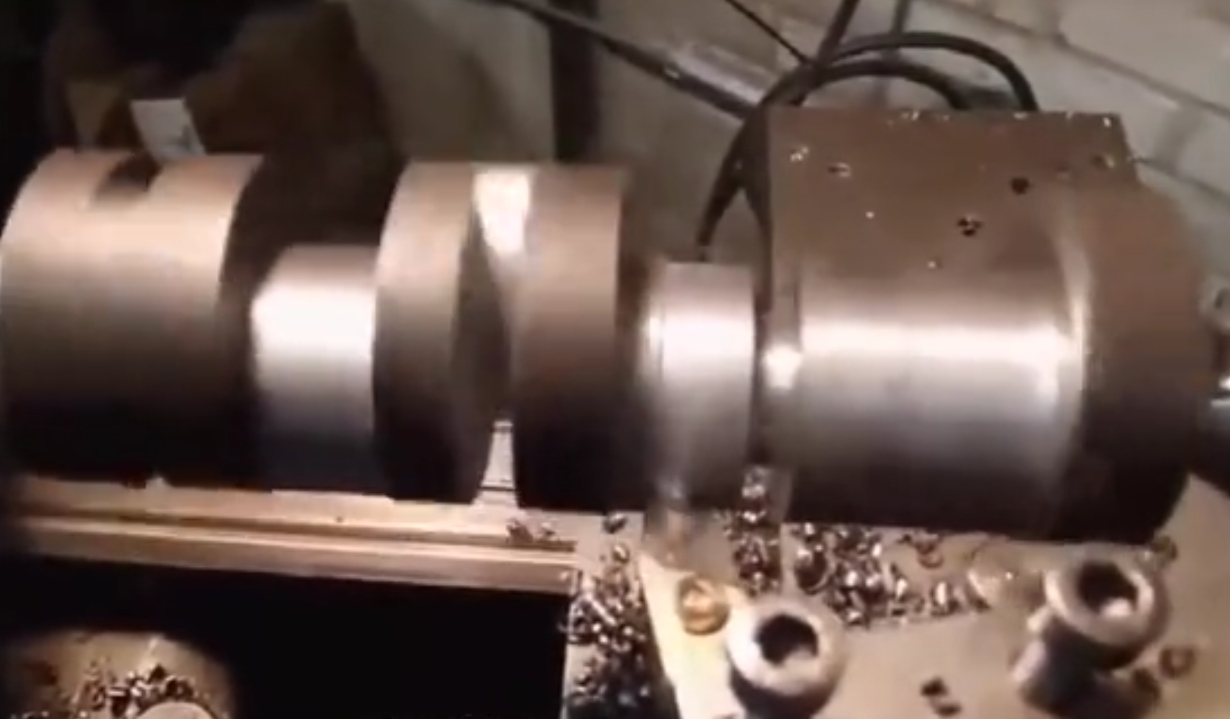

Izinto ezininzi ezinegalelo ekugqwethekeni kwamacandelo e-aluminium ngexesha lenkqubo yokuvelisa, kubandakanya iipropathi zezinto eziphathekayo, inxalenye yejometri, kunye neeparitha zokuvelisa.

Izinto eziphambili zibandakanya uxinzelelo lwangaphakathi ngaphakathi kwemathiriyeli ekrwada, ukugqwetheka okubangelwa kumandla omatshini kunye nobushushu, kunye ne-deformation ebangelwa uxinzelelo olubambekayo.

1. Imilinganiselo yenkqubo yokunciphisa ukuguqulwa kokulungiswa

1. Ukunciphisa uxinzelelo lwangaphakathi olungenanto

Uxinzelelo lwangaphakathi lwemathiriyeli ekrwada lunokuthi luthotywe ngandlel’ ithile ngokuguga kwendalo okanye okokwenziwayo kunye neenkqubo zokungcangcazela. Ukusetyenzwa kwangaphambili kukwayindlela esebenzayo. Kwimeko yemathiriyeli ekrwada ene-overhangs enesisa kunye neeprotrusions ezinkulu, ukugqwethwa kwe-post-processing nako kubalulekile.

Ukusetyenzwa kwentsalela yemathiriyeli ekrwada kwangaphambili kunye nokunciphisa ukuxhoma kwecandelo ngalinye akunako nje ukuthomalalisa ukugqwethwa kokusetyenzwa kwiinkqubo ezilandelayo, kodwa kukwavumela ukuba kubekelwe bucala ixesha lasemva kokuqhubekela phambili, okunokuthi kunciphise ngakumbi ezinye uxinzelelo lwangaphakathi.

2. Ukuphucula ukukwazi ukusika isixhobo

Amandla okusika kunye nokushisa okusika ngexesha lomatshini kuchaphazeleka kakhulu ngokubunjwa kwezinto kunye nesimo esithile sesixhobo. Ukukhetha isixhobo esifanelekileyo kubalulekile ekunciphiseni ukugqwetheka ngexesha lokulungiswa kwenxalenye.

1) Khetha ngokufanelekileyo isixhobo iiparamitha zejometri.

①I-angle yeRake idlala indima ebalulekileyo kwimisebenzi yokusika. Kubalulekile ukukhetha ngononophelo i-engile yeraki enkulu ngelixa uqinisekisa ukuba amandla e-blade agciniwe. I-engile enkulu yeraki ayincedi nje ukufezekisa i-edge yokusika ebukhali kodwa inciphisa ukugqwesa ukusika kwaye iququzelele ukususwa kwe-chip okusebenzayo, okukhokelela ekunciphiseni amandla okusika kunye nobushushu. Izixhobo ezineengile ezingezizo iirake kufuneka ziphetshwe ngazo zonke iindleko.

②I-angle yokukhulula: Ubukhulu be-angle yokukhulula buchaphazela kakhulu ukunxiba kwiflanki kunye nomgangatho womhlaba owenziwe ngoomatshini. Ukukhethwa kwe-angle yokunceda kuxhomekeke kubukhulu be-cut. Kwi-milling erhabaxa, apho kukho isantya esikhulu sokutya, umthwalo onzima wokusika, kunye nokuveliswa kobushushu obuphezulu, kubalulekile ukuqinisekisa ukuchithwa kobushushu ngesixhobo. Ngenxa yoko, kufuneka kukhethwe i-angle encinci yokunceda. Ngakolunye uhlangothi, ukugaya okulungileyo, umgca wokusika obukhali uyafuneka ukunciphisa ukungqubuzana phakathi kweflanki kunye nomgangatho owenziwe ngomatshini kunye nokunciphisa i-elastic deformation. Ngenxa yoko, kucetyiswa i-angle enkulu yokucoca.

③I-engile ye-Helix: Ukuze wenze ukungqusha kube mtyibilizi kunye nokunciphisa amandla okusila, i-engile ye-helix kufuneka ibenkulu kangangoko.

④ I-angle yokuphambuka ephambili: Ukunciphisa ngokufanelekileyo i-angle yokuphambuka ephambili kunokuphucula iimeko zokutshatyalaliswa kobushushu kunye nokunciphisa ubushushu obuphakathi kwendawo yokucubungula.

2) Ukuphucula isakhiwo sesixhobo.

①Ukuphucula ukuphuma kwetshiphu, kubalulekile ukunciphisa ubuninzi bamazinyo kwisisiki sokusila kunye nokwandisa indawo yetshiphu. Ngenxa yobuninzi beplastiki yamalungu e-aluminiyam, kukho ukonyuka kokuguqulwa kokusika ngexesha lokucubungula, kufuna indawo enkulu ye-chip. Ngenxa yoko, iradiyasi enkulu esezantsi ye-chip groove kunye nokuncipha kwenani lamazinyo okusika okusila kuyacetyiswa.

②Yenza ukugaya okuchanekileyo kwamazinyo e-blade, uqinisekise ukuba ixabiso elibukhali le-cut cut lingaphantsi kwe-Ra=0.4um. Xa usebenzisa imela entsha, kuyacetyiswa ukuba usile kancinane ngaphambili nangasemva kwamazinyo usebenzisa ilitye elicikizekileyo leoli ukuze kususwe naziphi na iziphako nezitenxo ezincinane ezibe zibangelwa kukulola. Le nkqubo ayinciphisi kuphela ukusika ubushushu kodwa inciphisa ukusika i-deformation.

③Kubalulekile ukujonga ngokusondeleyo imigangatho yokunxiba yezixhobo zokusika. Njengoko isixhobo siphela, ixabiso loburhabaxa bomphezulu liyenyuka, ubushushu bokusika buyanda, kwaye i-workpiece deformation icaca ngakumbi. Ukongeza ekukhetheni izixhobo zokusika izixhobo ezinokuxhathisa ukunxiba okugqwesileyo, kubalulekile ukubambelela kumthamo omkhulu wokunxiba isixhobo we-0.2mm ukuthintela ukwenzeka komphetho owakhelwe phezulu. Ngethuba lemisebenzi yokusika, kucetyiswa ukuba kugcinwe ukushisa kwe-workpiece ngaphantsi kwe-100 ° C ukukhusela ukuguqulwa.

3. Phucula indlela yokubamba yee-workpieces

Kwizixhobo zokusebenza ze-aluminiyam ezinodonga olucekethekileyo ezinokuqina okubuthathaka, ezi ndlela zilandelayo zokubambelela zingasetyenziselwa ukunciphisa ukonakala:

①Xa usebenza ngeendawo ezinodonga olucekethekileyo, usebenzisa i-chuck enemihlathi emithathu yokuzimisa ngaphakathi okanye i-spring chuck ukuze ubambe iindawo ngeradially kunokubangela uguquko lwesixhobo sokusebenza xa ukhululwe emva kokulungiswa. Kwiimeko ezinjalo, kuyacetyiswa ukuba usebenzise indlela yoxinzelelo oluqinileyo lwe-axial ekupheleni kobuso. Qala ngokufumana umngxuma ongaphakathi wenxalenye, udala i-mandrel enemisonto yesiko, kwaye uyifake kumngxuma ongaphakathi. Sebenzisa ipleyiti yokugubungela ukufaka uxinzelelo kubuso bokuphela, uze uyikhusele kwindawo nge nut. Ngokusebenzisa le ndlela, unokuthintela i-clamping deformation ngexesha lokusetyenzwa kwesangqa sangaphandle, okukhokelela ekuphuculeni ukuchaneka kokusebenza.

②Xa usebenza ngeentsimbi ezinodonga olucekethekileyo, kuyacetyiswa ukuba usebenzise itekhnoloji yokuqinisa imagnethi ukufezekisa amandla okubamba afanayo, adityaniswa neeparamitha zokusika ezicolekileyo. Le ndlela inciphisa ngokufanelekileyo umngcipheko we-workpiece deformation ngexesha lokucubungula. Njengenye indlela, inkxaso yangaphakathi ingaphunyezwa ukunyusa ukuzinza kwamacandelo amancinci.

Ngokufakela i-workpiece nge-medium exhasayo, njengesisombululo se-urea esine-3% ukuya kwi-6% ye-nitrate ye-potassium, amathuba okuba nokuguqulwa ngexesha lokudibanisa kunye nokusika kunokunciphisa. Esi sigcwalisi sinokunyibilika emva koko kwaye sisuswe ngokuntywiliselwa i-workpiece emanzini okanye utywala emva kokulungiswa.

4. Lungiselela inkqubo ngokufanelekileyo

Ngexesha lokusikwa kwesantya esiphezulu, inkqubo yokusila ithanda ukungcangcazela ngenxa yesibonelelo esikhulu somatshini kunye nokusika okuphakathi, okukhokelela kwiimpembelelo ezimbi ekuchanekeni komatshini kunye noburhabaxa bomhlaba. Ngenxa yoko, inkqubo yokusika isantya esiphezulu se-CNC ibandakanya izigaba ezahlukeneyo, ezizezi, umatshini orhabaxa, ukugqiba, ukucoca ikona, kunye nokugqiba, phakathi kwezinye.

Kwiimeko apho iikhomponenti zifuna ukuchaneka okuphezulu, kunokuba yimfuneko ukwenza ukugqiba kwesiqingatha sesibini kulandelwe kukugqiba. Emva komatshini orhabaxa, kuluncedo ukuvumela iindawo ukuba ziphole ngokwendalo ukuthomalalisa uxinzelelo lwangaphakathi olubangelwa kukwenziwa ngoomatshini kunye nokunciphisa inguquko. Umda oshiywe emva komatshini onzima kufuneka udlule inqanaba lokuguqulwa, ngokuqhelekileyo ukusuka kwi-1 ukuya kwi-2 mm.

Ngaphezu koko, xa uqhuba ukugqiba, kunyanzelekile ukuba kugcinwe isibonelelo somatshini esingaguqukiyo kumphezulu ogqityiweyo wenxalenye, ngokuqhelekileyo ukusuka kwi-0.2 ukuya kwi-0.5mm. Lo mkhuba uqinisekisa ukuba isixhobo sihlala sikwimeko ezinzileyo ngexesha lokucutshungulwa, ngaloo ndlela sinciphisa kakhulu i-deformation yokusika, ukufezekisa umgangatho ophezulu wokucubungula umphezulu, kunye nokugcina ukuchaneka kwemveliso.

2. Izakhono zokusebenza ukunciphisa ukuguqulwa kokulungiswa

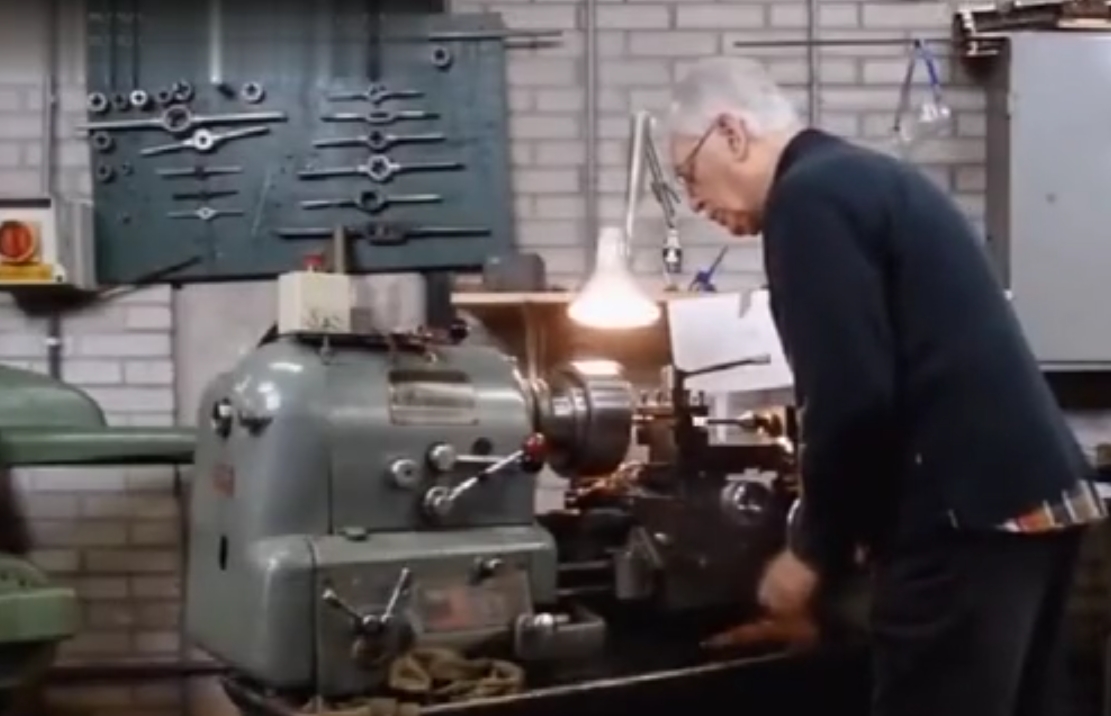

Iinxalenye ezenziwecnc amacandelo aluminiyam ngoomatshinizikhubazeke ngexesha lokusetyenzwa. Ukongeza kwezi zizathu zingasentla, indlela yokusebenza nayo ibaluleke kakhulu ekusebenzeni kwangempela.

1. Kumacandelo anesibonelelo esikhulu somatshini, kubalulekile ukusebenzisa iindlela zokusetyenzwa kwee-symmetrical ukunyusa ukukhutshwa kobushushu ngexesha lomatshini kunye nokuthintela ukuxinana kobushushu. Njengomzekeliso, xa unciphisa i-90mm yeshiti elishinyeneyo ukuya kwi-60mm, ukuguba elinye icala kwaye ngoko nangoko ukuguba elinye, kulandelwa yinkqubo enye yokugqibela yokulinganisa isiphumo sokucaba kwe-5mm. Ngokwahlukileyo koko, ukusebenzisa i-symmetrical processing ngokuphindaphindiweyo, kunye necala ngalinye eligayiweyo kwizigaba ezibini, liqinisekisa ubungakanani bokugqibela kunye ne-flatness ye-0.3mm.

2. Ukuba kukho i-indentations ezininzi kwi-component yeplate, akukhuthazwa ukuba kuqeshwe indlela yokucubungula inyathelo ngesinyathelo kwi-indentation nganye. Oku kunokukhokelela ekuhanjisweni koxinzelelo olungaqhelekanga kunye nokuguqulwa okulandelayo kwecandelo. Endaweni yoko, qwalasela ukuphumeza ukusetyenzwa kwe-maleya kumatshini zonke ii-indentations ngaxeshanye kumaleko ngamnye, ngaphambi kokuba udlulele kumaleko olandelayo. Oku kuya kunceda ekuqinisekiseni ukusasazeka koxinzelelo kunye nokunciphisa i-deformation.

3. Ukunciphisa amandla okusika kunye nokushisa, inani lokusika lingalungiswa. Phakathi kwezinto ezithathu zokusika isixa, isixa sokusikwa ngasemva sichaphazela kakhulu amandla okusika. Isibonelelo esigqithisileyo soomatshini kunye namandla okusika kunokukhokelela kuguquko lwenxalenye, ukuthomalalisa ukuqina kwesixhobo somatshini, kunye nokunciphisa ukuqina kwesixhobo. Ukuncipha kwixabiso lokusika umva kunokunciphisa kakhulu ukusebenza kakuhle kwemveliso. Nangona kunjalo, ukugaya ngesantya esiphezulu kumatshini we-CNC kunokujongana nalo mbandela. Ngokunciphisa kwangaxeshanye ukusika umva inani kunye nokunyusa ukondla kunye nesantya sesixhobo somatshini, amandla okusika anokuncipha ngelixa kugcinwa ukusebenza kakuhle.

4. Kufuneka kuqwalaselwe kwakhona kulandelelwano lokusika. Kumatshini wokwenza izinto ezirhabaxa, kugxininiswa ekuphuculeni ukusebenza kakuhle kunye nokuzabalazela ukususwa kwemathiriyeli ephezulu kwiyunithi nganye yexesha. Ngokuqhelekileyo, ukunyusa umgangatho kuyakhethwa. Oku kuthetha ukuba i-surplus material on the surface of workpiece isuswa ngesantya esiphezulu kwaye ngexesha elifutshane kunokwenzeka ukuseka ulwandlalo lwejometri olufunekayo lokugqiba. Kwelinye icala, inkqubo yokugqiba ibeka phambili ukuchaneka okuphezulu kunye nomgangatho ophezulu, kungoko kunconyelwa ukugaya. Njengoko ubungqingqwa bokusika besixhobo buncipha ngokuthe ngcembe ukusuka kubuninzi ukuya kwi-zero ngexesha lokusila, kunciphisa kakhulu ukuqina komsebenzi kwaye kunciphisa i-deformation.

5. Ukuguqulwa kwee-workpieces ezinodonga oluncinci olubangelwa ukubethelwa ngexesha lokucubungula ngumba ongenakuphepheka, nasemva kokuba sele ugqityiwe. Ukunciphisa i-deformation workpiece, kuyacetyiswa ukuba ukhulule uxinzelelo ngaphambi kokugqiba ukufezekisa imilinganiselo yokugqibela. Oku kuvumela i-workpiece ukuba ibuyele ngokwemvelo kwisimo sayo sokuqala. Emva koko, uxinzelelo lunokuqiniswa ngononophelo de i-workpiece ibanjwe ngokupheleleyo, ukufezekisa umphumo oyifunayo. Ngokufanelekileyo, i-clamping force kufuneka isetyenziswe kwindawo exhasayo, ihambelane nokuqina kwe-workpiece. Ngelixa uqinisekisa ukuba i-workpiece ihlala ikhuselekile, kuyakhethwa ukuba usebenzise amandla amancinci okubamba.

6. Xa umatshini wokucoca unendawo engenanto, kuyacetyiswa ukuba uphephe umsiki wokusila ukuba angene ngokuthe ngqo kwindawo efana ne-drill ngexesha lenkqubo. Oku kunokukhokelela kwindawo elinganiselweyo yetshiphu yesisiki sokusila, ukukhutshwa kwetshiphu okuthintelekileyo, kunye nesiphumo sokufudumeza, ukwanda, kunye nokuwohloka kwamalungu. Izehlo ezingathandekiyo ezifana nokugqwetheka kunye nokwaphuka kwesixhobo kusenokuvela. Kucetyiswa ukuba uqale usebenzise i-drill bits enobungakanani obulinganayo okanye obukhudlwana kancinane kunesisiki sokusila ukubhoboza umngxuma kwaye emva koko uqeshe isisiki sokusila ukwenza machining. Kungenjalo, inkqubo yokusika i-spiral inokuveliswa kusetyenziswa isoftware yeCAM.

Umceli mngeni ophambili ophembelela ukuchaneka kwenxalenye ye-aluminium kunye nomgangatho wokugqitywa komphezulu wayo kukuchaphazeleka kwala malungu ukuba agqwetheke ngexesha lokulungiswa. Oku kufuna ukuba umqhubi abe nenqanaba elithile lobuchule bokusebenza kunye nobuchule.

I-Anebon ixhomekeke kumandla obuchule obuchwephesha kwaye ngokuqhubekayo idala itekhnoloji ephucukileyo ukuhlangabezana nemfuno yomatshini wesinyithi we-cnc,I-5 axis cnc millingkunye nemoto yokulahla. Zonke izimvo kunye neengcebiso ziya kuthakazelelwa kakhulu! Intsebenziswano elungileyo ingasiphucula sobabini kuphuhliso olungcono!

ODM Manufacturer ChinaAmacandelo e-Aluminiyam e-CNC elungiselelweyokunye namacandelo oomatshini okwenza, Okwangoku, izinto ze-Anebon zithunyelwe kumazwe angaphezu kwamashumi amathandathu kunye nemimandla eyahlukeneyo, njengaseMzantsi-mpuma Asia, eMelika, eAfrika, eMpuma Yurophu, eRashiya, eCanada njl. zombini eTshayina nakwilizwe liphela.

Ukuba ufuna ukwazi ngakumbi ngathi okanye ufuna ukubuza, nceda uthumele i-imeyile kuyoinfo@anebon.com

Ixesha lokuposa: Feb-02-2024