Uyilo lwezixhobo zokusebenza yinkqubo elungiselelwe iimfuno ezithile zenkqubo yokwenziwa kwemveliso. Oku kwenziwa emva kokuba inkqubo yomatshini yamacandelo igqityiwe. Xa uphuhlisa inkqubo yokuvelisa, kubalulekile ukuqwalasela ukuba nokwenzeka kokuphunyezwa kwezixhobo. Ukongeza, uhlengahlengiso kwinkqubo inokuphakanyiswa ngexesha lokuyilwa komdlalo ukuba kubonwa kuyimfuneko. Umgangatho woyilo lwesixhobo ulinganiswa ngokukwazi kwawo ukuqinisekisa umgangatho ozinzileyo wokusetyenzwa kwesixhobo sokusebenza, ukusebenza kakuhle kwemveliso, ixabiso eliphantsi, ukususwa kwetshiphu ezifanelekileyo, ukusebenza ngokukhuselekileyo, ukonga abasebenzi, kunye nokwenza lula kunye nokugcinwa.

1. Imigaqo esisiseko yoyilo lwezixhobo zokusebenza yile ilandelayo:

1. Ukulungiswa kufuneka kuqinisekise ukuzinza kunye nokuthembeka kwendawo yokusebenza ngexesha lokusetyenziswa.

2. I-fixture kufuneka ibe nomthwalo owaneleyo wokuthwala okanye amandla okubamba ukuqinisekisa ukuqhutyelwa komsebenzi.

3. Inkqubo yokubamba kufuneka ibe lula kwaye ikhawuleze ukusebenza.

4. Iinxalenye ezinxibekayo kufuneka zitshintshwe ngokukhawuleza, kwaye kungcono ukuba ungasebenzisi ezinye izixhobo xa iimeko zivuma.

5. Ukulungiswa kufuneka kuhlangabezane nokuthembeka kokubeka ngokuphindaphindiweyo ngexesha lohlengahlengiso okanye ukutshintshwa.

6. Gwema ukusebenzisa izakhiwo eziyinkimbinkimbi kunye neendleko ezibiza kangangoko kunokwenzeka.

7. Sebenzisa amalungu asemgangathweni njengamacandelo ecandelo nanini na kunokwenzeka.

8. Yenza i-systematization kunye nomgangatho weemveliso zangaphakathi zenkampani.

2. Ulwazi olusisiseko lwezixhobo kunye noyilo lwezixhobo

Isixhobo esigqwesileyo somatshini kufuneka sifezekise ezi mfuno zilandelayo:

1. Isitshixo sokuqinisekisa ukuchaneka komatshini silele ekukhetheni ireferensi yokubeka, indlela, kunye namacandelo ngokuchanekileyo. Kukwabalulekile ukuhlalutya iimpazamo zokubeka kwaye kuqwalaselwe impembelelo yesakhiwo somatshini ekuchanekeni komatshini. Oku kuya kuqinisekisa ukuba i-fixture ihlangabezana neemfuno zokuchaneka kwendawo yokusebenza.

2. Ukuphucula ukusebenza kakuhle kwemveliso, sebenzisa iindlela ezikhawulezayo nezisebenzayo zokubopha ukuze unciphise ixesha elincedisayo kunye nokuphucula imveliso. Ubunzima bezinto ezilungisiweyo kufuneka bulungelelaniswe nomthamo wemveliso.

3. Ukulungiswa okukhethekileyo kunye nokusebenza kakuhle kwenkqubo kufuneka kube nesakhiwo esilula nesinengqiqo esenza kube lula ukuvelisa, ukudibanisa, ukulungiswa kunye nokuhlolwa.

4. Izixhobo zokusebenza ezisebenza kakuhle kufuneka zibe lula, zonge abasebenzi, zikhuseleke, kwaye zithembeke xa zisebenza. Ukuba kunokwenzeka, sebenzisa izixhobo zokubamba umoya, i-hydraulic, kunye nezinye izixhobo zokucinezela ezingoomatshini ukunciphisa ubungakanani bomsebenzi walowo usebenzayo. Isixhobo kufuneka siququzelele ukususwa kwetshiphu. Isakhiwo sokususwa kwetshiphu sinokuthintela iitshiphusi ekonakaliseni indawo yokusebenza kunye nesixhobo kunye nokuthintela ukuqokelelwa kobushushu ekugqweseni inkqubo yenkqubo.

5. Izixhobo ezikhethekileyo ezinoqoqosho olulungileyo kufuneka zisebenzise amacandelo asemgangathweni kunye nezakhiwo zokunciphisa iindleko zokwenziwa kwezinto. Uhlalutyo oluyimfuneko lobugcisa kunye noqoqosho lwesisombululo sokulungiswa kufuneka luqhutywe ukuze kuphuculwe inzuzo yezoqoqosho kwimveliso, ngokusekelwe kumyalelo kunye nomthamo wokuvelisa ngexesha loyilo.

3. Isishwankathelo sokumiselwa komgangatho wezixhobo kunye noyilo lwezixhobo

1. Iindlela ezisisiseko kunye namanyathelo ezixhobo kunye noyilo lwe-fixture

Ukulungiswa phambi koyilo Idatha yentsusa yezixhobo kunye noyilo loyilo ibandakanya oku kulandelayo:

a) Nceda uphonononge olu lwazi lulandelayo lobugcisa: isaziso soyilo, imizobo yenxalenye egqityiweyo, iindlela zenkqubo yemizobo erhabaxa, kunye nezinye iinkcukacha ezinxulumeneyo. Kubalulekile ukuqonda iimfuno zobugcisa benkqubo nganye, kubandakanywa neskimu sokumisa kunye ne-clamping, umxholo wokucubungula inkqubo yangaphambili, imeko enqabileyo, izixhobo zomatshini kunye nezixhobo ezisetyenziselwa ukucubungula, izixhobo zokulinganisa ukuhlola, izibonelelo zomatshini, kunye nokusika ubuninzi.Isaziso soyilo. , imizobo yenxalenye egqityiweyo, iindlela zenkqubo yemizobo erhabaxa, kunye nolunye ulwazi lobugcisa, ukuqonda ukusetyenzwa kweemfuno zobugcisa benkqubo nganye, ukumisa kunye neskimu sokubambelela, isiqulatho sokucubungula inkqubo yangaphambili, imeko erhabaxa, izixhobo zoomatshini kunye izixhobo ezisetyenziselwa ukusetyenzwa, izixhobo zokulinganisa uHlolo, izibonelelo zomatshini kunye nezixa zokusika, njl.;

b) Ukuqonda ubungakanani bebhetshi yemveliso kunye nesidingo sokulungiswa;

c) Qonda iiparitha eziphambili zobugcisa, ukusebenza, ukucaciswa, ukuchaneka, kunye nemilinganiselo enxulumene nesakhiwo soqhagamshelo lwenxalenye yesixhobo somatshini esisetyenzisiweyo;

d)Uluhlu lwezinto ezisemgangathweni.

2. Imiba ekufuneka iqwalaselwe kuyilo lwezixhobo zokusebenza

Uyilo lwe-clamp lubonakala lulula, kodwa lunokubangela iingxaki ezingeyomfuneko ukuba aluqwalaselwa ngenyameko ngexesha loyilo. Ukwanda kokuthandwa kwee-clamps ze-hydraulic kuye kwenza lula ukwakheka komatshini wokuqala. Nangona kunjalo, izinto ezithile kufuneka zithathelwe ingqalelo ukuphepha iingxaki kwixesha elizayo.

Okokuqala, umda ongenanto womsebenzi oza kusetyenzwa mawuthathelwe ingqalelo. Ukuba ubungakanani besithuba esingenanto bukhulu kakhulu, ukuphazamiseka kwenzeka. Ke ngoko, imizobo erhabaxa kufuneka ilungiswe ngaphambi kokuyila, ishiye indawo eninzi.

Okwesibini, ukususwa kwe-chip egudileyo ye-fixture kubalulekile. Uluhlu luhlala luyilwe kwindawo edibeneyo, enokuthi ikhokelele ekuqokeleleni iifayili zentsimbi kwiikona ezifileyo, kunye nokungahambi kakuhle kolwelo lokusika, okubangela iingxaki kwixesha elizayo. Ngoko ke, iingxaki ezivela ngexesha lokucubungula kufuneka ziqwalaselwe ekuqaleni kokusebenza.

Okwesithathu, ukuvuleka ngokubanzi komdlalo kufuneka kuthathelwe ingqalelo. Ukungahoyi ukuvuleka kwenza kube nzima kumqhubi ukuba afake ikhadi, elichitha ixesha kunye nomsebenzi onzima, kwaye i-taboo kuyilo.

Okwesine, imigaqo yethiyori esisiseko yoyilo lwefixture kufuneka ilandelwe. Isixhobo kufuneka sigcine ukuchaneka kwayo, ngoko ke akukho nto kufuneka iyilwe ngokuchasene nomgaqo. Uyilo olulungileyo kufuneka lume uvavanyo lwexesha.

Okokugqibela, ukutshintshwa kwamacandelo okumisa kufuneka kuthathelwe ingqalelo. Amacandelo okumisa anxitywe kakhulu, ngoko ke ukutshintshwa ngokukhawuleza nokulula kufuneka kwenzeke. Kungcono ukuba ungayila iinxalenye ezinkulu.

Ukuqokelelwa kwamava oyilo lwezixhobo kubalulekile. Uyilo oluhle yinkqubo yokuqokelela okuqhubekayo kunye nesishwankathelo. Ngamanye amaxesha uyilo luyinto enye kwaye ukusetyenziswa okusebenzayo kuyenye. Ke ngoko, kubalulekile ukuqwalasela iingxaki ezinokuvela ngexesha lokusetyenzwa kunye noyilo ngokufanelekileyo. Injongo yezixhobo kukuphucula ukusebenza kakuhle kunye nokuququzelela ukusebenza.

Izixhobo zokusebenza ezisetyenziswa ngokuqhelekileyo zohlulwe ngokwezi ndidi zilandelayo ngokokusebenza kwazo:

01 ibumba lokubumba

02 Ukwemba kunye nezixhobo zokusila

03 CNC, isixhobo chuck

04 Isixhobo sokuvavanya igesi namanzi

05 Ukucheba kunye nokubetha izixhobo

06 Ukufakwa kwezixhobo zokuwelda

07 Ijig yokupholisha

08 Izixhobo zeNdibano

09 Ukuprintwa kwePad, isixhobo sokukrola ngelaser

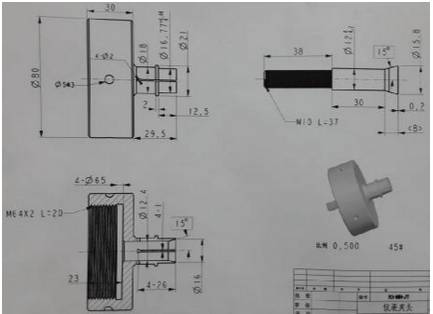

01 ibumba lokubumba

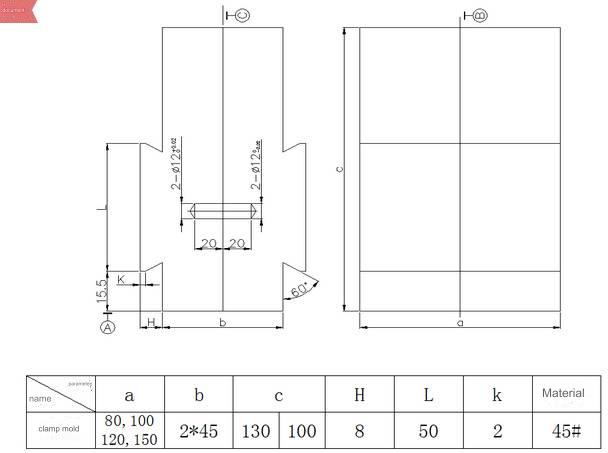

Ingcaciso:Isixhobo sokubeka kunye nokubambelela ngokusekelwe kwimilo yemveliso

Amanqaku oyilo:

1. Olu hlobo lwe-clamp lusetyenziswa kakhulu kwii-vises, kwaye ubude bayo bunokunqunyulwa njengoko kufuneka;

2. Ezinye izixhobo ezincedisayo zokumisa zingayilwa kwi-clamping mold, kwaye i-clamping mold ixhunywe ngokubanzi nge-welding;

3. Lo mfanekiso ungentla ngumzobo owenziwe lula, kwaye ubungakanani besakhiwo sombhobho wesikhunta sinqunywe yimeko ethile;

4. Faka i-pin yokubeka kunye nobubanzi be-12 kwindawo efanelekileyo kwi-mold eshukumayo, kunye nomngxuma wokumisa kwindawo ehambelanayo yesilayidi sokubumba esisisigxina ukuze ulungele i-pin yokubeka;

5. I-cavity ye-asembly kufuneka ihlanjululwe kwaye yandiswe nge-0.1mm ngokusekelwe kumphezulu we-outline we-non-shrunk blank umzobo xa uyilwa.

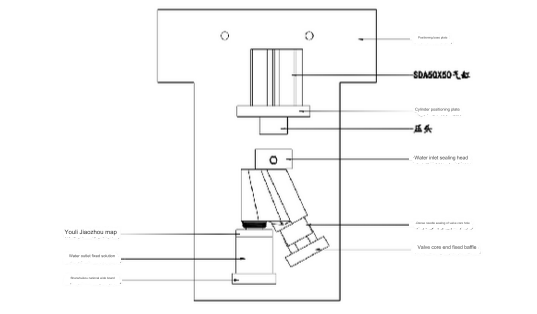

02 Ukwemba kunye nezixhobo zokusila

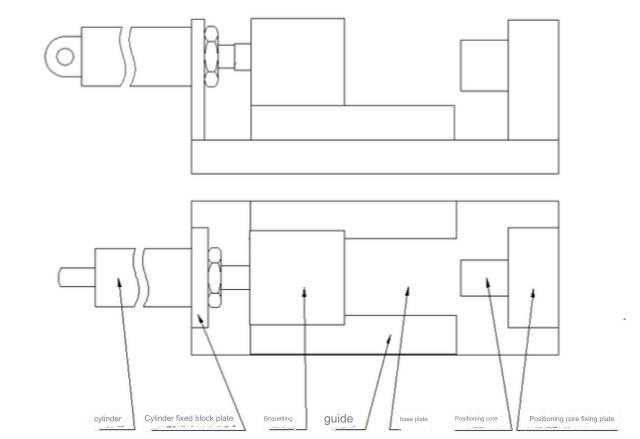

Amanqaku oyilo:

1. Ukuba kuyimfuneko, ezinye izixhobo zokubeka ezincedisayo zinokuthi zenziwe kwi-core fixed kunye neplate yayo ehleliweyo;

2. Lo mfanekiso ungentla ngumzobo wolwakhiwo olula. Eyona meko ifuna uyilo oluhambelanayo ngokweiindawo zecncubume

3. I-cylinder ixhomekeke kubukhulu bemveliso kunye noxinzelelo ngexesha lokucubungula. I-SDA50X50 isetyenziswa ngokuqhelekileyo;

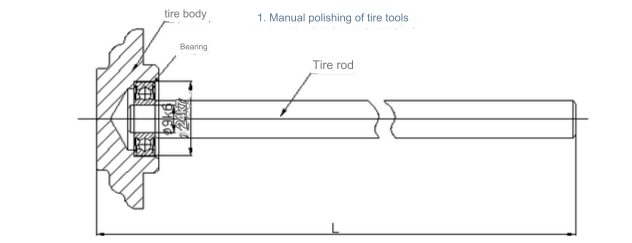

03 CNC, isixhobo chuck

I-CNC chuck

Toe-in chuck

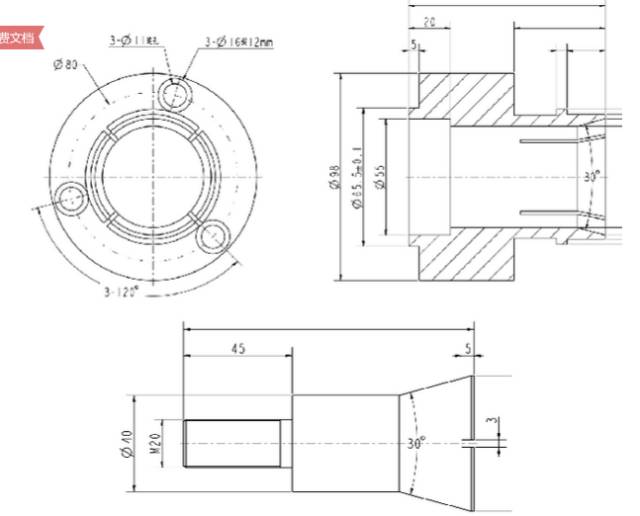

Amanqaku oyilo:

Nceda ufumane ngezantsi isicatshulwa esihlaziyiweyo nesilungisiweyo:

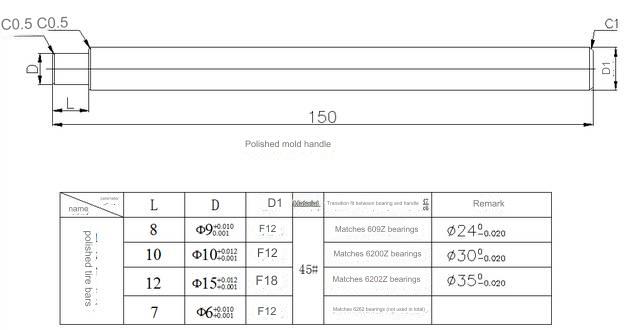

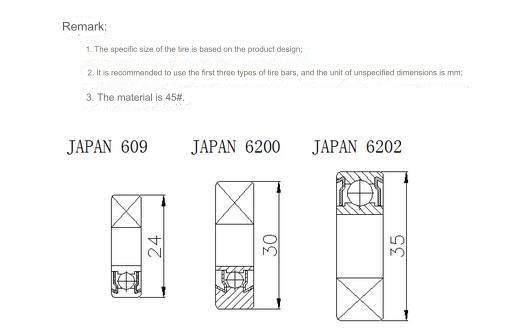

1. Imilinganiselo engabhalwanga kumfanekiso ongentla isekelwe kwisakhiwo sobungakanani bomngxuma ongaphakathi wemveliso yangempela.

2. Ngethuba lenkqubo yokuvelisa, isangqa sangaphandle esikuyo ekudibaneni kwendawo kunye nomngxuma wangaphakathi wemveliso kufuneka ushiye umda we-0.5mm kwelinye icala. Ekugqibeleni, kufuneka ifakwe kwisixhobo somatshini we-CNC kwaye iguqulwe ngokucokisekileyo kwisayizi, ukukhusela nayiphi na i-deformation kunye ne-eccentricity ebangelwa yinkqubo yokucima.

3. Kucetyiswa ukuba kusetyenziswe intsimbi yasentwasahlobo njengento yokudibanisa inxalenye kunye ne-45 # ye-tie rod part.

4. Intambo ye-M20 kwinqanaba le-tie rod yintambo esetyenziswa ngokuqhelekileyo, enokuthi ihlengahlengiswe ngokwemeko yangempela.

Amanqaku oyilo:

1. Lo mfanekiso ungentla ngumzobo wereferensi, kwaye imilinganiselo yendibano kunye nesakhiwo sisekelwe kwimilinganiselo yemveliso kunye nesakhiwo;

2. Izinto eziphathekayo ziyi-45 # kwaye zicinywe.

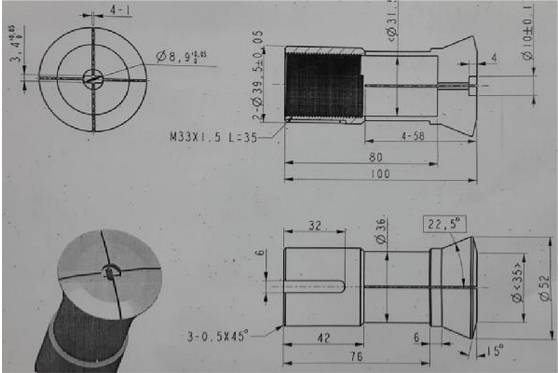

Isixhobo sokubamba sangaphandle

Amanqaku oyilo:

1. Lo mfanekiso ungentla ngumzobo wereferensi, kwaye ubungakanani bokwenene buxhomekeke kwisakhiwo sobungakanani bomngxuma wangaphakathi wemveliso;

2. Isangqa sangaphandle esikwindawo yokunxibelelana nomngxuma wangaphakathi wemveliso kufuneka sishiye umda we-0.5mm kwelinye icala ngexesha lemveliso, kwaye ekugqibeleni sifakwe kwisixhobo sombane kwaye siguqulwe ngokucokisekileyo sibe sisayizi ukunqanda ukuguqulwa kunye ne-eccentricity ebangelwa. ngenkqubo yokucima;

3. Izinto eziphathekayo ziyi-45 # kwaye zicinywe.

04 Isixhobo sokuvavanya igesi

Amanqaku oyilo:

1. Umfanekiso ongasentla ngumfanekiso wesalathiso wesixhobo sokuvavanya igesi. Ulwakhiwo oluthile kufuneka luyilwe ngokuhambelana nesakhiwo sangempela semveliso. Injongo kukutywina imveliso ngendlela elula kakhulu, ukwenzela ukuba inxalenye yokuvavanya kwaye itywinwe izaliswe ngegesi ukuqinisekisa ukuqina kwayo.

2. Ubungakanani be-cylinder bunokulungelelaniswa ngokobukhulu bokwenene bemveliso. Kwakhona kuyimfuneko ukuqwalasela ukuba i-stroke ye-cylinder ingaba lula ukuthabatha kunye nokubeka imveliso.

3. Umphezulu wokutywina onxibelelana nemveliso ngokubanzi usebenzisa izinto ezinomthamo olungileyo wokucinezela njenge-Uni glue kunye nezangqa zerabha ze-NBR. Ukongezelela, nceda uqaphele ukuba kukho iibhloko zokubeka ezijongene nokubonakala kwendawo yemveliso, zama ukusebenzisa iibhloko zeplastiki ezimhlophe kwaye ngexesha lokusetyenziswa, gubungela isigqubuthelo esiphakathi ngendwangu yekotoni ukukhusela umonakalo ekubonakaleni kwemveliso.

4. Isalathiso sokumisa imveliso kufuneka sithathelwe ingqalelo ngexesha lokuyila ukukhusela ukuvuza kwegesi ekubanjweni ngaphakathi kwendawo yemveliso kwaye kubangele ukufunyanwa kobuxoki.

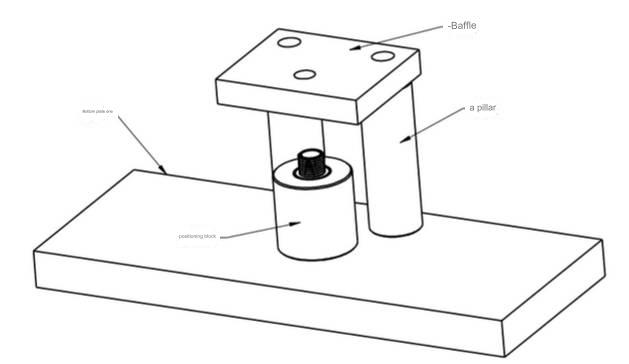

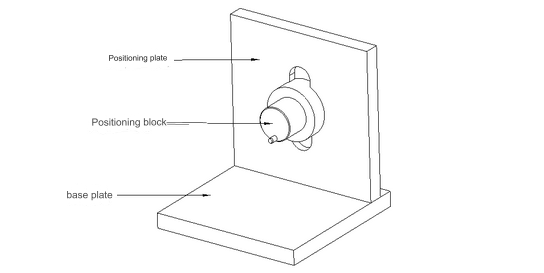

05 Ukubetha izixhobo

Amanqaku oyilo:Umfanekiso ongasentla ubonisa ubume obuqhelekileyo besixhobo sokubhoboza. Ipleyiti esezantsi isetyenziselwa ukuncamathelisa i-workbench yomatshini wepunch ngokulula, ngelixa ibhloko yokumisa isetyenziselwa ukukhusela imveliso. Ulwakhiwo lwezixhobo luyilwe ngokwemeko yokwenyani yemveliso. Indawo esembindini ijikelezwe ngendawo esembindini ukuze kuqinisekiswe ukukhethwa okukhuselekileyo nokufanelekileyo kunye nokubekwa kwemveliso. I-baffle isetyenziselwa ukwahlula ngokulula imveliso kwi-punching knife, ngelixa iintsika zisetyenziswa njenge-baffles esisigxina. Izikhundla zendibano kunye nobukhulu bezi nxalenye zingenziwa ngokwezifiso ngokusekelwe kwiimeko zangempela zemveliso.

06 Ukufakwa kwezixhobo zokuwelda

Injongo ye-welding tooling kukulungisa indawo yecandelo ngalinye kwindibano ye-welding kunye nokulawula ubungakanani obunxulumene necandelo ngalinye. Oku kufezekiswa ngokusebenzisa ibhloko yokumisa eyenzelwe ngokwesakhiwo sangempela semveliso. Kubalulekile ukuba uqaphele ukuba xa ubeka imveliso kwi-welding tooling, indawo evaliweyo akufanele idalwe phakathi kwezixhobo. Oku kukuthintela ukunyanzeliswa okugqithisileyo kokwakhiwa kwendawo evaliweyo, enokuchaphazela ubungakanani bamacandelo emva kwe-welding ngexesha lokufudumala.

07 Ukulungiswa kokugudiswa

08 Izixhobo zeNdibano

Isixhobo seNdibano sisixhobo esinceda ekubekeni amacandelo ngexesha lenkqubo yokuhlanganisa. Ingcamango emva koyilo kukuvumela ukuthabatha lula kunye nokubekwa kwemveliso ngokusekelwe kwisakhiwo sendibano yamacandelo. Kubalulekile ukuba ukubonakala kweiindawo ze-aluminiyam yesiko cncazonakaliswa ngexesha lenkqubo yendibano. Ukukhusela imveliso ngexesha lokusetyenziswa, inokugqunywa ngendwangu yekotoni. Xa ukhetha izinto zokusetyenziswa, kuyacetyiswa ukuba usebenzise izinto ezingezizo ezentsimbi ezifana neglue emhlophe.

09 Ukuprintwa kwePad, isixhobo sokukrola ngelaser

Amanqaku oyilo:

Yila ubume bokumisa isixhobo ngokweemfuno zokukrola eyona mveliso. Nikelani ingqalelo kubuchule bokukha kunye nokubeka imveliso, kunye nokukhuselwa kwembonakalo yemveliso. Ibhloko yokumisa kunye nesixhobo esincedisayo sokudibanisa nemveliso kufuneka senziwe ngeglue emhlophe kunye nezinye izinto ezingezona zetsimbi kangangoko kunokwenzeka.

I-Anebon izinikele ekudaleni izisombululo ezikumgangatho ophezulu kunye nokwakha ubudlelwane nabantu abavela kwihlabathi liphela. Banomdla kakhulu kwaye bathembekile ekuhambiseni ezona nkonzo zibalaseleyo kubathengi babo. Basebenza ngokukhethekileyo kwiimveliso zokuphosa i-aluminium yaseTshayina,iipleyiti zokugaya i-aluminiyam, yenziwe ngokwezifisoiinxalenye ezincinci ze-aluminium CNC, kunye ne-Original Factory China Extrusion Aluminium kunye neProfayili yeAluminiyam.

I-Anebon ijolise ekubambeleleni kwifilosofi yoshishino "Umgangatho wokuqala, ukugqibelela ngonaphakade, abantu-abajoliswe kuyo, iteknoloji entsha". Basebenza nzima ukwenza inkqubela kwaye bavelise izinto ezintsha kushishino ukuze babe lishishini lodidi lokuqala. Balandela imodeli yolawulo lwezenzululwazi kwaye bazabalazela ukufunda ulwazi lobuchwephesha, baphuhlise izixhobo zokuvelisa eziphambili kunye neenkqubo, kwaye benze iimveliso ezikumgangatho wokuqala. I-Anebon inikezela ngamaxabiso afanelekileyo, iinkonzo ezikumgangatho ophezulu, kunye nokuhanjiswa ngokukhawuleza, ngenjongo yokudala ixabiso elitsha kubathengi babo.

Ixesha lokuposa: Mar-25-2024