Kutheni le nto kufuneka sikhuphe iimveliso ezilungisiweyo?

Ukhuseleko:

I-Burrs inokudala imiphetho ebukhali kunye neeprotrusions, ezinokubeka umngcipheko kubasebenzi kunye nabasebenzisi bokugqibela.

Umgangatho:

Ngokususa ii-burrs, unokuphucula umgangatho kunye nenkangeleko yemveliso yakho.

Ukusebenza:

IiBurrs zinokuchaphazela ukusebenza kwamacandelo kunye nojongano lwazo namanye amalungu.

Ukuthotyelwa koMgaqo

Amashishini athile anemimiselo engqongqo malunga namanqanaba okunyamezela i-burr ukuze kuqinisekiswe ukusebenza kwemveliso kunye nokhuseleko.

Ukudibanisa kunye nokuphatha

Iimveliso ezichithwayo zenza kube lula ukuphatha kunye nokudibanisa, okunciphisa umngcipheko womonakalo.

IiBurrs zihlala ziveliswa ngexesha lenkqubo yokusika isinyithi. I-Burrs inokunciphisa ukuchaneka kokulungiswa kunye nomgangatho ongaphezulu we-workpiece. Zikwachaphazela nokusebenza kwemveliso kwaye, kwezinye iimeko, zibangela iingozi. Ukukhupha imali ngokuqhelekileyo kusetyenziselwa ukusombulula umba we-burr. Ukuchithwa kwemali akuyona inkqubo enemveliso. Ukuchithwa kwemali yinkqubo engenzi mveliso. Yandisa iindleko, yandisa imijikelo yemveliso kwaye inokukhokelela ekuyilahleni yonke imveliso.

Iqela le-Anebon lihlalutye kwaye lichaze izinto ezichaphazela ukubunjwa kwee-milling burrs. Baphinde baxoxa ngeendlela kunye nobuchwepheshe obukhoyo bokunciphisa i-milling burrs kunye nokulawula, ukusuka kwinqanaba loyilo lwesakhiwo ukuya kwinkqubo yokuvelisa.

1. Ukuphelisa i-burrs yokugaya: iintlobo eziphambili

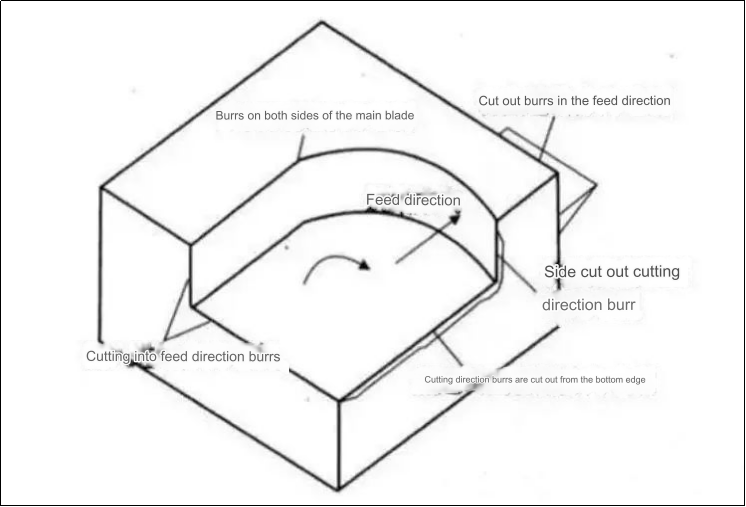

Ngokwenkqubo yokuhlelwa kwee-burrs ngokusekwe kwintshukumo yokusika kunye nesixhobo sokusika, ii-burrs eziphambili ezenziwa ngexesha lokusila zibandakanya ii-burrs zombini kumacala omgangatho ophambili, ii-burrs ecaleni kwicala lokusika, ii-burrs ecaleni kwezantsi. kwicala lokusika, kwaye usike ngaphakathi nangaphandle kweefedi. Zintlanu iintlobo zeebhura ezikhomba indlela.

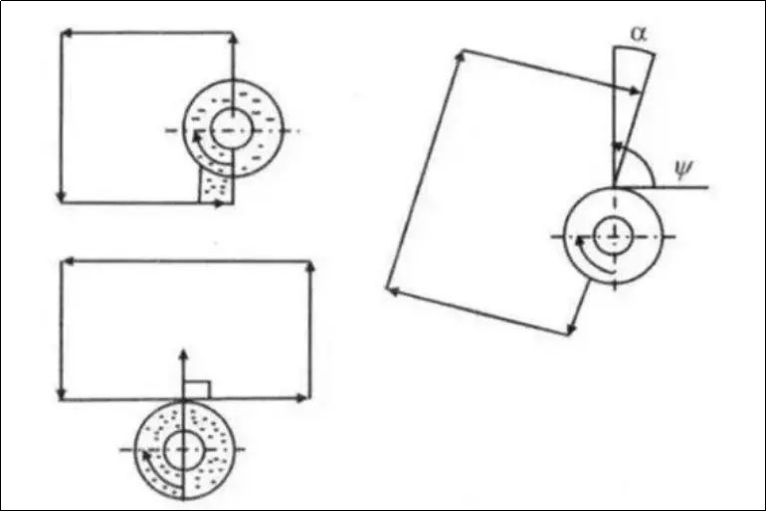

Umzobo 1 IiBurrs ezenziwe ngokusila ekupheleni

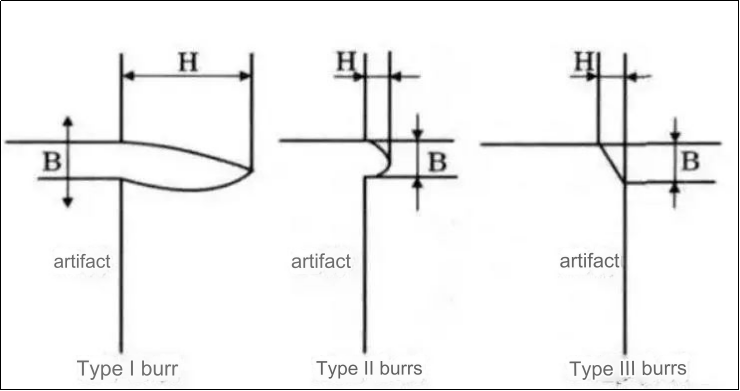

Ngokubanzi, ubukhulu beebhula ezikwicala lokusika kumda ongezantsi bukhulu kwaye kunzima kakhulu ukususa. Eli phepha ligxininise kwii-burrs ezisezantsi ezikwiindlela zokusika. Ubungakanani kunye nokumila kungahlelwa kwiintlobo ezintathu ezahlukeneyo ze-burrs ezifumaneka kwi-end milling cutting direction. Uhlobo lwe-I burrs lunokuba nzima ukususa kwaye lubiza kakhulu, uhlobo lwe-II burrs lunokususwa ngokulula, kwaye uhlobo lwe-III burrs lunokuba lubi (njengoko kubonisiwe kumfanekiso wesi-2).

Umzobo 2 Iintlobo zeBurrs kwicala lokusila.

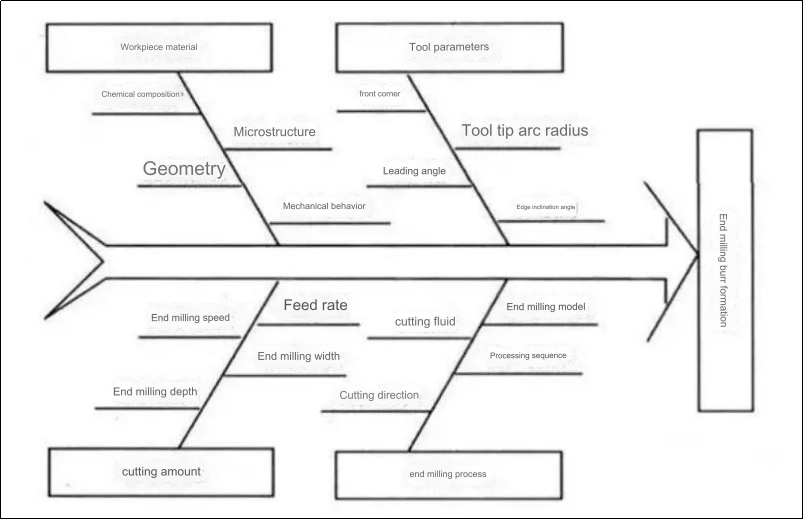

2. Izinto eziphambili ezichaphazela ukubunjwa kwee-burrs kwi-end milling machines

Ukwakhiwa kweBurr yinkqubo enzima yokuguqulwa kwezinto. Ukubunjwa kwe-burrs kuchatshazelwa yizinto ezininzi, kubandakanywa iimpawu eziphathekayo ze-workpiece, ijometri yayo, unyango olungaphezulu, ijometri yesixhobo kunye nendlela yokusika, ukunxiba izixhobo, iiparamitha zokusika, ukusetyenziswa kwe-coolant, njl. ibonisa izinto ezichaphazela isiphelo milling burrs. Imilo kunye nobungakanani ekupheleni millings burrs ixhomekeke kwisiphumo cumulative leempembelelo ezahlukeneyo phantsi kweemeko ezithile lokusila. Nangona kunjalo, izinto ezahlukeneyo zineempembelelo ezahlukeneyo ekubunjweni kwe-burr.

Umzobo 3: Itshathi yeMbangela kunye neMpembelelo yeMilling Burr Formation

1. Ukungena/ukuphuma kwesixhobo

I-burrs eveliswayo xa isixhobo sijikeleza kude ne-workpiece ithande ukuba nkulu kunezo zenziwe xa zijikeleza ngaphakathi.

2. Susa i-angle kwinqwelomoya

Ii-angles ezisikiweyo zendiza zinempembelelo enkulu kwi-burrs yokwakheka ecaleni komphetho ongezantsi. Xa umphetho wokusika ujikeleza kude kumphezulu wesiphelo somphezulu womsebenzi kwinqwelomoya, udlula kwindawo ethile perpendicular i-axis yokusila ngelo xesha, indibaniselwano yevektha yesixhobo sokuhamba kunye nesantya sokutya ilingana ne-engile phakathi kolwalathiso lobuso besiphelo se-engile. umsebenzi. Isiphelo sobuso bomsebenzi sibaleka ukusuka kwisikrufu sesixhobo ukuya kwindawo yesixhobo. KuMfanekiso 5, uluhlu lwe-Ps, i-angle enqunywe kwinqwelo-moya yi-0degPs=180deg.

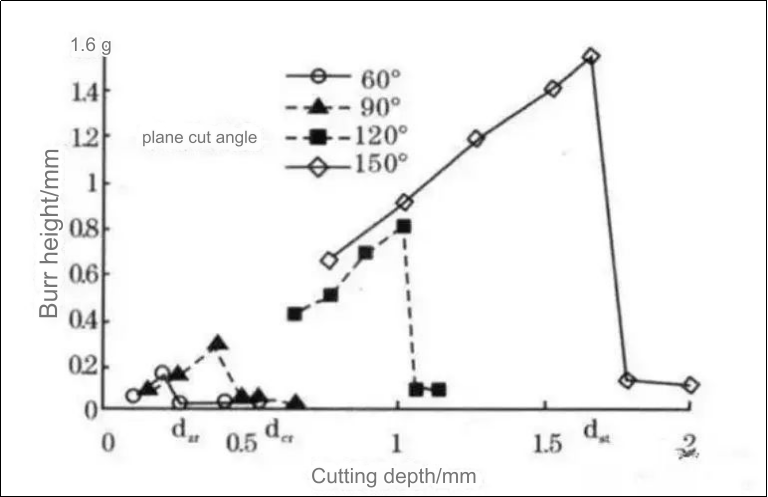

Iziphumo zovavanyo zibonisa ukuba njengoko ukusika ubunzulu kwandisa utshintsho burrs ukusuka kuhlobo I ukuya kuhlobo II. Ngokuqhelekileyo, ubunzulu obuncinane bokusila obufunekayo ukuvelisa uhlobo lwe-II burrs (ekwaziwa ngokuba bubunzulu bokusika umda okanye i-dcr) bubizwa ngokuba bubunzulu bokusila obuncinci. Umzobo we-6 ubonisa impembelelo yee-engile zokusika inqwelomoya kunye nokusika ubunzulu kumphakamo we-burr ngexesha lokwenziwa kwe-aluminium alloy machining.

Umzobo we-6 I-angle yokusika i-angle, ifom ye-burr kunye nobunzulu bokusika

Umzobo 6 ubonisa ukuba, xa i-angle yokusika indiza inkulu ukuba i-120deg uhlobo lwe-burrs lukhudlwana kwaye ubunzulu abatshintsha ngalo uhlobo lwe-II burrs luyanda. I-angle encinci yokusika i-angle iya kukhuthaza ukubunjwa kohlobo lwe-II burrs. Isizathu kukuba ixabiso eliphantsi le-Ps, ubukhulu bokuqina komphezulu kwi-terminal. Oku kwenza ukuba kube lula ukuba burrs.

Isantya sokutya kunye nesalathiso saso siya kuba nefuthe kwisantya kunye ne-angle yokusika kwendiza kunye nokwakheka kwee-burrs. Ixabiso elikhulu lokutya kunye ne-offset ye-edge ekuphumeni, a, kunye ne-Ps encinci, iyasebenza ngakumbi ekucinezeleni ukubunjwa kwe-burrs enkulu.

Umfanekiso wesi-7 Iimpembelelo zendlela yokutya kwimveliso ye-burr

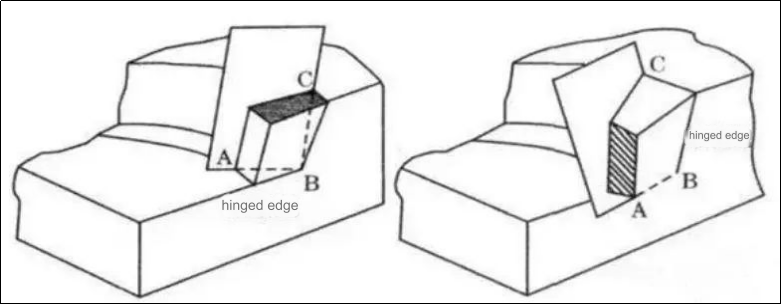

3. Isixhobo ingcebiso EOS ukuphuma ngokulandelelana

Ubungakanani be-burr bumiselwa ubukhulu becala ngolandelelwano apho incam yesixhobo iphuma kwi-mill yokugqibela. KuMzobo 8, inqaku A limele umgca wokusika omncinci. Inqaku C limele iindawo eziphambili zokusika. Kwaye inqaku B limele incam yencam. Iradiyasi yencam yesixhobo ayihoywa kuba icingelwa ukuba ibukhali. Iitshiphusi ziya kuxhonywa kumphezulu womsebenzi owenziwe ngoomatshini ukuba udini uAB ushiya umsebenzi phambi komphetho BC. Njengoko inkqubo yokusila iqhubeka, iitshiphusi zityhalwa ukusuka kwindawo yokusebenza zenza umphetho omkhulu wokusika iburr. Ukuba edge AB ushiya workpiece phambi komphetho BC, iitshiphusi ziya kuxhonywa kumphezulu utshintsho. Emva koko banqunyulwa kwi-workpiece kwindlela yokusika.

Umfuniselo ubonisa:

①Isixhobo sokuphuma ngokulandelelana kwesixhobo ABC/BAC/ACB/BCA/CAB/CBA esonyusa ubungakanani beburr ngokulandelelana.

②Iziphumo ze-EOS ziyafana, ngaphandle kwento yokuba ubukhulu be-burr obuveliswe kwizinto zeplastiki phantsi kokulandelelana okufanayo kokuphuma bukhulu kunoko kuveliswa kwizinto ezinqabileyo. Ulandelelwano lokuphuma lwengcebiso yesixhobo alunxulumananga kuphela nejiyometri yesixhobo kodwa nezinto ezinje ngereyithi yokutya, ubunzulu bokugaya, ijometri yesixhobo sokusebenza, kunye neemeko zokusika. IiBurrs zenziwe yindibaniselwano yezinto ezininzi.

Umzobo 8 Ukwenziwa kwengcebiso yesixhobo kunye nolandelelwano lokuphuma

4. Impembelelo yezinye izinto

① Iiparamitha zokugaya (ubushushu, indawo yokusika, njl.). Ukubunjwa kwee-burrs kuya kuchatshazelwa zizinto ezithile. Impembelelo yezinto eziphambili ezifana nesantya sokutya, umgama wokusila, njl. Andizukungena kwiinkcukacha apha;

② Okukhona iplastiki eninzi imathiriyelicnc ukuguqula iindawo, kuya kuba lula ukwenza ukuba ndichwetheze ii-burrs. Xa isiphelo milling brittle izinto, izixa feed ezinkulu okanye inqwelomoya cutting engile ezinkulu kunokukhokelela uhlobo III iziphene.

③ Ukuqina okwandisiweyo komphezulu kunokucinezela ukubunjwa kwee-burrs xa i-engile phakathi kwesiphelo somphezulu kunye nenqwelomoya eyenziwe ngomatshini idlula i-engile ekunene.

④ Ukusetyenziswa kolwelo lokusila kuluncedo ekwandiseni ubomi bezixhobo, ukunciphisa ukuguga nokukrala, ukuthambisa inkqubo yokusila kunye nokunciphisa ubungakanani bebhar;

⑤ Ukuguga kwesixhobo kunempembelelo ebalulekileyo ekwakhekeni kwebhula. I-arc ye-tip iyanda xa isixhobo sigqoke kwinqanaba elithile. Ubungakanani be-burr buyanda kwicala lokuphuma kwesixhobo, kunye nakwindlela yokusika. Uphononongo olongezelelweyo luyafuneka ukuze kuqondwe indlela. Yemba nzulu.

⑥ Eminye imiba, efana nesixhobo, nayo inokuphembelela ukumila kweburr. Izixhobo zedayimani zicinezela i-burrs ngcono kunezinye izixhobo phantsi kweemeko ezifanayo.

3. Ukulawula ukwenziwa kwe-milling burrs kulula.

Izinto ezininzi zinempembelelo ekubunjweni kwee-burrs zokugqibela. Inkqubo yokugaya yinto enye kuphela echaphazela ukubunjwa kwe-end milling burrs. Ezinye izinto ziquka ijometri yesixhobo, isakhiwo kunye nobukhulu be-workpiece, njl. Ukuze kuncitshiswe inani le-burrs yokugaya isiphelo esiveliswayo, kuyimfuneko ukulawula nokunciphisa isizukulwana se-burr kwii-engile ezininzi.

1. Uyilo lwesakhiwo olufanelekileyo

Ubume be-workpiece yinto ebalulekileyo ekubunjweni kwee-burrs. Ubume kunye nobukhulu emva kokucutshungulwa kwee-burrs emacaleni kuya kwahluka ngokuxhomekeke kwisakhiwo somsebenzi. Xa izinto kunye nonyango umphezulu weiindawo zecncziyaziwa, ijometri kunye nemiphetho idlala indima enkulu ekubunjweni kwe-burrs.

2. Ulandelelwano lokucubungula

Umyalelo okwenziwa ngawo ukusetyenzwa kunokuba nefuthe kubungakanani be-burr kunye nokumila. Ukuchithwa kwe-deburring kuchaphazeleka kwimilo kunye nobukhulu, kunye nomthwalo wokuhlawula umsebenzi kunye neendleko. Iindleko zokuhlawula imali zingancitshiswa ngokukhetha ulandelelwano oluchanekileyo lokucubungula.

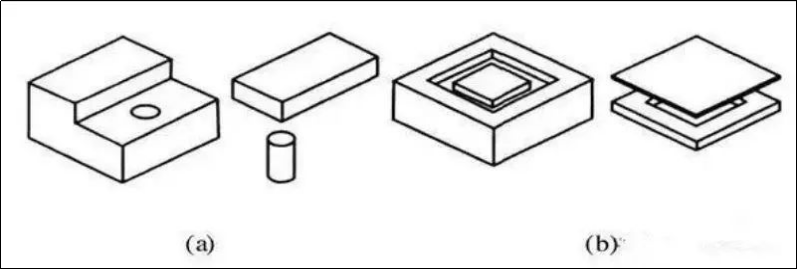

Umzobo 9 Ukukhetha indlela yokulawula ulandelelwano lwenkqubo

Ukuba inqwelomoya ekuMzobo we-10a iqale igrunjwe ize icolwe, ngoko kuya kubakho iibhula ezinkulu zokugaya ezijikeleze umngxuma. Nangona kunjalo, ukuba i-milled iqala kwaye igrunjwe, ngoko kubonakala kuphela iibhubhu ezincinci zokomba. KuMzobo we-10b, i-burr encinci yenziwa xa umphezulu we-concave uqala ukucola, ulandelwa kukusila komphezulu ongaphezulu.

3. Kuphephe ukuphuma kwisixhobo

Kubalulekile ukuphepha ukuhoxiswa kwesixhobo, njengoko le nto iyona nto ibangela ukuba i-burrs yenze isalathiso sokusika. Iibhula eziveliswayo xa isixhobo sokusila sijikeleziswa kude nesixhobo sokusebenza sithande ukuba sikhulu kunezo ziveliswayo xa sijijwe kuso. Umzobo we-4 ubonisa ukuba i-burr eyenziwe ngokusebenzisa i-Figure 4b yayincinci kuneyo iveliswa nguMfanekiso 4.

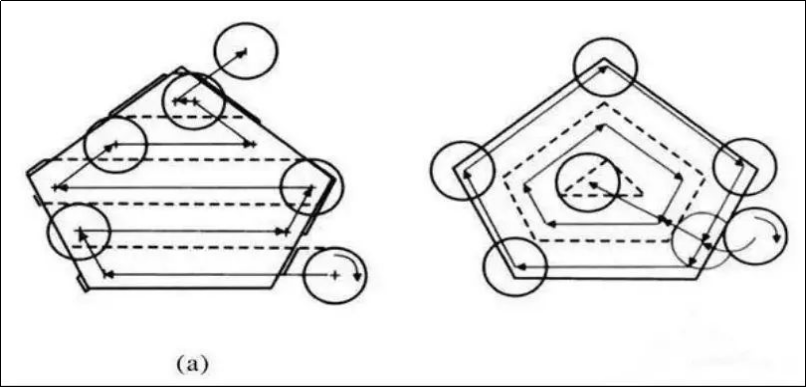

4. Khetha indlela yokusika echanekileyo

Uhlalutyo lwangaphambili lubonisa ukuba ubungakanani be-burr buncinci xa i-angle yokusika indiza ingaphantsi kwenani elithile. Utshintsho kububanzi bokugaya, isantya sokujikeleza kunye nesantya sokutya kunokutshintsha i-angle yokusika indiza. Ngokukhetha indlela yesixhobo esifanelekileyo, kunokwenzeka ukuba ugweme ukudala i-burrs yohlobo lwe-I (jonga uMzobo 11).

Umzobo 10: Ukulawula indlela yesixhobo

Umfanekiso we-10a ubonisa indlela yesixhobo semveli. Indawo enomthunzi womzobo ibonisa indawo enokwenzeka apho i-burrs ingenzeka kwisikhokelo sokusika. Umzobo we-10b ubonisa indlela ephuculweyo yesixhobo enokunciphisa ukubunjwa kwee-burrs.

Indlela yesixhobo eboniswe kuMzobo we-11b inokuba nde kancinane kwaye ithathe i-milling engaphezulu kancinane, kodwa ayifuni naluphi na uhlobo lokuhlawula olongezelelweyo. Umzobo we-10a, kwelinye icala, ufuna ukuchithwa okukhulu (nangona kungekho burrs ezininzi kule ndawo, ngokwenene, kufuneka ususe zonke ii-burrs emaphethelweni). Isishwankathelo, indlela yesixhobo ye-Figure 10b isebenza ngakumbi ekulawuleni ii-burrs kune-Figure 10a's.

5. Khetha iiparamitha ezifanelekileyo zokusila

Iiparameters ze-end milling (ezifana ne-feed-per-tooth, ubude be-milling ekupheleni, ubunzulu, kunye ne-engile yejometri) ingaba nempembelelo ebalulekileyo ekubunjweni kwee-burrs. Ii-Burrs zichatshazelwa ziiparamitha ezithile.

Izinto ezininzi zinefuthe ekuyilweni kweeswarfs zokuphelisa. Izinto eziphambili zibandakanya: ukungena kwesixhobo / ukuphuma, ii-angles zokusika indiza, ukulandelelana kweengcebiso zesixhobo, iiparamitha zokugaya njl. Ubume kunye nobukhulu be-burr yokugaya isiphelo sisiphumo sezinto ezininzi.

Inqaku liqala ngoyilo lwesakhiwo se-workpiece, inkqubo yomatshini, inani lokugaya kunye nesixhobo esikhethiweyo. Emva koko ihlalutya kwaye ixoxe ngezinto eziphembelela i-milling burrs kwaye inike iindlela zokulawula iindlela zokusika, ukhethe ulandelelwano olufanelekileyo kunye nokuphucula uyilo lwesakhiwo. Itekhnoloji, iindlela, kunye neenkqubo ezisetyenziselwa ukucinezela okanye ukunciphisa ii-burrs zokugaya zibonelela ngezisombululo ezinobuchwephesha ezinokusebenziseka ekusetyenzweni kokusila kulawulo olusebenzayo lobungakanani kunye nomgangatho, ukuncitshiswa kweendleko, kunye nemijikelo emifutshane yemveliso.

Qaphela "uMthengi wokuqala, umgangatho ophezulu kuqala" engqondweni, i-Anebon isebenza ngokusondeleyo nabathengi bethu kwaye ibabonelele ngeenkonzo ezisebenzayo kunye neengcali zeFactory ForCNC yokugaya iinxalenye ezincinci, cnciindawo ze-aluminiyam ezenziwe ngoomatshinikwaye Die iinxalenye zokuphosa. Kuba iAnebon ihlala ihlala nalo mgca ngaphezulu kweminyaka eyi-12. I-Anebon ifumene inkxaso yababoneleli abasebenzayo ngokugqwesileyo kunye nexabiso. Kwaye iAnebon yayinabaxhasi bokhula abanomgangatho ophantsi ophantsi. Ngoku iifektri ezininzi ze-OEM zisebenzisana nathi.

I-Factory ye-China ye-Aluminiyam iCandelo kunye ne-Aluminiyam, i-Anebon inokuhlangabezana neemfuno ezahlukeneyo zabathengi ekhaya nakwamanye amazwe. Samkela abathengi abatsha nabadala ukuba beze kuthethathethwano kunye nathi. Ukwaneliseka kwakho yinkuthazo yethu! Vumela i-Anebon isebenze kunye ukubhala isahluko esitsha esiqaqambileyo!

Ukuba ungathanda ukwazi ngakumbi okanye ukufumana ikowuti, nceda uqhagamshelaneinfo@anebon.com

Ixesha lokuposa: Dec-06-2023