Ngaba uyazi kangakanani malunga nendlela yokusika intambo yesinyithi?

Ukusika intsimbi yokuthunga ngokuqhelekileyo kubandakanya iinkqubo ezinjengokucofa, ukugaya intambo, kunye nokuthunga inqaku elinye. Ezi ndlela ziqhelekileyo zisetyenziselwa ukuvelisa ukudala imicu yangaphakathi okanye yangaphandle kumacandelo esinyithi.

Ukucofa yinkqubo apho isixhobo sempompo sisetyenziselwa ukusika imisonto kwimingxuma egrunjwe ngaphambili. Ngokuqhelekileyo isetyenziselwa ukudala imicu yangaphakathi. Ukusila umsonto, kwelinye icala, kusebenzisa isixhobo sokusika esijikelezayo esinamazinyo amaninzi ukusika ngokuthe ngcembe iprofayile yomsonto. Le ndlela isoloko isetyenziselwa imisonto yangaphakathi nangaphandle.

I-single-point threading ibandakanya ukusebenzisa isixhobo sokusika kunye nomgca owodwa wokusika ukusika imicu kwi-workpiece. Le ndlela isoloko isetyenziswa kwiileyile okanye kumatshini wokujika ukwenza imisonto echanekileyo.

Ukukhethwa kwendlela kuxhomekeke kwizinto ezifana nohlobo lwezinto ezixutywayo, iprofayili efunwayo yentambo, ukuchaneka okufunekayo, kunye nomthamo wemveliso. Izixhobo ezahlukeneyo, oomatshini, kunye nobuchule bunokusetyenziswa kwizicelo ezahlukeneyo kunye neemfuno zeshishini.

1. Ulwazi olusisiseko olubalulekileyo lokulungisa umsonto

1. Inkcazo yamagama

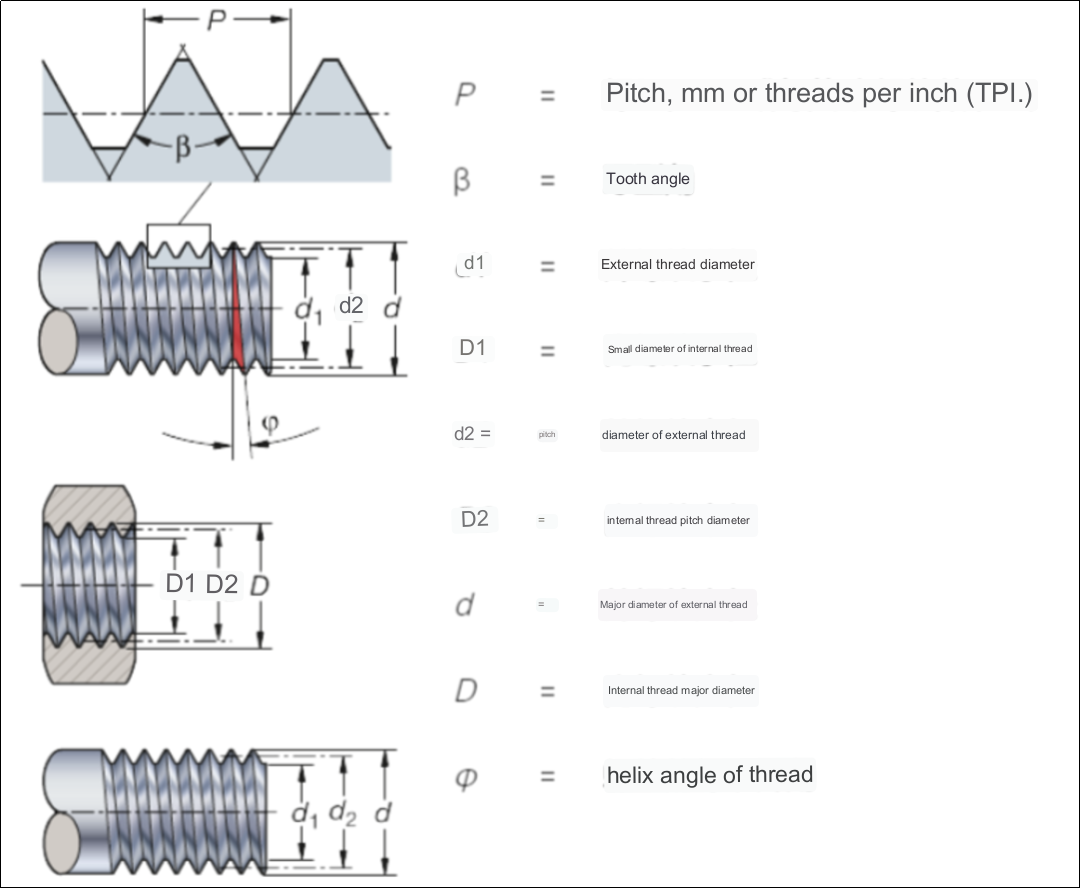

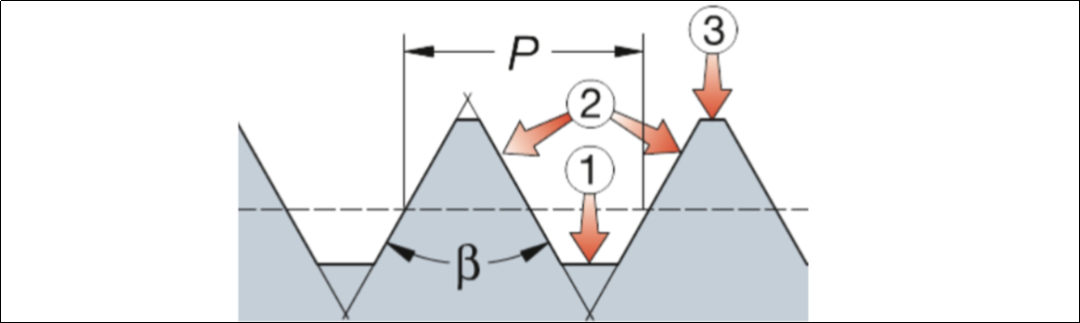

①Emazantsi ezinyo ②Icala lezinyo ③Ngaphezulu kwezinyo

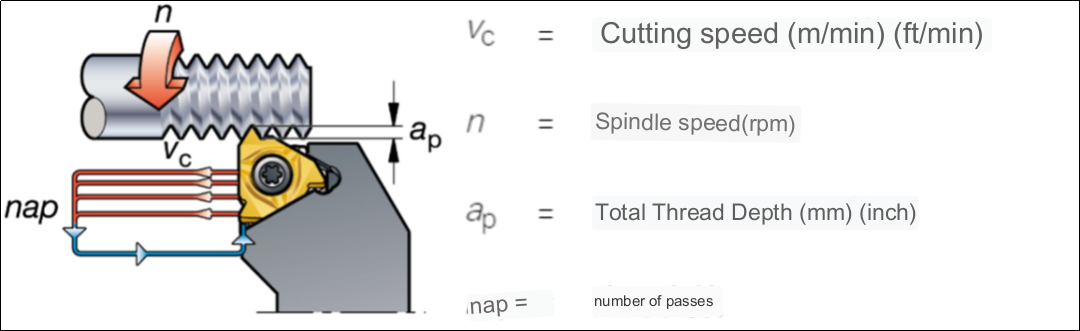

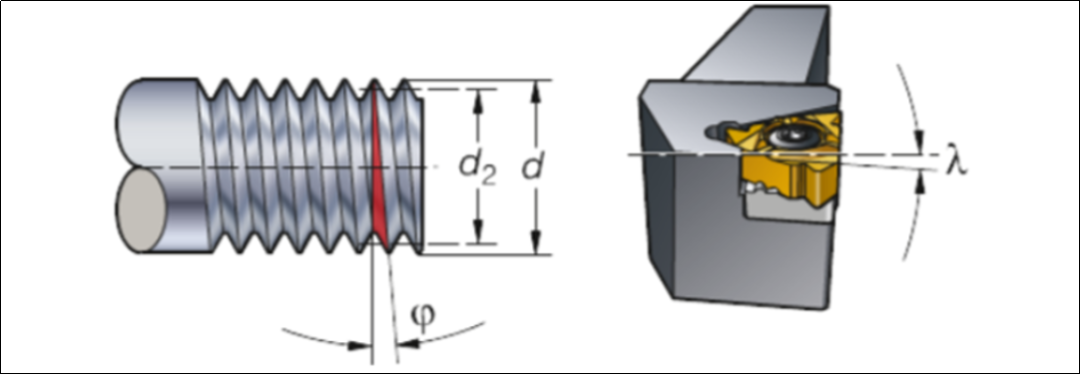

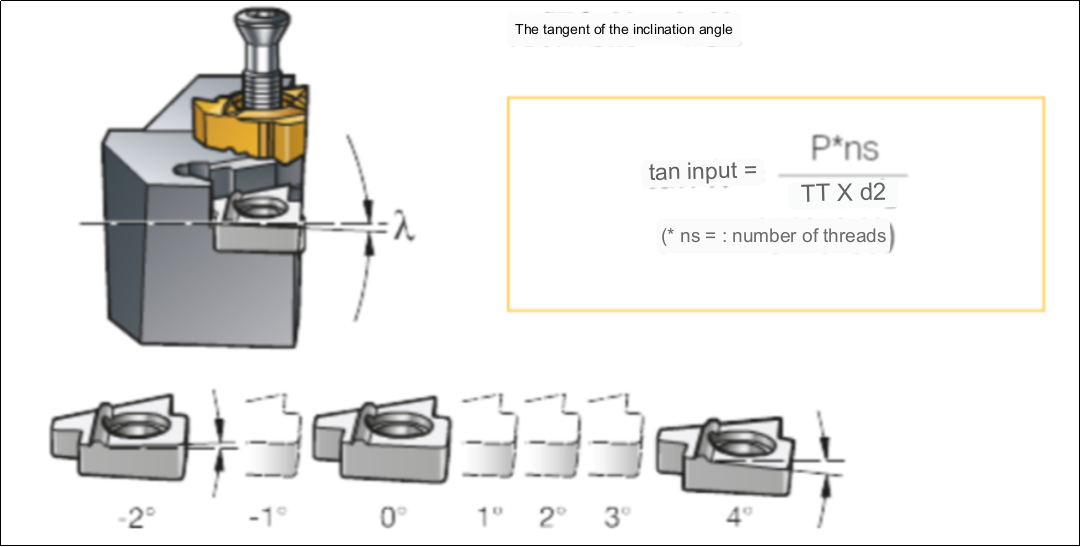

I-engile ye-Helix:

I-angle ye-helix ixhomekeke kububanzi kunye ne-pitch yomsonto.

Lungisa ukukhululeka kweflank yeblade ngokutshintsha ishim.

I-engile yokuthambekela kweblade ngu-γ. I-angle ye-bevel eqhelekileyo yi-1 °, ehambelana ne-shim eqhelekileyo kwisibambi.

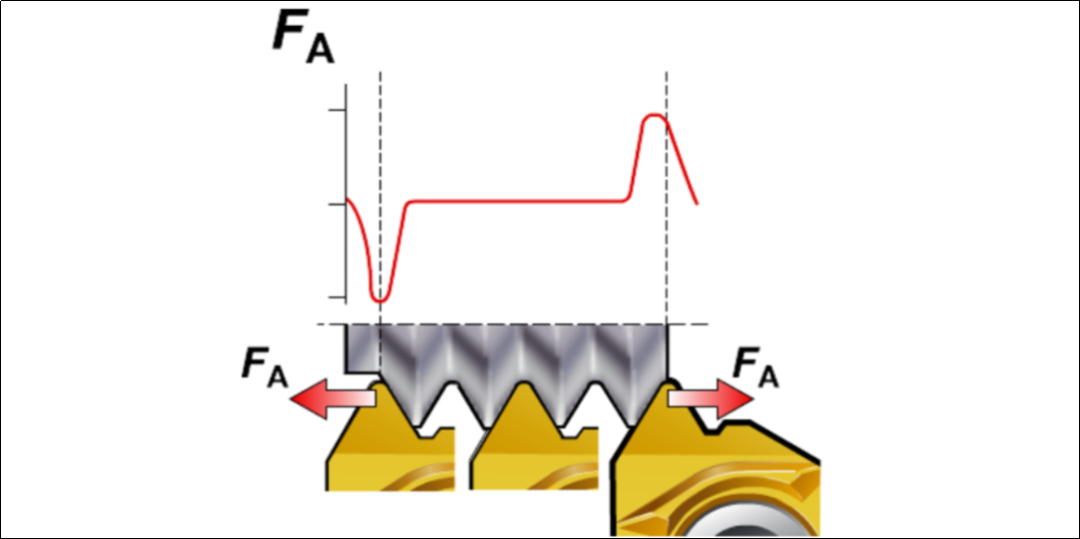

Ukusika amandla xa ungena kwaye uphuma kumsonto:

Amandla aphezulu okusika i-axial kwimisebenzi yokudibanisa iyenzeka ngexesha lokungena kunye nokuphuma kwesixhobo sokusika kwi-workpiece.

Ukusika idatha ephezulu kakhulu kunokubangela ukunyakaza kokufaka okungathembekiyo.

Cheka iblade ukuze ucoceke:

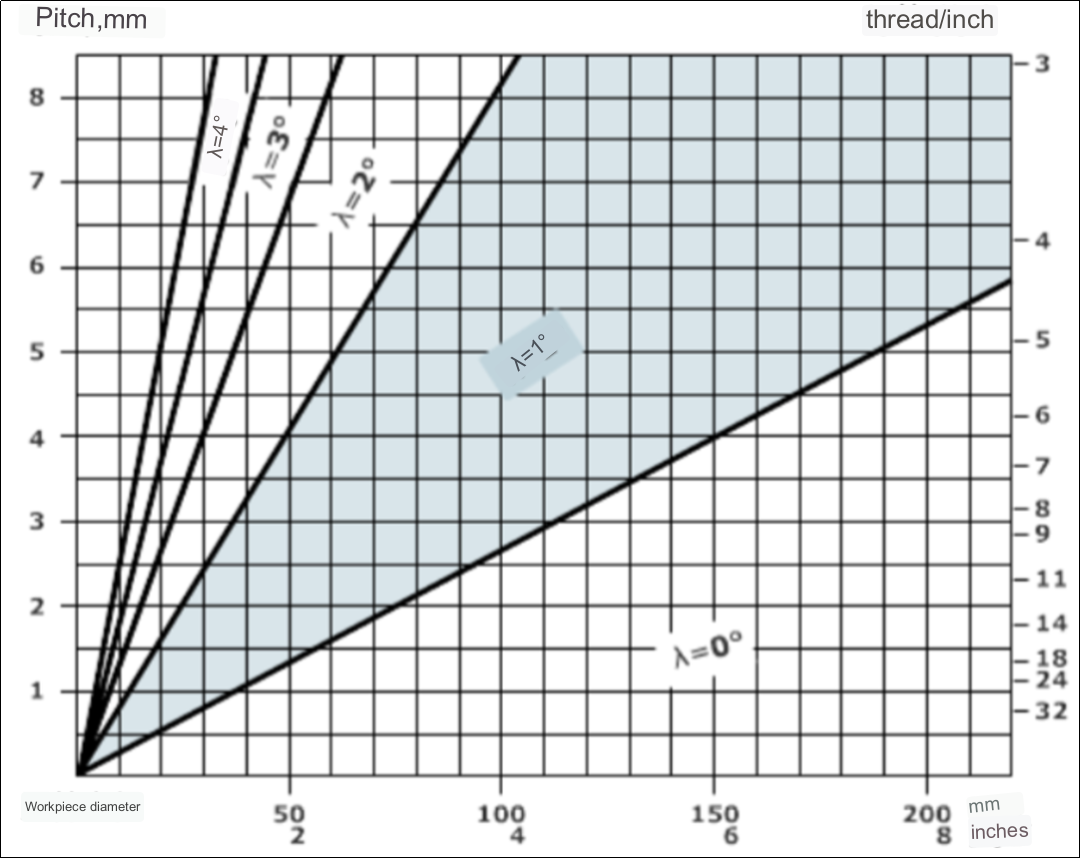

I-angle ye-bevel inokusekwa kunye ne-shim phantsi kwe-blade kwisibambo. Jonga kwitshathi ekwikhathalogu yesixhobo ukukhetha ukuba yeyiphi ishim omawuyisebenzise. Zonke izibambi ziza neeshim eziqhelekileyo ezisetwe kwi-1° i-engile yeraki.

Khetha i-shim ngokwe-engile ye-bevel. Idayamitha yesixhobo sokusebenza kunye nenowuthi yomsonto ichaphazela i-engile yeharika. Njengoko kunokubonwa kumfanekiso ongezantsi, ububanzi beiindawo ze-cnc latheyi-40mm kunye ne-pitch yi-6mm, i-shim efunekayo kufuneka ibe ne-engile ye-bevel ye-3 ° (ii-shim eziqhelekileyo azinakusetyenziswa).

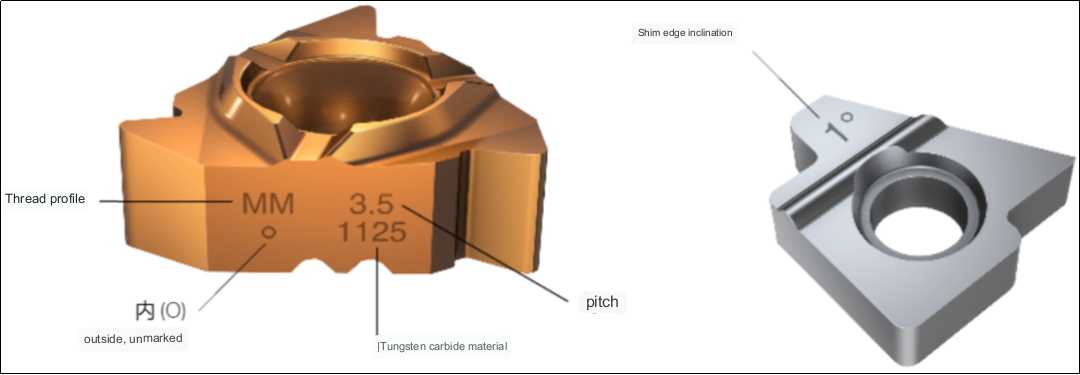

Iimpawu zokufakela imisonto kunye neeshim:

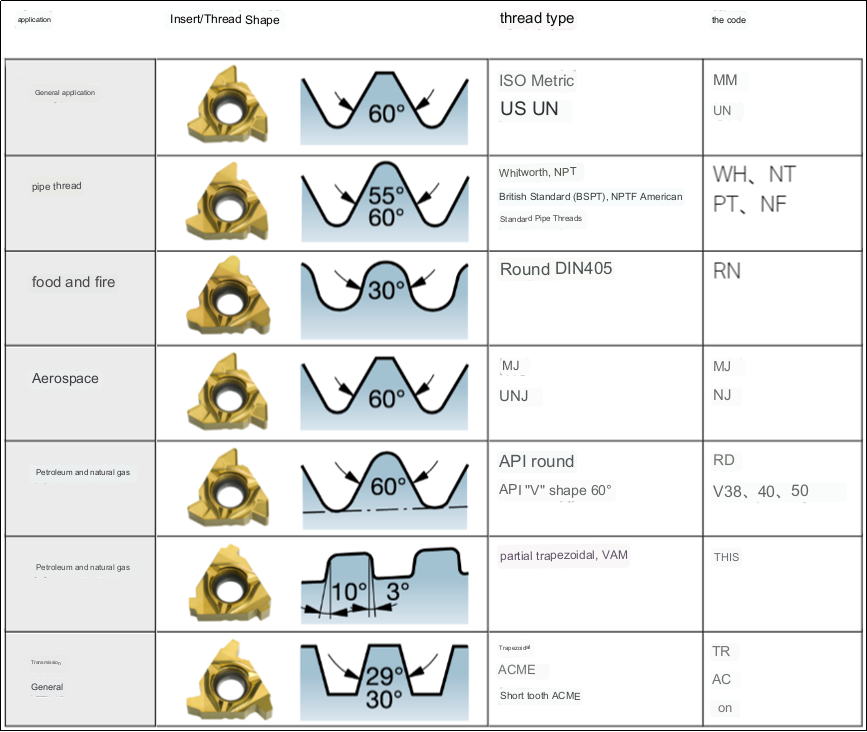

Ubume bomsonto kunye nokusetyenziswa kwawo:

2. Uhlobo lokufaka umsonto kunye neskimu sokubambelela

1. Intsimbi yezinyo ezininzi

I-advanteji:

Nciphisa inani lokutya

Imveliso ephezulu kakhulu

Ukusilela:

Kufuneka i-clamping ezinzileyo

Isithuba esaneleyo sokurhoxa siyafuneka emva kokuthunga

2. Iblade yeprofayili epheleleyo

I-advanteji:

Ulawulo olukhulu kwimilo yomsonto

iiglitches ezincinci

Ukusilela:

Iblade enye inokusika inowuthi enye kuphela

3. Iblade yeprofayile ye-V

I-advanteji:

Ukuguquguquka, ukufaka okufanayo kungasetyenziselwa iipatshi ezininzi.

Ukusilela:

Iza kubangela ukuba ii-burrs zenzekile kwaye kufuneka zihlawulwe.

Isisombululo sokuQhwaba i-LOCK:

Intambo engqongqo kakhulu enezifakelo ezisisigxina

Ukukhokelwa ngumzila wesikhokelo, i-blade ibekwe kwindawo echanekileyo

Isikrufu sicinezela ufakelo kumzila kaloliwe ubuyela kwisikhululo seradial kubuso obunye bokudibana (ubuso obubomvu bokudibana) kwisitulo sokufaka.

Ujongano lofakelo oluthembekileyo luqinisekisa ubomi besixhobo obude kunye nomgangatho ophezulu womsonto

Iziphatho ezahlukeneyo:

3. Iintlobo ezintathu ezahlukeneyo zeendlela zokutyisa

Indlela yokutya ingaba nefuthe elikhulu kwi-threading process. Ichaphazela: Ukulawula ukusika, ukufaka ukunxiba, umgangatho wentambo, ubomi besixhobo.

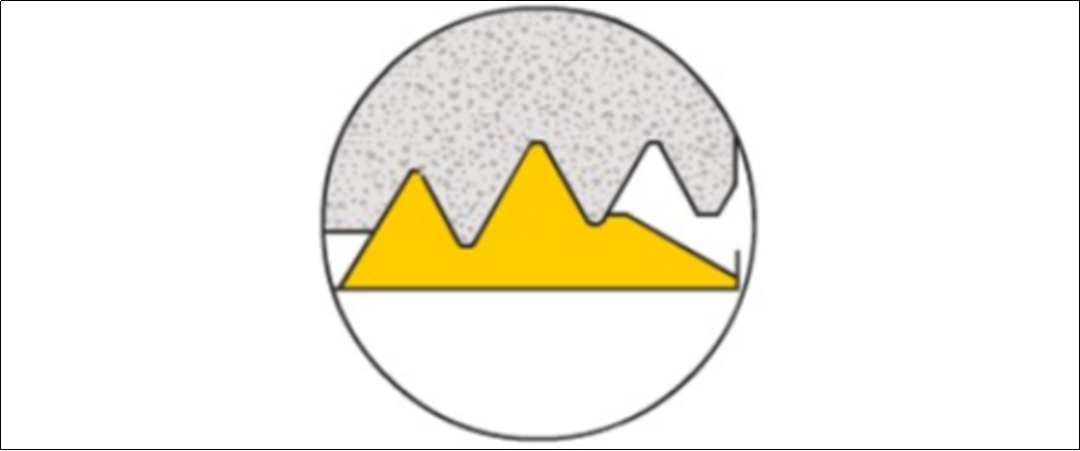

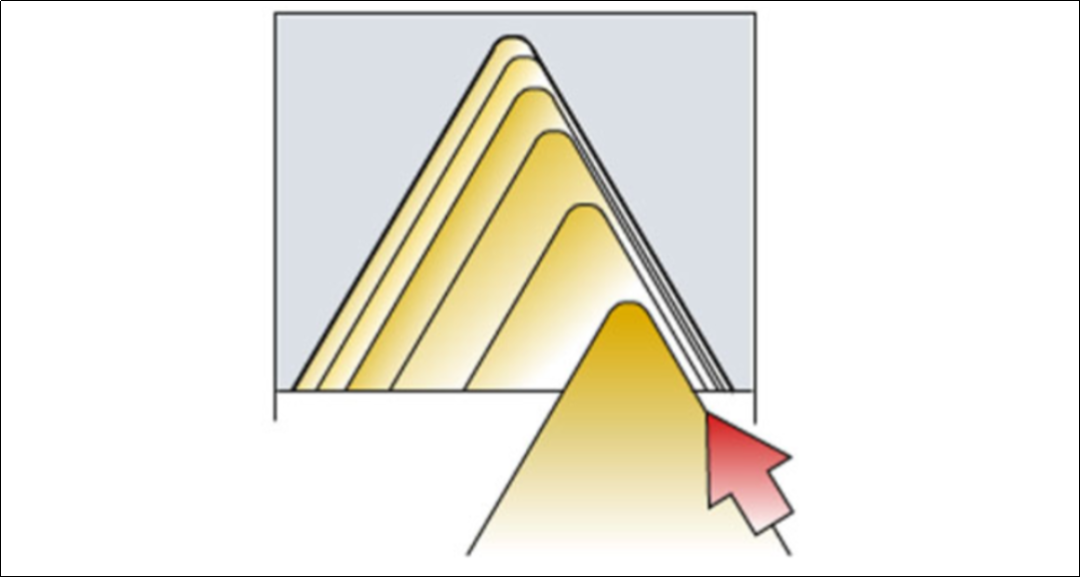

1. Isondlo esisecaleni esiphuculweyo

Uninzi lwezixhobo zoomatshini be-CNC zinokusebenzisa le ndlela yokondla ngeenkqubo zomjikelo:

Iichips ngokuchasene neentlobo eziqhelekileyo zokujika - kulula ukwenza kunye nokukhokela

Amandla okusika axial anciphisa umngcipheko wokungcangcazela

Iichips zishinyene kodwa zibambe kuphela icala elinye lofakelo

Ukunciphisa ukuhanjiswa kobushushu kwi-blade

Inketho yokuqala kwimisebenzi emininzi yokuthunga

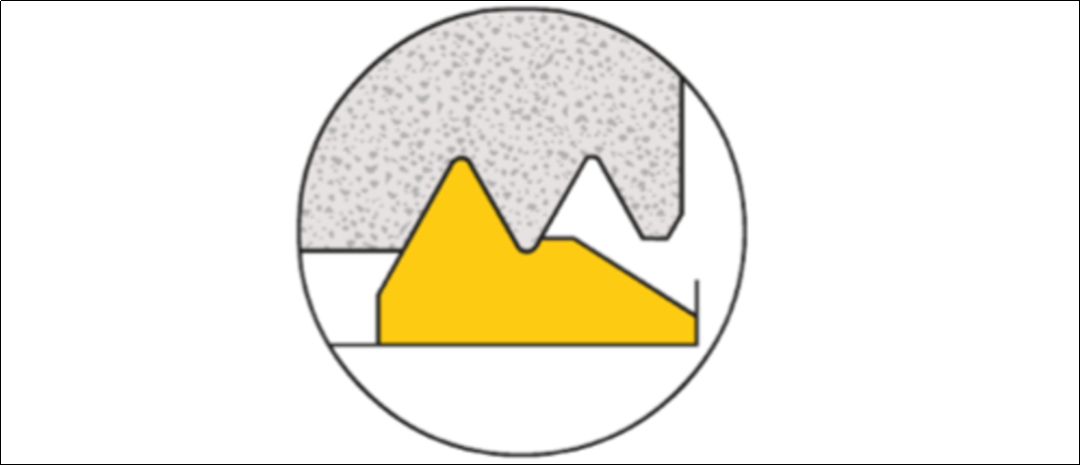

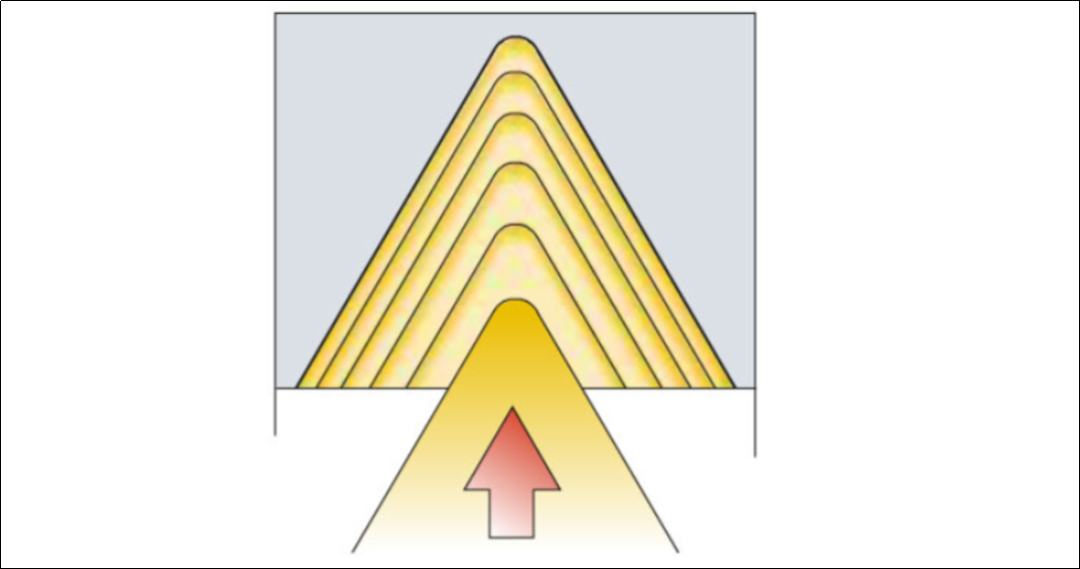

2. I-radial feed

Eyona ndlela ixhaphakileyo - ekuphela kwendlela yokuba iilathe ezindala ezingezizo ze-CNC zikwazi ukuzisebenzisa:

Ivelisa iitshiphusi eziqinileyo ezimile "V".

Iyunifomu yokunxiba iBlade

Iipokotho zokufaka zibonakaliswe kumaqondo aphezulu, ukunciphisa ubunzulu be-feed

Ilungele ukusetyenzwa komsonto ocolekileyo

Ukungcangcazela okunokwenzeka kunye nolawulo lwetshiphu olulambathayo xa usenza imisonto erhabaxa

Ukhetho lokuqala lomsebenzi owenziwe nzima

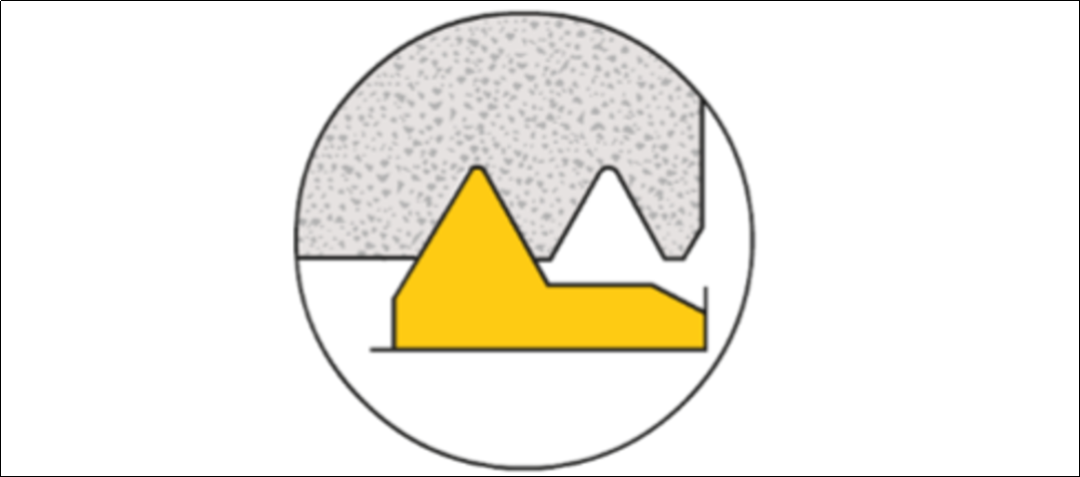

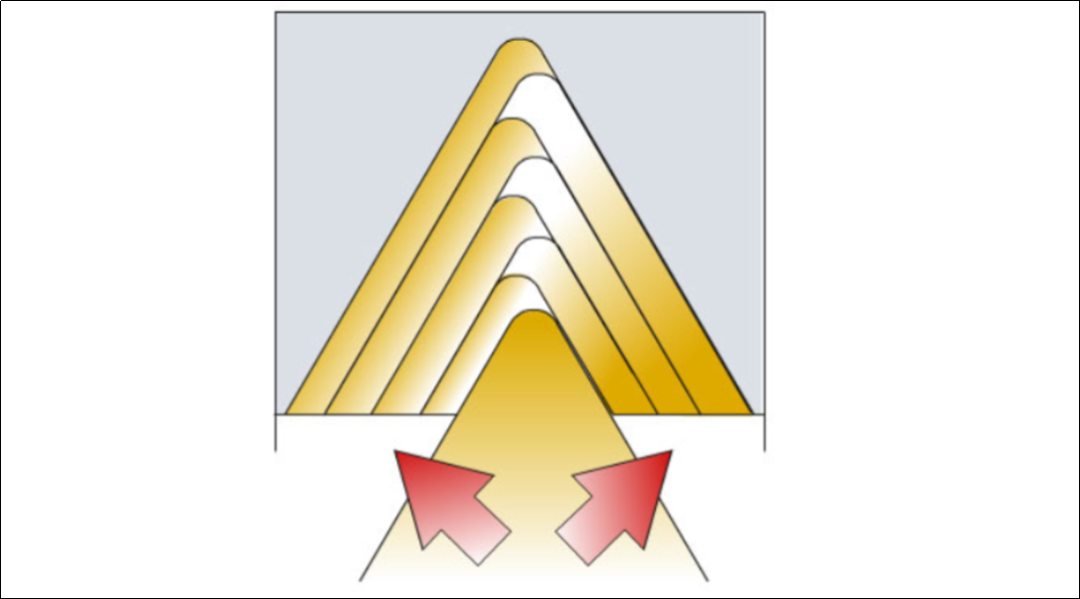

3. Ukondla ngenye indlela

kucetyiswa amazinyo amakhulu

Ukunxiba okulinganayo kunye nobomi besixhobo esiphezulu xa usenza imisonto yepitch enkulu kakhulu

Iichips zikhokelwa kumacala amabini, okwenza kube nzima ukulawula

4. Iindlela zokuphucula iziphumo zokucubungula

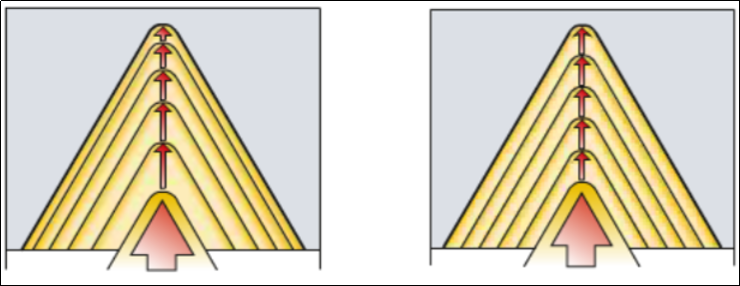

Ukunciphisa ubunzulu bokusikwa (ekhohlo), ubunzulu obuqhubekayo bokusikwa (ekunene)

1. Ubunzulu bokusikwa buyancipha umaleko ngomaleko (indawo ye-chip ihlala ingatshintshi)

Iyakwazi ukufezekisa indawo ye-chip eqhubekayo, eyona ndlela isetyenziswa kakhulu kwiinkqubo ze-NC.

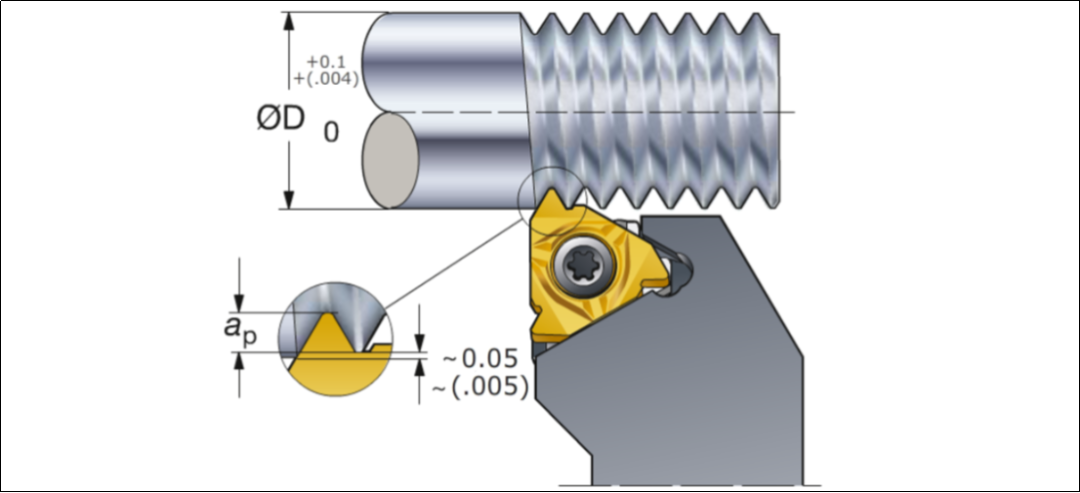

Eyona ipase yokuqala

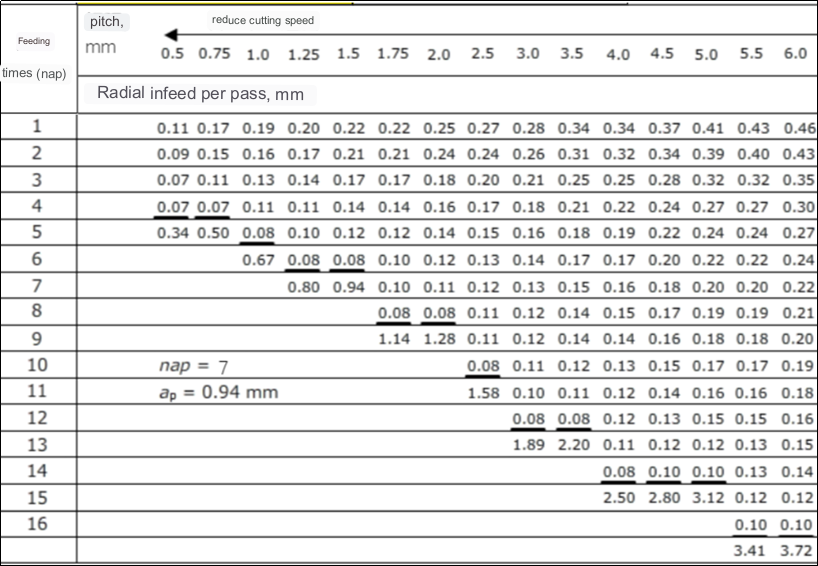

Landela iingcebiso kwitheyibhile yokutya kwikhathalogu

Indawo ye-chip "elungeleleneyo".

Ukudlula kokugqibela malunga ne-0.07mm

2. Ubunzulu obuqhubekayo bokusika

Ipasi ngalinye linobunzulu obufanayo nokuba lingakanani na inani lokupasa.

Kukho iimfuno eziphezulu kwi-blade

Qinisekisa ulawulo lwetshiphu olululo

Akufanele isetyenziswe xa i-pitch inkulu kune-TP1.5mm okanye i-16TP

Gqibezela iicrests zomsonto ngesitokhwe esongezelelweyo:

Akukho mfuneko yokujika isitokhwe ukuya kwidayamitha echanekileyo ngaphambi kokuthunga, sebenzisa isitokhwe eyongezelelweyo / imathiriyeli ukugqiba iicrests zomsonto. Ukugqiba ukufakwa kwe-crest, inkqubo yokujika yangaphambili kufuneka ishiye i-0.03-0.07mm yezinto eziphathekayo ukuvumela ukuba i-crest yenziwe ngokufanelekileyo.

Ixabiso lesondlo somsonto wangaphandle (inkqubo yemetric ye-ISO):

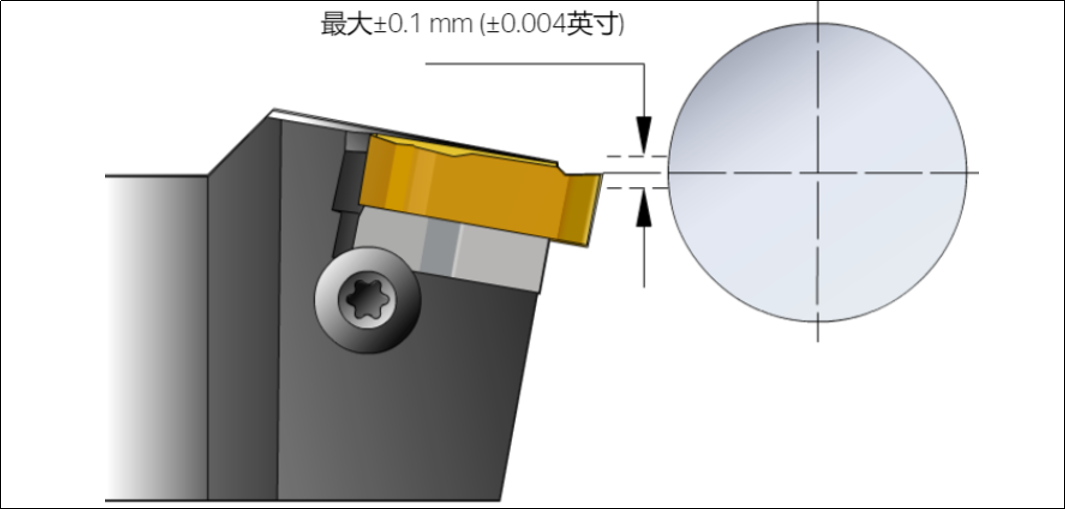

Ukuqinisekisa umsebenzi kunye nokulungelelaniswa kwesixhobo:

Sebenzisa owona mgangatho uphezulu wokutenxa ±0.1mm. Iphezulu kakhulu indawo yokusika kunye ne-angle yokunceda iya kuncipha kwaye i-cutting edge iya kutshitshiswa (iqhekezwe); iphantsi kakhulu indawo yokusika kwaye iprofayili yomsonto isenokungachaneki.

5.umsonto ujika izakhono zesicelo impumelelo

1) Phambi kokuba umsonto ujike, khangela ukuba iiinxalenye ze-aluminium machiningIdayamitha inesibonelelo esichanekileyo somatshini, kwaye yongeza i-0.14mm njengesibonelelo sesithsaba.

2) Ukubekwa ngokuchanekileyo kwesixhobo kwisixhobo somatshini.

3) Khangela ukusekwa komgca wokusika ngokumalunga nobubanzi be-pitch.

4) Qinisekisa ukuba usebenzisa i-geometry echanekileyo yokufaka (A, F okanye C).

5) Qinisekisa ukucocwa okukhulu ngokwaneleyo kunye nokufana (ishim ethambekileyo) ngokukhetha i-shim efanelekileyo ukufumana imvume echanekileyo yeflank.

I-6) Ukuba intambo ayifanelekanga, khangela ukuseta yonke into kuquka isixhobo somatshini.

7) Khangela iinkqubo ezikhoyo zeNC zokuguqula intambo.

8) Lungiselela indlela yokutya, inani lokudlula kunye nobukhulu.

9) Qinisekisa isantya esichanekileyo sokusika ukuhlangabezana neemfuno zesicelo.

I-10) Ukuba i-pitch ye-workpiece thread ayilungile, khangela ukuba i-pitch yesixhobo somatshini ichanekile.

11) Ngaphambi kokusika kwi-workpiece, kucetyiswa ukuba isixhobo kufuneka siqale ngomgama omncinci wamaxesha ama-3 kwi-pitch.

I-12) Ukupholisa okuchanekileyo okuphezulu kunokwandisa ubomi besixhobo kunye nokuphucula ulawulo lwe-chip.

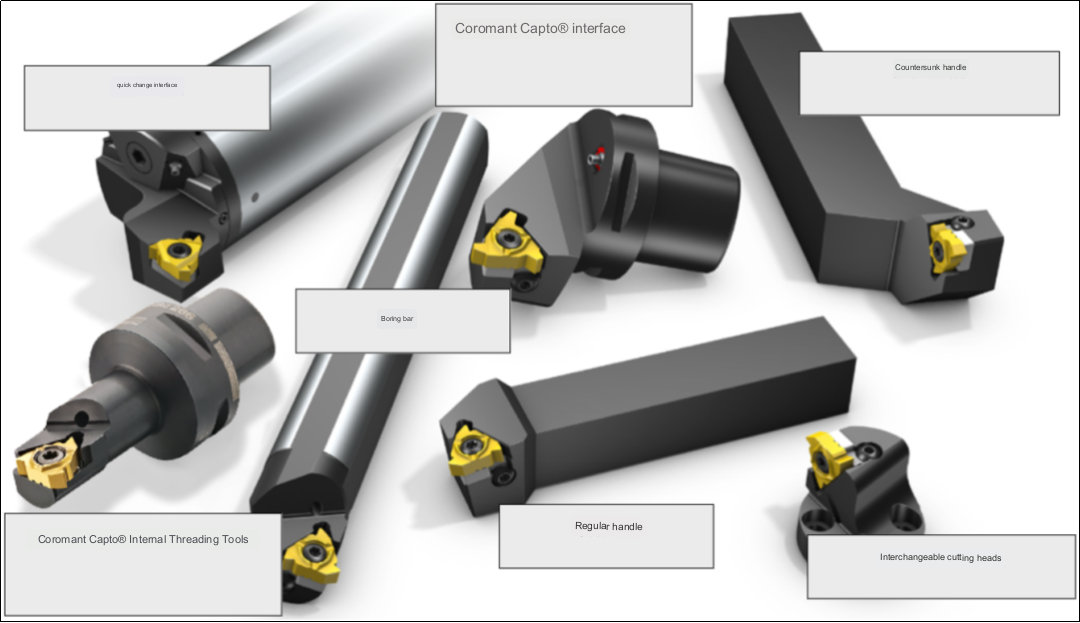

I-13) Inkqubo yokutshintsha ngokukhawuleza iqinisekisa i-clamping elula kwaye ngokukhawuleza.

Xa ukhetha izixhobo zokuguqula umsonto, qwalasela:

Qwalasela ii-overhangs kunye naluphi na ucoceko olufunekayo (umz. igxalaba, i-sub-spindle, njl.njl.)

Nciphisa ukuxhoma kwesixhobo ukuseta ngokukhawuleza

Ukulungiselela ukuseta okuncinci, khetha ukufakwa kunye namandla okusika asezantsi

Ukujika okuphezulu kwe-cncIsipholisi sandisa ubomi besixhobo kwaye siphucula ulawulo lokusika

Ufikelelo olulula kwisipholisi ngeplug-and-play iadaptha yokupholisa

Ukuze kuqinisekiswe imveliso kunye nobomi besixhobo, ukufakwa kweeprofayili ezininzi zikhethwayo, ukufakwa kwe-single-edge full-profile lukhetho lwesibini, kunye nokufakwa kwe-V-profile yimveliso ephantsi kunye neyona ndlela imfutshane yobomi besixhobo.

Faka ukunxiba kunye nobomi besixhobo:

Indlela yokutya, lungiselela indlela yokutya, inani lokudlula kunye nobunzulu

Ukuthambekela kweblade ukuqinisekisa ukucocwa okukhulu ngokwaneleyo kunye nokufana (ishim enencakuba ethambekileyo)

Faka ijometri, qinisekisa ukuba usebenzisa ijometri echanekileyo (A, F okanye C geometry)

Izinto zeBlade, khetha izinto ezichanekileyo ngokwezinto eziphathekayo kunye neemfuno zokuqina

Ukusika iiparamitha, ukuba kuyimfuneko, tshintsha isantya sokusika kunye nenani lokudlula kwinkquboiindawo zokugaya ze-cnc.

I-Anebon ibambelele kwinkolelo yakho "yokwenza izisombululo ezikumgangatho ophezulu kunye nokwenza abahlobo nabantu abavela kwihlabathi liphela", i-Anebon ihlala ibeka umdla wabathengi ukuba baqale ngayo kwiChina Manufacturer yemveliso yokuphosa i-aluminium yaseChina, ipleyiti yokugaya i-aluminium, i-aluminium eyenziwe ngokwezifiso encinci. amalungu cnc, ngothando olumangalisayo kunye nokuthembeka, bakulungele ukukubonelela ngeenkonzo ezingcono kwaye baqhubela phambili nawe ukwenza ikamva eliqaqambileyo elibonakalayo.

I-Aluminiyam yoMzimveliso wokuqala waseChina kunye ne-Aluminiyam yeProfayili, i-Anebon iya kubambelela "kuMgangatho wokuqala,, ukugqibelela ngonaphakade, okujoliswe ngabantu, ukusungula iteknoloji" ifilosofi yoshishino. Umsebenzi onzima wokugcina usenza inkqubela, ukuvelisa izinto ezintsha kushishino, yenza zonke iinzame kwishishini lodidi lokuqala. Sizama konke okusemandleni ethu ukwakha imodeli yolawulo lwezenzululwazi, ukufunda ulwazi oluninzi lobuchwephesha, ukuphuhlisa izixhobo zokuvelisa kunye nenkqubo yokuvelisa, ukwenza iimveliso zomgangatho wokuqala, ixabiso elivakalayo, umgangatho ophezulu wenkonzo, ukuhanjiswa ngokukhawuleza, ukukunika ukudala. ixabiso elitsha .

Ixesha lokuposa: Jun-14-2023