kwezinto zokusebenza kunye ne-deformation epheleleyo yenkqubo yokucubungula.

Ukusika amandla kunye nokuchaneka komatshini

Impazamo ye-cylindricity yenziwa xa inxalenye yomatshini ingqindilili phakathi kwaye incinci ekupheleni, ngokusekelwe kwi-deformation ebangelwa ngumatshini. Ukucutshungulwa kwamacandelo e-shaft, kuphela i-deformation kunye noxinzelelo lwe-workpiece iqwalaselwa. Iworkpiece ibonakala ingqindilili embindini kwaye ibhityile ekupheleni. Ukuba deformation kuphela ukuba kuthathelwa ingqalelo ukusetyenzwa kwecnc shaft machining iindawoyi-deformation okanye isixhobo somatshini, ngoko ke imilo ye-workpiece emva kokucubungula iya kuba ngokuchasene neendawo ezicutshungulwayo zeshaft.

Isiphumo sokunyanzelisa amandla ekuchanekeni komatshini

I-workpiece iya konakala xa ibambekile ngenxa yokuqina kwayo okuphantsi okanye amandla okubamba ngokungafanelekanga. Oku kukhokelela kwimpazamo yoqhubekeko.

⑦ Ukuguqulwa kwe-thermal kwiinkqubo zenkqubo

Inkqubo yenkqubo iba shushu kwaye ikhubazeke ngexesha lokulungiswa ngenxa yobushushu obuveliswa ngumthombo wobushushu wangaphandle okanye umthombo wobushushu wangaphakathi. I-Thermal deformation inoxanduva lwe-40-70% yeempazamo ze-machining kwi-workpiece enkulu kunye nokuchaneka kwe-machining.

Kukho iintlobo ezimbini ze-thermal deformation ye-workpiece enokuthi ichaphazele ukusetyenzwa kwegolide: ukufudumeza okufanayo kunye nokufudumala okungalinganiyo.

⑧ Ukuxinezeleka okushiyekileyo ngaphakathi kwiNdawo yokuSebenza

Ukuveliswa koxinzelelo kwimeko yentsalela:

1) Uxinzelelo olushiyekileyo oluveliswa ngexesha lokunyanga ubushushu kunye nenkqubo yokuvelisa i-embryo;

2) Ukulungiswa okubandayo kweenwele kunokubangela uxinzelelo olushiyekileyo.

I-3) Ukusika kunokubangela uxinzelelo oluseleyo.

⑨ Ukusetyenzwa kwempembelelo yokusingqongileyo kwindawo

Ngokuqhelekileyo kukho ezininzi iincinci ezincinci zetsimbi kwindawo yokucubungula. Ezi chips zetsimbi ziya kuba nefuthe ekuchanekeni komatshini inxalenye ukuba zibekwe kufuphi nendawo yomngxuma okanye umphezulu womhlaba.iindawo eziguqukayo. Iitshiphusi zetsimbi ezincinci kakhulu ukuba zingabonwa ziya kuba nefuthe ekuchanekeni kokulungiswa okuphezulu. Kuyaziwa ukuba le mpembelelo inokuba yingxaki, kodwa kunzima ukuyisusa. Ubuchule bomsebenzisi bukwangunobangela ophambili.

Eyona njongo iphambili ye-Anebon iya kuba kukukunika abathengi bethu ubudlelwane obunobuzaza nobunoxanduva lweshishini, ukunika ingqwalasela yomntu kubo bonke kuYilo lweFashion entsha yeOEM Shenzhen Precision Hardware Factory Custom Fabrication CNC process, precision casting, prototyping service. Ungafumana elona xabiso lisezantsi apha. Kwakhona uya kufumana iimveliso ezisemgangathweni kunye nezisombululo kunye nenkonzo emangalisayo apha! Akufanele ube madolw' anzima ukubamba iAnebon!

Uyilo olutsha lweFashion ye-China CNC Machining Service kunye neSikoInkonzo yoMatshini ye-CNC, I-Anebon inamanani amaqonga orhwebo angaphandle, ayi-Alibaba,i-Globalsources,i-Global Market,Made-in-china. "XinGuangYang" Imveliso ye-HID brand kunye nezisombululo zithengisa kakuhle kakhulu eYurophu, eMelika, kuMbindi Mpuma nakweminye imimandla kumazwe angaphezu kwama-30.

Ukuba ufuna ukucaphula iindawo ezenziwe ngoomatshini, nceda uzive ukhululekile ukuthumela imizobo kwi-imeyile esemthethweni yase-Anebon: info@anebon.com

Ixesha lokuposa: Dec-20-2023