Ukubaluleka kokusetyenziswa kwezixhobo zokulinganisa kwi-CNC machining

Ukuchaneka nokuchaneka:

Izixhobo zokulinganisa zenza ukuba oomatshini bafikelele kwimilinganiselo echanekileyo kunye nechanekileyo yeendawo ezenziweyo. Oomatshini be-CNC basebenza ngokusekelwe kwimiyalelo echanekileyo, kwaye nakuphi na ukungafani kwimilinganiselo kunokubangela ukuba kubekho iindawo eziphosakeleyo okanye ezingasebenziyo. Izixhobo zokulinganisa ezifana ne-calipers, i-micrometers, kunye neegeji zinceda ukuqinisekisa nokugcina imilinganiselo efunekayo, ukuqinisekisa ukuchaneka okuphezulu kwinkqubo yomatshini.

Ukuqinisekisa umgangatho:

Izixhobo zokulinganisa zibalulekile kulawulo lomgangatho kwi-CNC machining. Ngokusebenzisa izixhobo zokulinganisa, oomatshini banokuhlola iindawo ezigqityiweyo, bathelekise ngokuchasene nokunyamezela okuchaziweyo, kwaye bachonge nakuphi na ukuphambuka okanye iziphene. Oku kuvumela uhlengahlengiso olungexesha okanye ulungiso ukuba lwenziwe, ukuqinisekisa ukuba iimveliso zokugqibela ziyahlangabezana nemigangatho yomgangatho ofunekayo.

Ukuseta isixhobo kunye noLungelelwaniso:

Izixhobo zokulinganisa zisetyenziselwa ukuseta kunye nokulungelelanisa izixhobo zokusika, izixhobo zokusebenza, kunye nokulungiswa koomatshini be-CNC. Ukulungelelaniswa okufanelekileyo kubalulekile ukuthintela iimpazamo, ukunciphisa ukunxiba kwesixhobo, kunye nokwandisa ukusebenza kakuhle komatshini. Izixhobo zokulinganisa ezifana ne-edge finders, izikhombisi zokudayela, kunye neegeji zobude zinceda ekubekeni ngokuchanekileyo kunye nokulungelelanisa amacandelo, ukuqinisekisa iimeko ezifanelekileyo zomatshini.

UPhuculo lweNkqubo:

Izixhobo zokulinganisa zikwaququzelela ukuphuculwa kwenkqubo kumatshini weCNC. Ngokulinganisa imilinganiselo yamacandelo omatshini kumanqanaba ahlukeneyo, oomatshini banokubeka iliso kwaye bahlalutye inkqubo yomatshini. Le datha inceda ukuchonga imiba enokubakho, njengokunxiba kwesixhobo, ukuguqulwa kwezinto, okanye ukulungelelaniswa komatshini, ukuvumela ulungelelwaniso lwenziwe ukuze kuphuculwe inkqubo yokuvelisa kunye nokuphucula ukusebenza kakuhle.

Ukungqinelana kunye nokuTshintsho:

Izixhobo zokulinganisa zinegalelo ekufezekiseni ukuhambelana nokutshintshiselana kweiindawo zoomatshini ze-cnc. Ngokulinganisa ngokuchanekileyo kunye nokugcina ukunyamezelana okuqinileyo, oomatshini baqinisekisa ukuba iinxalenye eziveliswe koomatshini abahlukeneyo okanye ngamaxesha ahlukeneyo ziyatshintshana kwaye zisebenza njengoko kucetywayo. Oku kubalulekile kumashishini apho ukuchaneka kunye nezinto ezisemgangathweni ziyimfuneko, ezifana ne-aerospace, icandelo leemoto kunye nezonyango.

Ukuhlelwa kwezixhobo zokulinganisa

Isahluko 1 Umlawuli weNsimbi, iiCalipers zangaphakathi nangaphandle kunye neFeeler Gauge

1. Irula yentsimbi

Umlawuli wensimbi yisixhobo esilula sokulinganisa ubude, kwaye ubude baso buneenkcukacha ezine: 150, 300, 500 kunye ne-1000 mm. Umfanekiso ongezantsi usetyenziswa ngokuqhelekileyo irula yentsimbi eyi-150 mm.

Umlawuli wensimbi osetyenziselwa ukulinganisa ubude bobude benxalenye ayichanekanga kakhulu. Oku kungenxa yokuba umgama phakathi kwemigca yokumakisha yomlawuli wensimbi ngu-1mm, kwaye ububanzi bomgca wokumakisha ngokwawo ngu-0.1-0.2mm, ngoko ke impazamo yokufunda inkulu ngexesha lokulinganisa, kwaye i-millimeters kuphela inokufundwa, oko kukuthi, ubuncinane bexabiso layo lokufunda yi-1mm. Amaxabiso angaphantsi kwe-1mm anokuqikelelwa kuphela.

Ukuba ubungakanani ubukhulu (shaft ububanzi okanye umngxuma ububanzi) yeiindawo zokugaya ze-cncilinganiswa ngokuthe ngqo ngerula yentsimbi, ukuchaneka komlinganiselo kubi nakakhulu. Isizathu sayo kukuba: ngaphandle kokuba impazamo yokufunda yerula yentsimbi ngokwayo inkulu, nangenxa yokuba irula yentsimbi ayinakubekwa nje kwindawo echanekileyo yobubanzi benxalenye. Ngoko ke, ukulinganiswa kobubanzi becandelo kunokuqhutyelwa ngokusebenzisa irula yensimbi kunye ne-caliper yangaphakathi nangaphandle.

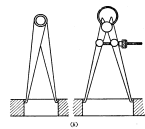

2. Iicaliper zangaphakathi nangaphandle

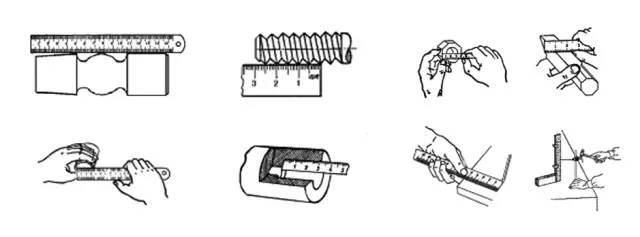

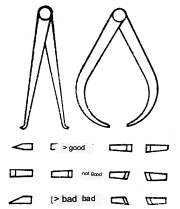

Umfanekiso ongezantsi ubonisa ii-calipers ezimbini eziqhelekileyo zangaphakathi nangaphandle. Iicalipers zangaphakathi nangaphandle zezona zilula zokuthelekisa igeji. I-caliper yangaphandle isetyenziselwa ukulinganisa i-diameter yangaphandle kunye ne-flat surface, kwaye i-caliper yangaphakathi isetyenziselwa ukulinganisa i-diameter yangaphakathi kunye ne-groove. Bona ngokwabo abakwazi ukufunda ngokuthe ngqo iziphumo zokulinganisa, kodwa bafunde imilinganiselo yobude obulinganisiweyo (i-diameter ibuye ibe yobude bobude) kwirula yentsimbi, okanye isuse ubungakanani obufunekayo kwirula yentsimbi kuqala, kwaye emva koko uhlolisisecnc ukuguqula iindawoNokuba i-diameter ye.

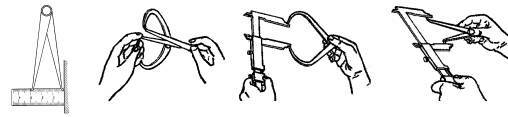

1. Ukulungelelaniswa kokuvula i-caliper Khangela imilo ye-caliper kuqala. Ubume be-caliper bunempembelelo enkulu ekuchanekeni kokulinganisa, kwaye ingqalelo kufuneka ihlawulwe ngokuphindaphindiweyo ukuguqula imilo ye-caliper. Umfanekiso ongezantsi ubonisa i-caliper

Umahluko phakathi kokumila kwemihlathi okulungileyo nokubi.

Xa ulungelelanisa ukuvulwa kwe-caliper, cofa kancinci amacala amabini onyawo lwe-caliper. Okokuqala sebenzisa izandla zozibini ukulungisa i-caliper kwindawo yokuvula efana nobukhulu be-workpiece, emva koko ucofe umphandle we-caliper ukunciphisa ukuvuleka kwe-caliper, kwaye ucofe ngaphakathi kwe-caliper ukwandisa ukuvuleka kwe-caliper. Njengoko kubonisiwe kuMfanekiso 1 ngezantsi. Nangona kunjalo, imihlathi ayikwazi ukubetha ngokuthe ngqo, njengoko kuboniswe kuMfanekiso 2 ngezantsi. Oku kunokubangela iimpazamo zokulinganisa ngenxa yemihlathi ye-caliper eyonakalisa ubuso bokulinganisa. Musa ukubetha i-caliper kumzila wesikhokelo wesixhobo somatshini. Njengoko kubonisiwe kuMfanekiso 3 ngezantsi.

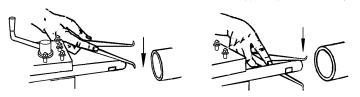

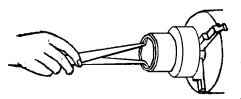

2. Ukusetyenziswa kwe-caliper yangaphandle Xa i-caliper yangaphandle isusa ubungakanani kwirula yensimbi, njengoko kuboniswe kumfanekiso ongezantsi, umgangatho wokulinganisa we-pliers foot foot uchasene nesiphelo somlawuli wensimbi, kunye nomgangatho wokulinganisa omnye. unyawo lwe-caliper luhambelana nomgca wokumakisha ubukhulu obufunekayo Embindini weziko, kwaye umgca wokudibanisa weendawo ezimbini zokulinganisa kufuneka uhambelane nomlawuli wensimbi, kunye nomgca wokubona umntu kufuneka perpendicular irula steel.

Xa ulinganisa i-diameter yangaphandle kunye ne-caliper yangaphandle eye yalinganiswa kwirula yensimbi, yenza umgca wemigangatho emibini yokulinganisa i-perpendicular kwi-axis yecandelo. Xa i-caliper yangaphandle isilayidi phezu kwesangqa sangaphandle senxalenye ngobunzima bayo, imvakalelo ezandleni zethu kufuneka ibe yinto yoqhagamshelwano phakathi kwecaliper yangaphandle kunye nesangqa sangaphandle senxalenye. Ngeli xesha, umgama phakathi kweendawo ezimbini zokulinganisa i-caliper yangaphandle yi-diameter yangaphandle yecandelo elilinganisiweyo.

Ngoko ke, ukulinganisa i-diameter yangaphandle kunye ne-caliper yangaphandle kukuthelekisa ukuqina koqhagamshelwano phakathi kwe-caliper yangaphandle kunye nesangqa sangaphandle senxalenye. Njengoko kubonisiwe kumzobo ongezantsi, kuyafaneleka ukuba ubunzima be-self-caliper bunokuthi bushelele phantsi. Ngokomzekelo, xa i-caliper isilayidi phezu kwesangqa sangaphandle, akukho mvakalelo yoqhagamshelwano ezandleni zethu, oko kuthetha ukuba i-caliper yangaphandle inkulu kunobubanzi obungaphandle becala. Ukuba i-caliper yangaphandle ayikwazi ukutyibilika phezu kwesangqa sangaphandle senxalenye ngenxa yobunzima bayo, oko kuthetha ukuba i-caliper yangaphandle incinci kunobubanzi obungaphandle bendawo.cnc machining amalungu metal.

Ungalokothi ubeke i-caliper kwi-workpiece e-oblique yokulinganisa, njengoko kuya kubakho iimpazamo. Njengoko kubonisiwe ngezantsi. Ngenxa yokuqina kwe-caliper, akulunganga ukunyanzela i-caliper yangaphandle kwisangqa sangaphandle, singasathethi ke ngokutyhala i-caliper ngokuthe tye, njengoko kubonisiwe kulo mfanekiso ungezantsi. Kwi-caliper yangaphandle yobungakanani obukhulu, uxinzelelo lomlinganiselo wokutyibilika kwisangqa sangaphandle senxalenye ngobunzima bayo sele siphezulu kakhulu. Ngeli xesha, i-caliper kufuneka ibanjwe ukulinganisa, njengoko kuboniswe kumzobo ongezantsi.

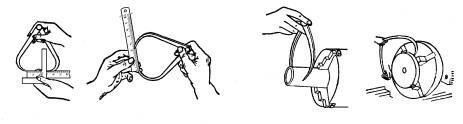

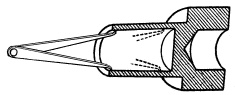

3. Ukusetyenziswa kwee-calipers zangaphakathi Xa ulinganisa i-diameter yangaphakathi kunye neecalipers zangaphakathi, umgca wemigangatho yokulinganisa ye-pincers ezimbini kufuneka ube yi-perpendicular kwi-axis yomngxuma wangaphakathi, oko kukuthi, imigangatho emibini yokulinganisa ye-pincers Iziphelo ezimbini zobubanzi bomngxuma ongaphakathi. Ngoko ke, xa ulinganisa, umgangatho wokulinganisa we-pincer ephantsi kufuneka umiswe eludongeni lomngxuma njenge-fulcrum.

Iinyawo zecaliper ephezulu zivavanywa ngokuthe ngcembe ngaphandle ukusuka emngxunyeni ukuya ngaphakathi kancinane, kwaye zijinga kwicala elijikelezayo lodonga lomngxuma. Xa umgama onokuthi ujiwulwe kwicala le-circumferential yodonga lomngxuma ungowona mncinane, oko kuthetha ukuba imigangatho emibini yokulinganisa yeenyawo ze-caliper yangaphakathi ikwimo ephakathi. Iziphelo ezimbini zombhobho wedayamitha. Emva koko susa i-caliper ngokucothayo ukusuka ngaphandle ukuya ngaphakathi ukujonga ukunyamezelwa kokungqukuva komngxuma.

Sebenzisa i-caliper yangaphakathi eye yalinganiswa kwirula yentsimbi okanye kwi-caliper yangaphandle ukulinganisa i-diameter yangaphakathi.

Kukuthelekisa ukuqina kwecaliper yangaphakathi kumngxuma wenxalenye. Ukuba i-caliper yangaphakathi ine-swing enkulu yamahhala emngxunyeni, kuthetha ukuba ubukhulu be-caliper buncinci kunobubanzi bomngxuma; ukuba i-caliper yangaphakathi ayikwazi ukufakwa emngxunyeni, okanye igxininise kakhulu ukuguqula ngokukhululekileyo emva kokufakwa emngxunyeni, kuthetha ukuba ubukhulu be-caliper yangaphakathi buncinci kunobubanzi bomngxuma.

Ukuba likhulu kakhulu, ukuba i-caliper yangaphakathi ifakwe emngxunyeni, kuya kubakho umgama wokuguquka wamahhala we-1 ukuya kwi-2 mm ngokwendlela yokulinganisa ingentla, kwaye ububanzi bomngxuma bulingana ngqo nobukhulu be-caliper yangaphakathi. Musa ukubamba i-caliper ngezandla zakho xa ulinganisa.

Ngale ndlela, imvakalelo yesandla iphelile, kwaye kunzima ukuthelekisa iqondo lokuqina kwecaliper yangaphakathi emngxunyeni wenxalenye, kwaye i-caliper iya kukhubazeka ukuze ibangele iimpazamo zokulinganisa.

4. Umda osebenzayo we-caliper Caliper sisixhobo sokulinganisa esilula. Ngenxa yesakhiwo sayo esilula, ukuveliswa okufanelekileyo, ixabiso eliphantsi, ukugcinwa okufanelekileyo kunye nokusetyenziswa, isetyenziswa ngokubanzi kumlinganiselo kunye nokuhlolwa kweendawo ezineemfuno eziphantsi, ngakumbi ukukhwabanisa kweeCalipers zezona zixhobo ezifanelekileyo zokulinganisa ukulinganisa kunye nokuhlolwa kokuphosa okungenanto. imilinganiselo. Nangona i-caliper sisixhobo esilula sokulinganisa, nje ngokuba

Ukuba siyiqonda kakuhle, sinokufumana ukuchaneka okuphezulu komlinganiselo. Umzekelo, ukusebenzisa ii-calipers zangaphandle ukuthelekisa ezimbini

Xa i-diameter ye-root shaft inkulu, umahluko phakathi kwe-shaft diameters yi-0.01mm kuphela.

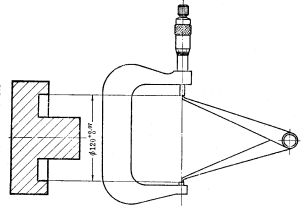

Iinkosi ezinamavanako ukwahlulwa. Omnye umzekelo xa usebenzisa i-caliper yangaphakathi kunye ne-diameter yangaphandle ye-micrometer ukulinganisa ubungakanani bomngxuma wangaphakathi, iinkosi ezinamava ziqinisekile ukuba zisebenzise le ndlela ukulinganisa umngxuma wangaphakathi ochanekileyo. Le ndlela yokulinganisa i-diameter yangaphakathi, ebizwa ngokuba yi-"inner snap micrometer", kukusebenzisa i-inner caliper ukufunda ubungakanani obuchanekileyo kwi-diameter yangaphandle ye-micrometer.

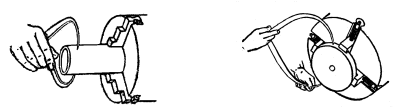

Uze ulinganise i-diameter yangaphakathi yecala; okanye uhlengahlengise iqondo lokuqina ekudibaneni nomngxuma kunye nekhadi elingaphakathi emngxunyeni, uze ufunde ubungakanani obuthile kwi-micrometer yedayamitha yangaphandle. Le ndlela yokulinganisa ayiyona nje indlela efanelekileyo yokulinganisa i-diameter yangaphakathi xa kukho ukunqongophala kwezixhobo ezichanekileyo zokulinganisa i-diameter yangaphakathi, kodwa kwakhona, kwi-diameter yangaphakathi yendawo ethile, njengoko kubonisiwe kuMfanekiso 1-9, kuba kukho i-diameter yangaphakathi. shaft emngxunyeni wayo, kuyimfuneko ukusebenzisa isixhobo sokulinganisa ngokuchanekileyo. Ukuba kunzima ukulinganisa i-diameter yangaphakathi, indlela yokulinganisa i-diameter yangaphakathi kunye ne-caliper yangaphakathi kunye ne-micrometer yangaphandle ye-diameter inokusombulula ingxaki.

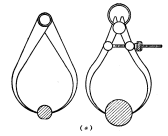

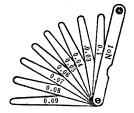

3. Igeyiji yokuvalelwa

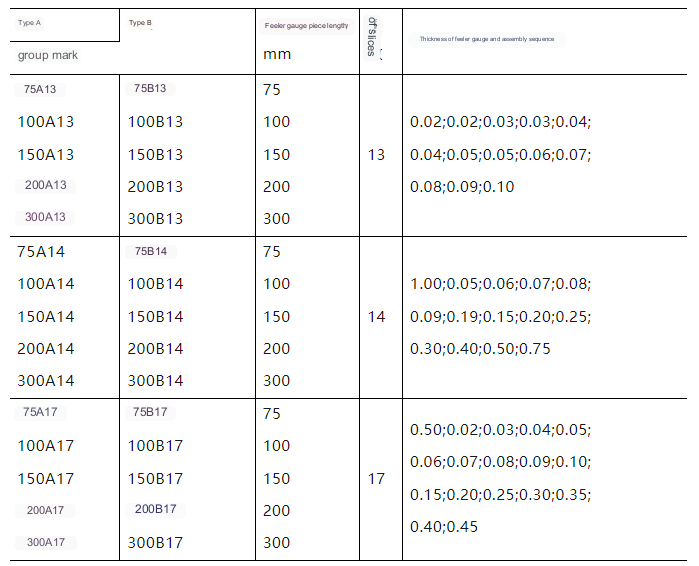

Igeyiji yefeeler ikwabizwa ngokuba yigeyiji yobukhulu okanye iqhekeza lesikhewu. Isetyenziselwa ukuvavanya indawo ekhethekileyo yokudibanisa kunye nomgangatho wokuqina wesixhobo somatshini, ipiston kunye nesilinda, i-piston ring groove kunye neringi yepiston, ipleyiti yesilayidi enqamlezayo kunye nepleyiti yesikhokelo, umphezulu wokungena kunye nevalve yokukhupha. kunye nengalo yeroki, kunye nesithuba phakathi kwemida emibini edibeneyo yegiya. ubungakanani besithuba. Igeyiji yokulinganisa yenziwe ngamacwecwe amaninzi entsimbi anobunzima obahlukeneyo.

Ngokweqela leegeyiji zokuziva, igeyiji nganye nganye iyenziwa, kwaye isiqwenga ngasinye segeyiji yokuziva sineenqwelo-moya ezimbini ezinxuseneyo zokulinganisa, kwaye zinamanqaku angqindilili okusetyenziswa ngokudibeneyo. Xa ulinganisa, ngokobukhulu besithuba somphezulu odibeneyo, enye okanye iziqwenga ezininzi zihlanganiswe kunye kwaye zifakwe kwi-gap. Umzekelo, phakathi kwe-0.03mm kunye ne-0.04mm, igeyiji ye-feeler ikwayigeji yomda. Jonga iTheyibhile 1-1 malunga neenkcukacha zegeyiji yokuziva.

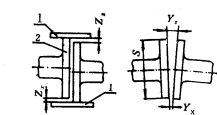

Kukuchongwa kokubeka i-injini engundoqo kunye ne-shafting flange. Qhoboshela irula kwigeyiji ye-m feeler kumgca ocacileyo wesangqa sangaphandle seflange esekwe kwishafti yokutyhala ye-shafting okanye i-shaft yokuqala ephakathi, kwaye usebenzise igeyiji yokulinganisa ukulinganisa irula kwaye uyidibanise. Izithuba ze-ZX kunye ne-ZS zesangqa sangaphandle se-crankshaft ye-injini ye-diesel okanye i-shaft ephumayo yesinciphisi ilinganiswa kwiindawo ezine eziphezulu, ezisezantsi, ekhohlo nasekunene zesangqa sangaphandle se-flange ngokulandelelana. Lo mzobo ungezantsi kukuvavanya umsantsa (<0.04m) we-fastening surface ye-tailstock yesixhobo somatshini.

Xa usebenzisa igeyiji yokuziva, kufuneka kuqwalaselwe la manqaku alandelayo:

1. Khetha inani lamaqhekeza egeyiji ngokwesikhewu somphezulu odibeneyo, kodwa elimbalwa inani lamaqhekeza, kokukhona kungcono;

2. Musa ukusebenzisa amandla amaninzi xa ulinganisa, ukwenzela ukuba ungagobi kwaye ungaphuli igeyiji yokuziva;

3. Izixhobo zokusebenza ezinokushisa okuphezulu azikwazi ukulinganiswa.

Eyona njongo iphambili ye-Anebon iya kuba kukukunika abathengi bethu ubudlelwane obunzulu noboxanduva lweshishini, ukubonelela ngengqwalasela yomntu kubo bonke kuYilo lweFashion entsha ye-OEM Shenzhen Precision Hardware Factory Custom Fabrication CNC process, precision casting, prototyping service. Ungafumana elona xabiso lisezantsi apha. Kwakhona uya kufumana iimveliso ezisemgangathweni kunye nezisombululo kunye nenkonzo emangalisayo apha! Akufanele ube madolw' anzima ukubamba iAnebon!

Uyilo olutsha lweFashoni ye-CNC yeNkonzo yokuMachining yaseTshayina kunye neNkonzo yokuLungisa i-CNC yesiNtu, i-Anebon inamanani amaqonga orhwebo angaphandle, ayi-Alibaba, i-Globalsources, i-Global Market, i-Made-in-china. "XinGuangYang" Imveliso ye-HID brand kunye nezisombululo zithengisa kakuhle kakhulu eYurophu, eMelika, kuMbindi Mpuma nakweminye imimandla kumazwe angaphezu kwama-30.

Ixesha lokuposa: Jun-28-2023